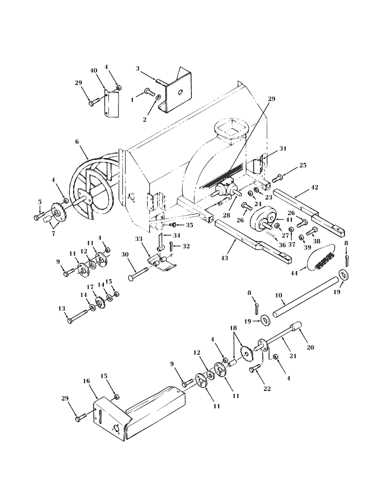

Complete Parts Diagram for Ariens Snowblower

When maintaining or repairing a winter device, it is essential to have a comprehensive guide that illustrates the various components. This visual reference helps to identify each part, ensuring that everything fits together properly and functions as expected.

Having a clear layout of all the elements involved is crucial, whether you are assembling, fixing, or upgrading the machine. The importance of accurately recognizing each section cannot be overstated, as it aids in a smooth and efficient maintenance process.

By understanding how different components interact, users can avoid errors during reassembly. This knowledge enhances both performance and safety, allowing for quicker troubleshooting and a longer lifespan for the device.

Understanding the Ariens Snowblower Structure

When it comes to winter equipment designed for clearing heavy snowfall, understanding its inner workings is crucial. The mechanism behind efficient removal involves multiple interconnected elements, each contributing to the overall performance. These components are engineered to work in harmony, ensuring reliability and ease of use when clearing outdoor surfaces.

Main Components Overview

At the core of this system lies a combination of propulsion, intake, and discharge mechanisms. These core parts ensure that snow is collected, processed, and ejected effectively. The interaction between these elements plays a vital role in achieving optimal efficiency during operation.

Key Structural Elements

Several distinct sections of the machine are responsible for various tasks. Understanding these components helps in troubleshooting and maintenance, ensuring the equipment lasts for years to come. Below is an overview of some of the key elements that make up the structure of this outdoor tool:

| Component | Function |

|---|---|

| Auger Assembly | Collects snow and directs it to the impeller. |

| Impeller | Forces snow into the chute for ejection. |

| Drive System | Transmits power to move the unit forward. |

| Chute | Controls the direction in which the snow is expelled. |

Identifying Key Components of the Model

Understanding the essential elements that make up the unit is crucial for proper maintenance and efficient operation. By recognizing these crucial elements, you can ensure smooth performance and quick repairs if necessary. This section will guide you through the main components that contribute to the overall functionality of the equipment.

Here are the key components you should be familiar with:

- Engine: The core power source responsible for driving the entire system.

- Transmission: The mechanism that transfers power from the engine to other parts, allowing for movement and control.

- Auger: The component that interacts with the surface to break and lift the material being processed.

- Chute: Directs the output material away from the working area to prevent buildup.

- Drive system: Controls the unit’s speed and movement, ensuring optimal handling on different terrains.

By knowing these elements, you’ll be able to recognize when each part is functioning properly or needs attention. Understanding the layout also simplifies troubleshooting and ensures more effective maintenance procedures.

Engine Layout and Functional Parts

The engine layout serves as the core of any outdoor equipment, providing the necessary power to drive the entire system. Its components work together in harmony, each playing a unique role in delivering optimal performance. Understanding how these elements interact can enhance efficiency and reliability, ensuring that every operation is smooth and effective. This section explores the key elements within the engine’s design and their contributions to the overall functionality.

Key Engine Components

The central unit is the engine block, which houses critical components such as the cylinder, crankshaft, and pistons. These parts work together to generate power through internal combustion, creating the force needed to drive the system. The ignition system ensures that the engine starts and continues to run smoothly, while the fuel delivery system manages the mixture of fuel and air, optimizing combustion.

Supporting Mechanisms for Operation

Additional systems like the cooling mechanism and lubrication system help maintain engine performance by preventing overheating and reducing friction, respectively. The exhaust system is another vital component, directing harmful gases away from the engine to improve efficiency and longevity. Each of these systems contributes to a balanced and functional engine design, enabling reliable operation in various conditions.

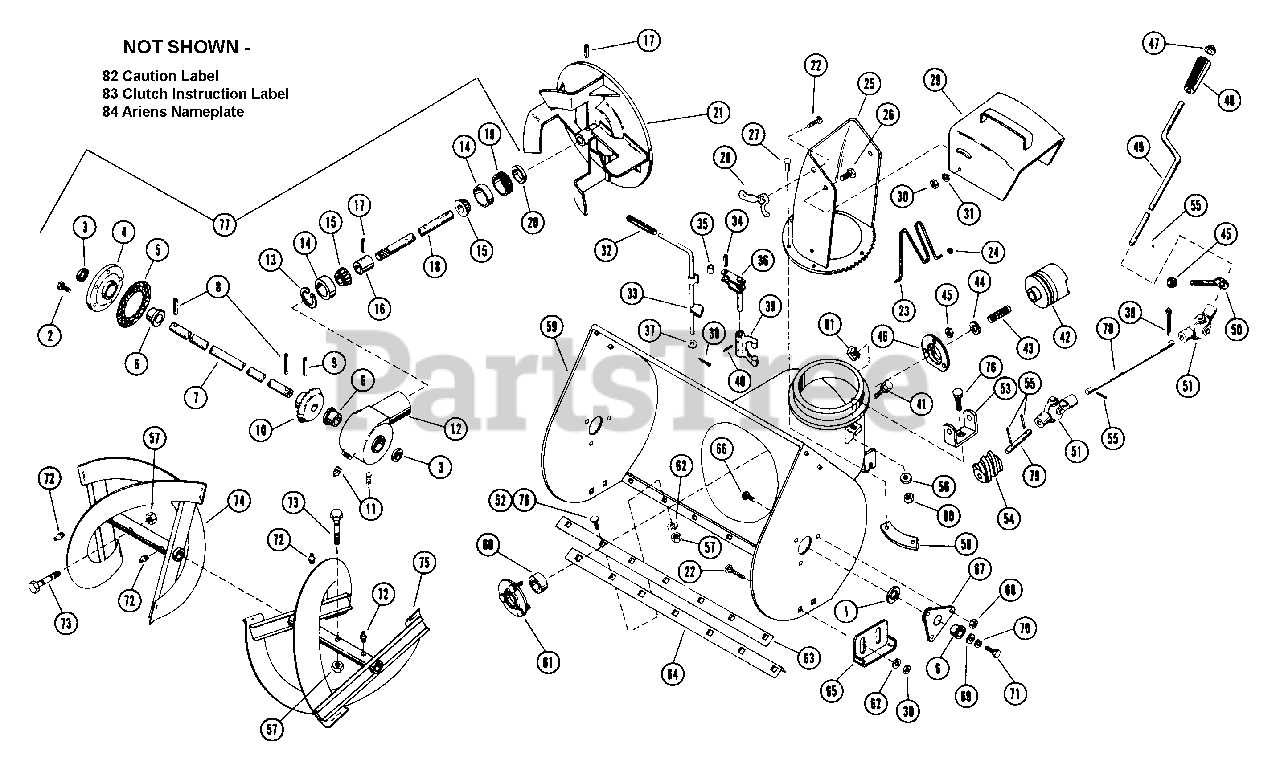

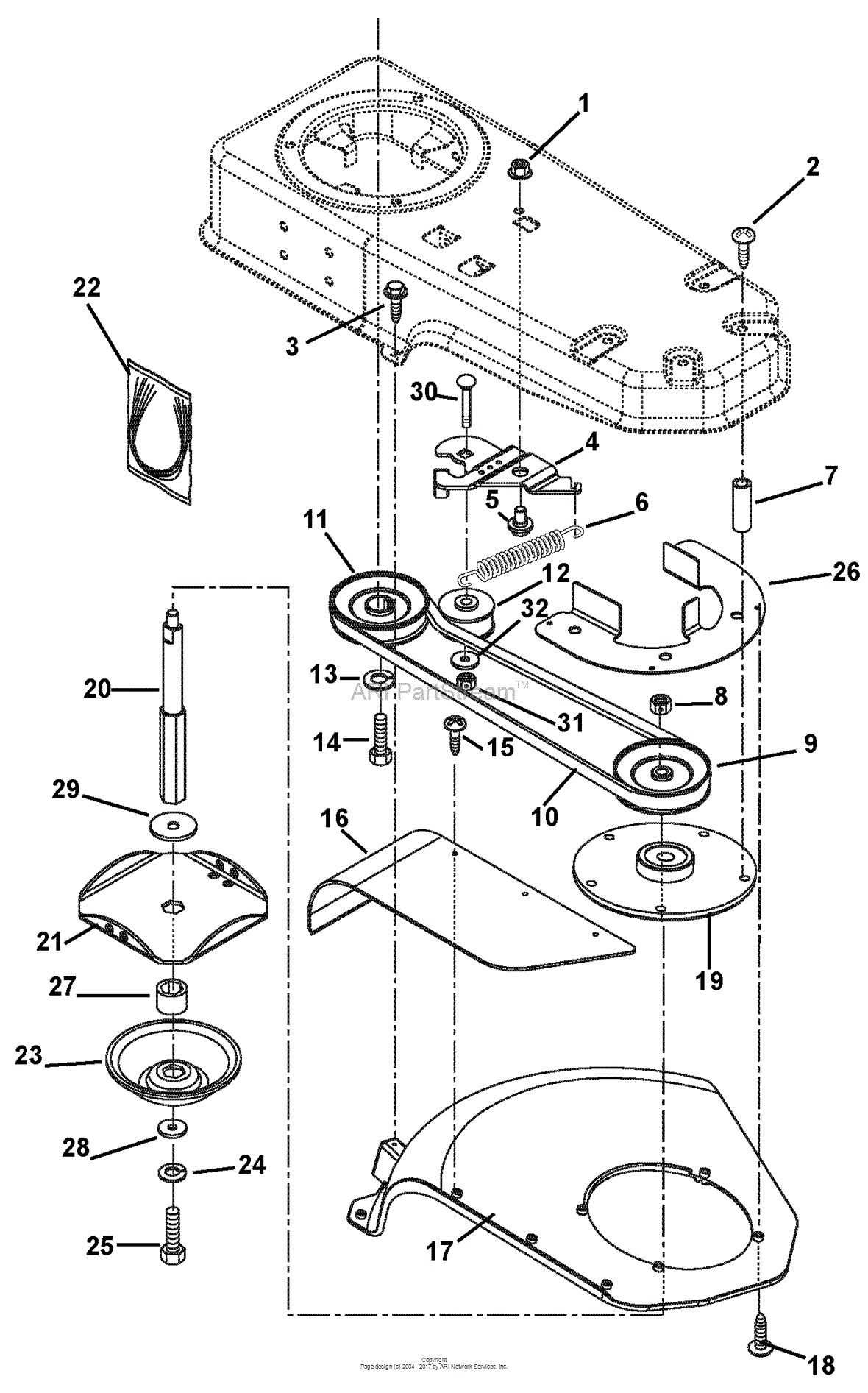

Drive Mechanism and Related Elements

The power transmission system in a snow-clearing machine is essential for converting the engine’s energy into movement. This mechanism includes a series of interconnected components that ensure smooth operation, allowing the machine to move and perform its functions effectively. Each part of this system plays a critical role in maintaining efficiency and control.

The drive mechanism consists of a variety of elements such as belts, pulleys, and gear assemblies that work together to transmit power from the engine to the wheels or tracks. These components are designed to handle different levels of torque and speed, depending on the specific needs of the equipment. Regular maintenance of these parts is crucial for the longevity and reliability of the machine’s operation.

Key components like the friction wheel, drive shaft, and tension springs provide the necessary force and adjustment to the transmission. Each part needs to be correctly aligned and adjusted to avoid unnecessary wear and tear, ensuring that the unit operates smoothly across various terrains and under different weather conditions.

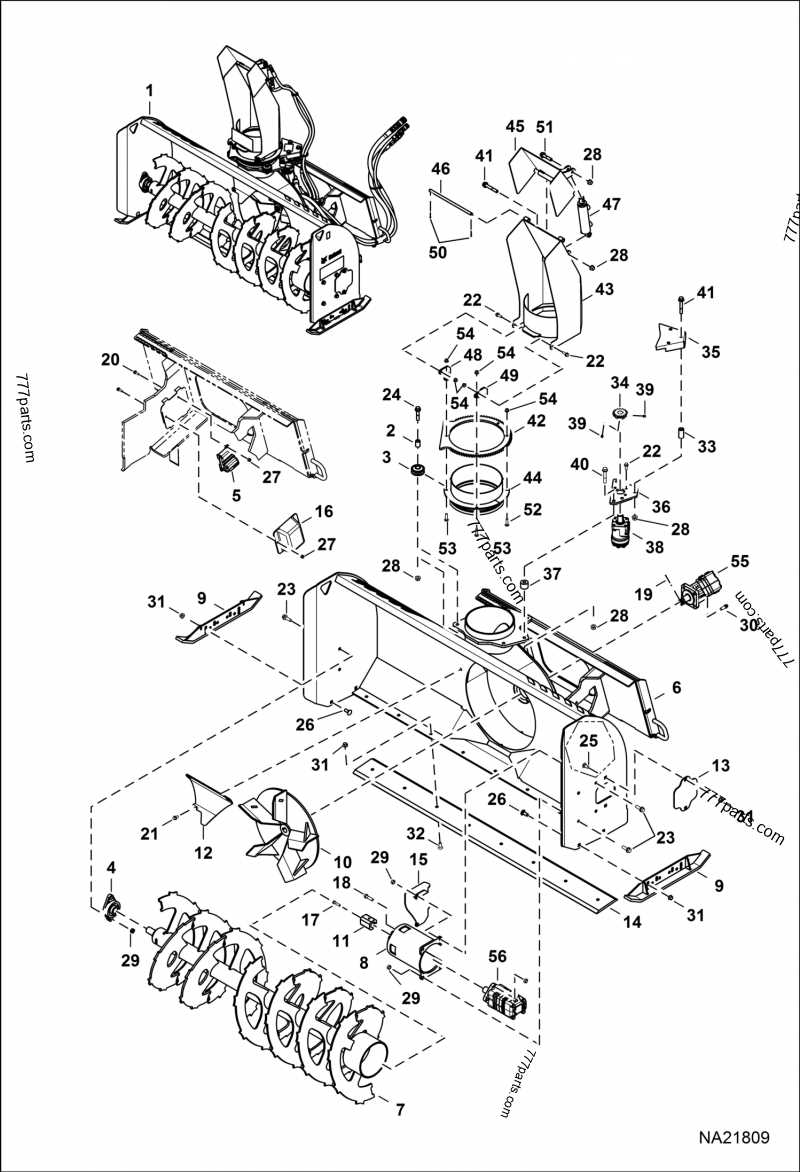

Snow Thrower Assembly and Operation

Understanding the proper setup and functioning of a winter clearing machine is essential for ensuring smooth operation in challenging weather conditions. The assembly process involves connecting key components, while proper operation ensures efficiency and safety during use. Following correct procedures helps maximize the lifespan and performance of the equipment.

Setting Up the Equipment

The assembly process begins by carefully attaching all primary elements of the machine. This includes securing the intake chute, the auger system, and the discharge mechanism. Each part must be aligned precisely to ensure optimal performance. Once everything is in place, it is important to check for any loose connections or obstructions before initiating the first use.

Safe Operation and Maintenance

Proper handling during operation is crucial to prevent accidents and ensure the best possible results. Always start the machine according to the manufacturer’s guidelines, paying close attention to the settings for speed and direction. Regular checks and basic maintenance, such as clearing any debris and lubricating moving parts, help maintain peak performance throughout the season.

Key Maintenance Parts and Tools

Proper upkeep of outdoor equipment requires a set of essential components and tools that ensure optimal performance and longevity. Identifying and utilizing the right items can significantly reduce the chances of mechanical failure during operation. Regular attention to specific elements is crucial to maintaining efficiency and safety during each use.

Essential Components: There are a few critical elements that require routine inspection, such as belts, filters, and lubricants. These should be checked regularly to prevent wear and tear that can lead to reduced functionality or unexpected breakdowns. Replacing or adjusting these components ensures smooth operation and protects the equipment from unnecessary damage.

Important Tools: Having the correct tools on hand is vital for performing regular maintenance. Basic tools such as wrenches, screwdrivers, and pliers are commonly needed for quick adjustments, while more specialized tools like oil drain pans and spark plug sockets might be necessary for more in-depth servicing. Keep these items well-maintained to guarantee ease of use when performing routine tasks.

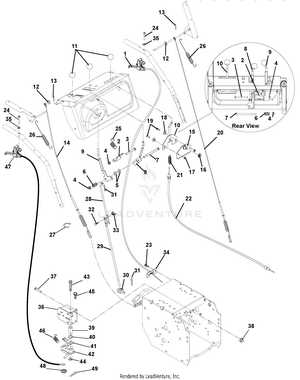

Electrical Wiring and Control Components

Understanding the electrical setup and control systems is essential for the proper functioning of outdoor equipment. This section outlines the key elements involved in the electrical circuits and control mechanisms, ensuring the efficient operation of the machinery. It includes the various connectors, switches, and wiring configurations that enable seamless interaction between different components.

The electrical network is designed to manage the power flow to vital sections, ensuring smooth operation. Key components such as the ignition system, motor controllers, and safety switches play crucial roles in controlling the overall performance. A clear understanding of their interconnections helps in troubleshooting and ensuring longevity.

The control components, which are typically located in accessible areas, allow the user to manage the machine’s settings. These include toggle switches, speed controls, and electrical relays that interact directly with the operational parts. Proper maintenance and inspection of these components are crucial to avoid potential malfunctions and ensure safe use.

Fuel System Components and Configuration

The fuel system plays a crucial role in ensuring proper operation of any engine. It is responsible for storing, delivering, and mixing fuel with air in a precise manner, allowing the engine to run efficiently. This section covers the essential components that make up the fuel delivery mechanism and how they work together to maintain engine performance.

Fuel Tank: The fuel tank holds the necessary fuel supply, providing the engine with the required resources for operation. It is typically sealed to prevent contamination and designed to be easily refilled when needed.

Fuel Lines: These flexible tubes are responsible for transferring fuel from the tank to the engine. They must be durable and resistant to wear and tear, as they are subjected to constant pressure and exposure to various elements.

Fuel Filter: This small but important element ensures that only clean fuel reaches the engine by trapping debris and contaminants. It helps prevent clogging and damage to the engine’s internal components.

Fuel Pump: The fuel pump delivers fuel from the tank to the carburetor or fuel injection system. Its efficiency ensures that the engine receives the right amount of fuel at the right time.

Carburetor or Fuel Injector: These components mix fuel with air before it enters the engine. A carburetor uses a mechanical process to achieve this, while fuel injectors provide a more precise and efficient mixture electronically.

Fuel Lines and Connections: Proper routing and maintenance of fuel lines and connections are essential for preventing leaks and ensuring a steady fuel flow. These lines must be checked regularly to avoid any disruptions in the system’s operation.

Each of these elements must be configured correctly for the fuel system to function optimally. Regular inspection and maintenance are key to ensuring smooth operation and longevity of the engine.

Safety Features and Associated Components

Ensuring safe operation is paramount when using equipment designed for clearing snow. Various built-in features and mechanisms contribute to minimizing the risk of accidents, providing users with peace of mind. These elements are integral to maintaining both the safety of the operator and the longevity of the machine.

Key Safety Mechanisms

- Safety Switches: These are designed to stop the engine when the user releases the handle or engages a safety lock, preventing accidental starts.

- Chute Deflector: This component helps control the direction of snow discharge, reducing the risk of the material hitting bystanders or obstacles.

- Electric Start Feature: Provides an easy and safe method of starting the engine, reducing the effort and potential strain on the user.

Important Protective Elements

- Hand Warmers: Often incorporated into the handles to ensure comfort during prolonged usage, which helps reduce the risk of strain and discomfort.

- Auger Lock: Prevents the auger from spinning when the machine is not in use, lowering the chance of injury during maintenance or transport.

- Engine Guards: Shields around the engine protect users from heat exposure and debris, enhancing overall safety during operation.

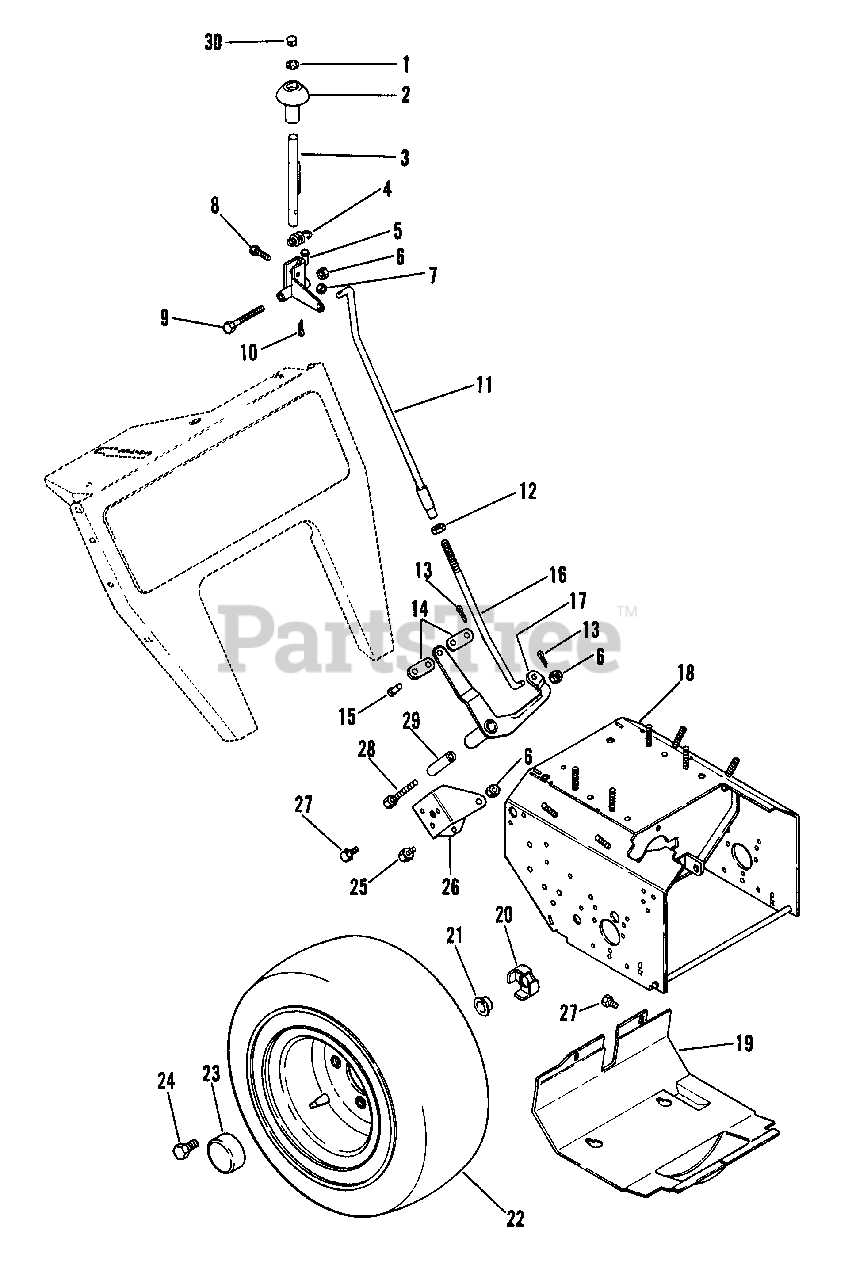

Chassis and Frame Parts Breakdown

Understanding the structure and components of the base unit is crucial for efficient maintenance and repairs. The foundation of the equipment consists of several key elements that ensure stability and provide the necessary framework for all moving parts. Identifying these components helps in diagnosing issues and ensuring long-lasting performance.

Key Structural Elements

The core of the device is made up of a sturdy framework that supports various mechanical systems. This includes the main body, which serves as the anchor for all other components, and the structural supports that maintain balance during operation. Strong, durable materials are essential for withstanding harsh conditions and heavy use.

Maintenance and Troubleshooting

Regular inspection of the structural components can prevent costly damage. Pay special attention to any signs of wear, rust, or damage that might compromise the integrity of the base assembly. Replacing damaged sections promptly ensures continued efficiency and avoids potential safety hazards.

Adjustable Skid Shoes and Their Function

These components play a vital role in controlling the height and balance of the equipment during operation. Their main purpose is to protect the underlying surface while providing stability and support. By adjusting these elements, users can ensure that the machine operates effectively across different terrains, avoiding damage to both the equipment and the ground.

Adjustability allows users to tailor the machine’s interaction with the surface, making it suitable for various conditions, from rough pavement to icy or snowy landscapes. This feature helps maintain the optimal clearance needed for smooth functioning.

When properly set, these features enhance the overall performance, making it easier to maneuver and prolonging the life of both the equipment and the surfaces it interacts with. Regular maintenance and fine-tuning are essential to ensure their continued effectiveness.

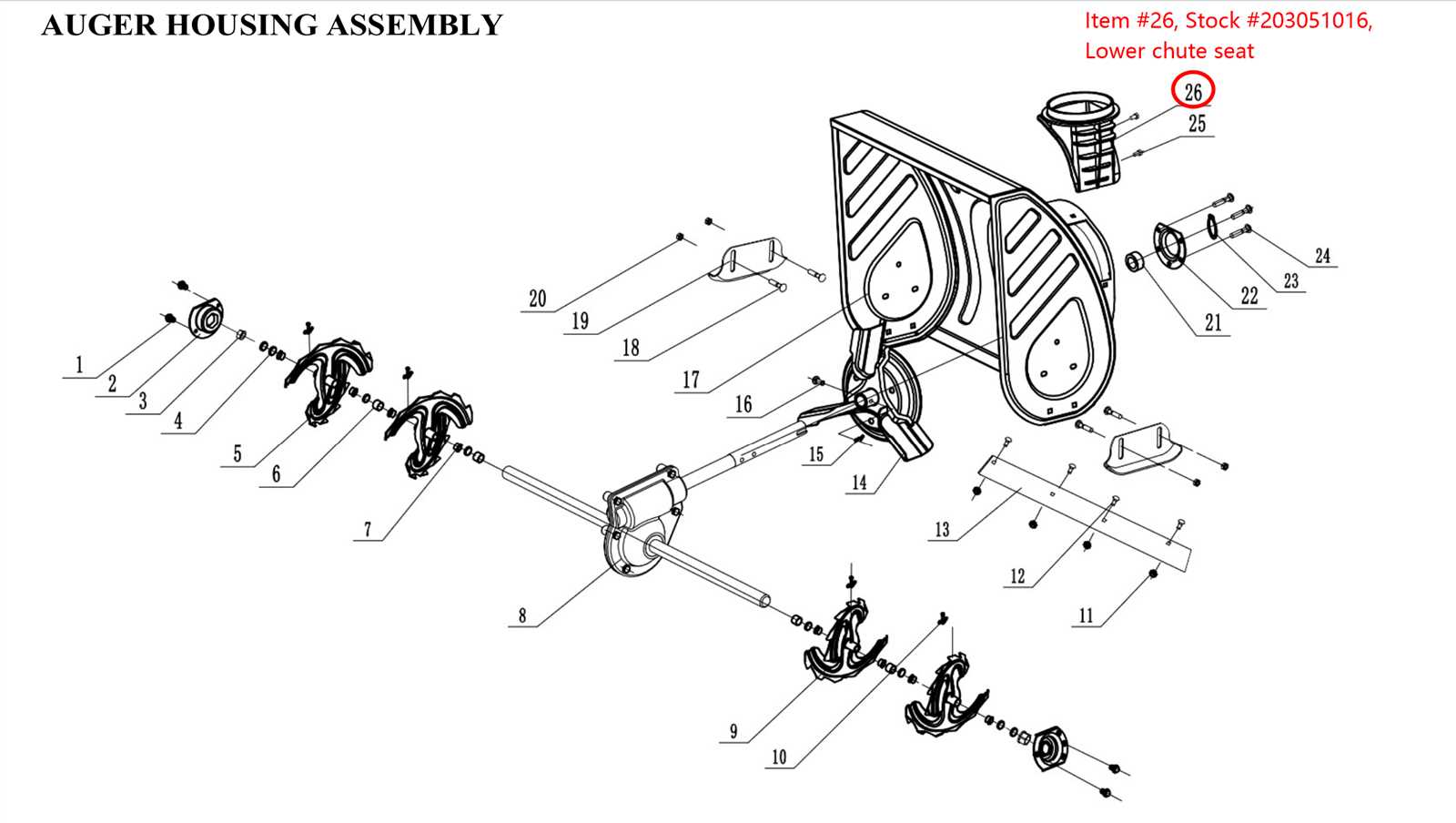

Auger and Impeller Mechanism Details

The system responsible for gathering and throwing snow consists of two key elements that work together to clear the path. The first component engages the collected material, while the second propels it away, ensuring efficient removal. These mechanisms rely on precise interaction to achieve optimal performance during operation.

Understanding the Auger Function

The initial stage of snow removal involves the mechanism that pulls the material toward the center. This rotating unit plays a critical role in gathering and directing snow towards the chute. Key aspects of its operation include:

- Rotational speed: Determines how effectively the snow is gathered.

- Blade design: Specially crafted to break through compacted snow and ice.

- Engagement with ground surface: Ensures proper traction and performance even in deep or heavy snow.

The Role of the Impeller

Once snow is moved towards the center, the next stage involves directing the material out through the chute. The impeller, a high-speed rotating component, is responsible for propelling the snow away from the machine. Considerations include:

- Speed: A higher rotational speed results in a further reach of thrown snow.

- Material strength: Ensures durability against constant impact and friction.

- Design: Typically features curved blades to improve snow discharge and reduce clogging.

Common Repair and Replacement Items

When maintaining a snow clearing machine, certain components are prone to wear and require regular attention. Identifying the most common parts that might need fixing or swapping out can help ensure optimal performance throughout the season.

Below are several key components that often need to be replaced or repaired:

- Drive belts – These are essential for transferring power and may wear out over time due to constant use.

- Auger blades – Frequently subject to damage from rocks, ice, and debris, these blades can become dull or bent.

- Fuel lines – Cracks or leaks in fuel lines can cause engine performance issues, leading to a potential fuel leak hazard.

- Ignition system – Issues with the spark plug or ignition coil can prevent the machine from starting properly.

- Chute control cables – Cables controlling the direction of the discharge chute may stretch, fray, or snap after extended use.

- Shifter linkages – These parts help adjust the speed and direction of the machine, and they may become stiff or break.

Routine inspections and timely replacements of these components can enhance the lifespan and efficiency of your equipment.