Understanding the Simplicity Snowblower Parts Diagram for Efficient Repairs

In the world of outdoor machinery, having a comprehensive grasp of the various elements that contribute to performance is essential. A well-structured overview of these components can significantly enhance your maintenance and repair efforts, ensuring your equipment operates smoothly.

Identifying each segment plays a crucial role in troubleshooting issues and performing routine care. A clear illustration or layout not only aids in understanding but also empowers users to handle repairs with confidence.

By exploring the intricate relationships between these vital sections, enthusiasts can delve into their workings, ultimately leading to more effective use and longevity of the machinery. Understanding these intricacies is the ultimate key to optimizing performance and reliability.

Understanding Simplicity Snowblower Parts

This section aims to provide insight into the essential components of a winter clearing machine, highlighting their functions and interconnections. Recognizing the roles of each element can significantly enhance maintenance and troubleshooting efforts.

Key Components

Several crucial elements contribute to the efficient operation of these machines. Familiarity with each component’s purpose will enable users to navigate challenges effectively.

| Component | Description |

|---|---|

| Auger | Grabs and moves snow towards the chute. |

| Chassis | The main frame that supports all other components. |

| Engine | Powers the entire machine, driving the auger and wheels. |

| Fuel Tank | Stores gasoline to power the engine. |

Maintenance Tips

Regular upkeep is vital for prolonging the lifespan of these winter machines. Checking oil levels, inspecting belts, and ensuring all moving parts are well-lubricated can prevent major issues down the line.

Importance of a Parts Diagram

Understanding the components of any machine is crucial for effective maintenance and repair. A visual representation can greatly enhance the clarity of this information, allowing users to identify each element with ease.

Key benefits of having a visual reference include:

- Facilitates quick identification of components.

- Streamlines the repair process by providing clear guidance.

- Helps in troubleshooting by highlighting potential issues.

Moreover, a well-organized visual aid can:

- Reduce the time spent searching for specific parts.

- Enhance communication among technicians and users.

- Ensure proper reassembly after maintenance or repair tasks.

Ultimately, having an accessible visual guide transforms complex maintenance tasks into manageable ones, promoting longevity and efficiency in machine operation.

Common Components of Snowblowers

Understanding the essential elements of a snow-clearing machine is crucial for efficient operation and maintenance. Each component plays a vital role in ensuring that the equipment performs optimally during winter conditions.

Engine: The heart of the machine, responsible for providing the necessary power to drive all other components. It can vary in size and type, influencing overall performance and efficiency.

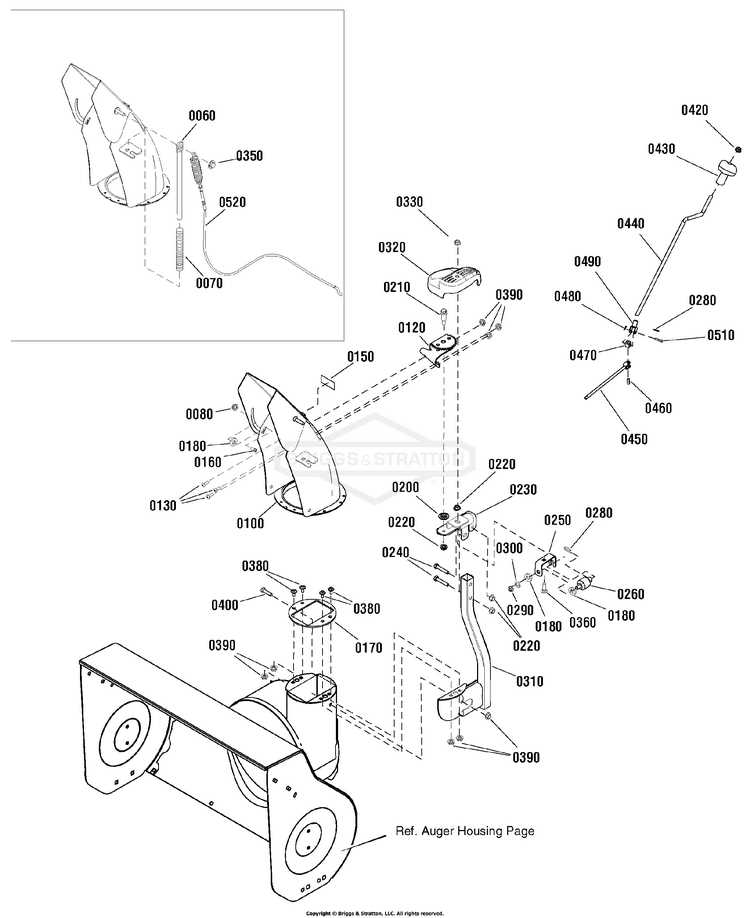

Auger: This rotating device is designed to scoop up and break apart the accumulated snow, allowing it to be directed towards the chute. Its effectiveness directly impacts the speed at which snow can be cleared.

Impeller: Located near the discharge chute, this component propels the snow out of the machine once it has been gathered by the auger. A well-functioning impeller is essential for achieving optimal throwing distance.

Chassis: The frame supports all other parts and provides stability during operation. A durable chassis ensures longevity and can withstand the rigors of heavy snowfall.

Controls: These are the interfaces that allow the operator to manage various functions, such as speed and direction. User-friendly controls enhance overall efficiency and ease of use.

Tires or Tracks: Essential for mobility, these components provide traction on slippery surfaces. The choice between tires or tracks can affect maneuverability and stability in different snow conditions.

Skid Shoes: Adjustable elements located at the base, allowing the operator to set the height of the machine, preventing damage to surfaces while optimizing performance in various snow depths.

Familiarity with these fundamental components aids in troubleshooting, maintenance, and understanding the overall functionality of winter equipment. Regular checks and servicing of these parts ensure reliable operation throughout the snowy season.

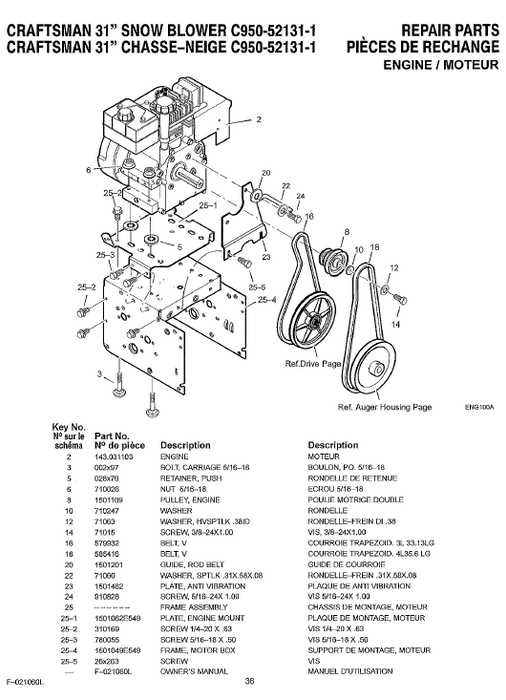

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repairs. These illustrations offer clarity on how various elements fit together, enabling users to identify necessary items with ease. Grasping the layout can significantly enhance the repair process, ensuring accuracy and efficiency.

Key Elements to Identify

When examining the visual layout, focus on specific features that guide you through the componentry. Notable elements often include labels, part numbers, and connection points. Recognizing these details can streamline your search for replacements or upgrades.

Utilizing the Information

Once familiar with the layout, you can use the information to gather the required items. This knowledge allows for informed decision-making when sourcing components, whether online or at a local retailer.

| Element | Description |

|---|---|

| Labels | Indicate specific components and their functions. |

| Part Numbers | Unique identifiers for ordering and tracking. |

| Connection Points | Show how various parts interact and connect. |

Identifying Replacement Parts Easily

Understanding how to locate and recognize components for your equipment can significantly enhance maintenance efficiency. By familiarizing yourself with the structure and function of each element, you can streamline the process of sourcing alternatives when needed.

Step one involves gathering resources that provide visual references. Detailed illustrations or online resources can guide you in pinpointing specific elements. This knowledge empowers you to make informed choices when seeking replacements.

Next, always keep track of model numbers and specifications. This information is crucial when contacting suppliers or searching online. Having precise details at hand ensures that you acquire the correct substitutes without unnecessary delays.

Finally, consider joining online communities or forums. Engaging with fellow users can offer valuable insights and recommendations, making it easier to navigate the selection process and ultimately find the exact replacements you require.

Maintenance Tips for Snowblower Parts

Proper upkeep of your winter equipment is essential for ensuring its longevity and efficiency. Regular maintenance can prevent breakdowns and enhance performance during harsh conditions. This guide offers valuable insights into caring for various components, ensuring they remain in optimal condition throughout the season.

Routine Inspections

Conducting regular checks on critical components is vital. Look for signs of wear, such as fraying belts or cracks in the housing. Early detection can save time and money by addressing issues before they escalate. Ensure that all fasteners are secure, and lubricate moving parts to reduce friction and wear.

Storage Practices

When the season ends, proper storage is crucial. Clean all surfaces to remove any debris or moisture, which can lead to rust or corrosion. Store the machine in a dry, sheltered location, and consider using a protective cover. Additionally, draining fuel can prevent clogging in the fuel system and ensure easier starts when needed again.

Where to Find Parts Diagrams

Locating schematics for machinery can significantly enhance your understanding of their components and functionality. Various resources are available to assist you in obtaining these valuable illustrations, ensuring you can effectively maintain or repair your equipment.

| Resource Type | Description |

|---|---|

| Manufacturer Websites | Official sites often provide downloadable guides and visual aids for their products. |

| Online Retailers | Many retailers showcase visuals alongside product listings, aiding in identification and ordering. |

| Forums and Community Groups | Enthusiast communities frequently share resources and insights, including links to illustrations. |

| Repair Manuals | Comprehensive manuals usually include detailed visuals that can assist in understanding assembly. |

Common Issues with Snowblower Components

When operating a machine designed for clearing snow, various components can encounter problems that hinder performance. Understanding these common issues can help in timely maintenance and repairs, ensuring smooth functionality during the winter season.

| Component | Common Issues | Possible Solutions |

|---|---|---|

| Engine | Difficulty starting, stalling | Check fuel levels, replace spark plug |

| Auger | Not rotating, clogs | Inspect for blockages, lubricate bearings |

| Chassis | Worn wheels, rust | Replace wheels, apply protective coating |

| Control Cables | Tension loss, fraying | Adjust tension, replace damaged cables |

| Skid Shoes | Excessive wear, uneven surface | Replace when worn, ensure proper adjustment |

By addressing these common issues proactively, operators can enhance the lifespan and efficiency of their machines, ensuring they perform optimally when needed most.

Benefits of Using Original Parts

Utilizing authentic components for your equipment ensures optimal performance and longevity. These elements are specifically designed to fit perfectly, maintaining the integrity and efficiency of the machinery. By choosing original items, users can significantly enhance the overall functionality of their devices.

Quality Assurance: Authentic components undergo rigorous testing to meet strict industry standards. This guarantees reliability and minimizes the risk of malfunction, providing peace of mind for users who rely on their equipment.

Compatibility: Original items are engineered to work seamlessly with your machinery. This compatibility prevents issues related to improper fit or functionality, which can arise from using generic alternatives.

Warranty Protection: Many manufacturers offer warranties that cover equipment when original components are used. This protection can save you from unexpected repair costs and extend the lifespan of your investment.

Enhanced Performance: Authentic components contribute to improved efficiency, ensuring that your equipment operates at its best. This can lead to better results and a more satisfying user experience.

In summary, opting for genuine components not only fosters optimal performance but also safeguards your investment in the long run. The choice of quality over convenience ultimately pays off in terms of reliability and satisfaction.

Upgrading Parts for Better Performance

Enhancing the functionality of your equipment can significantly improve its efficiency and longevity. By focusing on key components that can be upgraded, you can ensure that your machine operates at its peak, adapting to various conditions and tasks with ease.

One of the primary areas to consider for enhancement is the engine. Investing in a higher-performance engine can lead to increased power output and efficiency, allowing for quicker and more effective operations. Additionally, upgrading the blades or augers can improve the cutting and clearing capabilities, enabling smoother handling of challenging materials.

Another critical aspect is the drive system. A more advanced drive mechanism can provide better traction and control, which is essential for navigating uneven terrains. Furthermore, evaluating and upgrading belts and cables can enhance responsiveness and reduce wear over time, contributing to overall reliability.

Incorporating high-quality filters and lubricants can also lead to better performance by ensuring that the machinery operates smoothly and efficiently. Regular maintenance, along with these upgrades, will extend the lifespan of your equipment and keep it running at optimal levels.

DIY Repairs with Parts Diagrams

Understanding how to repair machinery can empower individuals to tackle maintenance tasks effectively. Utilizing visual representations of components can significantly simplify the process, allowing enthusiasts to identify and replace necessary elements without professional assistance.

When embarking on a repair journey, consider the following steps:

- Gather necessary tools and materials.

- Study the visual reference to familiarize yourself with each component’s location and function.

- Identify the specific parts that require replacement or repair.

- Carefully disassemble the machinery, taking note of the order of parts.

- Replace or repair the faulty components as needed.

- Reassemble the machinery, ensuring all pieces fit correctly.

- Test the equipment to ensure proper functionality.

By following these steps, you can confidently manage repairs and extend the lifespan of your equipment. Engaging with the visual guides not only enhances your understanding but also cultivates a sense of accomplishment.

Remember to document your process, as this can serve as a valuable resource for future repairs or for others seeking guidance.