Understanding the Snow Chief Snowblower Parts Diagram

When it comes to efficient performance during the cold months, a comprehensive understanding of the inner workings of winter machinery is essential. This knowledge not only enhances functionality but also ensures longevity and reliability of the equipment. Proper maintenance hinges on being well-acquainted with the various components that contribute to optimal operation.

In this section, we will explore the intricate layout and relationships between different elements of these essential machines. By dissecting their structure, users can gain valuable insights into troubleshooting and repairs. Whether for seasonal upkeep or unexpected malfunctions, familiarity with these mechanisms is crucial for any operator.

Delving into the specifics, we will highlight the ultimate components that play pivotal roles in achieving peak efficiency. Understanding these features will empower users to make informed decisions regarding maintenance and enhancements, ultimately leading to a smoother experience in challenging weather conditions.

Understanding Snow Chief Snowblowers

This section aims to explore the essential features and functionalities of a particular type of outdoor machinery designed to manage winter precipitation. Users often seek clarity on how these machines operate and the components involved in their effective performance.

Key Features

- Powerful engine capabilities for efficient clearing.

- Adjustable chute direction for targeted snow removal.

- Ergonomic controls for user comfort and ease of use.

Maintenance Considerations

- Regularly check and replace worn components.

- Ensure fuel and oil levels are adequate before operation.

- Clean the machine after each use to prevent rust and damage.

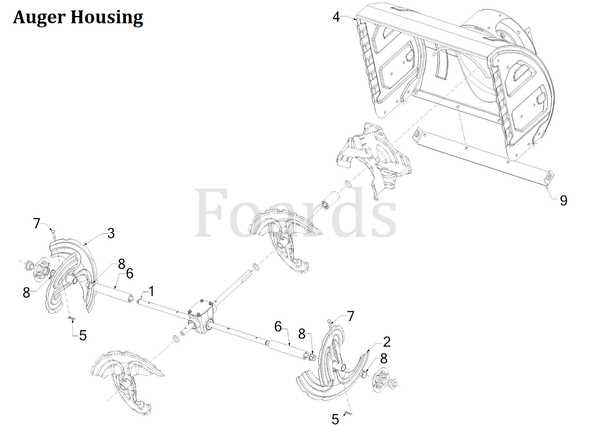

Key Components of Snow Chief Models

Understanding the essential elements of these winter machines is crucial for effective maintenance and optimal performance. Each unit comprises various integral parts that contribute to its functionality and efficiency.

Essential Parts

- Engine: The powerhouse driving the entire system.

- Auger: Responsible for breaking and gathering the frozen material.

- Chute: Directs the discharge of cleared debris.

- Skids: Provide stability and adjust height for surface clearance.

- Controls: Allow for user operation and adjustments.

Additional Features

- Transmission: Facilitates movement and speed settings.

- Headlight: Enhances visibility during low-light conditions.

- Rubber paddles: Aid in efficient material handling and minimize surface damage.

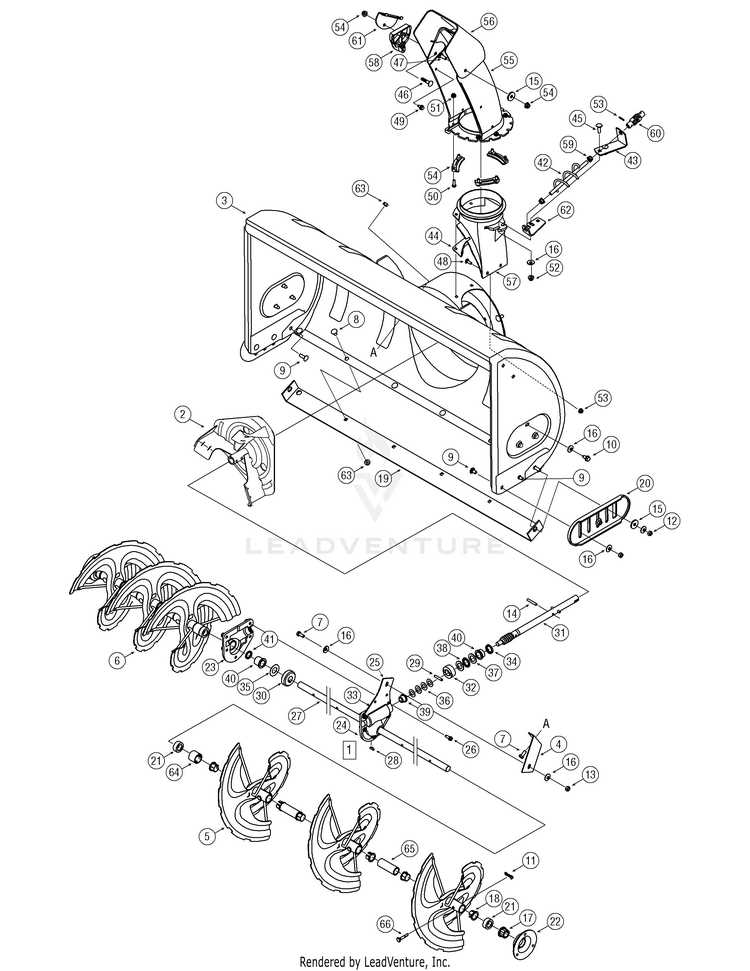

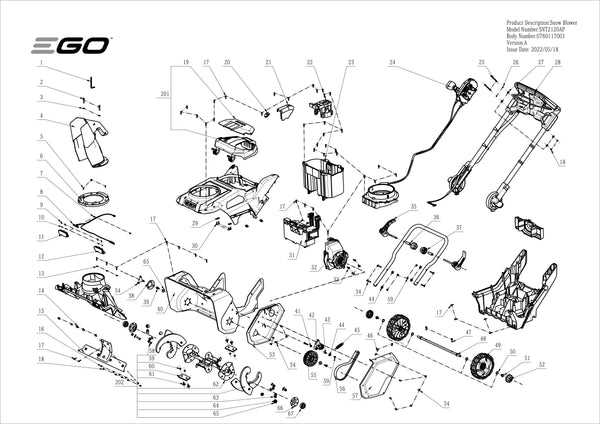

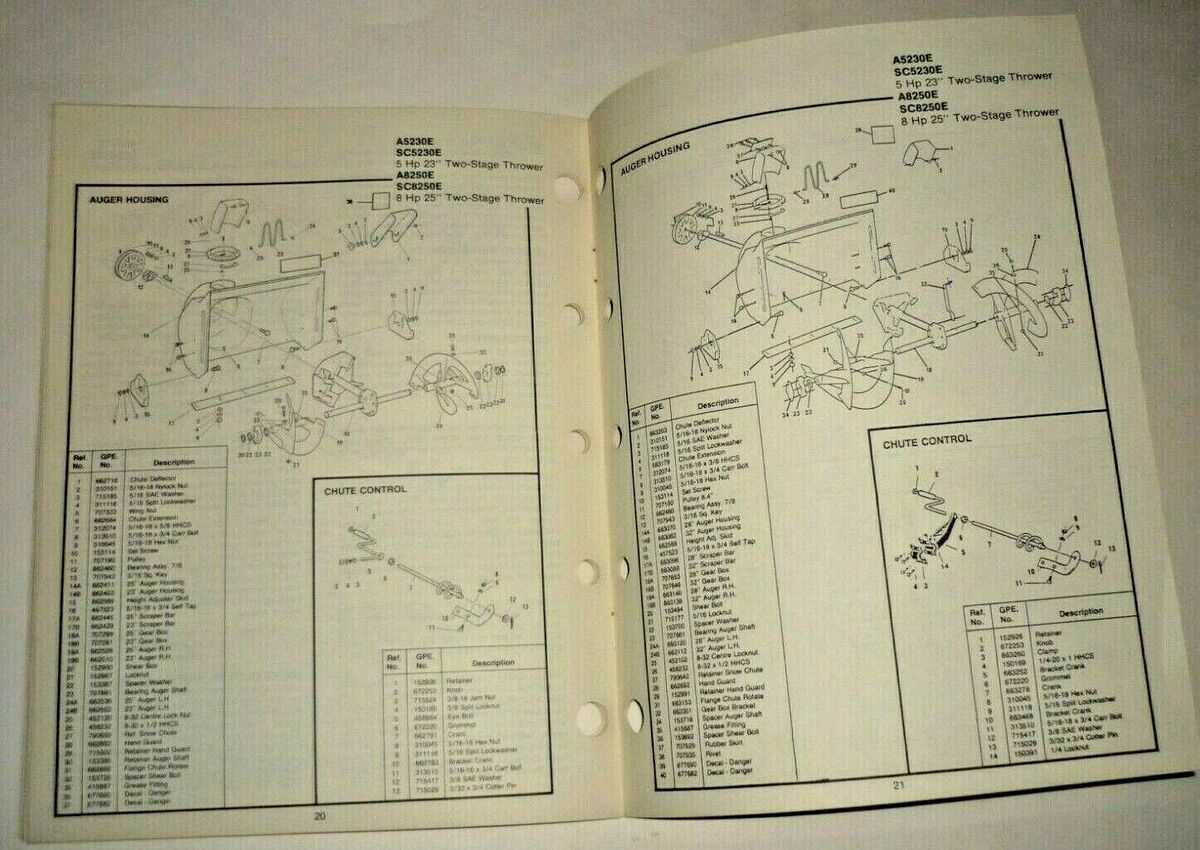

How to Interpret Parts Diagrams

Understanding assembly schematics is essential for efficient maintenance and repair. These visual representations provide a detailed look at components and their relationships, facilitating troubleshooting and part identification. By familiarizing yourself with these illustrations, you can streamline your repair processes and ensure accuracy in replacements.

Start by familiarizing yourself with the layout of the schematic. Each element is typically labeled with a unique identifier, allowing for easy cross-referencing with lists or catalogs. Pay attention to the arrangement, as it often reflects the actual setup of the machine, guiding you on how parts fit together.

Next, note the different symbols used to represent various components. Understanding these symbols is crucial, as they can vary between manufacturers. A clear grasp of what each symbol signifies will enhance your ability to navigate the illustration effectively.

Finally, refer to accompanying documentation that may provide additional context, such as installation guidelines or maintenance tips. Combining the schematic with this supplementary information will give you a comprehensive understanding of the assembly, ensuring that repairs are both precise and efficient.

Common Issues and Solutions

When operating outdoor clearing equipment, users may encounter several recurring challenges that can hinder performance. Understanding these common problems and their resolutions is essential for maintaining efficiency and prolonging the lifespan of the machine.

One frequent issue is the equipment failing to start. This can often be attributed to a drained battery or insufficient fuel. Regularly checking the battery charge and ensuring proper fuel levels can mitigate this problem. Additionally, inspecting the ignition system and fuel lines can reveal any underlying issues that require attention.

Another common concern is clogging, which can occur when the intake becomes blocked by debris or ice. To resolve this, operators should frequently clear any obstructions from the chute and housing. It is also advisable to avoid working in extremely wet or heavy conditions that contribute to buildup.

Vibrations during operation may indicate loose components or worn parts. Regularly inspecting bolts and fasteners can help identify loose elements. Furthermore, examining belts and blades for wear will ensure smooth functioning and prevent damage.

Lastly, decreased clearing efficiency can arise from dull blades or improper settings. Regular maintenance and sharpening of blades, along with adjustments to operational settings based on the environment, can enhance performance. Keeping the machine clean and well-lubricated will also support optimal functionality.

Essential Maintenance Tips for Longevity

Proper upkeep is vital for ensuring the durability and efficiency of your outdoor equipment. Regular attention to specific components can significantly extend the lifespan and enhance performance, making it essential to follow a routine maintenance schedule.

Regular Inspection

Frequent evaluations can help identify wear and tear early. Look for signs of damage, corrosion, or loose connections to address issues promptly.

Cleaning Procedures

Keeping your machine clean from debris and buildup is crucial. This not only improves functionality but also prevents premature deterioration of parts.

| Maintenance Task | Frequency |

|---|---|

| Inspect belts and cables | Monthly |

| Change oil | Every season |

| Clean filters | Every use |

| Check fuel system | Before storage |

Replacement Parts: Where to Find Them

When it comes to maintaining and restoring your outdoor equipment, sourcing high-quality components is crucial. Whether you’re looking for essential items or specific enhancements, knowing where to seek them can make all the difference in performance and longevity.

Online Retailers offer a vast selection of options, often at competitive prices. Websites dedicated to outdoor machinery often have extensive inventories, making it easy to compare various brands and models.

Local Hardware Stores can be invaluable for immediate needs. Many carry a range of components, and their staff can provide personalized assistance, ensuring you find what you need.

Specialty Shops focused on outdoor equipment often stock hard-to-find items. These establishments are typically staffed by knowledgeable professionals who can guide you in your search.

Manufacturer’s Websites are a reliable source for authentic components. They provide detailed information and direct access to the latest products designed specifically for your machinery.

Online Marketplaces like auction sites or classifieds can yield surprising finds. However, exercise caution and ensure the quality of items before purchase.

Ultimately, exploring multiple avenues will enhance your chances of locating the right components for your needs. With a little diligence, you can restore your equipment to optimal condition.

Step-by-Step Assembly Guide

This section provides a detailed procedure for assembling your equipment effectively. Following these instructions will ensure that all components fit together correctly, enhancing performance and longevity. Each step is designed to be straightforward, making the process accessible for users of all skill levels.

Tools and Materials Needed

Before starting the assembly, gather the necessary tools and materials. You will typically need a wrench set, screwdrivers, and the main components of your device. Make sure all items are clean and free of debris to avoid any complications during assembly.

Assembly Instructions

1. Prepare the Base: Begin by laying the foundation on a flat surface. Ensure it is stable and secure. This will provide a solid starting point for the rest of the assembly.

2. Attach Components: Follow the order specified in your manual. Start with the primary unit, ensuring all connections are tight. Use appropriate fasteners to secure each part, checking for alignment as you proceed.

3. Final Checks: Once all pieces are assembled, review the structure for any loose connections. Tighten any bolts or screws as needed. This final inspection will help prevent any issues during operation.

Safety Precautions During Use

When operating machinery designed for clearing surfaces, prioritizing safety is essential. Understanding the potential hazards and following proper guidelines can prevent accidents and ensure effective performance.

Protective Gear

Always wear appropriate protective equipment, such as gloves, goggles, and sturdy footwear. Ear protection is also advisable, as machinery can generate significant noise levels.

Operational Guidelines

Before use, familiarize yourself with the equipment’s manual and ensure that all safety features are functional. Avoid wearing loose clothing that could get caught in moving parts. Additionally, never operate the machine under the influence of alcohol or drugs. Awareness of your surroundings is crucial to prevent injury to yourself and others.

Upgrades for Enhanced Performance

Improving the efficiency and functionality of your outdoor equipment can significantly enhance its performance. Upgrades not only extend the lifespan of your machinery but also increase its effectiveness in tackling various tasks. Here are some modifications you can consider to maximize productivity.

Key Enhancements

- Engine Tuning: Fine-tuning the engine can lead to improved power output and fuel efficiency.

- Blade Replacement: Upgrading to high-quality blades ensures better cutting performance and durability.

- Enhanced Tires: Installing superior traction tires can improve maneuverability on slippery surfaces.

- Advanced Controls: Adding electronic controls can provide better responsiveness and ease of use.

Additional Features

- LED Lighting: Installing brighter, energy-efficient lights enhances visibility during low-light conditions.

- Heated Handles: Upgrading to heated grips can improve comfort during extended use in cold conditions.

- Sound Dampening: Implementing sound-reducing components can lead to a quieter operation, making it more pleasant to use.

Considering these upgrades can help you achieve better results and make your outdoor tasks more efficient and enjoyable.

Comparing Different Snowblower Models

When it comes to winter equipment, selecting the right model can greatly affect efficiency and ease of use. Various options on the market come with distinct features, power levels, and designs, catering to different needs and preferences. Understanding these differences helps users make informed decisions, ensuring they choose the most suitable machine for their specific requirements.

Types of Machines: There are primarily two categories: single-stage and two-stage units. Single-stage models are generally lighter and more maneuverable, making them ideal for smaller areas with lighter accumulations. Conversely, two-stage machines are more robust and capable of handling deeper snow, making them a preferred choice for larger driveways and heavier conditions.

Power Sources: Another crucial aspect is the source of power. Electric variants offer convenience and are quieter, while gasoline-powered options provide more power and autonomy, allowing for extended use without the need for a power outlet. Evaluating the trade-offs between these power sources can help users find the right balance for their environment.

Features and Accessories: Many models come equipped with various features such as heated handles, adjustable augers, and multiple speed settings. These enhancements can significantly improve user comfort and operational efficiency. It’s important to assess which features are essential and which are simply nice to have, as this can influence overall satisfaction with the purchase.

In summary, comparing different winter machines involves analyzing their design, power source, and available features. By carefully evaluating these aspects, users can select a model that best fits their needs and ensures effective performance during challenging winter conditions.

DIY Repairs: Tools You Need

When tackling home repairs, having the right equipment is crucial for successful outcomes. Equipping yourself with essential tools not only simplifies the process but also enhances your efficiency and safety.

- Screwdrivers: A set of both flathead and Phillips options is vital for various fasteners.

- Wrenches: Adjustable and socket wrenches help in loosening or tightening bolts.

- Drill: A reliable power drill is necessary for making holes and driving screws quickly.

- Pliers: Essential for gripping and manipulating objects securely.

- Measuring Tape: Ensures accuracy when measuring spaces or components.

Having these fundamental tools at your disposal allows you to address most repairs with confidence and ease.

Maximizing Efficiency in Winter Conditions

In the frigid months, ensuring optimal performance in clearing surfaces is essential for maintaining safety and accessibility. Understanding how to enhance functionality and productivity during harsh weather can make a significant difference in your efforts.

Preparation is Key: Before the onset of icy weather, it is crucial to equip yourself with the right tools and resources. Regular maintenance and checks on equipment can prevent breakdowns and ensure everything operates smoothly when it matters most.

Technique Matters: Adopting effective strategies for maneuvering can greatly impact efficiency. Whether it’s mastering the right angle or employing systematic patterns, these techniques help minimize effort while maximizing coverage.

Utilizing Technology: Modern advancements provide numerous options to enhance performance. From heated grips to automated systems, leveraging technology can alleviate physical strain and improve outcomes.

Safety First: Ensuring personal safety should always be a priority. Wearing appropriate gear and being mindful of your surroundings reduces the risk of accidents, allowing for a more focused and effective approach to the task at hand.

By implementing these strategies, one can significantly enhance productivity and effectiveness during the winter months, ensuring that all surfaces remain clear and safe for use.