Understanding the Wheel Horse Snowblower Parts Diagram

Maintaining the functionality of your outdoor machinery is crucial for ensuring efficient performance, especially during the colder months. Familiarity with the various components and their arrangements can greatly enhance your ability to troubleshoot issues and perform necessary repairs. A comprehensive understanding of how each element interacts will empower you to tackle any challenges that may arise.

In this section, we will explore the intricate layout of essential components that contribute to the overall operation of these machines. By dissecting the arrangement and purpose of each part, you will gain valuable insights into their roles and how they work together to deliver optimal results. This knowledge not only aids in maintenance but also enhances your overall experience when using this equipment.

Furthermore, recognizing the specific functions of individual elements can assist in identifying potential problems early on. Whether you’re a seasoned user or a novice, being equipped with this information will prepare you for effective management of your machinery, ensuring it remains in peak condition throughout its lifespan.

Understanding Wheel Horse Snowblower

This section delves into the intricacies of a specific type of outdoor machinery designed for winter maintenance. It is essential for ensuring that pathways, driveways, and yards remain clear during snowy conditions. By grasping its components and functionalities, users can optimize performance and enhance reliability in challenging weather.

Key Features

- Efficient clearing capabilities for various snow depths

- Robust construction to withstand harsh winter conditions

- User-friendly controls for ease of operation

Maintenance Tips

- Regularly check and replace the oil to ensure smooth operation.

- Inspect the blades for wear and sharpen as needed.

- Clean the machine after each use to prevent rust and buildup.

- Store in a dry place to protect from moisture damage.

Key Components of Snowblower

Understanding the essential elements of a snow-clearing machine is crucial for effective maintenance and operation. Each component plays a significant role in ensuring optimal performance during harsh winter conditions, enabling efficient removal of accumulated snow from various surfaces.

Engine and Power System

The engine serves as the powerhouse of the machine, providing the necessary energy to drive all functions. Typically, it is powered by gasoline or electricity, offering different advantages in terms of efficiency and convenience. The power system is responsible for transferring this energy to the various moving parts, ensuring smooth operation.

Auger and Discharge Chute

The auger is vital for breaking up and collecting snow, while the discharge chute directs the cleared snow away from the path. Together, these components work in tandem to enhance the effectiveness of the clearing process, allowing users to tackle different snow depths and conditions efficiently.

Importance of Maintenance Practices

Regular upkeep is essential for ensuring the longevity and efficiency of any machinery. By adhering to a consistent maintenance schedule, operators can prevent unexpected breakdowns and enhance performance, ultimately saving time and resources.

Benefits of Routine Maintenance

Implementing systematic care practices provides numerous advantages. It helps identify potential issues before they escalate, thus reducing repair costs and downtime. Moreover, well-maintained equipment operates more efficiently, contributing to improved productivity and safety.

Key Maintenance Tasks

To maintain optimal functioning, several key tasks should be regularly performed:

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 50 hours | Ensures smooth operation and prevents engine wear. |

| Filter Replacement | Every 100 hours | Maintains air quality and engine efficiency. |

| Belt Inspection | Every 25 hours | Checks for wear and proper tension to avoid failures. |

| Spark Plug Check | Every season | Ensures reliable starting and optimal combustion. |

By prioritizing these essential maintenance tasks, operators can enhance the performance and reliability of their equipment, ultimately leading to greater satisfaction and productivity.

Identifying Common Wear Parts

Understanding the components that experience frequent use is crucial for maintaining optimal performance. These elements are essential to the overall functionality and durability of your machine. Recognizing the signs of wear can help ensure that your equipment remains reliable through various conditions.

Among the most susceptible items are belts, which can degrade over time due to friction and exposure to harsh elements. Additionally, blades and augers can become dull or damaged, affecting efficiency. Regular inspections of these items can prevent unexpected breakdowns and enhance longevity.

Furthermore, bearings and seals often require attention, as they can wear down from continuous operation. Noticing any unusual noises or vibrations may indicate the need for replacement. By keeping an eye on these vital components, users can mitigate potential issues and achieve the ultimate performance from their machinery.

Benefits of Using Original Parts

Utilizing authentic components for your machinery ensures optimal performance and longevity. These elements are specifically designed to fit perfectly and function seamlessly, reducing the risk of malfunctions.

Original components often come with warranties, providing peace of mind and financial protection against unforeseen issues. This assurance allows users to operate their equipment with confidence.

Additionally, genuine parts maintain the integrity of the machine, preserving its value over time. When repairs are necessary, using original replacements simplifies the process and ensures compatibility.

In conclusion, opting for authentic components ultimately enhances reliability, safety, and overall satisfaction with your equipment, making it a wise investment for any user.

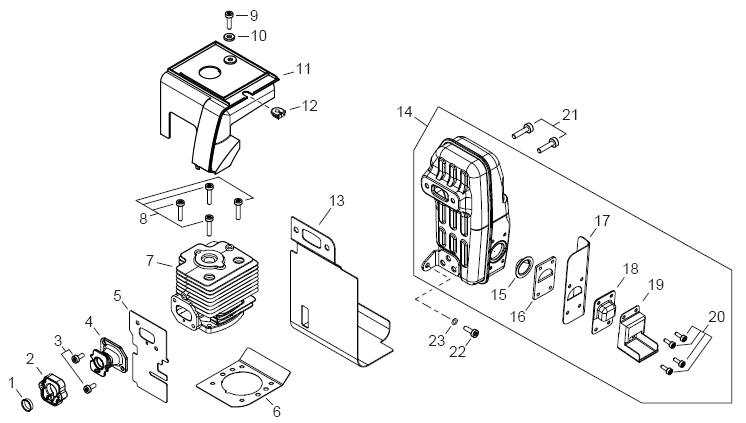

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair. These visuals provide a comprehensive overview of components, allowing users to identify and locate specific items quickly. Familiarity with the layout and symbols used can significantly enhance your ability to interpret these resources.

Begin by examining the overall structure, noting how various elements are grouped. Each section typically corresponds to a specific functionality or assembly. Pay attention to labels, as they often indicate part numbers or descriptions, helping you to match them with actual components.

Next, look for reference keys or legends that clarify symbols or colors used throughout the illustration. These can guide you in understanding the relationship between parts and their respective roles in the overall system. Cross-referencing with a manual can provide additional insights.

Lastly, practice by identifying individual components and tracing their connections within the system. This will improve your familiarity and confidence, making it easier to tackle repairs or replacements in the future.

Top Issues Faced by Users

When it comes to operating outdoor equipment designed for winter tasks, users often encounter a variety of challenges that can hinder performance and efficiency. Understanding these common issues is crucial for effective troubleshooting and maintenance, ultimately ensuring that the equipment remains reliable during harsh conditions.

Performance Problems

One of the most frequently reported challenges involves inadequate functionality, such as weak throwing power or inconsistent operation. These issues can stem from various factors, including blockages, worn components, or improper adjustments. Users should regularly inspect the machinery to identify and address these problems promptly.

Maintenance Concerns

Another significant concern revolves around upkeep and repair. Many users find it difficult to access replacement components or understand the maintenance requirements for their equipment. Regular maintenance, including oil changes and part inspections, is essential to prolong the lifespan and performance of the machine.

Finding Replacement Parts Online

Locating components for your equipment can be a straightforward process with the right approach. Understanding where to search and how to assess options can lead you to the best solutions.

- Utilize manufacturer websites for original components.

- Explore online marketplaces that specialize in outdoor machinery.

- Join forums and community groups for recommendations and shared experiences.

When browsing online, keep these tips in mind:

- Check compatibility with your model before purchasing.

- Read customer reviews to gauge quality and reliability.

- Look for warranties or return policies to protect your investment.

By taking these steps, you can delve into a range of options and secure the ultimate components you need for optimal performance.

Comparing Aftermarket vs OEM Parts

When maintaining outdoor equipment, choosing the right components can significantly impact performance and longevity. Understanding the differences between alternative and original manufacturer options is essential for making informed decisions.

Quality and Performance

Alternative components often provide a cost-effective solution, but their quality can vary widely. Original manufacturer components are designed to meet specific standards, ensuring compatibility and reliability.

Cost Considerations

While alternative options can be cheaper upfront, the long-term value should be assessed. Investing in original components may prevent potential issues that could arise from using lower-quality alternatives.

| Aspect | Aftermarket | OEM |

|---|---|---|

| Price | Typically lower | Generally higher |

| Quality | Varies widely | Consistent and reliable |

| Warranty | Limited | Comprehensive |

| Availability | Widely accessible | Dependent on manufacturer |

Assembly Instructions for Beginners

Getting started with the assembly of your outdoor equipment can seem daunting, but with the right guidance, it can be a straightforward process. This section aims to provide clear, step-by-step instructions to ensure you can confidently piece together your machine.

- Gather Your Tools: Ensure you have the necessary tools at hand, such as a wrench, screwdriver, and any specific tools mentioned in the manual.

- Read the Manual: Familiarize yourself with the instruction manual to understand the components and assembly sequence.

- Organize Components: Lay out all parts on a clean surface, checking them against the parts list to ensure everything is present.

- Follow Steps Sequentially: Start with the first step in the manual, assembling each section before moving on to the next.

- Secure Connections: As you assemble, ensure all bolts and screws are tightened properly to maintain stability.

- Test the Assembly: Once fully assembled, conduct a thorough check to confirm everything is secure and functioning as intended.

By following these simple steps, beginners can delve into the assembly process with confidence and achieve a successful setup.

Common Repair Tips and Tricks

Maintaining machinery can often seem daunting, but with the right guidance, anyone can tackle minor issues efficiently. Understanding the common challenges and knowing some handy solutions can make the repair process smoother and more rewarding.

Routine Maintenance

- Check and replace filters regularly to ensure optimal performance.

- Keep all moving parts lubricated to prevent wear and tear.

- Inspect belts and cables for signs of fraying or damage.

Troubleshooting Common Issues

- If the machine won’t start, verify the fuel supply and connections.

- For inconsistent operation, check spark plugs and replace them if needed.

- Address any unusual noises by tightening loose components or replacing worn parts.

Safety Precautions When Repairing

When undertaking maintenance or repair tasks on machinery, prioritizing safety is essential. Proper precautions can prevent accidents and injuries, ensuring a smooth and efficient working process. Below are key safety measures to consider before getting started.

Personal Protective Equipment (PPE)

- Always wear safety goggles to protect your eyes from debris.

- Use gloves to shield your hands from sharp edges and chemicals.

- Wear steel-toed boots to safeguard your feet from heavy objects.

- Consider ear protection if working with loud tools or equipment.

Workspace Preparation

- Ensure your workspace is well-lit and organized.

- Remove any obstacles that could cause trips or falls.

- Keep fire extinguishers accessible in case of emergencies.

- Read the manufacturer’s manual for specific safety recommendations.

By adhering to these safety guidelines, you can minimize risks and ensure a successful repair experience.

Resources for Snowblower Owners

Maintaining your winter equipment can significantly enhance its performance and longevity. Accessing the right resources is crucial for effective upkeep and troubleshooting. This section provides valuable information and tools to help you ensure your machinery operates smoothly throughout the snowy season.

Essential Guides

Owners can benefit from comprehensive manuals and online tutorials that cover everything from basic maintenance to advanced repairs. These resources often include step-by-step instructions, safety tips, and seasonal checklists.

Community Support

Joining online forums or local clubs can provide you with a network of fellow enthusiasts. Sharing experiences, advice, and solutions can help you navigate any challenges you encounter.

| Resource Type | Description | Link |

|---|---|---|

| User Manuals | Detailed guides for maintenance and operation. | View Manuals |

| Video Tutorials | Visual instructions for common repairs and maintenance. | Watch Tutorials |

| Online Forums | Platforms for discussion and advice sharing among users. | Join Forums |

| Local Workshops | Hands-on learning experiences for equipment care. | Find Workshops |