Understanding the Club Car Steering Parts Diagram for Optimal Maintenance

Every vehicle relies on intricate systems that ensure smooth navigation and control. Gaining insight into these essential components can enhance your overall experience and performance. By familiarizing yourself with the various elements involved, you can address potential issues and optimize functionality.

Visualizing the structure of these systems is crucial for effective maintenance and repair. A detailed representation allows enthusiasts and owners alike to grasp how different components interact with one another. This knowledge not only empowers users but also enhances their ability to troubleshoot and make informed decisions.

In this guide, we will delve into the intricate world of vehicle control mechanisms, exploring their roles and relationships. Understanding these aspects is the ultimate way to ensure longevity and reliability in your driving experience.

Understanding Club Car Steering Systems

Grasping the functionality of a vehicle’s navigation mechanism is essential for optimal performance and safety. This section delves into the intricate components that contribute to the maneuverability of your vehicle, ensuring a smooth and responsive driving experience.

Key Components

- Column Assembly: The central structure that connects the wheel to the rest of the system, facilitating directional control.

- Linkage: A series of rods and joints that transfer the driver’s input to the wheels.

- Gear Mechanism: This crucial element converts rotational movement into linear motion for enhanced precision.

- Wheel Interface: The connection point between the steering device and the actual wheels, allowing for effective turning.

Maintenance Tips

- Regularly inspect the column assembly for wear and tear.

- Lubricate all moving parts to ensure smooth operation.

- Check alignment periodically to maintain proper handling.

- Replace worn components promptly to avoid further damage.

Understanding these elements will empower you to maintain and enhance the efficiency of your vehicle’s navigation system.

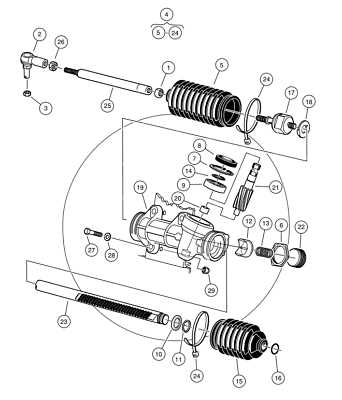

Essential Components of Steering Mechanism

The functionality of a directional control system relies on a variety of key elements working in harmony. Each component plays a crucial role in ensuring that the user can effectively navigate their vehicle with precision and ease. Understanding these vital pieces not only aids in maintenance but also enhances overall driving experience.

1. Rack and Pinion: This system transforms rotational motion into linear movement, allowing for responsive maneuvering. The interaction between the gears enables quick adjustments to direction.

2. Tie Rods: These links connect the steering gear to the wheels, facilitating movement. Their durability is essential for reliable handling and stability.

3. Steering Column: Acting as the central shaft, this element houses the controls and transmits driver inputs to the mechanism. A well-designed column enhances comfort and accessibility.

4. Steering Wheel: The interface between the driver and the system, it provides the means to initiate turns and adjustments. Ergonomic design is key for effective control.

5. Pitman Arm: This lever converts rotational movement from the column into lateral motion, influencing the angle of the wheels. Its strength and precision are vital for accurate directional changes.

6. Idler Arm: This component helps maintain proper alignment in the system, ensuring smooth operation and reducing wear on other elements.

In summary, each element within the directional control framework contributes to the overall functionality and safety of vehicle operation. Understanding these components allows for better upkeep and enhances driving confidence.

Common Issues in Steering Parts

When it comes to the control mechanisms of vehicles, various challenges can arise that impact functionality and safety. Understanding these complications is essential for maintaining optimal performance and ensuring a smooth experience on the road.

Wear and Tear

Over time, components can deteriorate due to constant use, leading to decreased responsiveness and potential failure. Regular inspections can help identify these issues early.

Alignment Problems

Miscalibration can result in uneven wear and handling difficulties. Ensuring proper alignment is crucial for stability and efficient maneuvering.

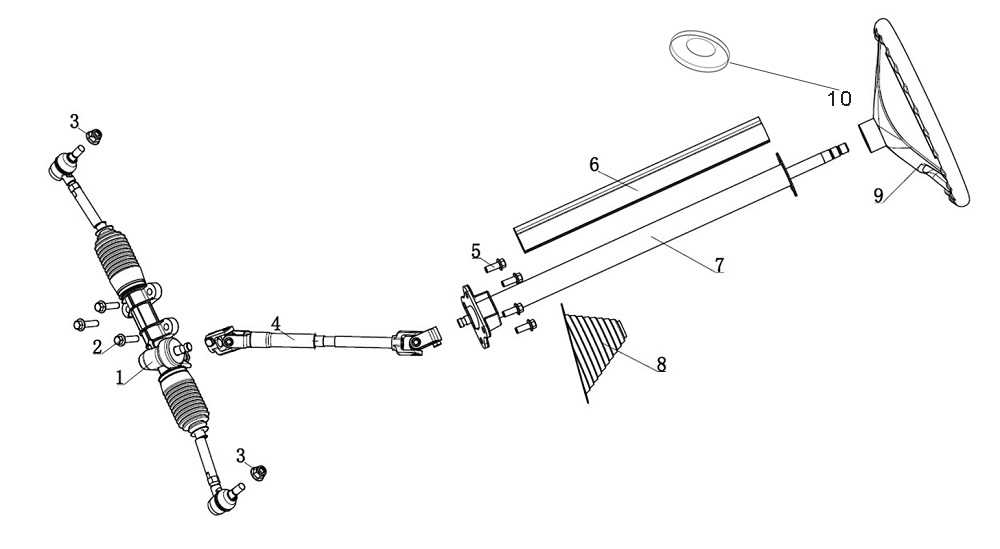

Visualizing Steering Parts Diagram

Understanding the intricate components that govern maneuverability is essential for effective maintenance and enhancement. By examining a visual representation of these elements, one can grasp their roles and relationships within the assembly, facilitating better troubleshooting and upgrades.

Importance of Clarity in Representation

A clear depiction aids both enthusiasts and professionals in identifying specific elements. This clarity streamlines the repair process, ensuring that any adjustments or replacements are performed accurately and efficiently.

Exploring Component Interactions

Delving into how these components interact provides insight into the overall functionality. Observing their connections can highlight potential points of failure and areas for improvement, ultimately leading to an optimized performance.

Step-by-Step Installation Guide

This guide provides a comprehensive approach to successfully install the necessary components of your vehicle’s directional control system. By following these clear and concise steps, you will ensure that each element is properly fitted, enhancing both functionality and safety.

Begin by gathering all required tools and components. Ensure that your workspace is clean and organized to facilitate a smooth installation process. It is advisable to refer to the manufacturer’s specifications for any unique requirements pertaining to your model.

Start with the removal of any existing assemblies. Carefully detach the components while taking note of their configuration. Documenting this process can aid in the reinstallation of new parts. Once everything is removed, inspect the area for any signs of wear or damage that may need addressing before proceeding.

Next, align the new elements according to the provided specifications. Make sure to follow the manufacturer’s instructions closely, paying attention to any torque specifications or alignment markers. Secure each component in place using the appropriate fasteners, ensuring a snug fit without over-tightening.

After all new components are installed, conduct a thorough inspection. Double-check all connections and ensure everything is properly secured. It is crucial to test the functionality of the system before concluding the installation. Conduct a few maneuvers to ensure that the directional control is responsive and operates smoothly.

Finally, clean up your workspace, disposing of any old components responsibly. It is recommended to keep a record of the installation date and any parts replaced for future reference. With everything in order, you can enjoy improved handling and safety on the road.

Maintenance Tips for Longevity

Ensuring the durability of your vehicle’s components requires consistent care and attention. Regular maintenance can significantly enhance performance and extend the lifespan of essential mechanisms. By following some practical guidelines, you can keep everything running smoothly and efficiently.

Regular Inspections

Frequent checks of all critical elements are vital. Look for signs of wear or damage, and address any issues promptly. This proactive approach helps in identifying potential problems before they escalate.

Proper Lubrication

Maintaining adequate lubrication is crucial for reducing friction and wear. Use quality products and apply them according to the manufacturer’s recommendations to ensure optimal functioning.

Upgrading Your Club Car Steering

Enhancing the control system of your vehicle can significantly improve the overall driving experience. By integrating advanced components and fine-tuning existing mechanisms, you can achieve a smoother and more responsive handling. This not only elevates comfort but also boosts safety during operation.

Consider replacing outdated elements with high-performance alternatives that offer greater durability and precision. Upgrading linkages and bushings can lead to better alignment and reduce wear over time. Additionally, exploring options for enhanced feedback and responsiveness will contribute to a more engaging ride.

Regular maintenance and timely upgrades can prevent issues and prolong the life of your system. Investing in quality materials ensures that your vehicle remains reliable, allowing you to navigate various terrains with confidence. Ultimately, a well-optimized control system is key to achieving the best performance possible.

Differences in Models and Designs

When exploring various models and their configurations, it’s essential to recognize the nuances that set them apart. Each iteration offers distinct features that cater to different user needs and preferences.

- Design Variations: The aesthetic and functional differences can significantly impact usability.

- Material Choices: Variations in materials used can influence durability and weight.

- Mechanism Types: Different mechanisms affect handling and responsiveness.

- Size Specifications: Dimensions can vary, impacting compatibility with other components.

Understanding these differences allows users to make informed choices based on their specific requirements.

Safety Considerations While Repairing

When undertaking any repair work, ensuring a safe environment is paramount. Proper precautions can prevent accidents and injuries, creating a more efficient workflow. Awareness of potential hazards and implementing safety measures will not only protect the individual but also extend the lifespan of the equipment being serviced.

Personal Protective Equipment (PPE) is essential. Always wear appropriate gear such as gloves, goggles, and steel-toed boots to safeguard against sharp objects and chemicals. This simple step can significantly reduce the risk of injury during maintenance tasks.

Furthermore, maintaining a clean workspace is critical. Clutter can lead to slips and falls, so keeping tools organized and surfaces tidy minimizes unnecessary risks. Ensure that any spills are promptly cleaned up to maintain a safe working area.

It is also advisable to disconnect power sources before starting repairs. This prevents accidental activation of machinery and protects against electric shocks. Additionally, make sure to follow manufacturer guidelines and specifications to avoid mishandling components.

Lastly, always work with a partner when performing complex tasks. Having someone nearby can provide assistance in case of emergencies, ensuring a safer and more efficient repair process.

Tools Required for Steering Repairs

Engaging in the repair of directional components requires a selection of essential implements. Proper tools ensure that tasks are executed efficiently and effectively, minimizing the risk of errors and enhancing overall safety.

Basic Tools

A comprehensive toolkit typically includes wrenches, sockets, and pliers, which are fundamental for loosening and tightening fasteners. Additionally, a reliable jack and jack stands are vital for lifting the vehicle securely.

Specialized Equipment

For more intricate adjustments, tools such as torque wrenches and alignment gauges are indispensable. These specialized devices facilitate precise measurements and alignments, ensuring optimal performance of the assembly.

Finding Quality Replacement Parts

When it comes to maintaining the functionality of your vehicle’s essential systems, sourcing high-quality components is crucial. Choosing the right items ensures longevity and performance, allowing for smoother operation and reducing the risk of future issues. This section will guide you through the process of identifying and acquiring top-notch replacements.

Where to Search

Start your journey by exploring both online and local suppliers. Online marketplaces often provide a wide variety, while local shops can offer personalized service and immediate availability. Consider customer reviews and ratings to assess the reliability of sources.

Criteria for Quality

When evaluating options, prioritize durability, compatibility, and manufacturer reputation. Well-known brands often guarantee higher standards, and thorough research can prevent costly mistakes in your selection process.

| Feature | Importance |

|---|---|

| Durability | Ensures longevity and performance under stress. |

| Compatibility | Prevents issues with fit and function. |

| Manufacturer Reputation | Indicates reliability and quality assurance. |

Expert Advice on Steering Troubleshooting

Addressing issues with vehicle maneuverability can often seem daunting. However, understanding the fundamental aspects and common problems can significantly ease the process. Identifying the signs of trouble early can lead to effective solutions and ensure a safer driving experience.

Common Symptoms to Watch For

When facing difficulties, it’s crucial to recognize the indicators that suggest a need for examination. Typical symptoms include unusual noises, unresponsive handling, or uneven movement. Paying attention to these cues can guide you toward the source of the issue.

Basic Troubleshooting Steps

Start by inspecting the connection between components for any visible damage or wear. Check fluid levels and ensure that everything is adequately lubricated. If problems persist, further investigation may be necessary.

| Symptom | Possible Cause | Suggested Action |

|---|---|---|

| Noise during turning | Worn bearings | Replace bearings |

| Stiff handling | Low fluid levels | Refill fluid |

| Pulling to one side | Misaligned components | Alignment adjustment |