Complete Guide to Craftsman LT1000 Steering Parts Diagram

Maintaining your lawn machinery is essential for optimal performance and longevity. A thorough comprehension of the various mechanisms involved can significantly enhance your ability to troubleshoot issues and execute repairs effectively. This section aims to provide valuable insights into the specific components that contribute to the maneuverability and control of your equipment.

Identifying the different elements of the steering assembly is crucial for anyone seeking to improve their understanding of lawn care machinery. Each component plays a pivotal role in ensuring a smooth operation, allowing users to navigate their outdoor spaces with ease. Familiarity with these features not only aids in maintenance but also empowers users to tackle any challenges that may arise.

In this guide, you will discover detailed information about the configuration and function of various essential components. By familiarizing yourself with this knowledge, you will be better equipped to make informed decisions regarding repairs and enhancements. This understanding will ultimately lead to a more efficient and enjoyable experience in managing your yard.

Understanding Craftsman LT1000 Steering Mechanism

The control system that directs movement plays a crucial role in the overall functionality of any garden tractor. A well-designed mechanism ensures precise handling and enhances the user experience. This section will explore the various components involved in this essential system, shedding light on their roles and interconnections.

Key Components of the Control System

Several elements work together to provide smooth maneuverability. Each part contributes to the overall operation, and understanding their functions is vital for effective maintenance.

- Wheel Assembly: The outer part that contacts the ground and provides traction.

- Column: The vertical structure that connects the steering wheel to the rest of the system.

- Linkages: These components transfer the motion from the wheel to the wheels on the ground.

- Bearings: These facilitate smooth rotation and minimize friction within the mechanism.

Maintenance Tips

Regular upkeep is essential to ensure optimal performance and longevity of the control system. Consider the following recommendations:

- Check for wear and tear on all moving parts.

- Lubricate components as needed to reduce friction.

- Inspect linkages for any signs of damage or misalignment.

- Ensure the wheel assembly is properly inflated and free from debris.

By understanding the intricacies of this mechanism, users can enhance both the performance and lifespan of their equipment, ensuring a smoother operation in the garden.

Essential Components of Steering System

The functionality of any guiding mechanism relies on a combination of crucial elements that work in unison. Understanding these components is vital for effective control and navigation, ensuring smooth operation and stability during movement.

Key Elements

Among the primary components are the framework, connectors, and the mechanism that facilitates directional changes. Each plays a pivotal role in enhancing responsiveness and precision.

Maintenance Considerations

Regular inspections and timely replacements of these components are essential for optimal performance. Neglecting any part can lead to compromised safety and efficiency.

| Component | Function |

|---|---|

| Framework | Supports and aligns the system |

| Connectors | Transmit motion and force |

| Control Mechanism | Facilitates directional adjustments |

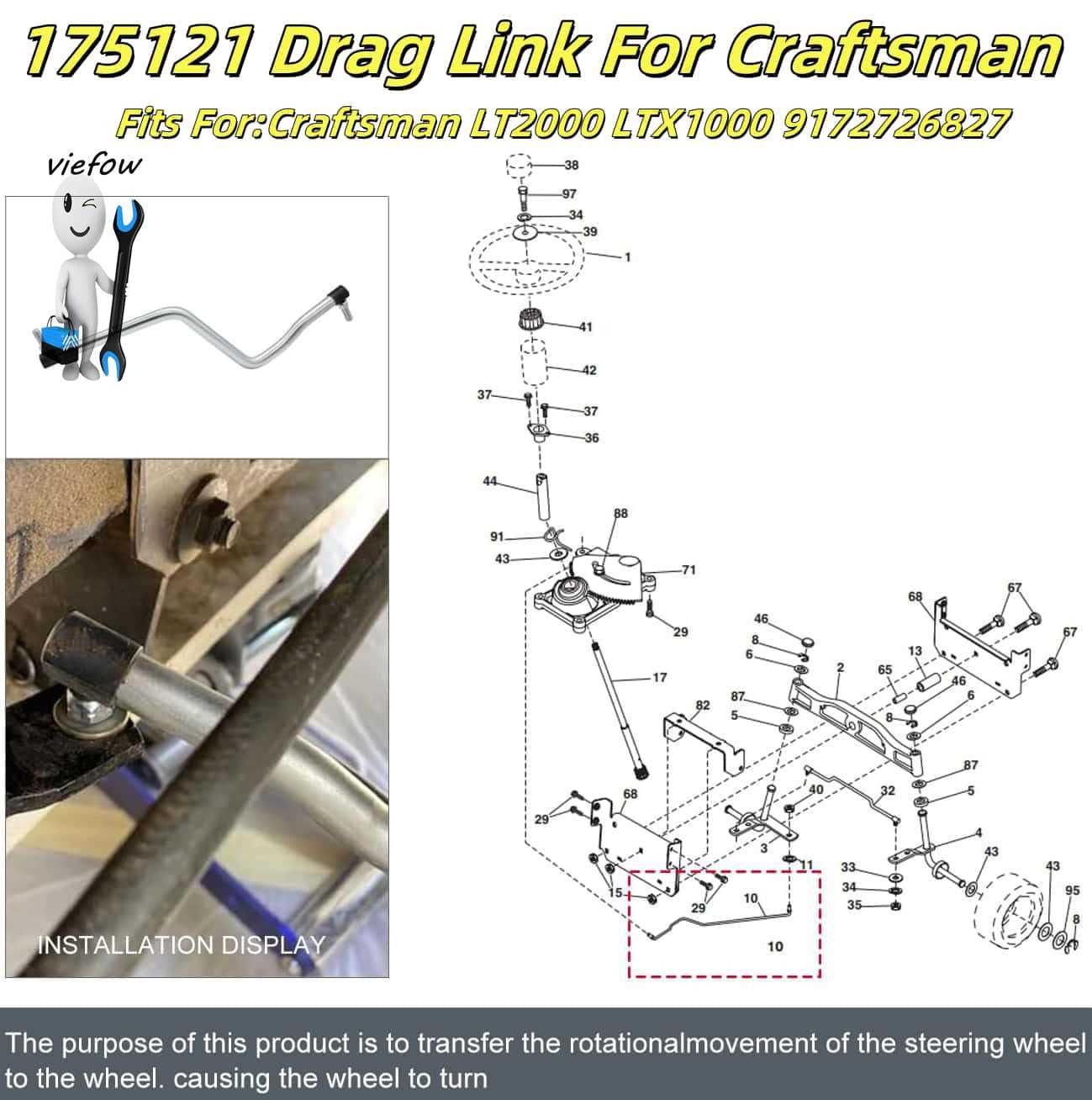

Visual Representation of Steering Parts

This section aims to provide a clear illustration of the components involved in directional control mechanisms. Understanding the layout and relationships between these elements can greatly enhance maintenance and troubleshooting efforts.

Key Components Overview

Among the critical elements are the control wheel, connecting rods, and pivots. Each plays a vital role in ensuring precise navigation and stability during operation. Recognizing their positions and functions allows for better handling and efficient repairs.

Importance of Accurate Depictions

Accurate visual guides are essential for both novice and experienced operators. They simplify the identification of issues and streamline the repair process. A well-structured representation not only clarifies functionality but also fosters a deeper understanding of overall mechanics.

Common Issues with Steering Assembly

The assembly responsible for directional control is crucial for safe operation. However, various complications can arise over time, leading to challenges in maneuverability and stability. Understanding these issues can help in timely maintenance and enhance overall performance.

Frequent Problems

Several common problems can affect the functionality of the control mechanism:

| Issue | Description | Potential Solution |

|---|---|---|

| Wear and Tear | Components may degrade due to regular use, affecting responsiveness. | Regular inspections and replacements of worn parts. |

| Loose Connections | Connections can become loose, leading to imprecise handling. | Tighten all bolts and fittings as necessary. |

| Misalignment | Parts may shift out of their proper positions, causing erratic behavior. | Realign the components and ensure proper calibration. |

Signs of Trouble

It’s essential to be aware of signs indicating that something may be amiss:

- Difficulty in turning

- Unusual noises during operation

- Vibrations felt through the control interface

How to Replace Steering Components

Replacing essential components of your machine’s maneuvering system is crucial for optimal performance. This guide provides step-by-step instructions to ensure a seamless replacement process, enhancing control and safety.

Preparation Steps

- Gather necessary tools: wrenches, sockets, and screwdrivers.

- Refer to your user manual for specific details regarding components.

- Ensure the machine is on a flat surface and securely parked.

Replacement Procedure

- Remove any coverings to access the mechanism.

- Disconnect the old components carefully, noting their positions.

- Install the new components, ensuring they align correctly.

- Reconnect any wiring or links that were detached.

- Test the system to confirm proper functionality before finalizing reassembly.

Tools Needed for Steering Repair

When addressing issues related to directional control systems, having the right tools at your disposal is crucial for a successful repair. Proper equipment not only ensures efficiency but also enhances safety during the process. Below is a guide to the essential tools required for effective maintenance and troubleshooting.

Essential Tools

Here’s a list of the primary instruments you’ll need:

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening various fasteners. |

| Screwdriver Set | To remove and install screws in assemblies. |

| Socket Set | Useful for accessing nuts and bolts in tight spaces. |

| Pliers | For gripping and twisting components securely. |

| Torque Wrench | Ensures that components are tightened to the correct specifications. |

Additional Recommendations

In addition to the primary tools, consider having the following on hand for a more streamlined experience:

| Tool | Purpose |

|---|---|

| Jack and Jack Stands | To lift the vehicle safely for undercarriage access. |

| Oil Pan | To catch any fluids that may leak during repairs. |

| Cleaning Supplies | To maintain a clean workspace and components. |

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment requires regular care and attention. By adopting a systematic approach to maintenance, you can prevent potential issues and enhance overall performance.

- Regular Inspections: Frequently check all components for signs of wear or damage. Look for cracks, rust, or loose connections.

- Lubrication: Apply appropriate lubricants to moving parts to minimize friction and reduce wear. Follow manufacturer guidelines for suitable products.

- Cleaning: Keep surfaces clean from debris, dirt, and moisture. Regular cleaning helps prevent corrosion and buildup that can impair functionality.

- Storage Practices: When not in use, store equipment in a dry and sheltered location to protect it from harsh weather conditions.

- Periodic Replacement: Replace worn or damaged components promptly to avoid further complications and ensure smooth operation.

Implementing these practices can significantly enhance the durability and efficiency of your machinery, allowing you to enjoy its benefits for years to come.

Identifying Steering Malfunctions

Understanding the signs of potential issues in the directional control system is essential for maintaining optimal performance. Various symptoms can indicate underlying problems, and recognizing them early can prevent further damage and enhance safety.

Common indicators of malfunctions include unusual noises, difficulty in maneuvering, and inconsistent response. Regular inspection and awareness of these symptoms can significantly aid in troubleshooting and ensuring a smooth operation.

| Symptoms | Possible Causes | Recommended Actions |

|---|---|---|

| Unusual sounds during operation | Worn components or misalignment | Inspect and replace damaged parts |

| Resistance or tightness when turning | Low fluid levels or blocked mechanisms | Check and refill fluid; clear obstructions |

| Inconsistent or delayed response | Loose connections or degraded elements | Tighten connections; evaluate for replacements |

| Vibrations felt during movement | Imbalance or faulty components | Conduct a balance check; replace as necessary |

Safety Precautions During Repairs

Ensuring safety during maintenance and repairs is essential for protecting oneself and the equipment. Adopting the right measures minimizes risks and promotes a secure working environment.

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use gloves, goggles, and sturdy footwear to safeguard against potential hazards. |

| Disconnect Power Source | Before starting any work, ensure the device is unplugged or the battery is removed to prevent accidental activation. |

| Work in a Well-Ventilated Area | Ensure the workspace is properly ventilated to avoid inhaling harmful fumes or dust. |

| Keep Tools Organized | Maintain a tidy workspace to prevent accidents caused by misplaced tools. |

| Read Manuals | Familiarize yourself with the equipment’s manual for proper procedures and safety guidelines. |

Upgrading Steering Parts for Performance

Enhancing maneuverability and responsiveness in your machinery can lead to an improved driving experience and greater control. By focusing on specific components that contribute to handling dynamics, you can achieve significant upgrades that cater to your performance needs.

Key Components to Consider

Several elements play a crucial role in optimizing the directional capabilities of your equipment. Evaluating these components will help you make informed decisions about upgrades:

| Component | Benefit |

|---|---|

| Linkages | Enhances precision and reduces play |

| Wheel Assembly | Improves stability and grip |

| Control Mechanism | Offers smoother operation and responsiveness |

Choosing Upgrades Wisely

Selecting the right enhancements requires careful consideration of your specific usage requirements. Researching compatibility and performance metrics will ensure that your investments yield the ultimate results in efficiency and handling.

Where to Buy Replacement Parts

Finding suitable components for your equipment can be a straightforward process if you know where to look. There are numerous options available, from online retailers to local shops, each offering various selections to meet your needs.

Online Retailers

- eCommerce websites: Look for specialized sites that focus on outdoor equipment.

- Marketplaces: Platforms like Amazon and eBay often have a wide variety of options.

- Manufacturer websites: Directly visiting the manufacturer’s site can provide original replacements.

Local Stores

- Hardware stores: Check your local hardware outlets for a selection of essential components.

- Garden centers: Many have sections dedicated to outdoor machinery.

- Repair shops: Local service centers can offer both parts and professional advice.

Comparative Analysis of Similar Models

This section explores the nuances between various models within the same category, emphasizing their unique characteristics and functionality. Understanding these distinctions aids users in making informed decisions tailored to their specific needs.

Key Features Comparison

- Design Efficiency: Models differ in structural integrity and ergonomic design.

- Ease of Use: User-friendliness varies significantly across different options.

- Durability: Material quality plays a crucial role in longevity and performance.

Performance Metrics

- Handling: Assess how each model responds during operation.

- Stability: Evaluate the stability offered in diverse conditions.

- Maintenance: Consider the ease of upkeep required for each option.