Cub Cadet LT1050 Steering Components Overview

The control mechanism of a lawn tractor plays a crucial role in ensuring smooth navigation and precise handling during operation. Recognizing the components that contribute to this system can enhance your ability to maintain and repair the equipment effectively. Knowledge of how these elements interact will help in troubleshooting issues and ensuring optimal performance.

Familiarity with the layout and function of various components is essential for any owner. By exploring the intricate relationships between different elements, users can gain insights into how to achieve better maneuverability and stability. This understanding can lead to improved efficiency and longevity of the machine.

Whether you are looking to replace specific components or simply wish to enhance your understanding of the equipment, a comprehensive exploration of the control system will provide valuable insights. Engaging with this information will empower you to make informed decisions regarding maintenance and upgrades.

Understanding the essential components of the maneuvering mechanism is crucial for maintaining optimal performance and safety. Each element plays a significant role in ensuring smooth directional control, contributing to the overall functionality of the equipment. Familiarizing oneself with these components helps in troubleshooting and repair processes.

Core Components

- Control Wheel: This is the primary interface used by the operator to change direction.

- Connecting Rods: These are responsible for transmitting motion from the control wheel to the directional mechanism.

- Pivot Points: These allow for rotational movement, enabling the equipment to turn efficiently.

- Brackets: Supporting structures that secure various elements in place, ensuring stability during operation.

Maintenance Tips

- Regularly inspect the control wheel for wear and tear.

- Check the connecting rods for any signs of bending or damage.

- Ensure that pivot points are lubricated to facilitate smooth movement.

- Tighten any loose brackets to maintain structural integrity.

Importance of Proper Steering Alignment

Correct alignment of the directional system is crucial for ensuring optimal performance and safety of any vehicle. When the angles of the wheels are precisely adjusted, it leads to smoother navigation, better handling, and improved fuel efficiency. Neglecting this aspect can result in uneven tire wear, compromised stability, and increased strain on the mechanical components.

Benefits of Accurate Adjustment

Having a well-aligned directional system not only enhances control but also contributes to the longevity of the tires. When wheels are aligned properly, they maintain uniform contact with the ground, reducing friction and promoting even wear. This can extend the lifespan of the tires, ultimately saving costs associated with frequent replacements.

Consequences of Misalignment

On the other hand, improper adjustment can lead to various issues, including erratic handling and reduced responsiveness. Drivers may notice their vehicle pulling to one side or experiencing difficulty in maintaining a straight path. This not only poses a safety risk but can also result in costly repairs if left unaddressed. Regular checks and maintenance of the directional system are essential for preventing such problems.

Maintenance Tips for Steering System

Ensuring the optimal performance of the directional control mechanism is crucial for safe and efficient operation. Regular upkeep not only extends the lifespan of the components but also enhances the overall driving experience. Here are some essential suggestions for maintaining this vital system.

| Task | Frequency | Description |

|---|---|---|

| Inspect for Wear | Monthly | Check all connections and elements for signs of wear or damage. Replace any components that show significant deterioration. |

| Lubricate Components | Every 50 Hours | Apply appropriate lubricant to moving parts to reduce friction and prevent premature wear. |

| Tighten Fasteners | Every 25 Hours | Ensure all bolts and fasteners are secure to prevent loosening during operation. |

| Check Alignment | Annually | Verify that all components are properly aligned to ensure smooth operation and handling. |

Implementing these maintenance strategies will significantly improve the reliability of the directional control system and enhance the overall performance of the machine.

Common Issues with Steering Parts

Many individuals encounter difficulties with the control mechanisms of their garden machinery. Understanding typical complications can lead to effective solutions and improved performance. This section delves into prevalent concerns related to these crucial components, helping users identify and address them promptly.

One common issue is the wear and tear of the components over time. Frequent usage can lead to degradation, resulting in decreased responsiveness. Additionally, improper alignment during installation may cause uneven wear, making it essential to ensure proper setup.

Another prevalent problem involves loose connections. Vibration and movement during operation can gradually loosen fittings, which can affect handling and stability. Regular inspections and tightening of these connections can prevent more severe issues from arising.

Lastly, lubrication is vital for maintaining functionality. Inadequate lubrication can lead to increased friction, resulting in overheating and potential failure of the system. Regular maintenance, including lubrication checks, is crucial for ensuring longevity and efficiency.

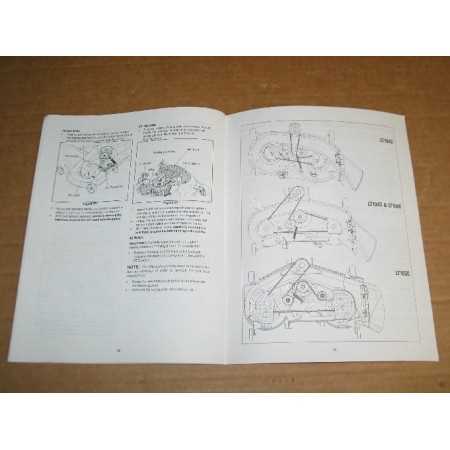

Step-by-Step Steering Repair Guide

This guide outlines the essential steps for effectively addressing issues related to directional control in your lawn equipment. Proper maintenance and repair techniques can enhance performance and extend the lifespan of your machine.

Follow these detailed instructions to ensure a successful repair process:

- Gather Necessary Tools:

- Wrenches

- Screwdrivers

- Replacement components

- Lubrication oil

- Identify Issues:

Before starting repairs, observe the equipment to pinpoint any signs of malfunction. Look for:

- Unusual noises

- Difficulty in maneuvering

- Excessive play in the control mechanism

- Remove Components:

Carefully detach any parts that obstruct access to the control assembly. Use the appropriate tools to avoid damaging surrounding areas.

- Inspect and Replace:

Examine the removed components for wear or damage. Replace any faulty items with high-quality alternatives to ensure durability.

- Reassemble and Test:

Reattach all components securely, following the reverse order of disassembly. Once assembled, perform a test to confirm that the equipment operates smoothly.

- Regular Maintenance:

Establish a routine for checking the functionality of the directional control system to prevent future issues. Regular lubrication and inspection can significantly enhance reliability.

By adhering to these guidelines, you can effectively restore the directional control of your equipment, ensuring optimal performance during use.

Tools Required for Steering Repair

When addressing issues related to the maneuverability of a lawn tractor, having the appropriate tools is essential for effective repairs. Proper equipment ensures that the maintenance process is smooth and efficient, reducing the risk of damage to components.

Essential tools include wrenches of various sizes for loosening and tightening bolts, as well as screwdrivers to remove covers and access internal mechanisms. A socket set can also be beneficial for securing parts that require additional torque. Pliers and wire cutters may be needed for handling smaller components, while a torque wrench ensures that all fittings are adjusted to the manufacturer’s specifications.

Additionally, a jack or lift is necessary to elevate the machine, providing better access to the underside where some components are located. Safety gear, such as gloves and goggles, should also be considered to protect against potential hazards during the repair process.

Parts Replacement Process Explained

Understanding the procedure for replacing components is crucial for maintaining the functionality of your equipment. This process typically involves several key steps that ensure successful installation and optimal performance. By following a systematic approach, one can efficiently address any issues related to worn-out or damaged elements.

Preparation for Replacement

Before initiating the replacement, it is essential to gather the necessary tools and components. Ensure you have the correct substitutes on hand, as well as any specialized equipment required for the task. Reviewing the manufacturer’s instructions can provide valuable insights into the process, helping to avoid common pitfalls.

Installation Steps

Once you are adequately prepared, proceed with the disassembly of the existing components. Take care to note the arrangement of parts, as this will facilitate accurate reassembly. After removing the old elements, install the new ones following the guidelines provided. Double-check all connections and secure the components firmly to ensure they function correctly.

Where to Find Replacement Parts

Locating suitable components for your equipment can be a straightforward process if you know where to look. There are several reliable sources that offer a variety of options for securing high-quality replacements.

Authorized Dealers are often the best starting point. They typically carry original components and can provide expert advice on compatibility and installation.

Online Retailers also present a vast selection. Websites dedicated to outdoor machinery and equipment usually have an extensive inventory, allowing you to compare prices and specifications easily.

Local Repair Shops may have parts available for purchase or can assist in sourcing them. Building a relationship with a knowledgeable technician can lead to valuable insights on maintaining your machine.

Finally, consider second-hand options. Online marketplaces and classifieds can yield unexpected finds, but ensure you verify the condition and compatibility before making a purchase.

Comparing Aftermarket vs OEM Parts

When it comes to replacing components in outdoor equipment, choosing between original equipment manufacturer (OEM) options and aftermarket alternatives can significantly impact performance and longevity. Understanding the key differences between these two types of products is essential for making informed decisions that suit individual needs and budgets.

OEM options are manufactured by the original company that produced the equipment, ensuring compatibility and adherence to specific quality standards. Conversely, aftermarket alternatives are produced by third-party companies, often at a lower cost. Here are some factors to consider when evaluating each option:

- Quality: OEM products typically undergo rigorous testing and quality assurance processes, while aftermarket items may vary in quality.

- Price: Aftermarket options are generally more affordable, but the savings can come at the cost of durability or fit.

- Availability: Aftermarket components may be easier to find and can offer a wider variety of choices compared to limited OEM options.

- Warranty: OEM products often come with warranties that guarantee performance, while aftermarket parts may have limited or no warranties.

Ultimately, the decision between OEM and aftermarket alternatives depends on individual priorities, whether that be cost-effectiveness, quality assurance, or product availability. Evaluating each option carefully ensures optimal performance and satisfaction with the equipment.

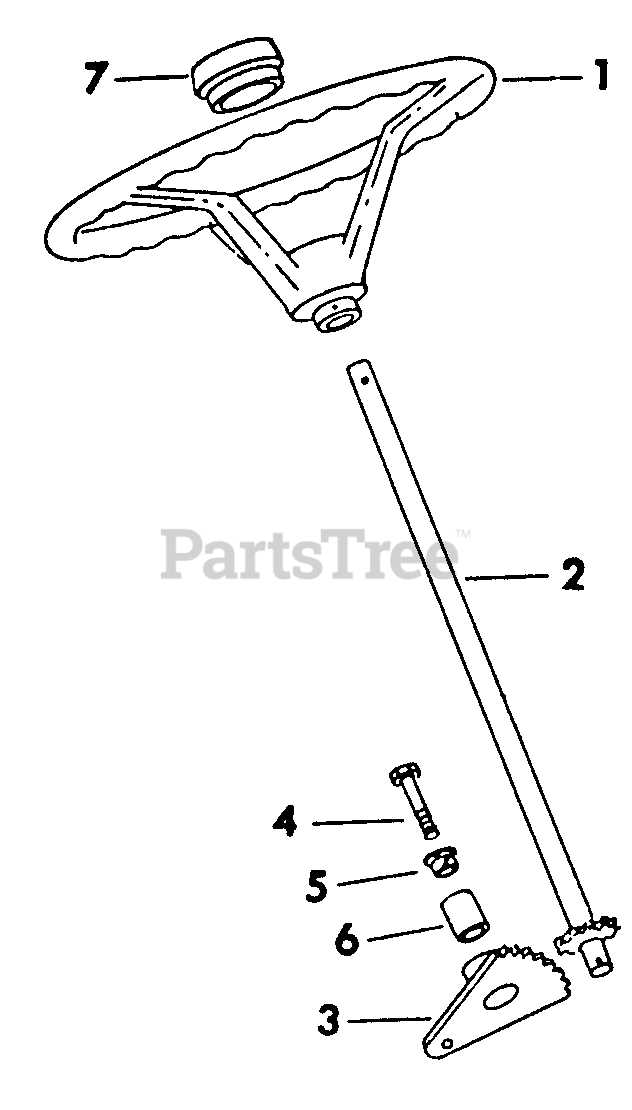

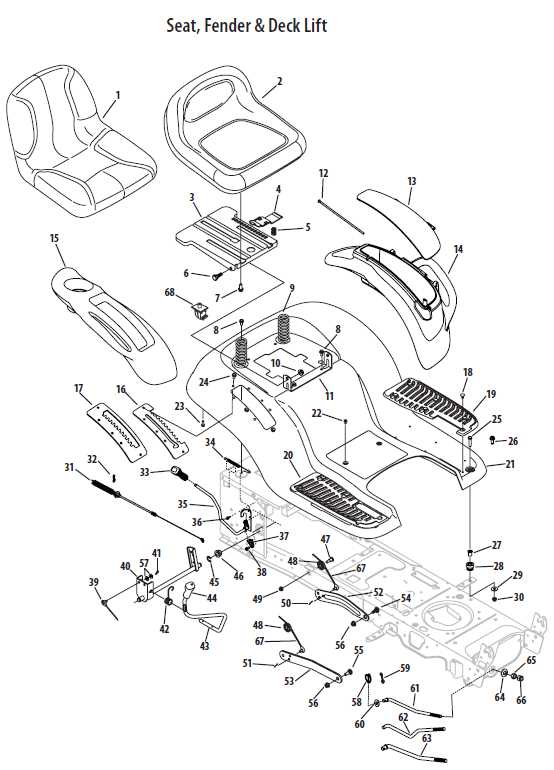

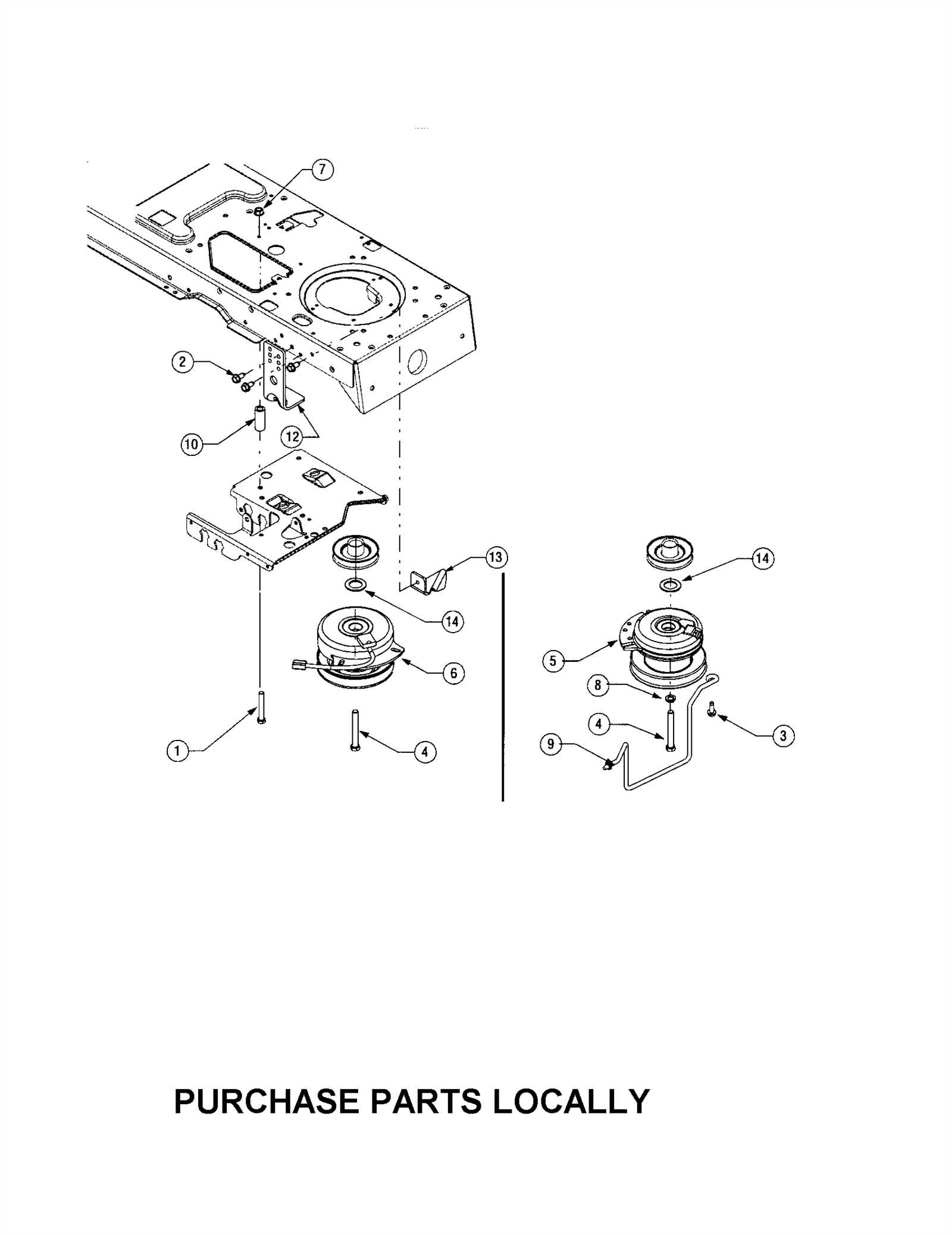

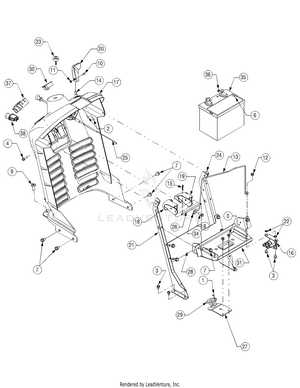

Visual Diagram of Steering Assembly

This section presents a comprehensive illustration of the guiding mechanism used in lawn care machinery. Understanding the configuration and relationship of the components involved in the control system is essential for effective maintenance and troubleshooting.

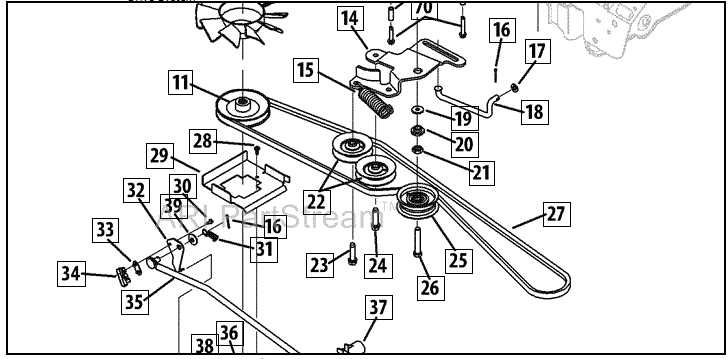

Overview of the Assembly Components

The assembly includes various elements that work in unison to ensure smooth navigation and maneuverability of the equipment. Key components typically consist of a wheel mechanism, linkages, and control units, which collectively facilitate precise adjustments during operation.

Importance of Accurate Representation

An accurate visual representation of the assembly allows users to identify individual components easily and understand their functionality. This knowledge is crucial for effective repairs and enhancements, ensuring the machinery operates optimally over time.

FAQs about Steering Components

This section addresses common inquiries related to the control mechanisms found in various machinery. Understanding these components is crucial for ensuring optimal performance and safety. Below are some frequently asked questions that cover essential aspects of these mechanisms.

What are the signs of wear in the control mechanism?

Common indicators of deterioration include unusual noises during operation, difficulty in maneuvering, or a loose feeling when handling the controls. Regular inspection can help identify these issues early.

How often should these components be maintained?

It is recommended to inspect and maintain the control mechanisms at least once a season or more frequently if the machinery is used heavily. Regular upkeep can prolong the lifespan of these components.

Can I replace these components myself?

Yes, many users choose to replace these components independently. However, it is essential to consult the manufacturer’s guidelines and ensure you have the right tools and replacement parts for a successful installation.

What should I do if I encounter difficulties while operating the controls?

If problems arise, it’s advisable to consult the user manual for troubleshooting tips. If the issue persists, seeking professional assistance may be necessary to prevent further damage.