Comprehensive Guide to Ford 3000 Power Steering Parts Diagram

Understanding the intricate elements that contribute to the enhanced maneuverability of machinery is crucial for effective maintenance and operation. A well-functioning system not only ensures smooth handling but also prolongs the lifespan of equipment. This guide delves into the key components involved in achieving optimal performance, providing insights into their structure and functionality.

Accurate identification of each element is vital for troubleshooting and repairs. By familiarizing oneself with the layout and role of each component, operators can efficiently address issues as they arise. The knowledge of these essentials empowers users to maintain peak performance and avoid unnecessary downtime.

In this article, we will explore the various components that play a significant role in achieving precision and control. Through detailed illustrations and descriptions, we aim to enhance your understanding and facilitate a smoother operational experience.

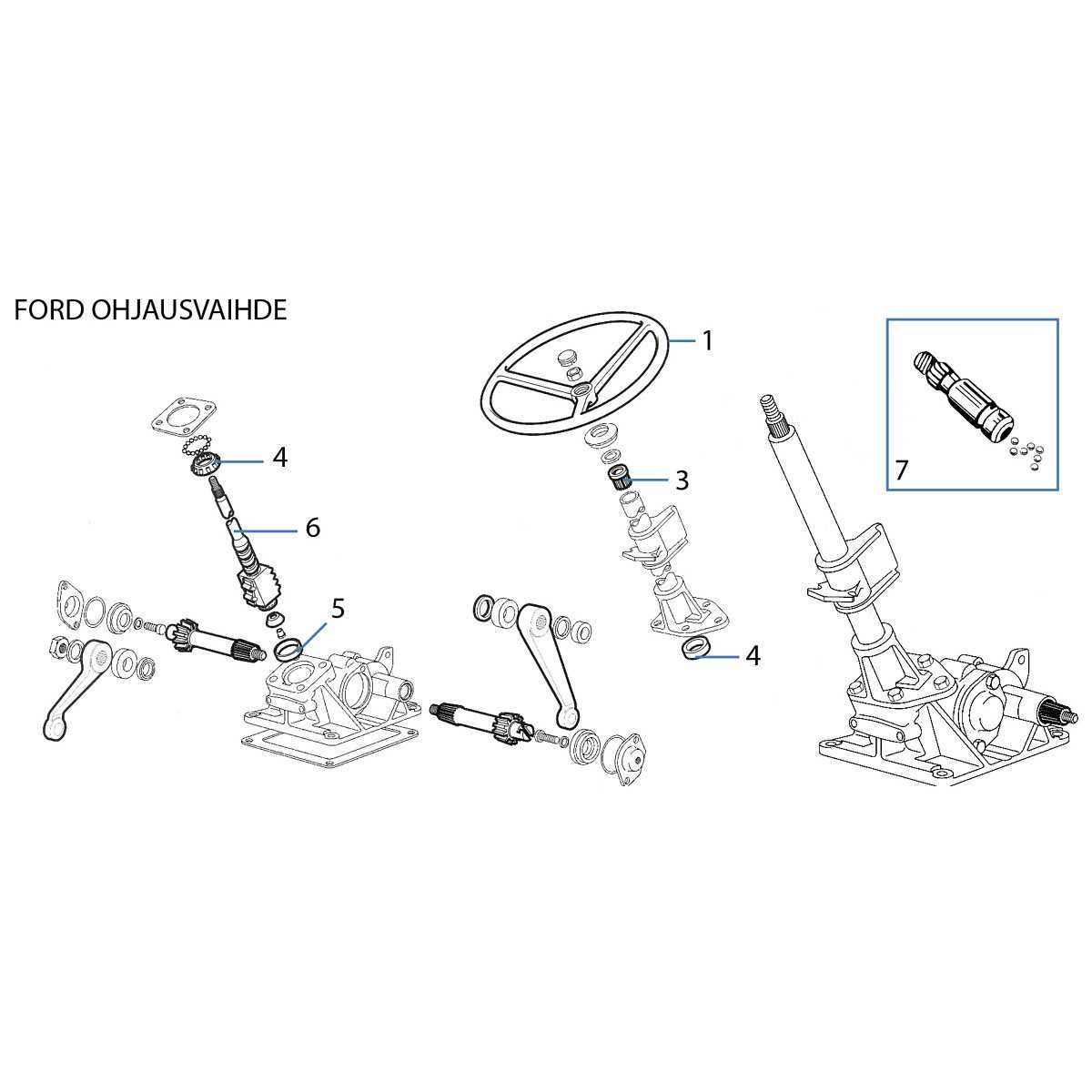

Understanding Ford 3000 Power Steering

This section explores the essential components and mechanisms that contribute to enhanced maneuverability in tractors. A well-designed system not only improves handling but also alleviates physical strain on the operator, allowing for smoother operation during extended tasks.

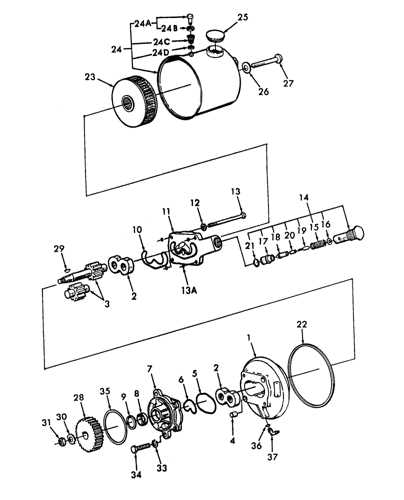

Key Components

- Hydraulic Pump

- Control Valve

- Actuator Cylinder

- Fluid Reservoir

- Hoses and Fittings

How It Functions

The operation of this system relies on hydraulic principles to amplify force. When the driver turns the wheel, the hydraulic pump engages, circulating fluid through the control valve. This process directs fluid to the actuator cylinder, enabling the tractor to turn with minimal effort.

- Fluid is drawn from the reservoir.

- The pump pressurizes the fluid.

- The control valve regulates flow direction.

- The actuator assists in the directional change.

Understanding these elements can help in maintenance and troubleshooting, ensuring optimal performance for efficient agricultural work.

Key Components of Power Steering

Understanding the essential elements of a hydraulic assistance system is crucial for effective operation and maintenance. These components work together to enhance vehicle maneuverability, allowing for easier handling and improved driver comfort.

Main Elements

Several core components contribute to the functionality of this assistance mechanism:

| Component | Description |

|---|---|

| Pump | Generates hydraulic pressure to facilitate the movement of fluid within the system. |

| Control Valve | Regulates the flow of hydraulic fluid based on steering input from the driver. |

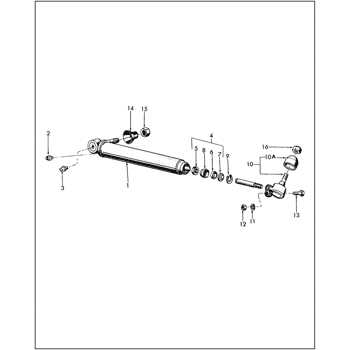

| Hydraulic Cylinder | Transforms hydraulic energy into mechanical force to assist in turning the wheels. |

| Fluid Reservoir | Holds hydraulic fluid necessary for the operation of the system. |

| Hoses and Fittings | Connect various components and allow for the efficient transfer of fluid. |

Conclusion

Each of these components plays a vital role in ensuring the smooth operation of the hydraulic assistance system. Regular maintenance and inspection of these elements can prevent malfunctions and enhance the overall driving experience.

Benefits of Power Steering Systems

Assistance mechanisms in vehicles significantly enhance maneuverability, offering numerous advantages for drivers. These systems facilitate smoother navigation, making it easier to control the vehicle, especially at low speeds or during tight turns.

Enhanced Comfort: The incorporation of assistance mechanisms greatly reduces the physical effort required to turn the wheel, providing a more relaxed driving experience.

Improved Handling: With better responsiveness and control, drivers can maintain stability, leading to safer handling in various driving conditions.

Less Fatigue: By minimizing strain on the driver, these systems contribute to decreased fatigue during long journeys, allowing for more enjoyable travels.

Increased Precision: The technology enables greater accuracy in steering inputs, resulting in smoother maneuvers and improved overall driving performance.

Common Issues with Ford 3000 Models

Understanding the frequent challenges encountered by these vintage agricultural machines can enhance their longevity and performance. Owners often face specific hurdles that, if addressed promptly, can ensure smoother operation and reduce downtime.

Typical Mechanical Problems

- Engine overheating due to coolant leaks.

- Transmission difficulties stemming from worn components.

- Electrical malfunctions, particularly in the ignition system.

Maintenance Challenges

- Inconsistent lubrication leading to premature wear.

- Difficulty in sourcing replacement components.

- Neglecting routine inspections, which can result in bigger issues.

How to Identify Steering Problems

Detecting issues within your vehicle’s maneuvering system is crucial for safe operation. Unusual sensations or noises can indicate underlying faults that require attention. Regular checks can help pinpoint these concerns early on.

Common Signs of Trouble: Pay attention to any excessive resistance while turning the wheel. If it feels unusually hard or too easy, there may be a malfunction. Additionally, listen for grinding or whining sounds, which can suggest component wear.

Fluid Leaks: Inspect for any fluid pooling beneath the vehicle. Leaks can lead to insufficient lubrication, causing parts to fail over time.

Vibrations and Pulling: Notice if the vehicle drifts to one side or if vibrations are felt in the steering mechanism. These symptoms often point to alignment or suspension issues.

Maintenance Tips for Longevity

Ensuring the durability of your machinery requires consistent care and attention. By implementing a few key practices, you can enhance the performance and extend the lifespan of your equipment, ultimately saving time and resources in the long run.

Regular Inspections

Conduct frequent assessments to identify any wear or damage. Inspect seals, hoses, and connections to prevent leaks and maintain optimal functionality. Early detection of issues can significantly reduce repair costs.

Fluid Management

Proper fluid maintenance is crucial. Ensure that liquids are topped off and replaced according to the manufacturer’s guidelines. Using the correct type of fluid will help in achieving the ultimate efficiency and protecting internal components.

Tools Required for Repairs

When undertaking maintenance tasks, having the right tools is essential for achieving optimal results. This section outlines the necessary equipment that will facilitate a smooth repair process.

- Wrenches: A variety of sizes for loosening and tightening bolts.

- Sockets: For accessing hard-to-reach areas with ease.

- Ratchet: To speed up the process of fastening and loosening.

- Torque wrench: Ensures components are secured to the correct specifications.

- Pliers: Useful for gripping and bending materials.

In addition to these basics, specialized tools may also be beneficial:

- Fluid transfer pump: For moving fluids without spills.

- Hose clamps: Essential for securing hoses effectively.

- Multimeter: For checking electrical connections and diagnostics.

Having these tools at hand will ultimately streamline your repair efforts and enhance overall efficiency.

Step-by-Step Repair Process

This section outlines a systematic approach to restoring the functionality of a hydraulic mechanism, ensuring optimal performance and longevity. By following a structured procedure, users can effectively address common issues and enhance their equipment’s efficiency.

| Step | Description |

|---|---|

| 1 | Begin by gathering all necessary tools and replacement components. |

| 2 | Carefully detach the existing assembly, noting the orientation of each component. |

| 3 | Inspect all parts for wear and damage, replacing any defective items. |

| 4 | Reassemble the mechanism, ensuring all connections are secure and properly aligned. |

| 5 | Test the functionality of the system before returning it to regular use. |

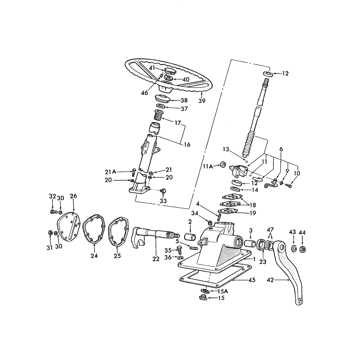

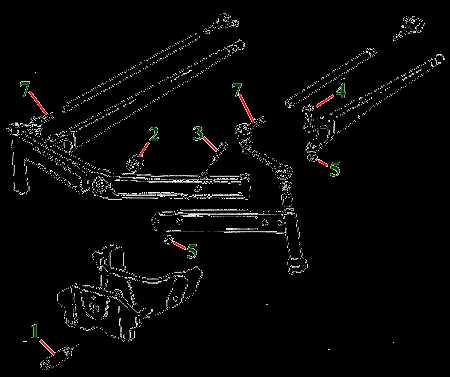

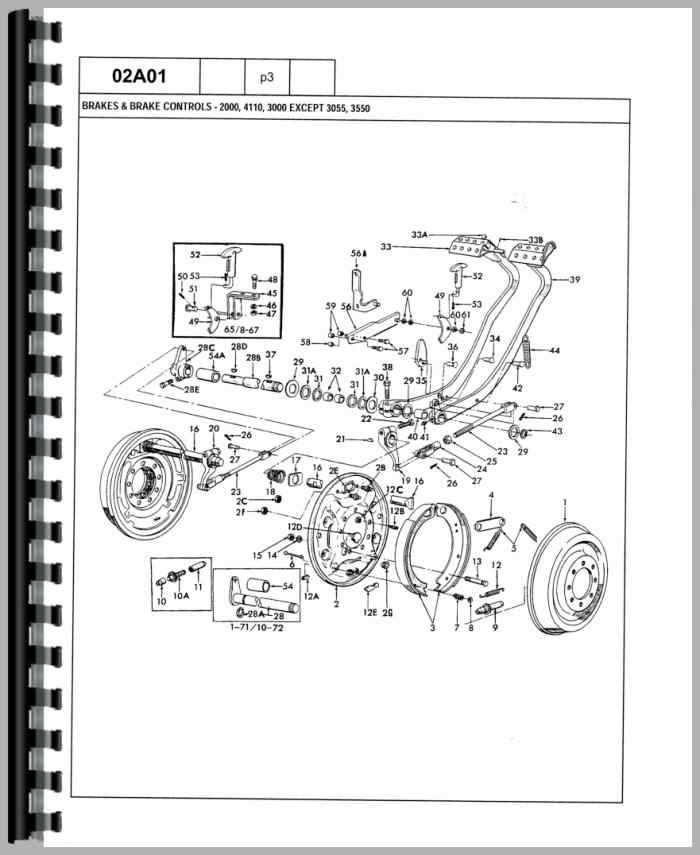

Importance of Accurate Diagrams

Precision in visual representations is crucial for effective maintenance and repair tasks. Accurate illustrations serve as essential tools for both professionals and enthusiasts, providing clarity and understanding of complex systems.

Here are key reasons why detailed visuals are vital:

- Enhanced Understanding: Clear images help users comprehend intricate components and their interconnections.

- Improved Efficiency: Accurate guides streamline the repair process, reducing time spent on troubleshooting.

- Safety Assurance: Correct information minimizes the risk of errors, ensuring safe operation of machinery.

- Resource Optimization: Well-defined visuals assist in identifying necessary tools and materials, leading to effective resource management.

Ultimately, investing in high-quality visual aids fosters better outcomes in repair and maintenance endeavors.

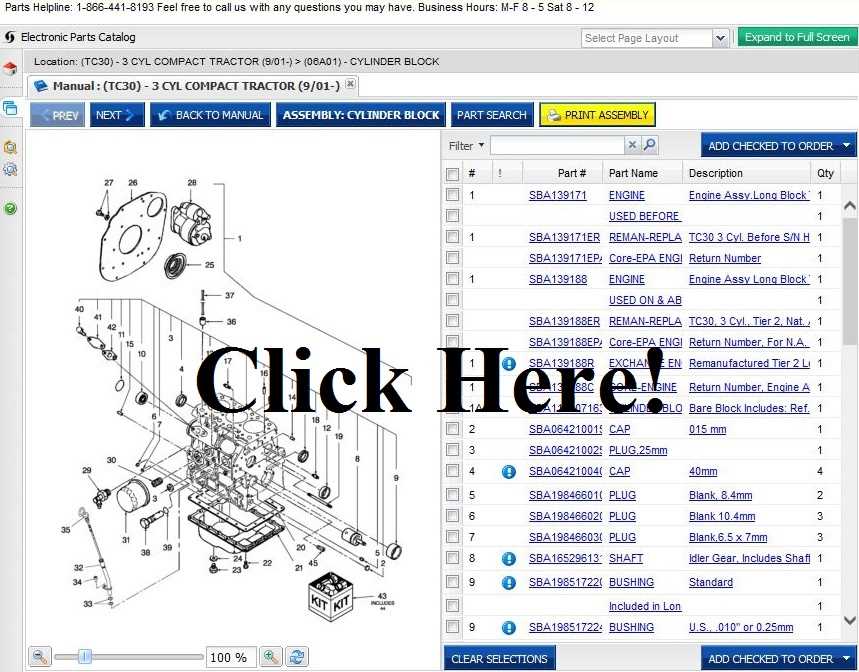

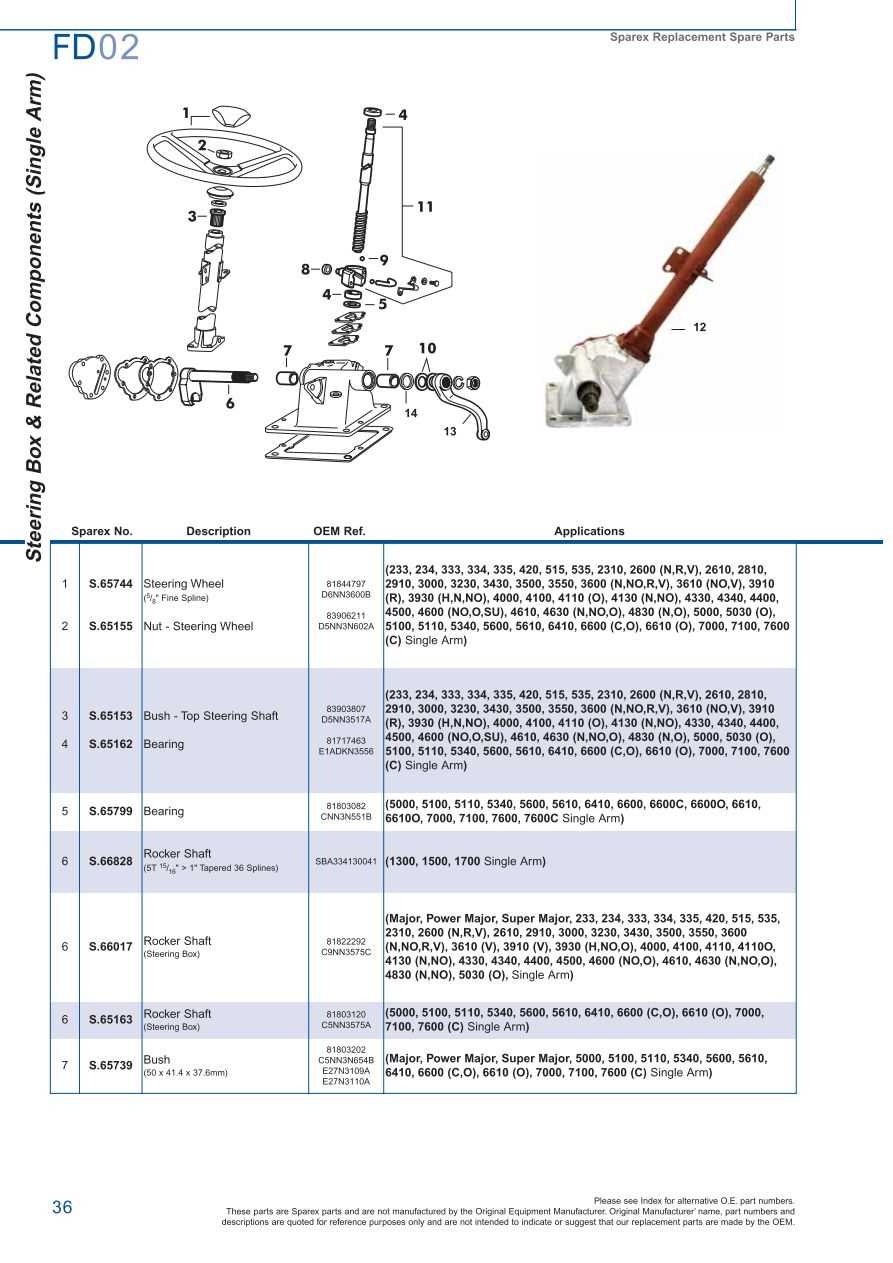

Where to Find Replacement Parts

Locating components for machinery maintenance can be a straightforward process if you know where to look. Various resources are available, including specialized retailers, online platforms, and local suppliers that cater to equipment enthusiasts and professionals alike.

For immediate needs, consider visiting local hardware stores or agricultural supply outlets, as they often carry essential items. Additionally, checking online marketplaces can yield a wide selection of options, including both new and refurbished pieces. Engaging with community forums and social media groups dedicated to machinery can also provide valuable leads and recommendations from fellow users.

Furthermore, exploring manufacturer websites can lead to official distributors who offer a reliable source for authentic replacements. Don’t overlook salvage yards or second-hand dealerships, which might have exactly what you need at a fraction of the cost.

Comparing Aftermarket vs. OEM Parts

When it comes to vehicle components, consumers often face a choice between original manufacturer offerings and alternatives produced by third parties. Each option presents distinct advantages and drawbacks, influencing both performance and cost. Understanding these differences can aid in making informed decisions tailored to individual needs.

Original manufacturer components are typically designed to meet specific quality standards, ensuring compatibility and reliability. In contrast, alternative products may vary widely in quality and performance, offering potentially lower prices but varying levels of durability and effectiveness.

| Criteria | OEM Components | Aftermarket Alternatives |

|---|---|---|

| Quality | Consistent, high standards | Varies significantly |

| Cost | Generally higher | Often more affordable |

| Warranty | Comprehensive warranty | Limited or no warranty |

| Availability | May require special order | Widely available |

| Compatibility | Perfect fit guaranteed | Potential fit issues |

Ultimately, the choice between these options depends on the specific requirements and budget of the user. Weighing the pros and cons can help in selecting the most suitable solution for maintaining vehicle functionality.

Understanding Hydraulic System Basics

The hydraulic system operates on the principle of fluid mechanics, enabling the transfer of force through incompressible liquids. This technology is vital in various applications, providing efficiency and power amplification in machinery. By employing the basic components such as pumps, cylinders, and valves, these systems facilitate controlled movement and heavy lifting.

Fluid Dynamics plays a crucial role, as the liquid’s flow and pressure dictate the system’s effectiveness. Understanding the behavior of hydraulic fluids is essential, as it influences performance and response times. Key factors include viscosity, temperature, and the ability to maintain consistent pressure throughout the system.

Maintenance is critical to ensure longevity and functionality. Regular checks for leaks, contamination, and component wear can prevent catastrophic failures. Thus, grasping these fundamental principles is imperative for anyone involved in machinery utilizing hydraulic technology.

FAQs About Ford 3000 Steering Systems

This section aims to address common inquiries related to the steering mechanisms of a specific model. Understanding these systems can enhance the overall driving experience and maintenance knowledge.

Common Questions

Here are some frequently asked questions regarding the steering system:

| Question | Answer |

|---|---|

| What are the signs of a failing steering system? | Common indicators include difficulty turning the wheel, unusual noises, and fluid leaks. |

| How often should I check the fluid levels? | It’s advisable to check fluid levels regularly, ideally every few months or before long trips. |

| Can I replace components myself? | Yes, many enthusiasts can replace components with basic tools, but consulting a professional is recommended for complex issues. |

Maintenance Tips

Regular inspection and maintenance can significantly extend the life of the steering mechanism. Keep the system clean and address any leaks promptly.