Comprehensive Guide to Ford 5000 Steering Parts Diagram

In the world of agricultural machinery, effective maneuverability is crucial for optimal performance and productivity. A comprehensive exploration of the control systems that facilitate precise navigation can greatly enhance the understanding of operators and technicians alike. This section delves into the intricate components that make up these essential mechanisms, ensuring that users can maintain and optimize their equipment effectively.

Identification and Maintenance of the various elements involved in these systems is vital for ensuring longevity and efficiency. By examining each component’s role and functionality, operators can better grasp how to troubleshoot issues and perform necessary upkeep. This knowledge not only empowers users but also contributes to smoother operations in the field.

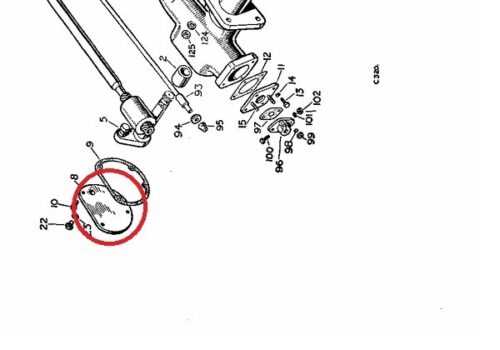

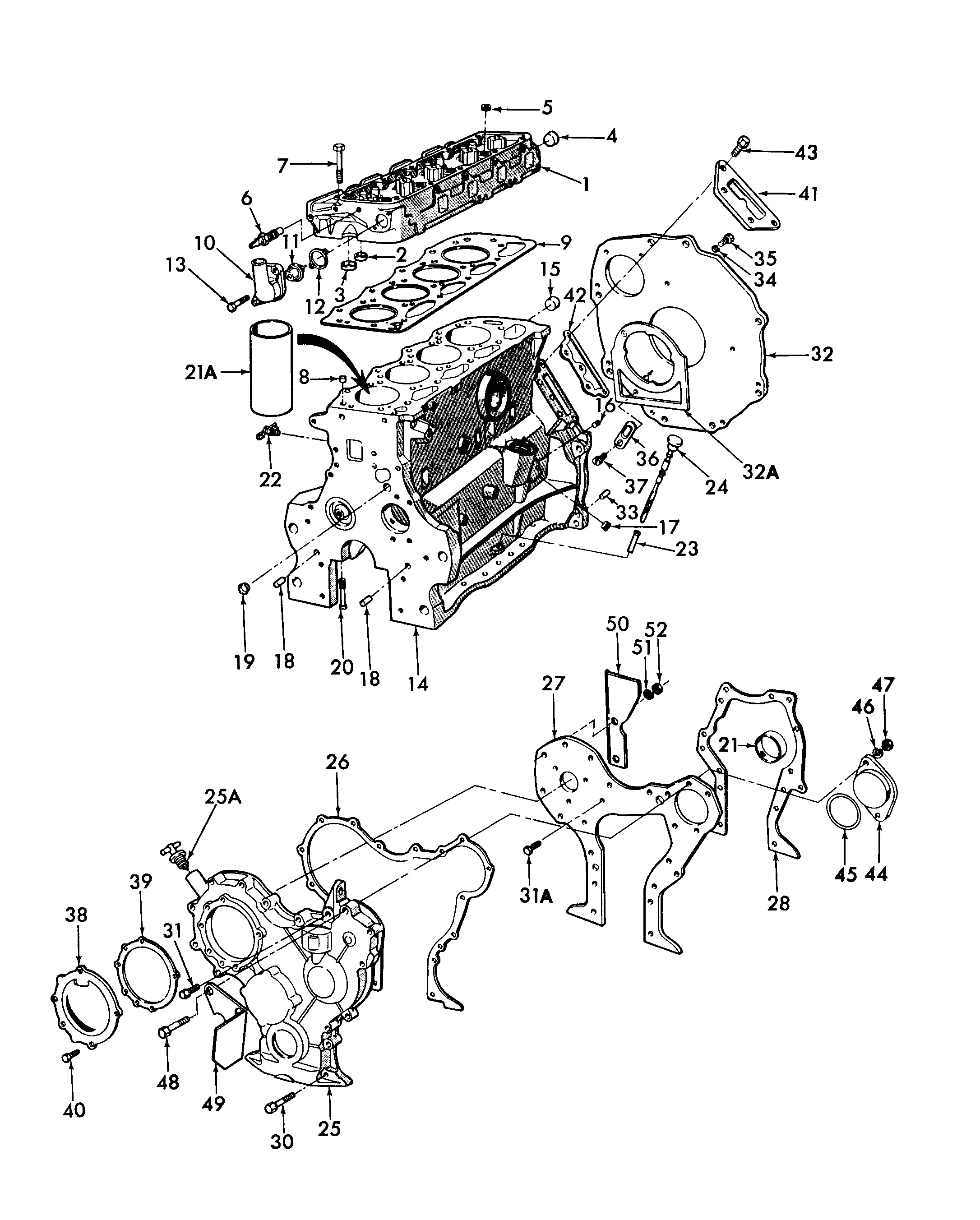

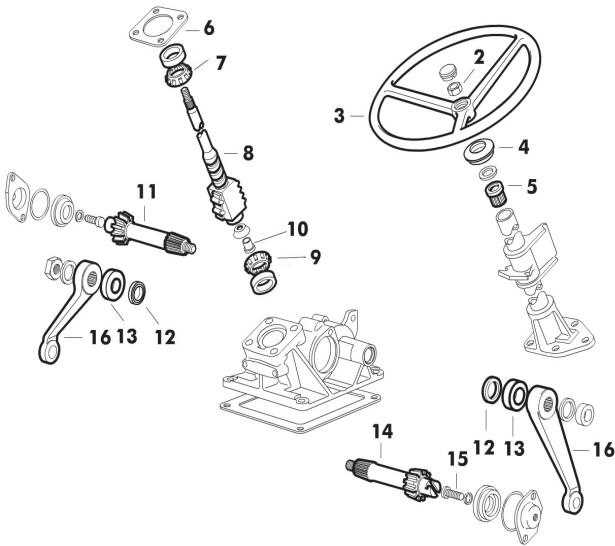

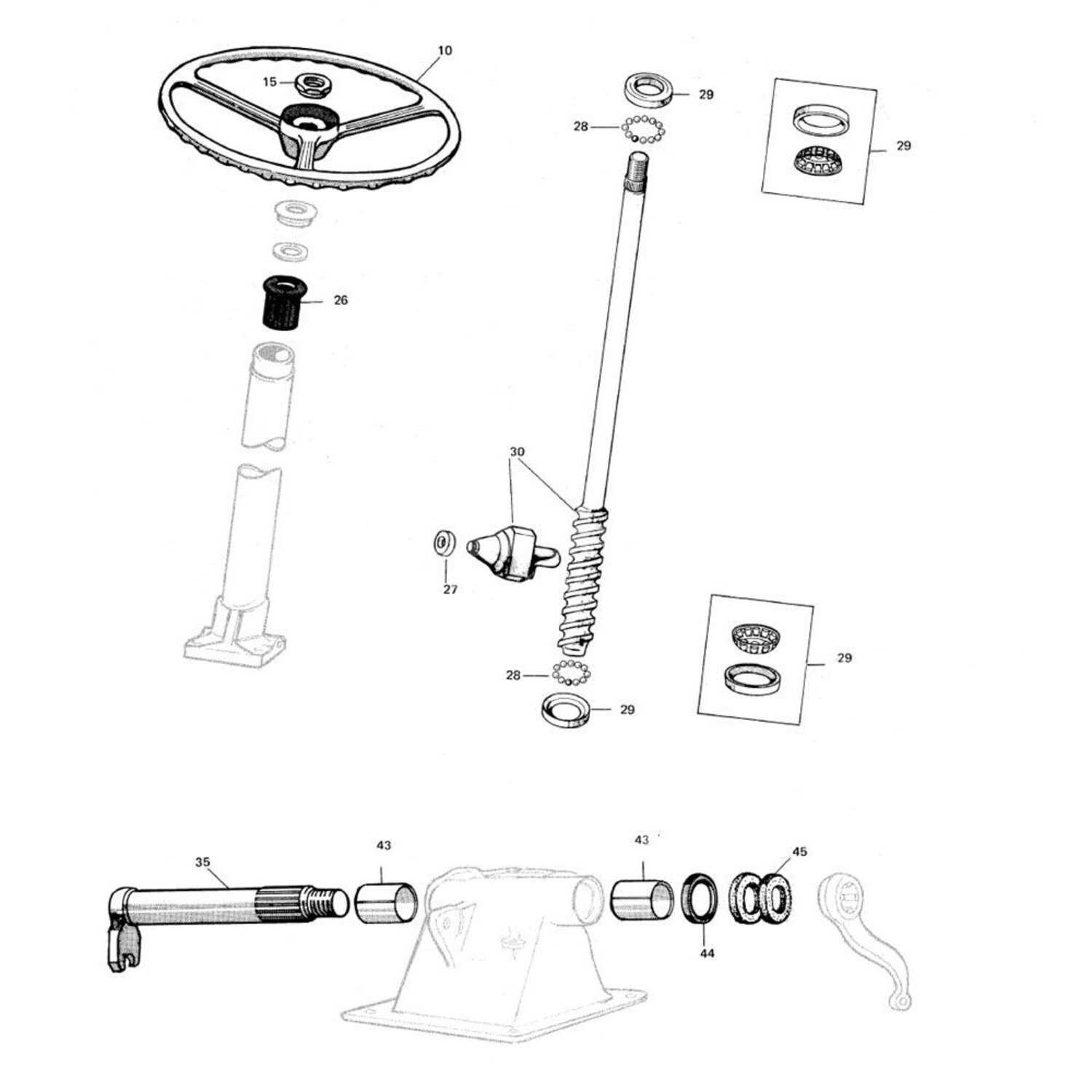

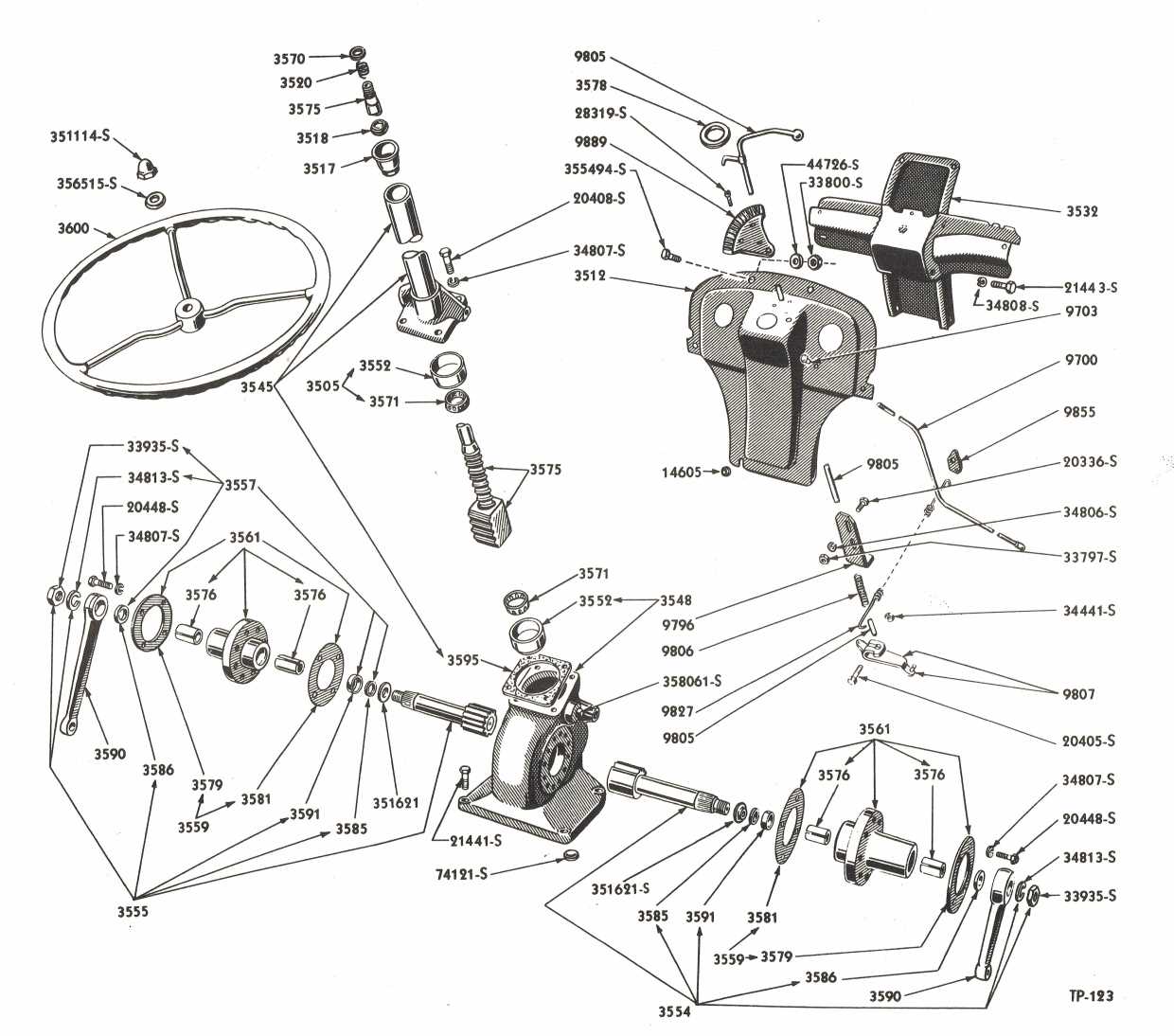

Moreover, visual aids play an instrumental role in facilitating a clearer understanding of these complex assemblies. Diagrams and illustrations can simplify the learning process, allowing for easier identification and recognition of components. As we navigate through this topic, a detailed overview will serve as a foundation for mastering the intricacies of control mechanisms in agricultural equipment.

Overview of Ford 5000 Steering System

This section explores the intricate framework responsible for vehicle maneuverability, focusing on essential components that enable precise control and stability. Understanding the various elements involved can enhance maintenance practices and improve overall functionality.

Key Components

The system comprises several crucial elements, including the column, linkage, and the hydraulic mechanism. Each part plays a vital role in ensuring seamless navigation, offering both responsiveness and comfort during operation.

Functionality and Maintenance

Regular upkeep of this assembly is imperative for optimal performance. Ensuring that all connections are secure and that fluid levels are maintained contributes significantly to the longevity and efficiency of the system.

Key Components of the Steering Assembly

The assembly responsible for guiding a vehicle’s direction consists of several crucial elements that work in harmony to ensure precise handling and control. Understanding these components can enhance maintenance and troubleshooting efforts.

- Column: This central shaft connects the steering wheel to the mechanisms that facilitate movement.

- Wheel: The interface for the driver, allowing for input and direction adjustment.

- Rack and Pinion: A system that converts rotational motion into linear movement, translating driver input into wheel motion.

- Linkages: Rods and joints that connect the various components, ensuring synchronized operation.

- Bearings: Support elements that reduce friction, allowing for smooth rotation and responsiveness.

- Bushings: These provide cushioning and reduce wear between moving parts, enhancing durability.

Each of these elements plays a vital role in the overall functionality of the directional control system, contributing to safe and efficient vehicle operation.

Importance of Steering Parts Diagram

A clear visual representation of components is crucial for understanding the intricate mechanisms that ensure smooth navigation and control of a vehicle. Such illustrations serve as valuable resources for both professionals and enthusiasts, providing essential insights into assembly and maintenance.

Having a comprehensive illustration allows technicians to identify and locate specific elements quickly, which enhances efficiency during repairs. This is especially vital when troubleshooting issues, as it helps pinpoint malfunctioning areas and facilitates informed decision-making.

Moreover, these visual guides play a significant role in educating new operators about the function and interaction of various components. By grasping the layout and relationships between elements, users can develop a deeper appreciation for the mechanics involved, leading to better care and handling of the machinery.

Additionally, accurate schematics can prevent costly mistakes during replacement or installation. Knowing the correct orientation and configuration of each piece ensures that everything is fitted correctly, minimizing the risk of future complications and enhancing overall performance.

In summary, well-structured representations are indispensable tools that aid in the maintenance, repair, and education surrounding vehicle navigation systems. They contribute to operational safety and efficiency, fostering a greater understanding of the equipment’s functionality.

Identifying Steering Issues in Ford 5000

Recognizing problems with directional control is crucial for maintaining optimal performance in any vehicle. Various symptoms can indicate underlying mechanical issues that, if left unchecked, may lead to more severe complications. Understanding these signs and knowing how to respond can enhance both safety and functionality.

Common Symptoms

Drivers may experience several noticeable signs when problems arise. These can include unusual noises during turns, difficulty in maneuvering, or inconsistent response from the wheel. Identifying these indicators early can prevent further damage.

Diagnostic Table

| Symptom | Possible Cause |

|---|---|

| Unusual noises | Worn bearings or loose components |

| Difficult turning | Low fluid levels or damaged seals |

| Uneven handling | Misaligned or worn linkages |

Maintenance Tips for Steering Parts

Proper upkeep of directional components is essential for optimal vehicle performance and safety. Regular inspections and maintenance not only prolong the lifespan of these elements but also ensure a smooth driving experience. Here are some valuable recommendations to maintain these crucial components effectively.

Regular Inspections

- Check for wear and tear: Look for any signs of damage or excessive wear on the components.

- Examine fluid levels: Ensure that hydraulic fluids are at appropriate levels to maintain efficiency.

- Inspect for leaks: Regularly check for any fluid leaks, which can indicate potential issues.

Maintenance Practices

- Lubrication: Regularly lubricate moving elements to minimize friction and wear.

- Tightening bolts: Ensure that all bolts and fasteners are securely tightened to prevent loosening over time.

- Replacement of worn components: If any parts show significant signs of degradation, replace them promptly to avoid further damage.

By adhering to these maintenance tips, vehicle owners can ensure the reliability and longevity of directional systems, ultimately leading to a safer and more enjoyable driving experience.

Common Repairs for Steering Components

Maintaining the directional control system of a vehicle is crucial for safety and performance. Over time, various elements may wear out or become damaged, necessitating timely repairs. Understanding common issues can help ensure smooth operation and longevity of the assembly.

Typical Issues

- Worn bushings that affect alignment

- Leaking hydraulic fluids leading to inadequate response

- Loose connections causing instability

Repair Solutions

- Replace damaged or worn bushings to restore alignment.

- Seal leaks and refill hydraulic fluid to ensure proper function.

- Tighten connections to enhance stability and control.

How to Read Steering Diagrams

Understanding technical illustrations can be crucial for effective maintenance and repair. These visual aids serve as a roadmap, detailing the arrangement and interaction of components within a mechanism. By mastering the art of interpreting these graphics, you can enhance your troubleshooting skills and ensure optimal functionality.

Begin with the Legend: Most illustrations include a legend that defines symbols and notations. Familiarizing yourself with these elements will clarify the relationships between different components.

Identify Key Components: Focus on major elements within the image. Recognizing primary parts will help you grasp how they fit into the overall system. Pay attention to their positions and orientations.

Trace the Connections: Follow lines and arrows that indicate relationships or pathways. Understanding how parts connect or interact is essential for diagnosing issues effectively.

Practice Makes Perfect: The more you engage with various technical illustrations, the more intuitive reading them will become. Over time, you will develop the ability to quickly extract necessary information.

Tools Needed for Steering Repair

When addressing the functionality of directional control systems, having the right tools is essential for effective maintenance and repair. A well-equipped workspace enables a smoother process and can significantly enhance the quality of the work performed.

Basic Hand Tools

Commonly required tools include wrenches, sockets, and screwdrivers. These are fundamental for loosening and tightening various components, ensuring everything is secured properly for optimal operation.

Specialized Equipment

For more intricate tasks, specialized instruments like torque wrenches, pullers, and alignment tools may be necessary. These help in achieving precise adjustments and ensure that all elements align correctly for safe and efficient use.

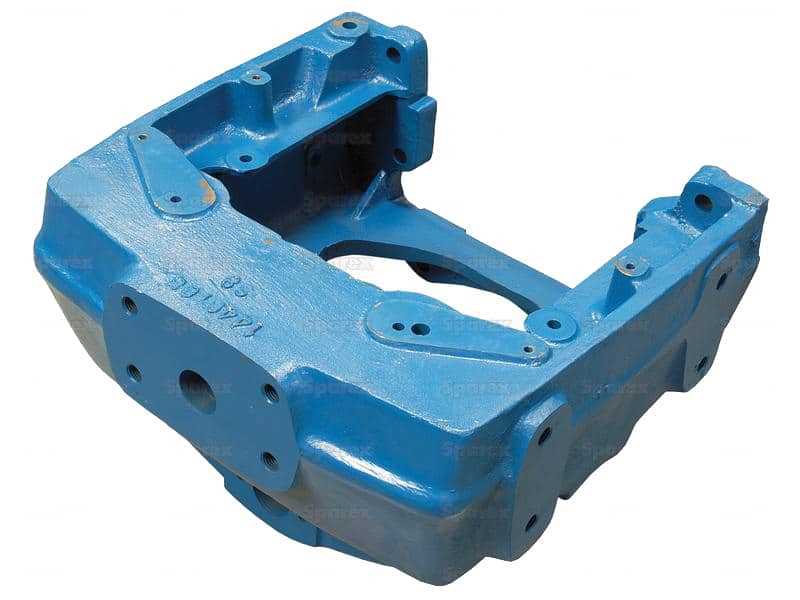

Replacement Parts for Ford 5000

Maintaining machinery requires the availability of suitable components to ensure optimal performance and longevity. Identifying quality replacements is essential for restoring functionality and efficiency.

When considering alternatives, focus on the following categories:

- Hydraulic Components

- Transmission Elements

- Electrical Systems

- Chassis Accessories

Here’s a list of key replacements to explore:

- Hydraulic Pumps

- Gaskets and Seals

- Brake Assemblies

- Filters

- Control Linkages

Utilizing quality substitutes not only enhances operational efficiency but also prolongs the lifespan of your equipment.

Upgrading Steering Mechanisms

Enhancing the control system of heavy machinery can significantly improve handling and maneuverability. Upgrades may involve replacing outdated components with modern equivalents, which can lead to better performance and comfort. This process often includes examining the existing configuration and identifying areas for improvement.

Benefits of Upgrading

- Improved responsiveness and precision.

- Increased durability and reduced wear.

- Enhanced comfort for the operator.

- Better compatibility with advanced technology.

Key Considerations

- Assess the current system: Identify which components are outdated or inefficient.

- Research modern alternatives: Look for upgraded mechanisms that provide better functionality.

- Evaluate compatibility: Ensure that new parts will work seamlessly with existing elements.

- Consult with professionals: Seek expert advice to make informed decisions on upgrades.

Safety Precautions During Repairs

When undertaking maintenance or repair tasks on machinery, prioritizing safety is essential. Proper precautions not only protect the individual performing the work but also ensure the longevity and efficiency of the equipment. By adhering to safety protocols, potential hazards can be minimized, making the repair process smoother and more effective.

Always wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and steel-toed boots. This gear acts as a barrier against potential injuries from sharp tools or heavy components. Furthermore, ensuring a clean and organized workspace reduces the risk of accidents and allows for easier access to necessary tools.

Before beginning any repair, it is crucial to disconnect power sources and depressurize systems. This step prevents unexpected activation of machinery, which could lead to serious injuries. Additionally, familiarizing oneself with the equipment’s manual can provide valuable insights into specific safety measures related to that particular model.

In case of working with heavy items, utilizing appropriate lifting techniques or equipment, such as hoists or jacks, can prevent strain injuries. Always work with a partner when handling large components to ensure stability and safety throughout the process.

Lastly, remain vigilant and focused during repairs. Distractions can lead to mistakes that compromise safety. Taking regular breaks to maintain mental clarity and physical stamina can enhance overall performance and prevent accidents.

Resources for Ford 5000 Owners

For enthusiasts of this iconic model, a variety of valuable resources are available to enhance the ownership experience. From manuals to community support, these tools can provide essential guidance and insight into maintenance and repairs.

Online Communities

- Forums dedicated to vintage machinery

- Social media groups for discussions and advice

- Dedicated websites featuring user-generated content

Maintenance Guides

- Service manuals for troubleshooting and repair

- Video tutorials for visual guidance

- Blogs with tips and best practices

FAQs About Steering Parts and Diagrams

This section aims to address common inquiries related to components and their schematics used in automotive maneuvering systems. Understanding these elements can enhance your knowledge and assist in maintenance or repairs.

What are the main components involved in the maneuvering system?

The key elements typically include the control wheel, linkage mechanisms, and the associated hydraulic or mechanical systems that enable effective handling.

How can I identify specific elements in a schematic?

Most visuals will label each component clearly. Familiarizing yourself with common terminology can help you pinpoint the parts more easily.

Where can I find reliable resources for diagrams?

Trusted automotive repair manuals and online forums dedicated to vehicle maintenance are excellent sources for accurate schematics and component information.

What should I do if a part is missing or damaged?

It’s essential to replace any faulty components promptly. Consulting with a professional or referring to your manual can guide you in obtaining the correct replacements.

Can I perform repairs myself?

With adequate knowledge and tools, many individuals can tackle minor repairs. However, complex issues might require professional expertise to ensure safety and functionality.