Understanding the Ford 8N Steering Parts Diagram

In the realm of agricultural machinery, precise maneuverability is essential for optimal performance. The intricate mechanisms that facilitate directional control play a crucial role in ensuring that operators can navigate their equipment with ease and efficiency. This section delves into the various elements that contribute to this essential function, providing clarity on their arrangement and interrelation.

Exploring the Anatomy of these control systems reveals a variety of elements, each with its specific function and importance. By gaining insights into the layout and operation of these components, operators can better appreciate the engineering that enables seamless navigation. Understanding these intricacies not only aids in effective usage but also enhances maintenance practices.

As we examine the configuration of these essential components, it becomes apparent how vital each part is to the overall functionality. Recognizing how these elements work together empowers users to address issues proactively, ensuring that their machinery remains reliable and efficient throughout its operational life.

Understanding the Ford 8N Steering System

This section explores the intricacies of the directional control mechanism in a specific tractor model, emphasizing its functionality and components. By examining how these elements interact, we can appreciate the design’s efficiency and reliability.

| Component | Description |

|---|---|

| Column | Central shaft that provides a connection for movement. |

| Gear Assembly | Facilitates the transfer of motion from the operator to the wheels. |

| Linkage | Connects the column to the wheels, ensuring responsive handling. |

| Bearings | Support smooth rotation and reduce friction in the system. |

Understanding these components allows for better maintenance and enhances the overall performance of the vehicle.

Importance of Steering Components

Effective maneuverability in any vehicle relies heavily on the precision and reliability of its directional control systems. These essential elements ensure that operators can guide their machinery accurately and safely, making them critical for both performance and safety.

Role in Vehicle Control

Directional control mechanisms play a vital role in maintaining stability and responsiveness. They allow for smooth navigation through various terrains and conditions, significantly impacting overall operational efficiency. A well-maintained system enhances the ability to respond quickly to changes in environment, which is crucial for preventing accidents and ensuring safety.

Impact on Longevity

Properly functioning directional components not only improve handling but also extend the lifespan of the vehicle. Regular maintenance and timely replacement of worn-out elements can prevent more significant damage and costly repairs. By prioritizing these mechanisms, operators can achieve better performance and reliability, ultimately leading to increased productivity.

Common Issues with Steering Parts

Understanding the frequent challenges associated with directional control components is essential for maintaining optimal performance. Various factors can lead to inefficiencies, affecting maneuverability and safety. Identifying these issues early can save time and resources in the long run.

1. Wear and Tear

Over time, components may experience degradation due to constant usage. Key signs include:

- Increased play in the mechanism

- Unusual noises during operation

- Difficulties in maintaining a straight path

2. Misalignment Problems

Components can become misaligned for several reasons, leading to significant handling difficulties. Common indicators include:

- Uneven tire wear

- Pulling to one side while driving

- Unstable or erratic handling

Regular inspections and maintenance can help mitigate these issues, ensuring longevity and reliability of the system.

How to Identify Steering Problems

Detecting issues with your vehicle’s control mechanism is crucial for maintaining safety and performance. Recognizing the signs of trouble early can prevent further complications and costly repairs. Observing changes in handling, unusual noises, or any vibrations can serve as indicators of underlying difficulties.

Look for inconsistencies: If the vehicle pulls to one side or the other, it may suggest alignment or balance issues. Pay attention to how the apparatus responds; a lack of responsiveness could indicate a malfunction.

Listen carefully: Uncommon sounds such as grinding or clunking noises when maneuvering might signify wear or damage in the system. These auditory cues are often the first signal of a problem.

Check fluid levels: Inspecting hydraulic fluids is essential, as low levels can lead to performance issues. Ensure there are no leaks that could compromise the system’s integrity.

Test for play: Examine the connection points for excessive movement. If there is noticeable play, it may indicate wear that requires immediate attention.

By being vigilant and proactive, you can ensure the longevity and reliability of your vehicle’s handling capabilities.

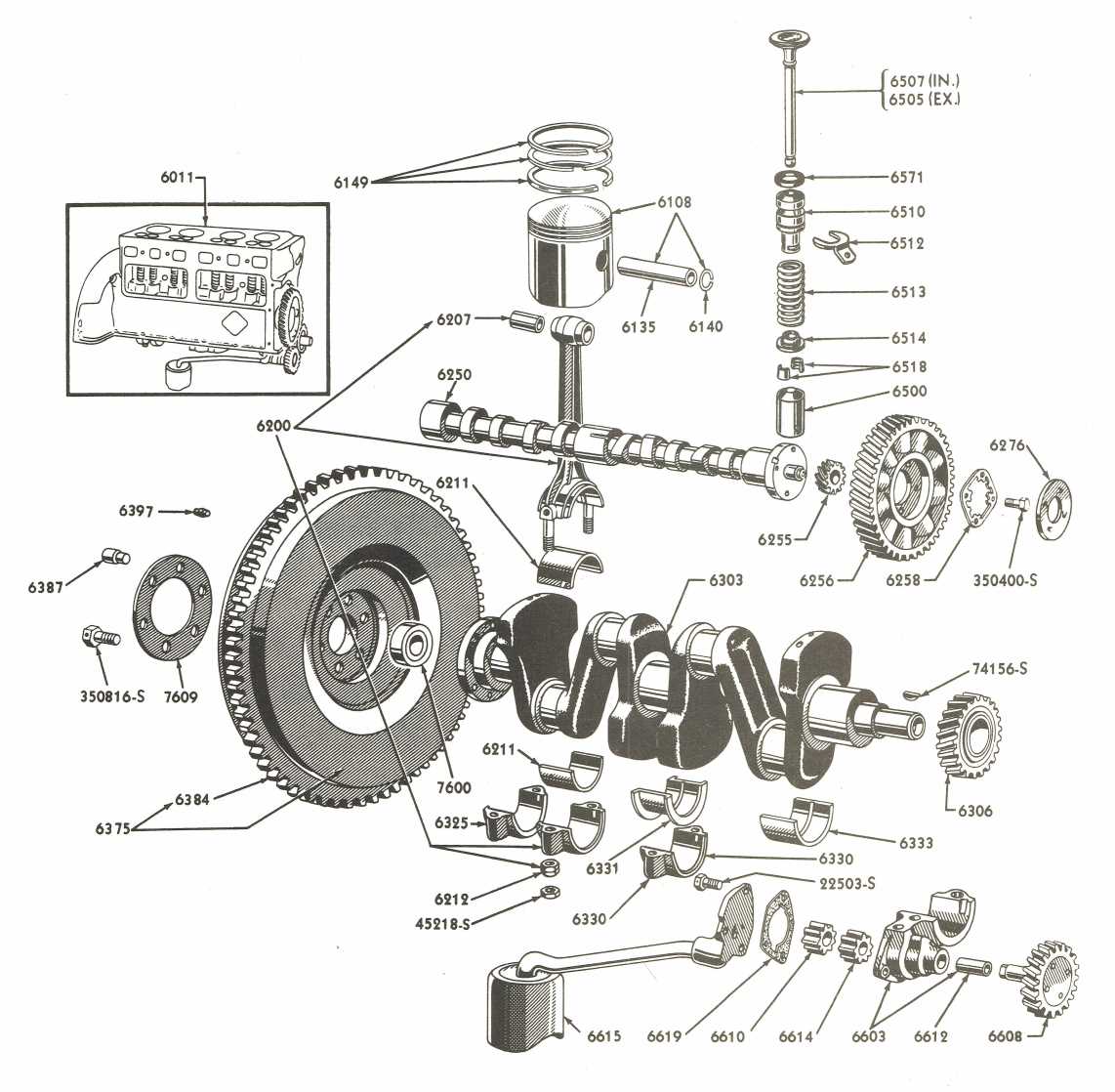

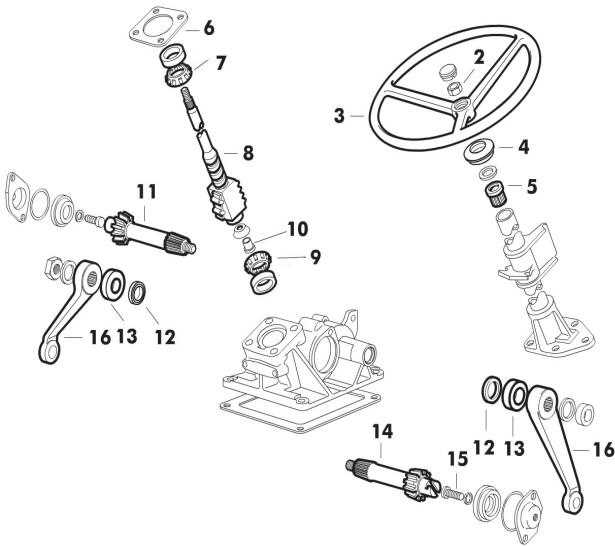

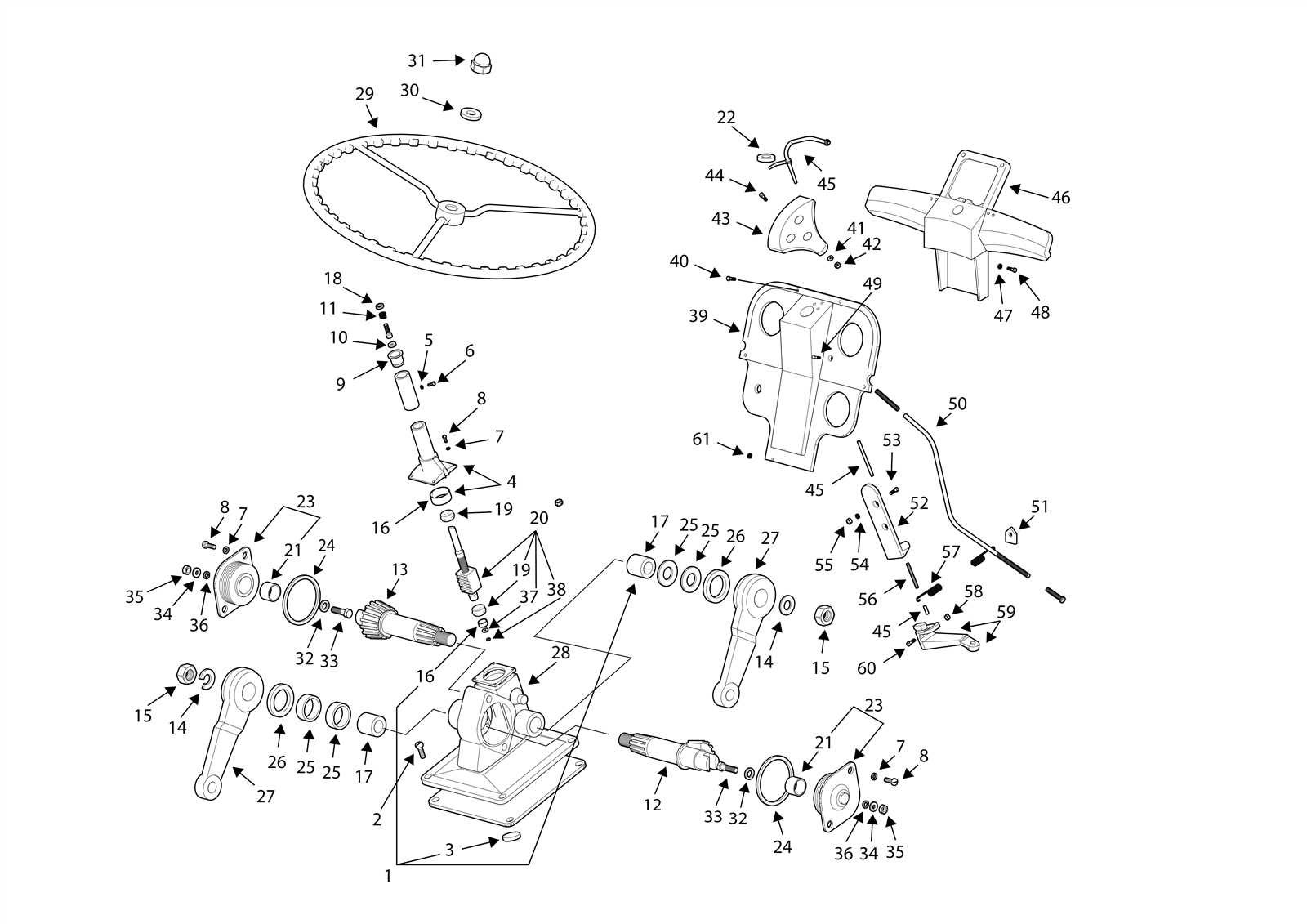

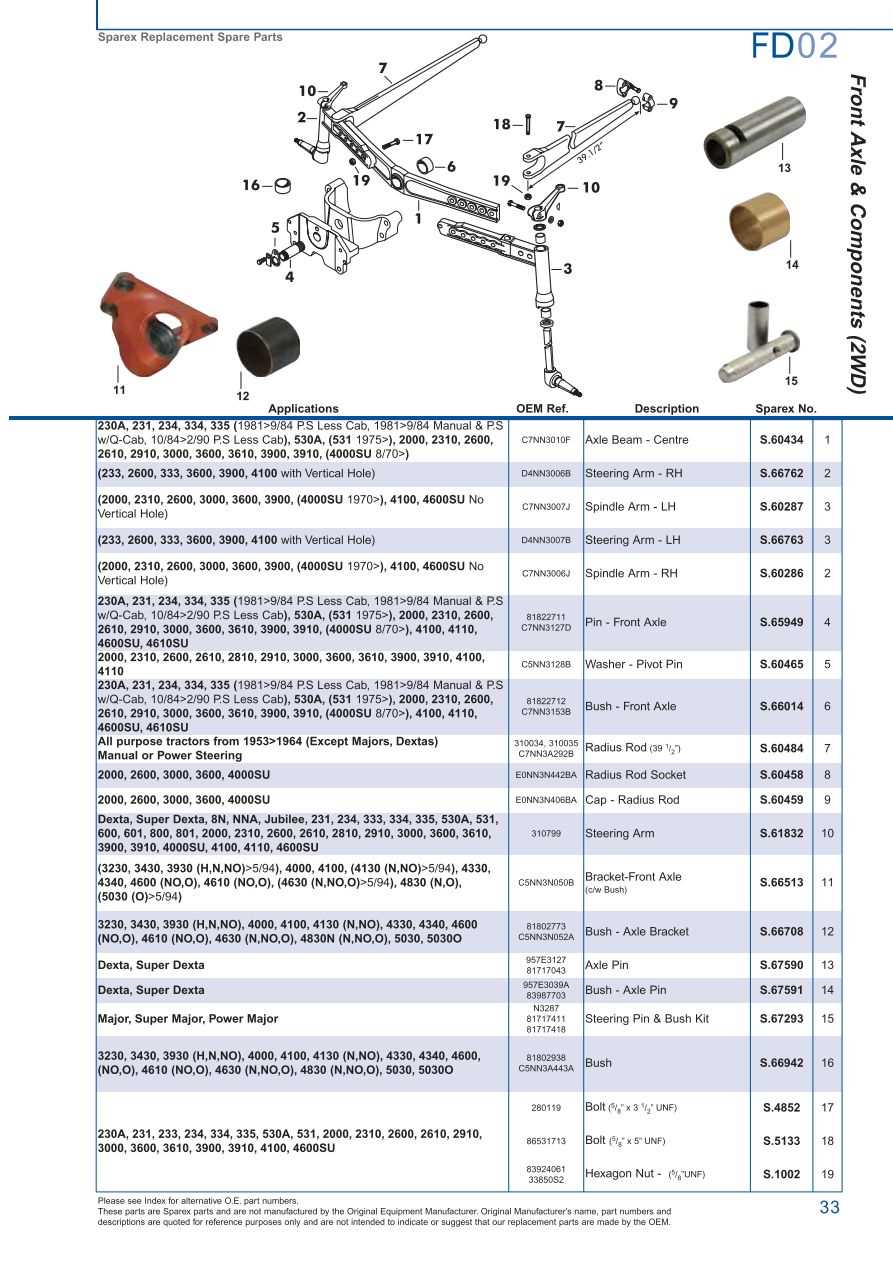

Components of the Steering Diagram

This section explores the essential elements that contribute to the overall functionality of the control mechanism in vehicles. Understanding these components is crucial for effective maintenance and troubleshooting.

- Wheel Mechanism

- Connecting Rods

- Pivot Points

- Linkages

Each element plays a pivotal role in ensuring smooth maneuverability and responsiveness. The interaction among these components ultimately enhances the driving experience.

- Wheel Mechanism: Facilitates direction change.

- Connecting Rods: Transmit movement between components.

- Pivot Points: Serve as rotational anchors.

- Linkages: Ensure coordinated movement across parts.

In-depth knowledge of these elements allows for better diagnostics and improvements in vehicle handling.

Replacing Worn Steering Parts

Over time, the components responsible for directional control can wear down, leading to compromised performance and handling. Addressing these issues promptly is essential to ensure safe operation and enhance maneuverability. This section will outline the steps necessary for the effective replacement of these vital components.

Identifying Worn Components

Before undertaking replacement, it is crucial to recognize the signs of wear. Look for the following:

- Excessive play in the control mechanism

- Unusual noises while turning

- Difficulties in maintaining a straight path

Replacement Process

- Gather the necessary tools and replacement items.

- Lift the vehicle securely to access the undercarriage.

- Remove the damaged components carefully.

- Install the new components, ensuring proper alignment.

- Test the functionality before returning the vehicle to regular use.

Maintenance Tips for Ford 8N Steering

Proper care and upkeep of your machinery’s directional control system can significantly enhance its performance and longevity. Regular maintenance ensures smooth operation and minimizes the risk of wear and tear. Here are some essential tips to keep your system in optimal condition.

Regular Inspections

Frequent evaluations of the components can help identify any potential issues early on. Look for signs of wear, looseness, or misalignment. Pay attention to lubrication points and ensure that all moving parts are adequately greased.

Lubrication Schedule

Establish a routine for applying lubricant to all relevant areas. This prevents friction and reduces the likelihood of rust and corrosion. Refer to your machinery’s manual for specific lubrication intervals and types of grease recommended.

| Maintenance Task | Frequency |

|---|---|

| Visual Inspection | Every Month |

| Lubrication | Every 3 Months |

| Alignment Check | Every 6 Months |

| Replace Worn Components | As Needed |

Tools Required for Steering Repair

Ensuring proper function in the control system of your vehicle requires the right set of tools. Each task may demand specific instruments to facilitate repairs and replacements effectively.

- Wrenches: Various sizes for loosening and tightening bolts.

- Sockets: Essential for working with fasteners in tight spaces.

- Ratchet: Helps in applying torque with ease.

- Screwdrivers: A set with different head types for versatility.

- Pry Bar: Useful for separating components or applying leverage.

In addition to the primary tools, you may find the following helpful:

- Torque Wrench: Ensures proper tightening to manufacturer specifications.

- Hammer: A rubber or plastic mallet can help avoid damage to delicate parts.

- Measuring Tools: Calipers or rulers for accurate assessments.

Having the right equipment on hand will streamline the repair process and contribute to the ultimate success of your maintenance efforts.

Where to Find Replacement Parts

Finding quality components for your machinery can be a daunting task, but there are various avenues to explore. Whether you’re looking for original pieces or aftermarket alternatives, knowing where to search is crucial for maintaining optimal performance.

Online Retailers

The internet offers a wealth of options for sourcing necessary components. Numerous websites specialize in agricultural machinery and can provide both new and refurbished items. Always check customer reviews and ratings to ensure reliability.

Local Dealers and Salvage Yards

Don’t overlook local dealers who may carry a selection of components specific to your equipment. Salvage yards can also be a treasure trove, often housing hard-to-find items at reasonable prices. Building relationships with these vendors can lead to great finds.

Benefits of OEM vs. Aftermarket Parts

When it comes to maintaining machinery, the choice between original equipment manufacturer (OEM) and alternative solutions can significantly impact performance and longevity. Each option presents its own advantages and considerations, influencing not only functionality but also the overall investment value.

Quality Assurance

OEM components typically guarantee higher quality standards, as they are designed specifically for the machinery in question. This often translates to improved reliability and a lower likelihood of malfunction, making them a safe choice for those prioritizing durability.

Cost Considerations

On the other hand, alternative options can be more budget-friendly, appealing to those looking to reduce expenses. However, it is essential to assess whether the lower initial cost might result in higher long-term maintenance or replacement needs.

Understanding the Steering Gearbox

The mechanism responsible for directional control in vehicles plays a crucial role in ensuring stability and maneuverability. It translates the driver’s input into movement, allowing for precise navigation. Understanding its components and functionality is essential for effective maintenance and repair.

Components and Functionality

This assembly consists of various elements that work in harmony to convert rotational motion into linear movement. Key components include the housing, sector shaft, and worm gear, each contributing to the overall effectiveness of the system. Proper knowledge of these parts aids in diagnosing issues and implementing solutions.

Maintenance Tips

Diagram Interpretation for Beginners

Understanding visual representations can be a challenging yet rewarding experience for newcomers. This section aims to simplify the process of deciphering illustrations related to machinery, enhancing both comprehension and practical application. By breaking down the elements, you can gain a clearer insight into how each component interacts within the system.

Identifying Key Components

Begin by familiarizing yourself with the various elements shown in the representation. Look for labeled parts and their respective functions, as this knowledge will form the foundation for your understanding. Pay attention to the relationships and connections that indicate how each segment operates within the broader assembly.

Following Connections and Flow

Once you have recognized the individual elements, focus on the pathways and interactions that illustrate the movement and operation of the entire mechanism. Tracing these connections will help you grasp the ultimate functionality of the system and enhance your troubleshooting skills in practical scenarios.

Ultimate Guide to Steering Adjustments

This section focuses on optimizing control mechanisms, ensuring smooth navigation and precise handling. Making the right modifications can enhance performance and comfort, allowing for an improved experience in operation.

Understanding Alignment and Responsiveness

Proper alignment is crucial for maximizing responsiveness and stability. Regular checks can identify issues early, leading to timely corrections and preventing more significant problems down the line.

Tools and Techniques for Fine-Tuning

Utilizing the right tools is essential for effective adjustments. Techniques such as tension calibration and periodic inspections can ensure everything functions harmoniously, enhancing overall performance.