Understanding Gm Steering Column Components

The intricate assembly of control mechanisms in vehicles plays a crucial role in their overall functionality and driver experience. Each element within this system contributes to smooth operation and safety, making it essential to comprehend their arrangement and interconnection.

Visual representations of these assemblies serve as valuable resources for both enthusiasts and professionals. They provide insights into how each component interacts and assists in troubleshooting potential issues. Grasping this layout enhances one’s ability to maintain and repair these essential systems effectively.

By exploring the various segments involved, one can appreciate the engineering marvels that enhance driving comfort and precision. A thorough understanding of these mechanisms can empower users to address concerns proactively, ensuring optimal performance on the road.

Overview of GM Steering Columns

General Motors has developed a sophisticated range of systems that facilitate driver control and vehicle navigation. These mechanisms are crucial for ensuring smooth operation and enhancing user experience. Various components work in harmony to provide functionality and comfort in modern vehicles.

Key Features

One of the primary attributes of these systems is their ergonomic design, which allows for easy adjustment and optimal positioning. The integration of advanced technology improves responsiveness and provides drivers with essential feedback. This seamless interaction between the components contributes to overall vehicle performance.

Maintenance and Repair

Regular upkeep is vital for preserving the integrity and efficiency of these systems. Addressing wear and tear promptly can prevent significant issues and enhance safety. Understanding the function of each component aids in effective troubleshooting and maintenance strategies.

Key Components of Steering Columns

The functionality of vehicle maneuvering systems relies heavily on several integral elements that work harmoniously to ensure precise control and safety. Understanding these vital components can enhance knowledge of vehicle operation and maintenance.

Main Elements

Among the essential components are the mechanisms that facilitate direction adjustment and stability. These elements are crafted to withstand the rigors of daily use while providing a seamless driving experience.

Importance of Each Component

Each part contributes to the overall effectiveness of the system, playing a crucial role in maintaining the driver’s control and vehicle response. Their durability and design are pivotal for safe navigation.

| Component | Function |

|---|---|

| Upper Housing | Encloses the mechanism and provides structural support. |

| Lower Housing | Houses the lower mechanisms and secures connection to the vehicle. |

| Adjustment Shaft | Allows for modification of the driver’s position for comfort. |

| Control Mechanism | Enables the driver to manipulate direction effectively. |

Understanding Steering Column Functionality

The mechanism that facilitates directional control in vehicles is a complex assembly, integral to the driving experience. This system serves as a vital link between the driver and the front wheels, enabling precise navigation through various terrains. Its design incorporates several components that work together to ensure smooth operation and responsiveness.

At its core, this assembly is designed to transmit input from the driver, translating movements into actions that direct the vehicle’s path. The integration of safety features, such as collapsible designs, enhances the overall functionality, protecting occupants in the event of a collision. Furthermore, the assembly often houses various controls, allowing easy access to essential vehicle functions without compromising comfort.

Maintenance and understanding of this system are crucial for optimal performance. Regular inspections can help identify wear or malfunction, ensuring reliability on the road. As technology evolves, advancements in materials and engineering continue to improve the efficiency and safety of this essential vehicle component.

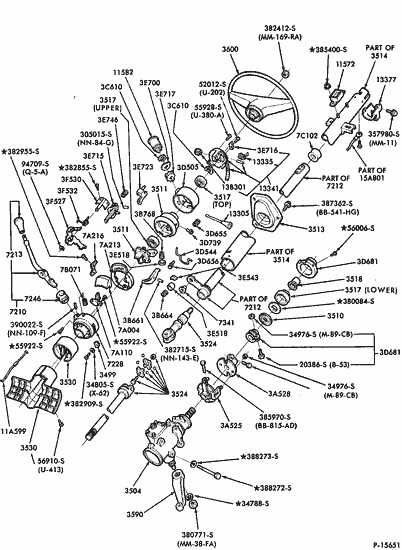

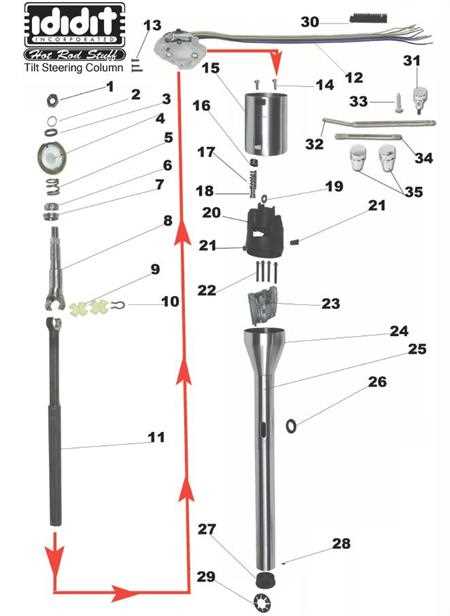

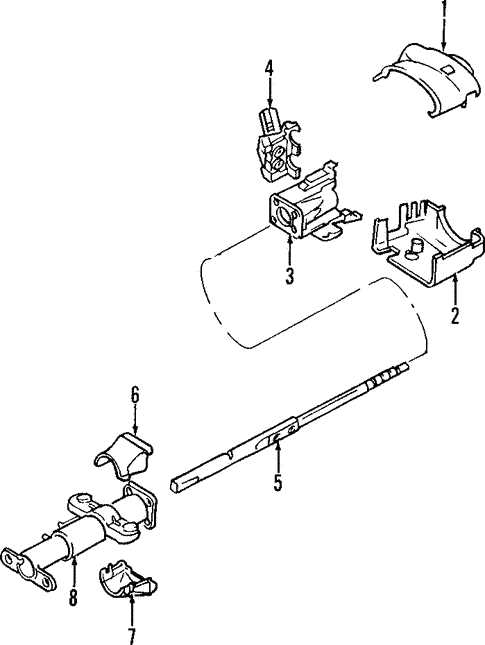

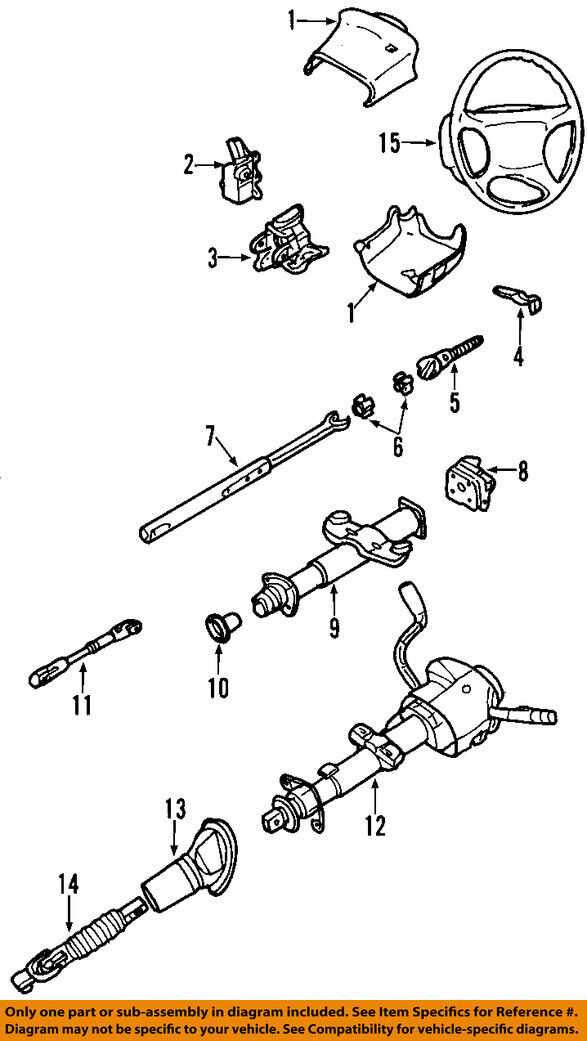

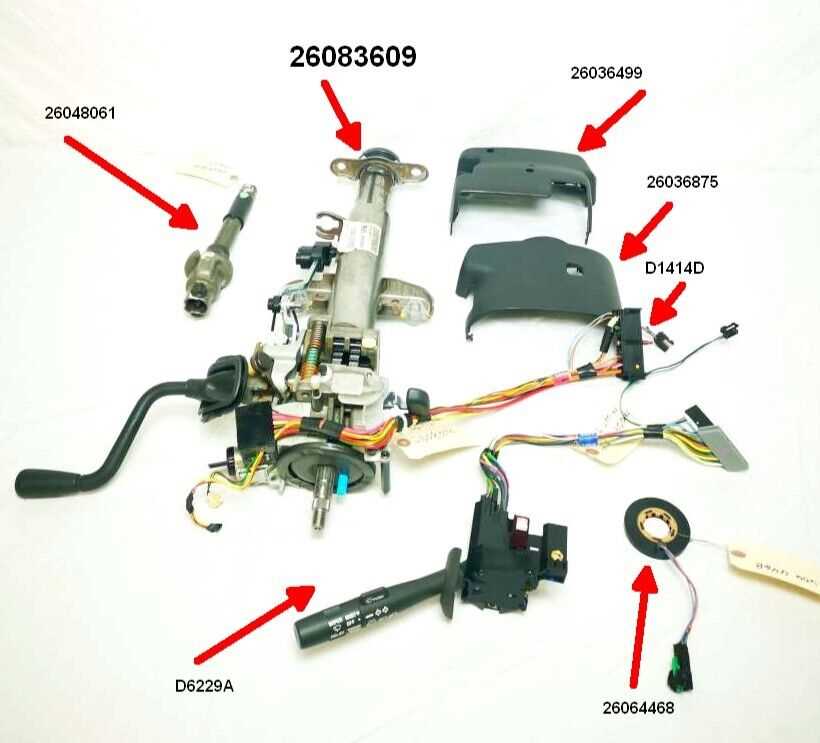

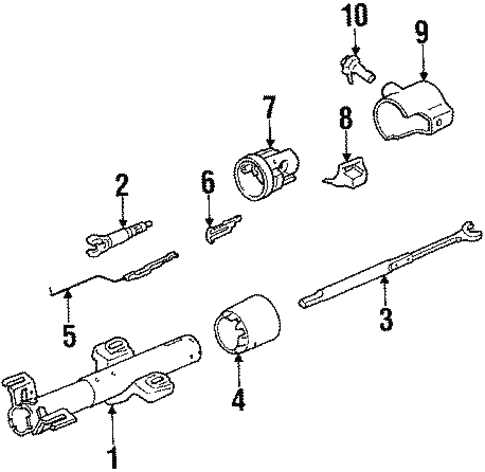

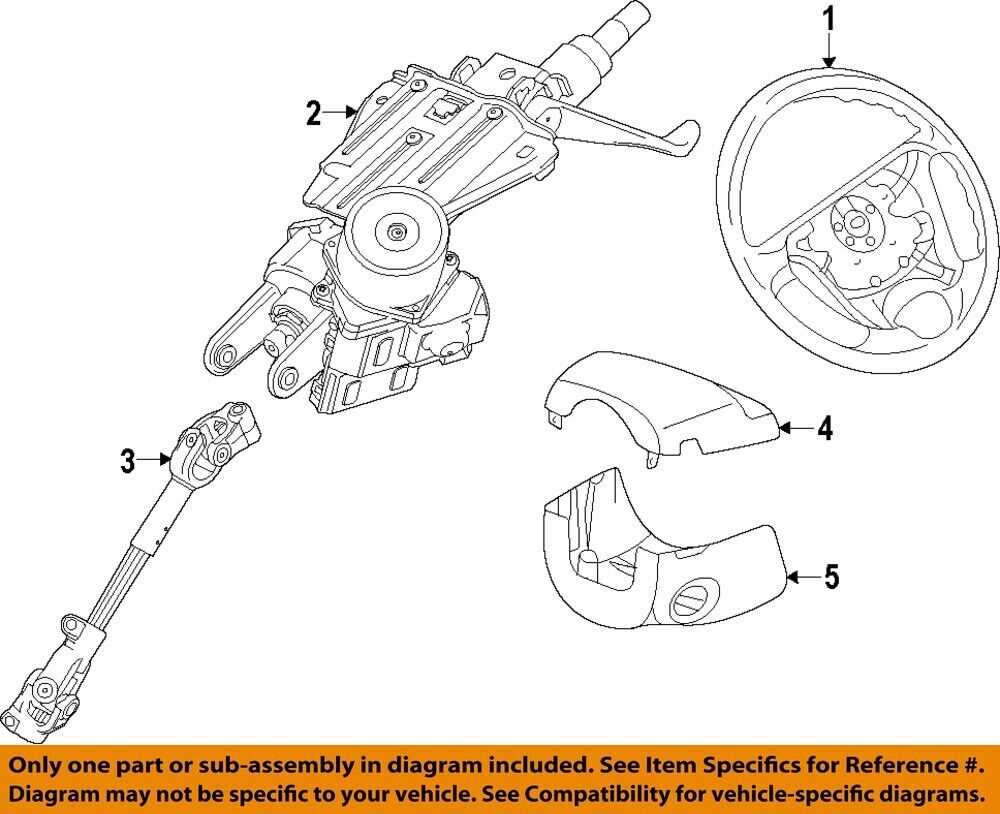

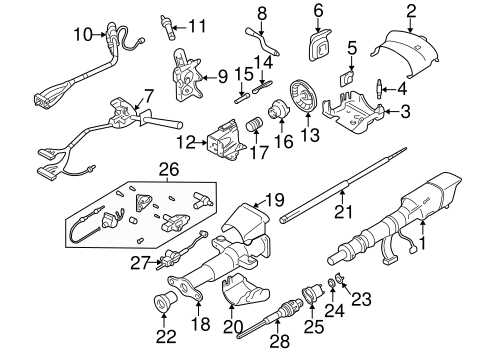

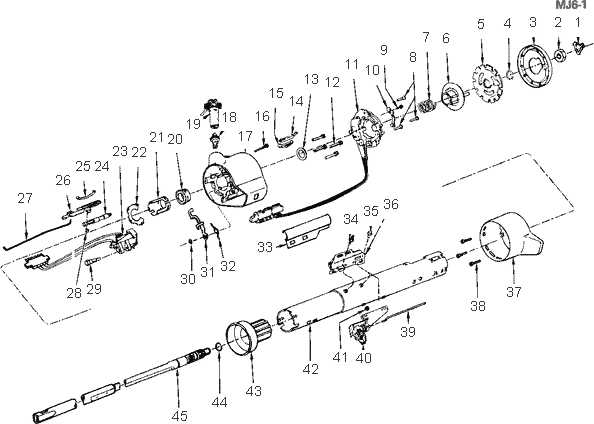

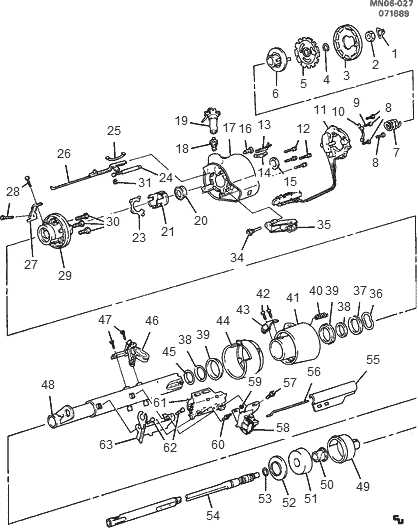

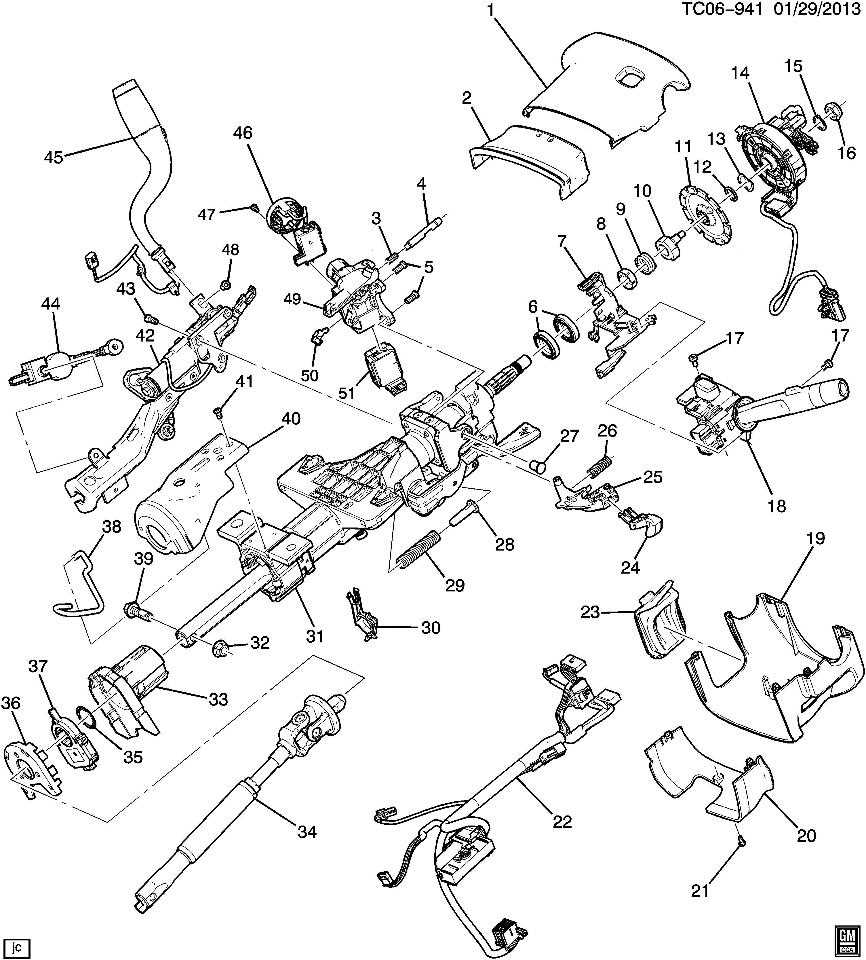

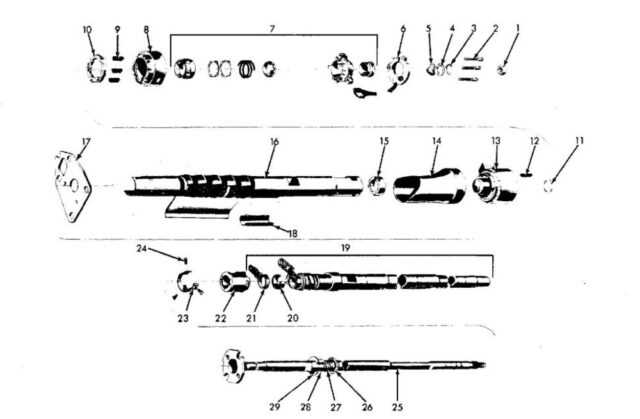

Parts Identification in Diagrams

Understanding the various components depicted in technical illustrations is crucial for effective assembly, repair, or enhancement of any vehicle. Each element serves a specific function, and recognizing these can streamline processes and improve outcomes. Proper identification enables technicians and enthusiasts to navigate complex schematics with confidence.

Typically, these illustrations categorize elements into distinct groups, allowing for easier comprehension and reference. Familiarity with the layout and labeling of each item is essential for successful identification. The following table outlines common features found in such visual representations and their corresponding descriptions.

| Feature | Description |

|---|---|

| Labeling | Each component is often labeled with a specific code or number, aiding in precise identification. |

| Symbolism | Certain icons represent specific functions or mechanisms, allowing for quick recognition. |

| Color Coding | Different colors may indicate various categories or systems, simplifying the distinction between them. |

| Reference Numbers | Cross-referenced numbers link to parts lists, facilitating easy access to detailed specifications. |

By mastering the identification of these elements, individuals can enhance their proficiency in vehicle maintenance and modifications, ultimately leading to improved performance and reliability.

Common Issues with Steering Components

Many vehicle owners encounter problems related to directional control mechanisms over time. These issues can lead to unsafe driving conditions and should be addressed promptly to ensure optimal performance and safety.

- Worn Bearings: Bearings can degrade due to friction and wear, resulting in poor handling and noise.

- Loose Connections: Bolts and fasteners may loosen, causing vibrations and instability during operation.

- Corrosion: Exposure to moisture can lead to rust, affecting the functionality of components and leading to failures.

- Fluid Leaks: Hydraulic systems may develop leaks, resulting in reduced efficiency and responsiveness.

- Misalignment: Components that are not properly aligned can cause uneven tire wear and compromised handling.

Regular maintenance and inspections can help identify these issues early, allowing for timely repairs and ensuring the vehicle remains safe and reliable.

Maintenance Tips for Steering Systems

Ensuring the proper functionality of your vehicle’s directional control system is vital for safety and performance. Regular upkeep can prevent unexpected failures and prolong the life of key components. Here are some essential tips to maintain this crucial aspect of your automobile.

Regular Inspections

Routine checks can identify issues before they escalate. Consider the following:

- Examine for any signs of wear or damage.

- Look for leaks in hydraulic systems.

- Test responsiveness during operation.

Fluid Maintenance

Maintaining the correct fluid levels is crucial for optimal function. Follow these steps:

- Check the fluid regularly and top off as needed.

- Replace old fluid according to manufacturer recommendations.

- Ensure there are no contaminants in the fluid.

By adhering to these guidelines, you can enhance the reliability of your vehicle’s directional control system and ensure a smoother driving experience.

Tools Needed for Steering Repairs

When undertaking repairs related to the directional control system of your vehicle, having the right tools is essential for a successful outcome. Proper equipment not only facilitates the repair process but also ensures safety and efficiency. Below is a list of necessary instruments that will aid in maintaining and fixing the system effectively.

1. Wrenches and Sockets: A set of wrenches and socket sizes is crucial for loosening and tightening various fasteners. These tools allow for precise adjustments and can handle different types of bolts and nuts commonly found in the assembly.

2. Pliers: Pliers are indispensable for gripping, twisting, and cutting wires or components. They can help with the manipulation of small parts that require a delicate touch.

3. Screwdrivers: A range of screwdrivers, including flathead and Phillips, is necessary for removing and securing screws that hold components in place. Ensure you have different sizes to accommodate various fittings.

4. Torque Wrench: This tool is essential for applying the correct amount of force to bolts, preventing overtightening or damage. It ensures that components are secured to manufacturer specifications.

5. Cleaning Supplies: Proper maintenance requires cleanliness. Have degreasers, rags, and brushes on hand to keep the area and parts clean during the repair process.

6. Diagnostic Tools: For modern vehicles, electronic diagnostic tools can help identify issues quickly. These devices provide valuable insights into the functionality of various systems.

7. Safety Gear: Always prioritize safety. Wear gloves, goggles, and other protective gear to shield yourself from potential hazards while working.

Equipping yourself with these tools will enhance your ability to effectively tackle any challenges that arise during repairs, leading to a more reliable and safe driving experience.

Step-by-Step Assembly Process

This section outlines the systematic approach to assembling the components of the control mechanism in vehicles. Following a clear sequence ensures that each element is correctly fitted, promoting safety and functionality.

Step 1: Begin by gathering all necessary components. Ensure that each piece is free of defects and meets quality standards. This preparation is crucial for a smooth assembly process.

Step 2: Familiarize yourself with the layout and the arrangement of each component. Understanding how the elements interact will help in achieving a coherent assembly.

Step 3: Start with the base component, securing it firmly in place. Use the appropriate tools to fasten it, ensuring stability before moving on to the next part.

Step 4: Gradually add the subsequent elements, checking for alignment and compatibility at each stage. It’s essential to maintain a methodical approach to avoid misalignment.

Step 5: Once all components are in place, conduct a thorough inspection. Ensure that every part is secure and functioning as intended. This step is vital for the overall safety of the assembly.

Step 6: Finally, perform a test to confirm the assembly’s efficiency. This evaluation allows you to identify any potential issues and make necessary adjustments.

Safety Precautions During Repairs

When engaging in vehicle maintenance or component replacement, ensuring safety is paramount. Adopting proper precautions not only safeguards the technician but also prolongs the lifespan of the vehicle. Awareness and preparation can prevent accidents and injuries during the process.

Essential Safety Measures

Before starting any repair work, it’s critical to prepare the workspace and tools. Here are some key measures to follow:

| Measure | Description |

|---|---|

| Personal Protective Equipment | Always wear gloves, goggles, and sturdy footwear to protect against debris and chemicals. |

| Proper Ventilation | Ensure that the workspace is well-ventilated to avoid inhaling fumes or dust. |

| Tool Inspection | Check all tools for damage or wear before use to prevent malfunctions. |

| Secure Vehicle | Ensure the vehicle is on a flat surface and secured with wheel chocks and jack stands. |

Awareness of Surroundings

Maintaining awareness of the environment is vital. Be cautious of potential hazards, such as moving parts or electrical components. Keep the area tidy and free from clutter to minimize risks during repairs.

Visual Aids for Assembly Guidance

Utilizing visual resources during the assembly process significantly enhances understanding and efficiency. Clear illustrations and diagrams can simplify complex tasks, allowing individuals to follow procedures with greater accuracy and confidence. By providing a visual representation, these aids bridge the gap between theoretical knowledge and practical application.

Types of Visual Resources

- Illustrations: Detailed drawings showcasing each component’s placement and orientation.

- Flowcharts: Step-by-step guides that outline the sequence of actions needed for assembly.

- Photographs: Real-life images that provide context and clarity for each phase of the process.

- Videos: Dynamic demonstrations that can effectively convey techniques and methods.

Benefits of Visual Aids

- Improved comprehension of complex instructions.

- Reduced likelihood of errors during assembly.

- Faster assembly times due to clearer guidance.

- Enhanced learning experiences for both novices and experienced individuals.

Comparison of Different GM Models

This section delves into the distinctive features and components across various General Motors models. By analyzing their engineering and design elements, we can gain insights into how each model caters to different driving experiences and consumer preferences.

Overview of Key Models

Each model from GM showcases unique characteristics that appeal to a wide audience. From compact cars to robust trucks, the diversity within the lineup reflects varying requirements in performance, comfort, and technology.

| Model | Type | Key Features |

|---|---|---|

| Cruze | Compact Car | Fuel Efficiency, Advanced Safety Features |

| Malibu | Midsize Sedan | Spacious Interior, Modern Infotainment System |

| Sierra | Pickup Truck | Heavy-Duty Towing Capacity, Off-Road Capabilities |

| Equinox | SUV | All-Wheel Drive, Versatile Cargo Space |

Comparison Insights

When comparing these models, it becomes evident that each is tailored to meet specific demands. While the compact Cruze excels in efficiency for city driving, the Sierra stands out in ruggedness and utility. The Malibu and Equinox, on the other hand, offer a balance of comfort and technology, appealing to family-oriented consumers.

Aftermarket vs. OEM Steering Parts

When it comes to replacing essential components in your vehicle, the choice between original equipment manufacturer (OEM) offerings and aftermarket alternatives is crucial. Each option presents its own set of advantages and disadvantages, which can significantly affect performance, longevity, and overall driving experience.

OEM options are designed specifically for your vehicle model, ensuring a perfect fit and compatibility. They often come with a higher price tag but are generally perceived as more reliable due to rigorous testing standards. Conversely, aftermarket alternatives can provide cost savings and a broader selection, yet the quality can vary greatly depending on the manufacturer.

| Criteria | OEM | Aftermarket |

|---|---|---|

| Quality | Consistent and reliable | Variable, depends on the brand |

| Cost | Higher price | Generally lower |

| Warranty | Manufacturer warranty | Varies by manufacturer |

| Fitment | Perfect fit | May require adjustments |

| Availability | Limited to dealer | Widely available |

Ultimately, the decision hinges on individual preferences and specific vehicle needs. Weighing the pros and cons of each option will guide you toward the most suitable choice for your automotive requirements.

Resources for Further Information

For those looking to deepen their understanding of automotive components and mechanisms, numerous resources are available. These materials provide valuable insights into the design and functionality of various vehicle systems, ensuring enthusiasts and professionals alike can enhance their knowledge and skills.

Online Platforms

Websites dedicated to automotive repair and maintenance often feature detailed articles and forums where individuals can exchange information. Platforms like YouTube host a plethora of tutorial videos that visually guide users through different processes. Online communities, such as those found on Reddit, offer a space for discussion and troubleshooting, making it easier to find answers to specific queries.

Books and Manuals

For a more structured approach, consider investing in comprehensive guides and manuals that cover vehicle maintenance. Service manuals published by manufacturers often include extensive information on system layouts and troubleshooting techniques. Additionally, textbooks focused on automotive engineering provide in-depth knowledge of vehicle functionality and design principles.