Comprehensive Guide to John Deere 455 Steering Parts Diagram

The intricate mechanisms that govern a tractor’s maneuverability play a crucial role in its overall performance and functionality. This section delves into the essential elements that ensure smooth navigation and responsive handling of agricultural machinery. Familiarity with these components is vital for maintenance, troubleshooting, and enhancing operational efficiency.

By examining the layout and relationships among various components, operators and technicians can better appreciate how each piece contributes to the tractor’s responsiveness. This knowledge not only aids in the effective operation of the vehicle but also extends its lifespan through informed care and timely repairs.

In this exploration, we will present a detailed visual representation of the control system’s elements, allowing readers to easily identify and understand their specific roles. Through this guide, you will gain insight into how to optimize the performance of your equipment and address any potential issues that may arise in the field.

Understanding John Deere 455 Steering

This section explores the intricacies of maneuvering systems in agricultural machinery, focusing on essential components that contribute to effective control and precision. A thorough comprehension of these mechanisms is vital for optimal performance and safety.

- Key components include linkages, gears, and hydraulic systems.

- Proper maintenance ensures longevity and efficiency.

- Identifying issues early can prevent costly repairs.

By familiarizing oneself with these crucial elements, operators can enhance their understanding of vehicle dynamics, leading to improved handling and responsiveness.

Importance of Steering Parts

The components that govern directional control play a crucial role in the performance and safety of any machinery. Their integrity and functionality directly influence maneuverability, ensuring smooth operation in various environments.

Key reasons for the significance of these components include:

- Safety: Properly functioning elements reduce the risk of accidents.

- Efficiency: Enhanced control leads to better productivity in tasks.

- Durability: Quality components contribute to the longevity of the machinery.

- Cost-effectiveness: Investing in reliable parts can minimize repair costs over time.

Understanding their importance allows operators to prioritize maintenance and ensure optimal performance in the field.

Common Issues with Steering Components

Challenges often arise with directional control systems in agricultural machinery, leading to potential performance issues. Understanding these common problems can help in timely maintenance and repair, ensuring optimal functionality.

| Issue | Description |

|---|---|

| Wear and Tear | Components may deteriorate over time due to regular usage, impacting responsiveness. |

| Fluid Leaks | Hydraulic fluids can escape through damaged seals, causing reduced efficiency. |

| Misalignment | Improper alignment can lead to uneven wear and hinder maneuverability. |

| Noise Issues | Unusual sounds during operation may indicate underlying mechanical problems. |

| Loose Connections | Connections that are not secure can lead to instability and control challenges. |

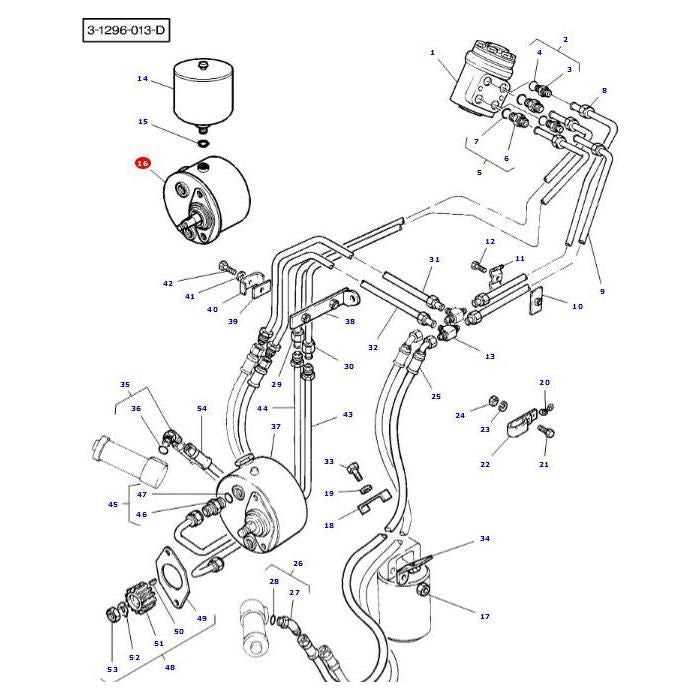

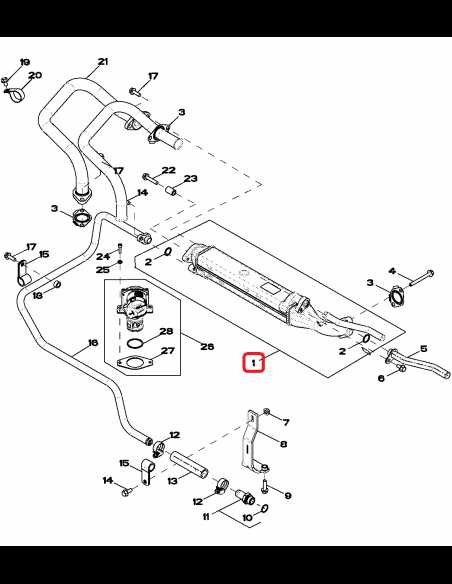

Overview of Steering System Functionality

The functionality of a control system is crucial for achieving precise maneuverability and ensuring stability during operation. This system comprises various components that work together seamlessly to facilitate responsive handling and maintain directional accuracy.

Key Components

- Control Wheel: Enables the operator to direct movement.

- Linkage Mechanism: Connects the wheel to the mechanism that alters direction.

- Hydraulic System: Provides necessary force for smooth transitions.

Operational Mechanics

When the control wheel is turned, the linkage mechanism engages, translating the motion into a change in direction. The hydraulic system amplifies this action, ensuring that even minimal inputs result in significant adjustments, enhancing overall maneuverability.

Key Components in the Steering Diagram

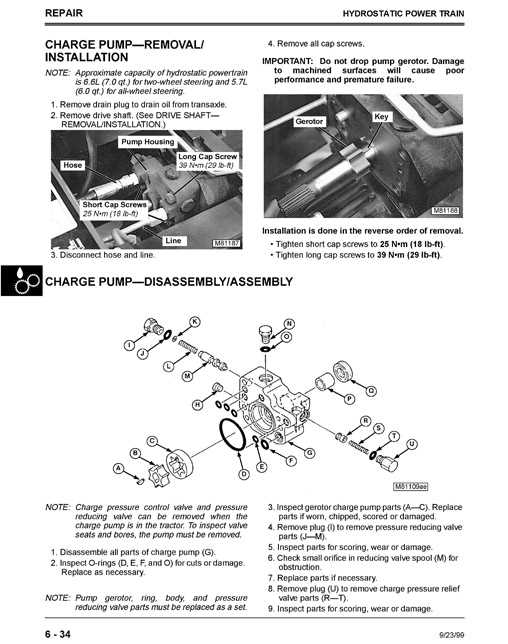

This section delves into the essential elements that make up the directional control system of the machinery. Understanding these crucial components is vital for ensuring optimal performance and ease of handling.

1. Control Mechanism: This element allows the operator to influence the movement direction effectively. It plays a pivotal role in the overall functionality, providing a direct connection between the operator’s inputs and the vehicle’s response.

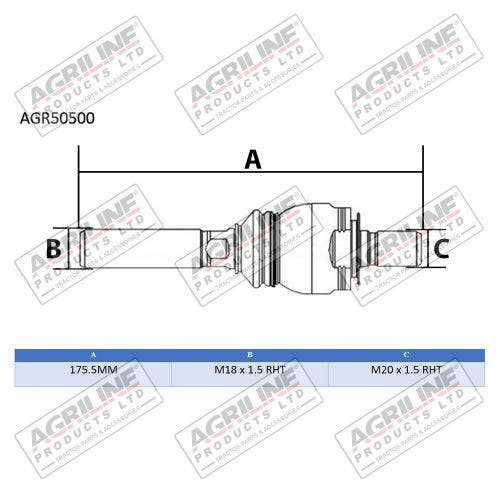

2. Linkages: These connectors serve to transmit force from the control mechanism to the wheels. Their design ensures smooth transitions and precise adjustments, contributing to enhanced maneuverability.

3. Hydraulic System: Many machines utilize hydraulic power to amplify the force exerted by the operator. This system enhances responsiveness, allowing for more effortless navigation, especially in challenging terrains.

4. Axles: Integral to the movement, these components support the weight of the machine while enabling rotation. Their durability and design influence the overall stability and handling capabilities.

5. Tires: Often overlooked, these are critical for traction and control. The right selection can significantly impact the effectiveness of the entire system, ensuring better grip and safety.

By familiarizing oneself with these fundamental components, operators can maintain and troubleshoot the system more effectively, leading to improved operational efficiency.

Maintenance Tips for Steering Parts

Proper care of directional control components is essential for ensuring optimal performance and longevity. Regular checks and maintenance can prevent wear and enhance safety while operating machinery. Establishing a routine can help identify issues before they escalate, ensuring smooth operation.

Regular Inspections

Conduct frequent evaluations of all control mechanisms. Look for signs of wear, corrosion, or looseness. Pay special attention to connections and pivot points, as these areas are prone to damage and may require immediate attention.

Lubrication and Cleaning

Keep moving components well-lubricated to reduce friction and prevent rust. Use appropriate lubricants and clean surfaces regularly to remove dirt and debris that can hinder performance. Proper maintenance not only improves functionality but also extends the life of the system.

Identifying Wear and Tear

Recognizing signs of deterioration is crucial for maintaining optimal functionality in any mechanical system. Regular inspection can prevent minor issues from escalating into major problems. Understanding the common indicators of wear allows operators to take timely actions, ensuring longevity and efficiency.

Common Indicators of Deterioration

Various signs can suggest that components are wearing out. These may include unusual noises, decreased responsiveness, and visible damage. Operators should be vigilant and familiar with these indicators to address them promptly.

Inspection Checklist

| Indicator | Description |

|---|---|

| Noise | Uncharacteristic sounds during operation can indicate misalignment or wear. |

| Response Time | Delayed reactions can suggest friction or component fatigue. |

| Visual Damage | Cracks, chips, or deformities may point to excessive stress or impact. |

| Fluid Leaks | Leaks can signify failing seals or connections, leading to inefficiency. |

By regularly monitoring these aspects, operators can maintain optimal performance and prolong the life of their machinery.

Replacing Steering Components Effectively

Maintaining optimal control of your machinery is crucial for performance and safety. When it comes to replacing essential control elements, a systematic approach can make all the difference. This section will guide you through the steps needed to ensure a smooth replacement process, maximizing efficiency and durability.

Here are the key steps to follow:

- Assess the Situation: Before starting, identify which elements require replacement. Look for signs of wear, unusual noises, or handling issues.

- Gather Necessary Tools: Ensure you have all required tools at hand, including wrenches, screwdrivers, and specialized equipment. Having everything ready will streamline the process.

- Consult Documentation: Refer to the relevant manuals or guides to understand the specifications and procedures for your model. This will help avoid mistakes during the installation.

- Disassemble Carefully: When removing old components, do so gently to prevent damaging surrounding parts. Take note of the order and orientation of each piece for easier reassembly.

- Install New Components: Follow the instructions meticulously to install the new elements. Ensure they are secured properly to maintain functionality.

- Test the System: After installation, conduct a thorough test to ensure everything operates smoothly. Check for any signs of issues before returning the equipment to service.

By following these steps, you can effectively replace essential control components and ensure the continued reliability of your equipment.

Tools Required for Repairs

When undertaking mechanical repairs, having the right tools is essential for efficiency and effectiveness. The appropriate equipment not only simplifies the process but also ensures that tasks are completed to a high standard. Below, we outline the necessary tools that will aid in achieving successful maintenance and restoration.

Essential Hand Tools

Start with basic hand tools such as wrenches, screwdrivers, and pliers. These items are fundamental for loosening and tightening components. Additionally, having a ratchet set can significantly improve access to tight spaces, making it easier to manipulate bolts and screws.

Specialized Equipment

For more intricate tasks, consider investing in torque wrenches and alignment tools. These specialized instruments help ensure that all components are adjusted to the correct specifications, ultimately enhancing performance and longevity. A toolbox for organization will also streamline your workflow, allowing for quick access to your equipment.

Finding Authentic John Deere Parts

Ensuring the quality and compatibility of components for your agricultural machinery is crucial for optimal performance. Locating genuine items can enhance longevity and reliability, minimizing maintenance issues over time. This guide will explore effective strategies for sourcing authentic replacements that meet the highest standards.

Where to Search

Utilizing official retailers, trusted online marketplaces, and authorized service centers can significantly improve your chances of finding legitimate components. It’s essential to verify the credentials of the seller and cross-check their reputation.

Identifying Genuine Components

When examining items, look for specific identifiers such as part numbers, logos, and packaging details that indicate authenticity. This diligence can prevent the pitfalls associated with counterfeit products.

| Source | Benefits |

|---|---|

| Authorized Dealers | Guaranteed quality and warranty options |

| Online Marketplaces | Convenient access and competitive pricing |

| Service Centers | Expert advice and installation services |

Understanding the Steering Geometry

The arrangement and interaction of various components that facilitate direction control in agricultural machinery play a crucial role in overall performance. A thorough grasp of this framework is essential for operators and technicians alike, as it influences handling, stability, and responsiveness.

Key Components of Direction Control

- Pivot Points: These are critical locations where movement occurs, allowing for effective turns and adjustments.

- Linkage Systems: These connections between parts enable the transfer of motion and force, influencing how the machine responds to input.

- Alignment Angles: The angles formed by the components impact maneuverability and tire wear, making their proper configuration vital.

Importance of Accurate Setup

- Ensures optimal maneuverability in various terrains.

- Promotes even tire wear, extending their lifespan.

- Enhances overall safety during operation, reducing the risk of accidents.

By understanding these elements, users can maintain equipment more effectively and enhance performance in the field.

Resources for Technical Support

Accessing reliable technical assistance is crucial for maintaining equipment functionality and longevity. Whether you are experiencing minor issues or major malfunctions, having the right resources at your disposal can make all the difference.

Here are some valuable avenues to explore for technical support:

- Manufacturer’s Website: Official sites often provide manuals, FAQs, and troubleshooting guides.

- Customer Service: Reach out directly via phone or email for personalized assistance.

- Online Forums: Communities of enthusiasts and experts share insights and solutions.

- Local Dealers: Authorized retailers can offer expert advice and repair services.

- Social Media Groups: Join dedicated groups to connect with fellow users and seek advice.

Utilizing these resources will help you delve deeper into resolving issues and enhancing your equipment’s performance.