Understanding the Steering Parts Diagram for John Deere L100

When it comes to maintaining a reliable lawn mowing machine, understanding the assembly of its directional control mechanism is crucial. This essential system ensures smooth maneuverability and overall efficiency, allowing users to navigate their landscapes with ease. Familiarity with these components not only enhances operational skills but also aids in effective troubleshooting and repairs.

In this section, we will explore the intricate layout of the directional control assembly, highlighting the various elements that contribute to its functionality. By delving into the specifics of each component, users can gain insight into how to properly maintain and replace them when necessary, ensuring that their equipment remains in optimal working condition.

Moreover, visual aids can greatly enhance comprehension of these mechanical elements. Utilizing a clear representation of the assembly will provide a valuable reference point, making it easier to identify parts during inspection or repair processes. Such knowledge empowers users to tackle any issues confidently, minimizing downtime and maximizing performance.

Understanding John Deere L100 Steering System

The maneuverability of any lawn maintenance equipment is crucial for achieving precision and efficiency. A well-functioning guidance mechanism allows operators to navigate through various terrains effortlessly, ensuring optimal performance. This section explores the key components and functioning of the control system in this specific model, highlighting its importance in overall operation.

- Key Components:

- Wheel assembly

- Linkage mechanisms

- Control handles

- Pivot points

- Functionality:

- Translates user input into movement

- Ensures stability and control during operation

- Facilitates smooth turns and navigation

- Maintenance Tips:

- Regularly inspect for wear and tear

- Lubricate moving parts to reduce friction

- Check alignment for optimal performance

Understanding the intricate details of this control system enables users to enhance their equipment’s functionality and longevity. By recognizing how each element contributes to the overall operation, operators can ensure a more enjoyable and efficient mowing experience.

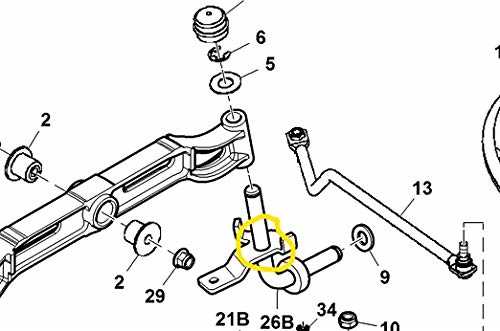

Components of the Steering Assembly

The functionality of any vehicle’s directional control system relies on a collection of essential elements that work in harmony. Each component plays a crucial role in ensuring smooth maneuverability and stability, ultimately enhancing the operator’s experience.

Key Elements

Among the most vital components are the wheel interface, which allows for precise adjustments, and the connecting rods that transmit movement. Additionally, the support structure provides necessary reinforcement, ensuring durability and reliability during operation.

Maintenance Considerations

Regular inspection of these elements is paramount. Wear and tear can significantly impact performance, leading to potential complications. Identifying issues early can prevent costly repairs and prolong the lifespan of the entire system.

How to Read the Diagram

Understanding a schematic representation of mechanical components is essential for effective maintenance and repairs. This guide will help you navigate through the visual layout, allowing you to identify key elements and their interconnections with ease.

Key Elements to Observe

Familiarize yourself with the symbols and labels used in the representation. These typically denote specific components and their functions. Pay attention to lines that illustrate how parts are linked, as they indicate movement and flow.

Interpreting Connections

Recognizing the relationship between elements is crucial for troubleshooting. Here’s a brief overview of common symbols:

| Symbol | Description |

|---|---|

| Circle | Connection point |

| Arrow | Direction of movement |

| Square | Fixed component |

Identifying Steering Problems

Recognizing issues in vehicle maneuverability is crucial for maintaining optimal performance and safety. Various symptoms may indicate underlying complications that require attention. Early detection can prevent further damage and enhance overall functionality.

Common signs include unusual noises, such as grinding or clunking sounds, which may suggest wear or misalignment. Additionally, difficulty turning or an off-center wheel can signal potential failures in the mechanism. Observing any excessive play in the control may also point to necessary adjustments or replacements.

Addressing these indicators promptly can lead to a smoother operation and prolong the lifespan of the equipment. Regular inspections and maintenance play a vital role in identifying and resolving these issues effectively.

Replacing Worn Steering Parts

Maintaining optimal control and safety of your machinery is crucial, especially when it comes to the components that facilitate maneuverability. Over time, certain elements may wear down due to regular use, affecting performance and handling. Addressing these worn components promptly can restore functionality and enhance the overall experience.

Before beginning the replacement process, it’s important to assess the condition of the components in question. Look for signs of wear, such as unusual noises, looseness, or decreased responsiveness. Proper identification will ensure you acquire the correct replacements for a successful repair.

| Component | Symptoms of Wear | Replacement Options |

|---|---|---|

| Rods | Excessive play, difficulty turning | OEM or aftermarket options |

| Bearings | Noisy operation, rough movement | High-quality replacements |

| Linkages | Inconsistent handling, misalignment | Adjustable or fixed replacements |

Once you’ve identified the worn components, gather the necessary tools and new parts. Follow the manufacturer’s guidelines for the removal and installation process to ensure a secure fit. Regular maintenance checks will help prevent future issues and keep your equipment running smoothly.

Maintenance Tips for Steering System

Ensuring the longevity and smooth operation of your vehicle’s directional mechanism is essential for optimal performance. Regular upkeep not only enhances safety but also prolongs the life of the components involved. Here are some practical suggestions to keep your navigation system in top condition.

Regular Inspections

Conduct frequent checks on all elements related to the guidance system. Look for signs of wear and tear, such as loose connections or frayed cables. Early detection of issues can prevent more significant problems down the line.

Lubrication and Cleaning

Apply appropriate lubricants to moving parts to minimize friction and wear. Additionally, ensure that all surfaces are clean and free from debris, which can hinder performance. A well-maintained system is crucial for responsive handling.

Tools Needed for Repair

When embarking on a repair project, having the right instruments at your disposal is essential for success. The correct tools not only streamline the process but also ensure safety and efficiency. This guide outlines the necessary equipment for tackling common maintenance tasks.

Essential Tools: A reliable set of wrenches is crucial for loosening and tightening various components. Additionally, a quality screwdriver set will facilitate the removal of screws with ease. For more intricate tasks, consider having pliers and a socket set handy.

Specialized Equipment: Depending on the complexity of the repair, you might require specific tools like a torque wrench to apply the right amount of force or a multimeter for electrical diagnostics. Investing in these specialized items can greatly enhance your ability to perform thorough repairs.

Safety Gear: Always prioritize safety by wearing appropriate protective equipment. Gloves, goggles, and a mask can safeguard against potential hazards, ensuring a secure working environment.

By gathering these tools and adhering to safety protocols, you will be well-prepared to delve into your repair endeavors with confidence and achieve the ultimate outcome.

Common Issues with L100 Steering

When operating a lawn tractor, several challenges can arise related to the control mechanism. Identifying these issues early can help ensure smooth operation and prevent further complications. Regular maintenance and awareness of common malfunctions can significantly enhance the lifespan and performance of your machine.

Typical Problems

Operators may experience a range of difficulties that can affect maneuverability. These include misalignment, wear and tear of components, and potential obstruction from debris. Understanding these factors can lead to timely interventions.

Impact of Issues

The performance of your vehicle can be severely affected by unresolved complications. Poor handling can result in inefficiency and may even pose safety risks. Regular inspections can help mitigate these concerns.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Alignment Problems | Uneven tracking, difficulty in turning | Adjustment of control links, regular checks |

| Component Wear | Excessive play in the mechanism | Replacement of worn parts, lubrication |

| Debris Obstruction | Sticking, unresponsive control | Cleansing of the area, routine maintenance |

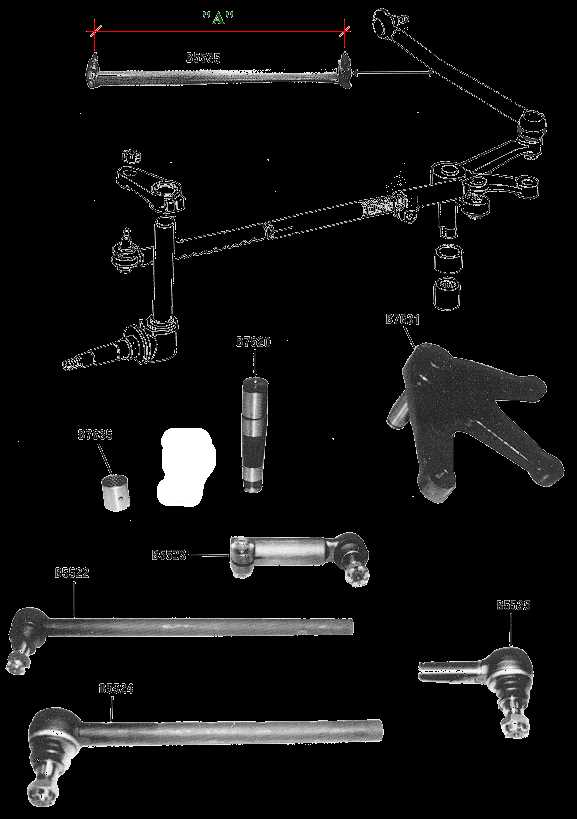

Visual Guide to Steering Parts

This section provides a comprehensive overview of the components that facilitate maneuverability in outdoor machinery. Understanding the various elements involved can enhance maintenance and troubleshooting efforts.

Key elements that contribute to the control mechanisms include:

- Connectors that link the wheel system to the frame

- Control rods that transmit movement

- Adjustable links for precision handling

- Support brackets that stabilize the framework

Each of these components plays a crucial role in ensuring smooth navigation. Below is a breakdown of their functions:

- Connectors: These are essential for transferring motion from the operator’s controls to the wheels.

- Control rods: These elements allow for directional changes, enabling the user to steer effectively.

- Adjustable links: These provide customization options for handling preferences, ensuring a personalized experience.

- Support brackets: Vital for maintaining structural integrity, they ensure stability during operation.

By familiarizing yourself with these components, you can improve your understanding of machine operation and enhance your ability to perform maintenance tasks effectively.

Ordering Replacement Components

When it comes to maintaining your outdoor equipment, acquiring the right replacement elements is crucial for ensuring optimal performance and longevity. The process of ordering these components should be approached with careful consideration to avoid unnecessary complications and to enhance the efficiency of your machine.

Identify Specific Needs: Begin by assessing the exact components that require replacement. Take the time to inspect the existing items thoroughly, noting any signs of wear or damage. This step is essential to ensure that you order the correct elements tailored to your model.

Consult Resources: Utilize various resources such as online manuals, manufacturer websites, or customer support to gather information on the required components. These platforms often provide detailed specifications, ensuring that you make informed decisions when placing your order.

Choose Reputable Suppliers: Select trusted suppliers or authorized dealers known for their quality and reliability. This helps in securing authentic items that meet the manufacturer’s standards, reducing the risk of compatibility issues.

Verify Compatibility: Before finalizing your order, double-check the compatibility of the components with your equipment model. Cross-referencing part numbers or consulting with a knowledgeable representative can save you time and effort.

Consider Availability: Keep in mind the availability of the components you need. Some elements may be in high demand or have longer lead times, so planning ahead is advisable to avoid delays in maintenance.

Finalize Your Order: Once you have all the necessary information, proceed to place your order confidently. Ensure that you have provided accurate details to facilitate a smooth transaction and timely delivery.

Following these steps will not only streamline the ordering process but also enhance the reliability of your machinery for years to come.

Adjusting Steering Alignment

Ensuring optimal directional control is essential for the efficient operation of your equipment. Proper alignment allows for smoother handling and reduces wear on components, ultimately enhancing performance and longevity.

Why Alignment Matters

- Improves maneuverability

- Reduces tire wear

- Enhances overall stability

Steps to Adjust Alignment

- Check the current settings using a level.

- Loosen the necessary bolts for adjustment.

- Make precise alterations to achieve the desired angle.

- Tighten the bolts securely.

- Test the equipment to ensure proper function.

DIY Repairs vs. Professional Help

When faced with mechanical issues, enthusiasts often grapple with the choice between tackling repairs independently or seeking external expertise. This decision can hinge on various factors, including the complexity of the problem, available resources, and individual skill levels. Understanding the benefits and drawbacks of both approaches is crucial for making an informed choice.

Opting for self-repair can foster a sense of accomplishment and save on costs, allowing individuals to gain hands-on experience. However, without proper knowledge, one may inadvertently exacerbate the situation, leading to more significant problems down the line. On the other hand, hiring a specialist ensures a higher level of expertise and potentially quicker resolution, albeit at a higher financial investment. Weighing these considerations is essential for determining the most effective course of action.

Resources for Further Assistance

Finding the right support and information can significantly enhance your experience and understanding of equipment maintenance. Below are some valuable resources that can aid you in your journey.

- Online Forums: Engage with communities of enthusiasts and professionals who share their knowledge and tips.

- Manufacturer Websites: Access official documentation, manuals, and troubleshooting guides directly from the source.

- YouTube Tutorials: Explore visual guides that demonstrate repair techniques and assembly processes step by step.

- Local Dealerships: Consult with experts who can provide advice and help with specific inquiries related to your machinery.

Utilizing these resources can help you delve deeper into the subject and find the ultimate solutions for your needs.