Comprehensive Guide to John Deere LX280 Steering Parts Diagram

In the realm of lawn maintenance machinery, the functionality of the control system is paramount for optimal performance. This intricate assembly plays a crucial role in guiding the equipment with precision and ease, ensuring that every maneuver is executed flawlessly. A comprehensive grasp of these elements can greatly enhance user experience and efficiency.

Within this section, we will delve into the various elements that comprise the guidance mechanism, exploring their interactions and the significance of each component. By familiarizing yourself with these crucial features, you can better appreciate the design and engineering that underpin modern lawn care machines.

Whether you’re a seasoned operator or a novice enthusiast, understanding the layout and function of these components can empower you to troubleshoot issues and perform maintenance tasks with confidence. Join us as we break down the essential elements of this vital system, enhancing your knowledge and skills in the world of outdoor machinery.

Understanding John Deere LX280 Steering System

The maneuverability of a lawn care machine relies heavily on its directional control mechanism. This essential component ensures precise navigation and responsiveness, allowing operators to tackle various terrains with ease. A well-functioning system not only enhances performance but also contributes to the overall safety of the equipment.

Within this mechanism, several key elements work in harmony to facilitate smooth turning and stability. Each component plays a vital role, from the wheel assemblies to the linkages that connect them, ensuring that input from the operator translates effectively into movement. Regular maintenance and awareness of wear and tear are crucial for sustaining optimal functionality.

Understanding the intricacies of this system can aid in troubleshooting common issues that may arise during operation. Familiarity with the various components and their arrangement can empower users to perform minor repairs and adjustments, ultimately prolonging the lifespan of their machinery.

In summary, grasping the workings of the directional control system not only enhances the user experience but also fosters a deeper appreciation for the technology behind these essential machines.

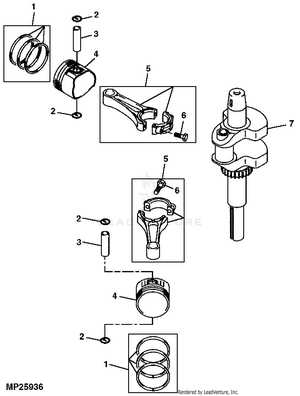

Components of LX280 Steering Mechanism

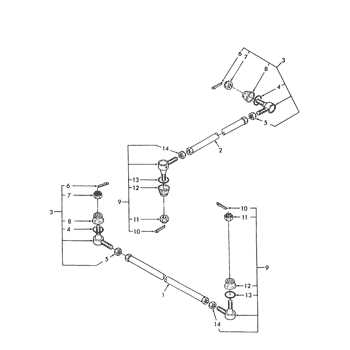

The steering system of a garden tractor is a crucial aspect of its functionality, allowing for precise maneuverability and control. Understanding its various elements can enhance maintenance and repair efforts, ensuring optimal performance.

At the core of the control system lies the column, which serves as the main conduit for driver input. Connected to this are the linkages, essential for transmitting motion and providing feedback to the driver. These linkages must be well-maintained to prevent wear and ensure smooth operation.

Another significant element is the gear assembly, which translates rotational motion into directional changes. This assembly typically includes gears and bearings that must be lubricated regularly to avoid friction and enhance longevity.

The pivot points are critical as they allow for the movement of the front wheels, ensuring responsive handling. Regular inspection of these points can help identify any signs of damage or wear.

Finally, the wheel hubs are vital for stability and control during operation. Ensuring they are securely fastened and free from debris can significantly impact overall performance.

Importance of Proper Steering Maintenance

Ensuring the optimal functionality of a vehicle’s directional system is crucial for safety and performance. Regular upkeep not only enhances maneuverability but also prolongs the lifespan of various components. Neglecting this aspect can lead to significant issues, affecting both the operator’s experience and the machinery’s overall efficiency.

Key Benefits of Maintenance

- Enhanced Safety: A well-maintained system reduces the risk of unexpected failures, ensuring a safer operating environment.

- Improved Performance: Regular checks can lead to smoother handling and better responsiveness.

- Cost Efficiency: Preventive care minimizes the likelihood of costly repairs down the line.

- Extended Lifespan: Proper maintenance helps preserve the integrity of components, resulting in a longer service life.

Best Practices for Upkeep

- Conduct regular inspections to identify wear and tear.

- Lubricate moving parts to ensure fluid motion.

- Replace any damaged or worn components promptly.

- Follow manufacturer guidelines for maintenance schedules.

By prioritizing this aspect of vehicle care, operators can enjoy a more reliable and efficient experience, ultimately leading to better performance in various tasks.

Common Steering Issues in LX280

Owners of this lawn care equipment often encounter various challenges related to directional control. Recognizing and addressing these problems is essential for maintaining performance and ensuring a smooth operation.

Typical Symptoms

- Difficulty in maneuvering the machine.

- Unusual noises when turning.

- Loose or unresponsive control mechanism.

- Uneven wear on tires.

Possible Causes

- Worn-out components that need replacement.

- Insufficient lubrication affecting movement.

- Misalignment of critical elements.

- Debris buildup obstructing mechanical parts.

Addressing these issues promptly can help maintain the functionality and longevity of the equipment, ensuring effective lawn maintenance.

How to Identify Steering Problems

Recognizing issues with your vehicle’s control mechanism is crucial for ensuring safe operation. There are several signs that may indicate a malfunction, and understanding these symptoms can help in diagnosing potential troubles before they escalate into serious repairs.

Common Symptoms of Control Issues

- Difficulty in turning the wheel

- Unusual noises when turning

- Vibrations felt through the control mechanism

- Uneven tire wear

- Vehicle pulling to one side

Steps to Diagnose Problems

- Inspect the control mechanism for visible damage.

- Check fluid levels if applicable, as low levels can affect performance.

- Examine tires for proper inflation and alignment.

- Test the operation by turning the vehicle and noting any resistance.

- Consult a professional if symptoms persist.

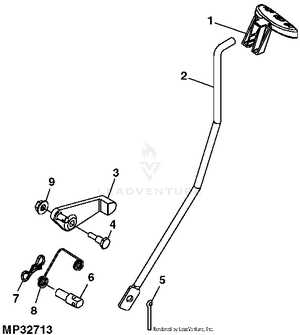

Replacing Steering Parts Effectively

Ensuring optimal maneuverability in your machine requires attention to critical components. Over time, wear and tear can lead to issues that impact performance. This section will guide you through the process of replacing these essential elements to restore functionality and improve handling.

Identifying Signs of Wear

Before initiating any replacements, it is vital to recognize the indicators that signal deterioration. Unresponsive movement, excessive play, or strange noises while navigating are common symptoms. Conducting regular checks will help you catch potential problems early, ensuring a smoother replacement process.

Steps for Effective Replacement

Once you’ve identified the need for replacement, follow these steps for a seamless experience:

- Gather Tools: Ensure you have all necessary tools at hand, including wrenches, pliers, and a repair manual.

- Safety First: Disconnect the power source to prevent any accidental operation while you work.

- Remove the Old Components: Carefully take out the worn items, paying attention to their arrangement for easier reinstallation.

- Install New Components: Follow the reverse order of removal, ensuring each piece is secured properly.

- Test Functionality: Once everything is in place, perform a thorough check to confirm everything operates smoothly.

By following these steps and addressing wear promptly, you can maintain optimal performance and extend the lifespan of your equipment.

Tools Required for Steering Repairs

When undertaking repairs related to the control mechanism of your vehicle, having the right tools is essential for a successful outcome. Proper equipment not only facilitates the process but also ensures safety and efficiency while working. Below is a comprehensive list of essential tools needed for effective maintenance and repair tasks.

Basic Hand Tools

First and foremost, a set of basic hand tools is crucial. These typically include wrenches, screwdrivers, and pliers. A socket set is also invaluable for loosening and tightening various components. Ensure that your toolkit has both standard and metric sizes to accommodate different fasteners.

Specialized Equipment

In addition to basic tools, some specialized equipment may be necessary. A torque wrench is important for applying the correct amount of force to bolts, preventing damage. Furthermore, a ball joint separator can assist in detaching components without causing harm. Always have lubricants on hand to ensure smooth operation of moving parts.

Step-by-Step Steering Assembly Guide

This section provides a detailed approach to assembling the directional control system of your machinery. By following these instructions, you can ensure that each component is correctly fitted, resulting in optimal performance and safety during operation.

Required Tools and Components

Before starting the assembly, gather all necessary tools and components. You will need a set of wrenches, screwdrivers, and possibly a torque wrench for proper fastening. Ensure that all parts are available, including the column, linkages, and fasteners, to streamline the process.

Assembly Process

Begin by positioning the main column in its designated place on the chassis. Secure it using the appropriate fasteners. Next, attach the linkages, ensuring they are aligned correctly to avoid any misalignment during use. Double-check all connections for tightness, and make adjustments as needed. Finally, test the assembly by manually rotating the control to confirm smooth movement without resistance.

By adhering to these steps, you can achieve a reliable and effective directional control system for your equipment.

Adjusting Steering for Optimal Performance

Achieving peak maneuverability in your equipment requires careful calibration of its directional control components. Fine-tuning these mechanisms not only enhances responsiveness but also extends the longevity of the machine. This section explores key methods to optimize the handling characteristics of your vehicle.

Regular Maintenance: Consistent upkeep is crucial. Check for wear and tear on critical components, ensuring everything functions smoothly. Lubrication of moving parts reduces friction and allows for effortless navigation.

Alignment Checks: Misalignment can lead to inefficient operation and uneven tire wear. Regularly assess the alignment of the control system to maintain straight tracking and stability while in motion.

Adjustable Settings: Many systems offer customizable settings. Familiarize yourself with the available adjustments to tailor the responsiveness to your specific needs, whether for tight corners or open fields.

Feedback Mechanisms: Pay attention to how the machine reacts to your inputs. Any unusual feedback may indicate the need for adjustments or repairs. Listening to the equipment can prevent larger issues down the line.

By following these guidelines, you can ensure that your vehicle operates with precision and efficiency, allowing for a smoother and more enjoyable experience in the field.

Safety Tips for Steering Maintenance

Ensuring the proper functioning of your vehicle’s directional control system is essential for safe operation. Regular upkeep not only enhances performance but also significantly reduces the risk of accidents. Following specific precautions during maintenance can prevent injuries and prolong the lifespan of your equipment.

Pre-Maintenance Checks

Before beginning any maintenance work, perform a thorough inspection to identify potential hazards. Always ensure that the equipment is turned off and secure. Utilize the following checklist:

| Checklist Item | Description |

|---|---|

| Power Source | Disconnect the battery or power source to avoid accidental activation. |

| Work Area | Clear the surrounding area of debris and obstacles for safe access. |

| Protective Gear | Wear appropriate safety equipment, including gloves and goggles. |

During Maintenance Procedures

While performing maintenance tasks, adhere to safe practices to minimize risks. Always use the right tools and follow manufacturer guidelines. Here are additional tips:

- Maintain a clean workspace to prevent slips and falls.

- Double-check connections and fittings before reassembling components.

- Engage a buddy system when handling heavy or awkward parts.

Where to Find Replacement Parts

When it comes to maintaining your equipment, sourcing high-quality components is essential for optimal performance and longevity. Whether you’re looking for specific items or general supplies, there are several avenues to explore for acquiring reliable replacements.

Authorized Dealers

One of the most reliable sources for obtaining genuine components is through authorized dealers. These retailers typically stock a comprehensive range of items that meet the original specifications of your machinery. Engaging with a dealer not only ensures quality but also provides access to expert advice and support.

Online Marketplaces

Another convenient option is to explore various online marketplaces. Websites dedicated to equipment parts often feature a wide selection, allowing you to compare prices and find exactly what you need. Look for platforms that offer customer reviews and ratings to gauge the reliability of sellers. Additionally, consider checking local classified ads or forums for community members selling their unused items.

Remember, always verify the compatibility of the components with your specific model before making a purchase to ensure a seamless installation and operation.

Cost Considerations for Steering Repairs

When addressing issues related to the guidance system of your equipment, understanding the financial implications is crucial. Repair expenses can vary widely depending on several factors, including the complexity of the malfunction and the availability of components. A thorough evaluation of these elements can help you budget effectively and make informed decisions.

Factors Affecting Repair Costs

Several elements contribute to the overall expenses associated with repairs. The type of malfunction plays a significant role; minor adjustments may be less costly than extensive replacements. Additionally, the availability of components can influence prices. Sourcing original or aftermarket items may lead to different cost outcomes. Lastly, the labor rates of the repair service you choose will impact the final bill, as more specialized technicians may charge higher fees.

Long-Term Investment vs. Short-Term Fixes

Considering whether to invest in high-quality components or opt for cheaper alternatives is essential. While initial savings may be appealing, low-cost solutions often lead to recurring issues and greater long-term expenses. Evaluating the potential lifespan and performance of each option can guide you toward a more sustainable choice, ensuring that your equipment remains reliable and efficient for years to come.