Massey Ferguson GC2300 Steering Parts Diagram Overview

In the realm of agricultural machinery, the functionality of a compact tractor’s control system plays a crucial role in enhancing operational efficiency. Familiarity with its components can lead to improved handling and performance. This section aims to provide a comprehensive overview of the essential elements involved in the maneuvering system.

Identifying the Components is key to mastering the functionality of your machine. By exploring the various sections and their interconnections, operators can gain insights into the overall mechanics that allow for smooth navigation across diverse terrains. Understanding these elements is essential for effective maintenance and troubleshooting.

Additionally, having a visual representation of these components can serve as an ultimate guide for both new and experienced users. This knowledge not only fosters confidence but also enhances the longevity and reliability of the equipment, ensuring it remains a valuable asset in your agricultural endeavors.

Massey Ferguson GC2300 Overview

This section provides a comprehensive insight into a compact utility machine known for its versatility and efficiency in various tasks. Ideal for both residential and agricultural applications, this equipment is designed to handle a range of implements and attachments.

Key Features

- Robust engine performance for reliable operation

- Compact size for easy maneuverability in tight spaces

- Compatible with multiple attachments for enhanced functionality

- Ergonomic design for operator comfort and control

Applications

- Lawn care and landscaping tasks

- Gardening and tilling

- Snow removal during winter months

- Light agricultural duties such as plowing and hauling

Importance of Steering Mechanisms

The ability to navigate efficiently is crucial in various machinery and vehicles. The systems that enable precise control not only enhance maneuverability but also ensure safety and operational effectiveness. Understanding the significance of these mechanisms can lead to better maintenance practices and improved performance.

First and foremost, the functionality of control systems directly impacts the overall driving experience. Smooth operation allows operators to execute complex maneuvers with confidence. This is particularly vital in tight spaces or challenging terrains where precision is paramount.

Furthermore, these systems contribute to the safety of both the operator and the surrounding environment. A well-maintained control mechanism reduces the risk of accidents by allowing for quick and responsive actions when necessary. In contrast, neglected systems can lead to catastrophic failures and potential hazards.

Additionally, regular assessment and understanding of these essential components can enhance the longevity of the machinery. By ensuring all elements are functioning correctly, operators can avoid costly repairs and downtime, ultimately leading to greater efficiency in operations.

In summary, the significance of control systems extends beyond mere navigation. They are integral to safety, performance, and longevity, highlighting the necessity for attention and care in their maintenance.

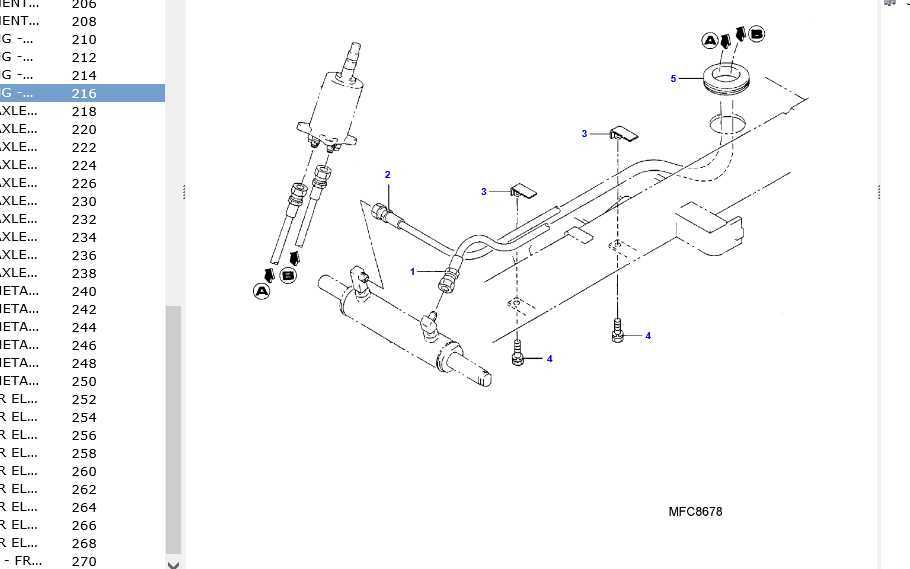

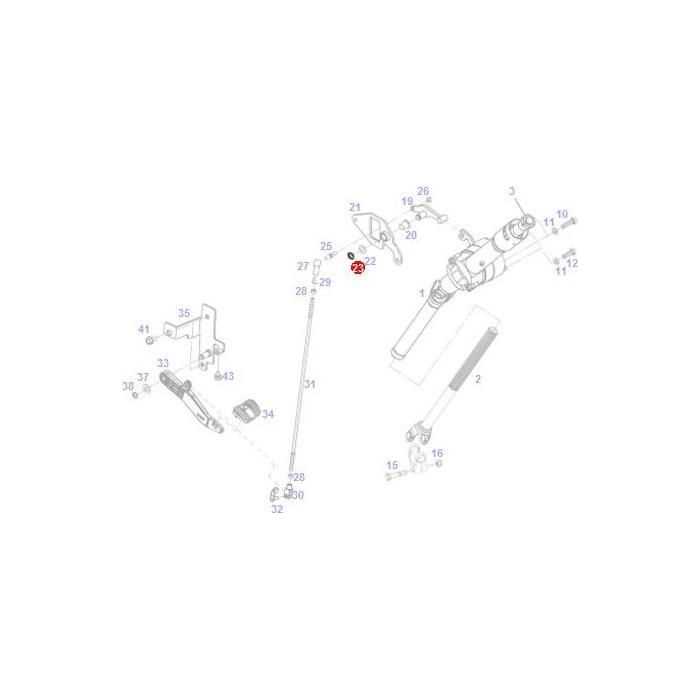

Identifying Key Steering Components

Understanding the essential elements that enable effective maneuverability is crucial for maintenance and repair. This section aims to highlight the primary components involved in the directional control system, ensuring optimal performance and longevity of the machinery.

Main Elements

Each crucial component plays a distinct role in facilitating movement and stability. Familiarizing oneself with these elements allows for more informed troubleshooting and replacement.

| Component | Function |

|---|---|

| Wheel Assembly | Transmits forces to the ground for movement. |

| Linkage | Connects the wheel to the control mechanism. |

| Control Rod | Directs the movement based on operator input. |

| Pitman Arm | Transfers motion from the control rod to the linkage. |

Conclusion

By recognizing these vital components, users can ensure the machinery operates smoothly and efficiently, leading to enhanced productivity and reduced downtime.

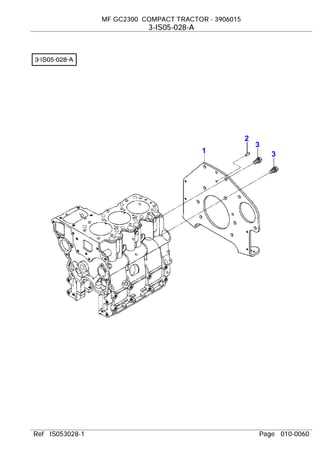

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide crucial information about the arrangement and function of various elements, enabling users to identify and procure the necessary items with ease.

Key Elements to Note

When analyzing these visuals, focus on the labels and corresponding numbers that associate parts with descriptions. This connection simplifies the identification process and ensures accurate replacements.

Tips for Efficient Reading

Start by familiarizing yourself with the overall layout before zooming in on specific sections. Use a checklist to mark identified components, enhancing your understanding as you progress.

| Component | Description |

|---|---|

| Item A | Main housing unit |

| Item B | Connector assembly |

| Item C | Adjustment lever |

Common Issues with Steering Components

Problems with maneuverability can arise from various mechanical elements involved in directional control. Understanding these issues is crucial for maintaining the efficiency and safety of your machinery.

Wear and Tear: Over time, essential components may degrade due to constant use. This can lead to diminished responsiveness and precision, making operation difficult.

Fluid Leaks: Hydraulic systems are often vulnerable to leaks, which can compromise functionality. Low fluid levels can result in poor performance, making it challenging to control direction.

Alignment Issues: Misalignment of critical components can lead to uneven wear and affect handling. Regular checks can help identify and rectify such discrepancies before they escalate.

Loose Connections: Fasteners and joints may become loose over time, causing instability. Ensuring all connections are secure is vital for reliable operation.

Corrosion: Exposure to the elements can lead to rust and corrosion, weakening components. Regular maintenance and protective measures can mitigate these risks.

Addressing these common issues promptly can enhance performance and prolong the lifespan of your machinery.

Maintenance Tips for Steering System

Ensuring the longevity and reliability of a maneuvering mechanism involves regular care and attention. Proper upkeep not only enhances performance but also prevents premature wear and potential failures. Here are essential recommendations to keep your system in optimal condition.

Regular Inspection

Conduct frequent examinations to identify any signs of wear or damage. Look for leaks, loose components, and unusual noises. Early detection can prevent more serious issues down the line.

Lubrication

Applying the correct lubricant to moving parts is crucial. Regularly grease bearings and joints to minimize friction. This practice significantly extends the lifespan of the mechanism.

Emphasize cleanliness by keeping the area free from debris. Taking these steps will ultimately enhance performance and safety.

Replacement Parts Availability

Access to high-quality components is essential for maintaining machinery efficiency. Ensuring the availability of suitable replacements enhances functionality and prolongs the lifespan of equipment. Various suppliers provide options to help owners keep their machinery in optimal condition.

Sources for Components

Several reputable suppliers offer a range of alternatives, including original and aftermarket solutions. These sources often feature online catalogs, making it easier to locate specific items quickly.

Commonly Available Items

| Component Type | Availability | Notes |

|---|---|---|

| Control Systems | Widely available | Original and aftermarket options |

| Linkages | Readily accessible | Variety of designs |

| Hydraulic Components | In stock | High compatibility |

Comparing OEM and Aftermarket Options

When it comes to selecting components for machinery, understanding the differences between original equipment manufacturer (OEM) options and aftermarket alternatives is essential. Each choice comes with its own set of advantages and potential drawbacks, influencing both performance and longevity.

- Quality Assurance: OEM parts typically undergo rigorous testing to meet specific standards, while aftermarket components can vary widely in quality.

- Cost: Aftermarket options often provide a more budget-friendly alternative, though the savings might come at the expense of durability.

- Availability: OEM parts may have limited availability, while aftermarket options are generally easier to find.

- Compatibility: OEM components are guaranteed to fit seamlessly, while aftermarket items may require modifications.

Ultimately, the decision between these two types hinges on individual needs, including budget constraints and the desired level of performance. Careful consideration can lead to optimal choices that enhance the functionality of your equipment.

Tools Needed for Repairs

When undertaking maintenance or repairs on agricultural machinery, having the right tools is essential for ensuring efficiency and effectiveness. The appropriate equipment not only simplifies the process but also minimizes the risk of damage to components. Below, we outline the primary tools that will facilitate a successful repair job.

Essential Hand Tools

Basic hand tools form the foundation of any repair toolkit. Items such as wrenches, screwdrivers, and pliers are indispensable for disassembly and reassembly tasks. Additionally, a socket set can provide the versatility needed for various fasteners, ensuring a secure fit during reinstallation.

Specialized Equipment

In some cases, specialized tools may be necessary to handle specific tasks. For example, a torque wrench is crucial for applying the correct force to fasteners, which is vital for maintaining the integrity of the machinery. Furthermore, a piston ring compressor might be required for engine-related repairs, highlighting the need for targeted tools based on the repair type.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial to prevent accidents and injuries. By following established guidelines, individuals can create a secure working environment, safeguarding themselves and their equipment.

Wear Appropriate Gear

Always use suitable protective equipment, such as gloves, goggles, and steel-toed boots. These items help mitigate risks associated with sharp objects, heavy components, and potential hazards.

Maintain a Clean Workspace

A tidy environment reduces the likelihood of accidents. Ensure that tools are organized and that spills are cleaned promptly. This practice promotes focus and efficiency while minimizing distractions.

Customer Reviews on Steering Parts

This section provides insights into user experiences and feedback regarding various components related to directional control systems. Understanding customer opinions can help potential buyers make informed decisions and identify the best options available in the market.

Quality and Performance

Many users highlight the durability and reliability of the components, noting that they perform exceptionally well under various conditions. Customers often appreciate how these elements enhance maneuverability, contributing to a smoother driving experience. Positive reviews frequently mention the longevity of the products, which reduces the frequency of replacements and repairs.

Installation and Support

Feedback on the ease of installation is generally favorable, with many users stating that the components fit seamlessly into existing systems. Additionally, customer service experiences receive commendations, as many report prompt assistance and clear guidance during the installation process. Overall, users express satisfaction with both the product quality and the support provided, making it a worthwhile investment for anyone in need of reliable directional control solutions.