Understanding Seastar Hydraulic Steering Parts Diagram

In the realm of marine navigation, the efficiency and reliability of control mechanisms are paramount. These systems play a crucial role in ensuring smooth operation and responsiveness while at sea, providing boaters with the confidence to maneuver their vessels with precision.

To grasp the intricate workings of these essential components, it is important to explore the relationships between various elements that contribute to overall functionality. A comprehensive breakdown of these mechanisms not only enhances one’s understanding but also aids in effective maintenance and troubleshooting.

By examining the structural components and their interactions, we can ultimately appreciate the engineering that underpins these sophisticated control systems. Delving into the specifics reveals the significance of each part, allowing for informed decisions when it comes to upgrades or repairs.

Understanding Seastar Hydraulic Steering Systems

This section explores the intricacies of a marine control mechanism designed to provide smooth navigation. It encompasses various components that work in tandem to ensure optimal performance and responsiveness, crucial for both recreational and commercial vessels. The focus lies in the functionality and interconnectivity of the system, highlighting how each element contributes to an efficient maneuvering experience.

Key Components and Their Functions

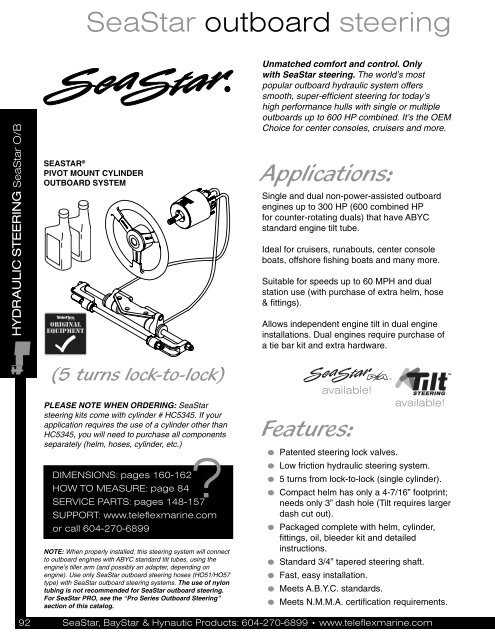

At the core of this system are several essential elements that collaborate seamlessly. The pump generates pressure, allowing for the transfer of fluid through the system. This pressurized fluid acts on a cylinder, enabling precise control of movement. Additionally, the linkages and fittings play a pivotal role in connecting various components, ensuring a reliable flow of motion and enhancing overall stability.

Benefits of an Efficient Control Mechanism

An advanced control system offers numerous advantages, including improved handling, reduced physical strain on the operator, and enhanced safety features. By allowing for effortless adjustments, it minimizes the risk of sudden maneuvers that could lead to instability. Furthermore, a well-designed setup promotes longevity and decreases maintenance requirements, ensuring a better overall experience on the water.

Components of Hydraulic Steering Mechanism

The operation of a fluid-driven directional control system relies on several essential elements that work in harmony to ensure smooth maneuverability. Understanding these components is crucial for anyone looking to maintain or enhance the functionality of their vessel’s navigation system.

Reservoir is the container that holds the fluid, providing the necessary volume for the system to function effectively. This component ensures that there is always an adequate supply to facilitate movement and control.

Pump plays a vital role in generating pressure within the system. It moves the fluid from the reservoir to the other elements, enabling the transfer of force required for directional changes.

Actuator translates the fluid pressure into mechanical motion. This element is responsible for converting the energy from the fluid into physical movement, allowing for precise adjustments and responsiveness in navigation.

Hoses and Fittings form the network that connects all components. They must be durable and resistant to wear, ensuring that the fluid can flow freely without leaks or interruptions.

Control Unit provides the interface for the operator. This element allows for the user to direct the system’s operation, facilitating easy and accurate handling of the vessel.

Each of these components plays a pivotal role in the overall efficacy of the fluid-based control mechanism, ensuring that vessels can be navigated with precision and ease.

How Hydraulic Steering Works

This section explores the mechanics behind fluid-driven navigation systems commonly utilized in marine vessels and vehicles. These systems rely on the principles of fluid dynamics to facilitate precise maneuverability, enhancing both performance and safety.

Principles of Operation

At the core of this technology is a fluid-filled mechanism that transfers force from the operator to the rudder or wheel. The key components include:

- Control Unit: Where the user initiates movement.

- Fluid Reservoir: Stores the necessary fluid to transmit force.

- Actuator: Converts the fluid pressure into physical movement.

- Connective Hoses: Transport fluid between components.

Benefits of Fluid-Based Systems

The adoption of this technology offers numerous advantages:

- Smooth Operation: Provides effortless control with minimal physical exertion.

- Precision: Allows for fine adjustments, leading to enhanced navigational accuracy.

- Durability: Designed to withstand harsh conditions, ensuring longevity and reliability.

Common Issues with Seastar Systems

When dealing with hydraulic control systems in marine applications, users may encounter a variety of challenges that can impact performance and safety. Understanding these common problems can help in troubleshooting and maintenance, ensuring smooth operation on the water.

- Fluid Leaks: One of the most frequent issues is the presence of leaks in the hydraulic lines. This can lead to a loss of pressure, resulting in impaired functionality.

- Air Trapped in the System: Air can enter the hydraulic system, causing erratic movements. Bleeding the system may be necessary to restore proper function.

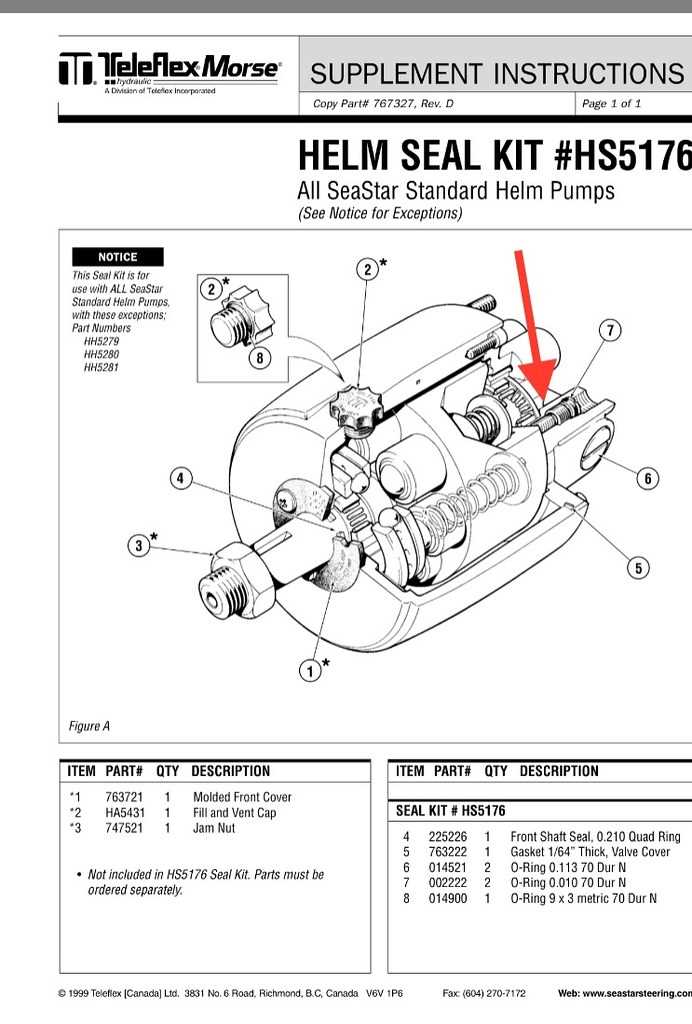

- Worn Components: Over time, seals, hoses, and other components can wear out. Regular inspection is essential to identify these issues before they lead to failure.

Being aware of these potential pitfalls can facilitate timely interventions and prolong the life of the system.

- Inconsistent Response: Users may notice that the control does not respond uniformly. This can be attributed to several factors, including the condition of the hydraulic fluid.

- Corrosion: Exposure to saltwater can cause corrosion in various components, leading to premature deterioration.

- Improper Installation: Incorrect setup during installation can result in operational difficulties. Following manufacturer guidelines is crucial.

Addressing these issues promptly can ensure optimal performance and enhance the overall experience on the water.

Maintenance Tips for Hydraulic Parts

Regular upkeep of fluid control components is essential for ensuring optimal performance and longevity. By following some straightforward guidelines, users can avoid common issues and maintain the efficiency of their systems. Proper care not only enhances functionality but also contributes to safety during operation.

1. Routine Inspection: Conduct frequent examinations to identify wear or damage. Look for leaks, corrosion, and loose connections. Early detection can prevent more significant problems down the line.

2. Cleanliness is Key: Keep all components free from dirt and debris. Contaminants can cause blockages and reduce efficiency. Use appropriate cleaning agents and tools designed for sensitive systems.

3. Fluid Quality: Monitor and replace the operating fluid regularly. Ensure that it meets manufacturer specifications and is free from contaminants. Degraded fluid can compromise performance and lead to component failure.

4. Proper Storage: When not in use, store equipment in a dry and sheltered environment. Protect components from extreme temperatures and humidity, which can lead to premature aging and deterioration.

5. Follow Manufacturer Guidelines: Always adhere to the recommended maintenance schedule and procedures outlined in the user manual. This ensures that all actions taken are in line with the design specifications and safety requirements.

6. Seek Professional Help: If any issues arise that cannot be easily addressed, consult a qualified technician. Professional assessment can save time and prevent further damage.

By implementing these maintenance tips, users can significantly extend the lifespan and reliability of their fluid control systems, ensuring safe and efficient operation over time.

Benefits of Using Hydraulic Steering

Utilizing fluid-based systems for maneuvering offers numerous advantages that enhance both performance and user experience. These mechanisms provide smoother handling, improved control, and reduced physical effort, making navigation easier for operators of various vessels.

| Advantage | Description |

|---|---|

| Smooth Operation | Fluid systems allow for seamless adjustments, minimizing abrupt movements. |

| Enhanced Control | Operators experience increased precision, leading to better handling in diverse conditions. |

| Reduced Fatigue | Less physical exertion is required, making long durations of use more comfortable. |

| Durability | These systems often feature robust designs that withstand harsh environments. |

| Adaptability | They can be tailored to fit a variety of vessels, catering to specific needs. |

Seastar Steering Parts Overview

This section provides an essential understanding of the components involved in the control system for marine vessels. Each element plays a crucial role in ensuring smooth and precise navigation, enhancing both safety and performance on the water. A thorough grasp of these elements is vital for maintenance and troubleshooting.

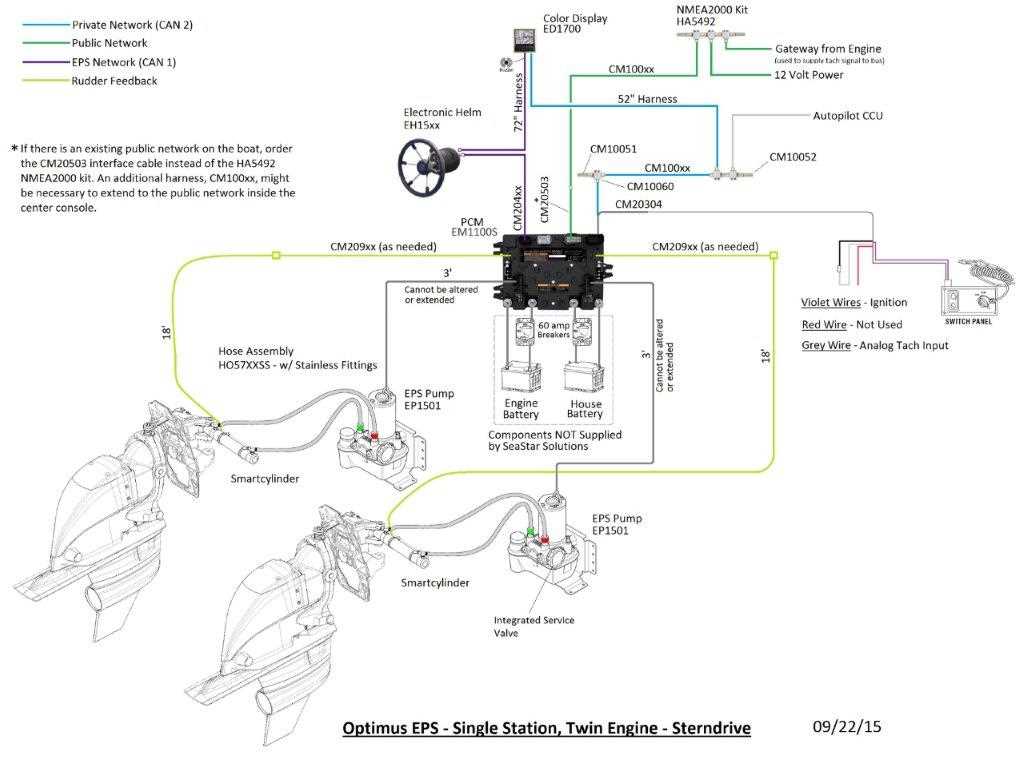

The key components include the actuator, which facilitates movement, and the pump, responsible for generating pressure. Additionally, hoses and fittings serve as the conduits for fluid transfer, while various control mechanisms allow for user input and adjustment. Understanding the function and interconnection of these components is fundamental for optimal functionality.

Regular inspection and replacement of worn or damaged components are necessary to maintain system integrity. Knowledge of each element’s role aids in effective repairs and upgrades, ultimately contributing to a more reliable and enjoyable boating experience.

Identifying Diagram Symbols Explained

Understanding the symbols used in technical illustrations is crucial for effectively interpreting complex systems. Each icon conveys specific information, allowing users to grasp the functionality and relationships of various components within the setup.

Common Symbols often represent fundamental elements such as pumps, valves, and connectors. Recognizing these can streamline troubleshooting and maintenance tasks, enhancing overall efficiency.

Functional Variations may arise depending on the application. For instance, similar shapes might indicate different operations based on their context within the schematic. Familiarity with these distinctions is key to accurate analysis.

Additionally, color coding can play a significant role in understanding. Different hues may signify operational status, pressure levels, or fluid types, guiding users in making informed decisions.

Ultimately, mastering these symbols enables a deeper engagement with the system, paving the way for effective implementation and problem-solving.

Installation Guide for Hydraulic Steering

This section provides essential instructions for the installation of a fluid-based directional control system. Proper setup is crucial for ensuring optimal performance and safety during operation. Following these guidelines will help achieve a reliable and efficient configuration.

1. Preparation: Before beginning, gather all necessary tools and components. Ensure you have a clean workspace and review the manufacturer’s specifications for compatibility with your vessel.

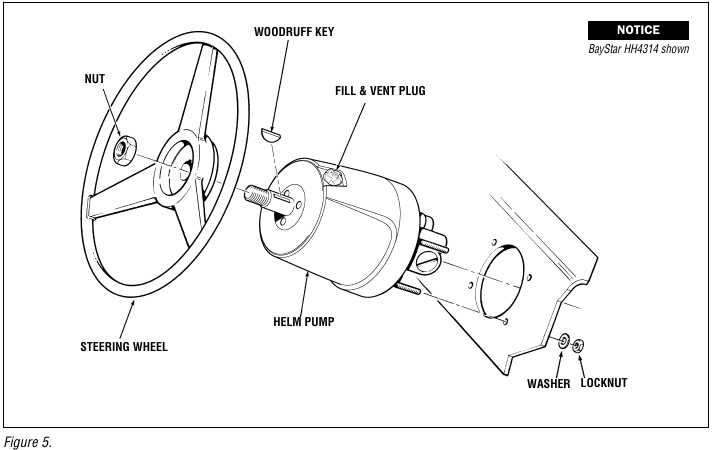

2. Mounting the System: Locate an appropriate area for the assembly. Securely attach the main unit, ensuring it is level and adequately supported. This stability is vital for smooth functionality.

3. Connecting Hoses: Carefully connect the fluid conduits as per the layout instructions. Ensure all connections are tight to prevent leaks. Utilize the recommended fittings to maintain system integrity.

4. Filling with Fluid: Introduce the designated fluid into the reservoir. Follow the filling procedure to avoid introducing air into the system, which can lead to performance issues.

5. Testing: After installation, conduct a thorough test. Check for any leaks and verify that the system responds correctly. Adjust any settings as necessary to achieve the desired responsiveness.

6. Final Checks: Once satisfied with the test results, perform a final inspection of all connections and components. Ensure everything is secure and functioning as intended before regular use.

By adhering to these steps, you will enhance the reliability and efficiency of the directional control system, contributing to a safer and more enjoyable experience on the water.

Safety Precautions When Handling Steering Parts

Ensuring safety while managing various components is crucial to prevent accidents and injuries. Understanding potential hazards and taking appropriate measures can significantly mitigate risks associated with equipment handling.

Proper Personal Protective Equipment

Always wear protective gear, such as gloves, goggles, and steel-toed boots, to shield yourself from sharp edges and heavy objects. This gear is essential for minimizing exposure to potential hazards during maintenance or installation.

Work Environment Considerations

Maintain a clean and organized workspace. Clear away any debris or obstacles that may cause slips or falls. Additionally, ensure proper lighting and ventilation to facilitate a safe handling process. Regularly inspect tools and equipment to confirm they are in good condition.

Upgrading Your Seastar Steering System

Enhancing your vessel’s control mechanism can significantly improve your overall navigation experience. By modernizing components and optimizing their functionality, you not only boost performance but also enhance safety and comfort on the water. This section explores effective strategies for revitalizing your current system.

Choosing the Right Components

When considering upgrades, selecting high-quality components is essential. Focus on materials that offer durability and resilience against harsh marine conditions. Research various options to find the best fit for your needs, ensuring compatibility with existing setups.

Installation and Maintenance Tips

Proper installation is crucial for optimal functionality. If you’re not experienced, consult a professional to guarantee accuracy. Additionally, regular maintenance can extend the lifespan of your upgraded system. Inspect components periodically and replace any worn-out parts to maintain peak performance.