Understanding the 028 Stihl Chainsaw Parts Diagram

In the world of outdoor equipment, certain machines stand out for their reliability and efficiency. These tools are essential for tasks ranging from landscaping to heavy-duty forestry work. A thorough understanding of their internal mechanisms is crucial for optimal performance and maintenance.

Every intricate tool consists of various elements that work in harmony to ensure smooth operation. Familiarizing oneself with these components can greatly enhance the user experience, whether for personal projects or professional use. Each piece plays a vital role in the overall functionality and longevity of the equipment.

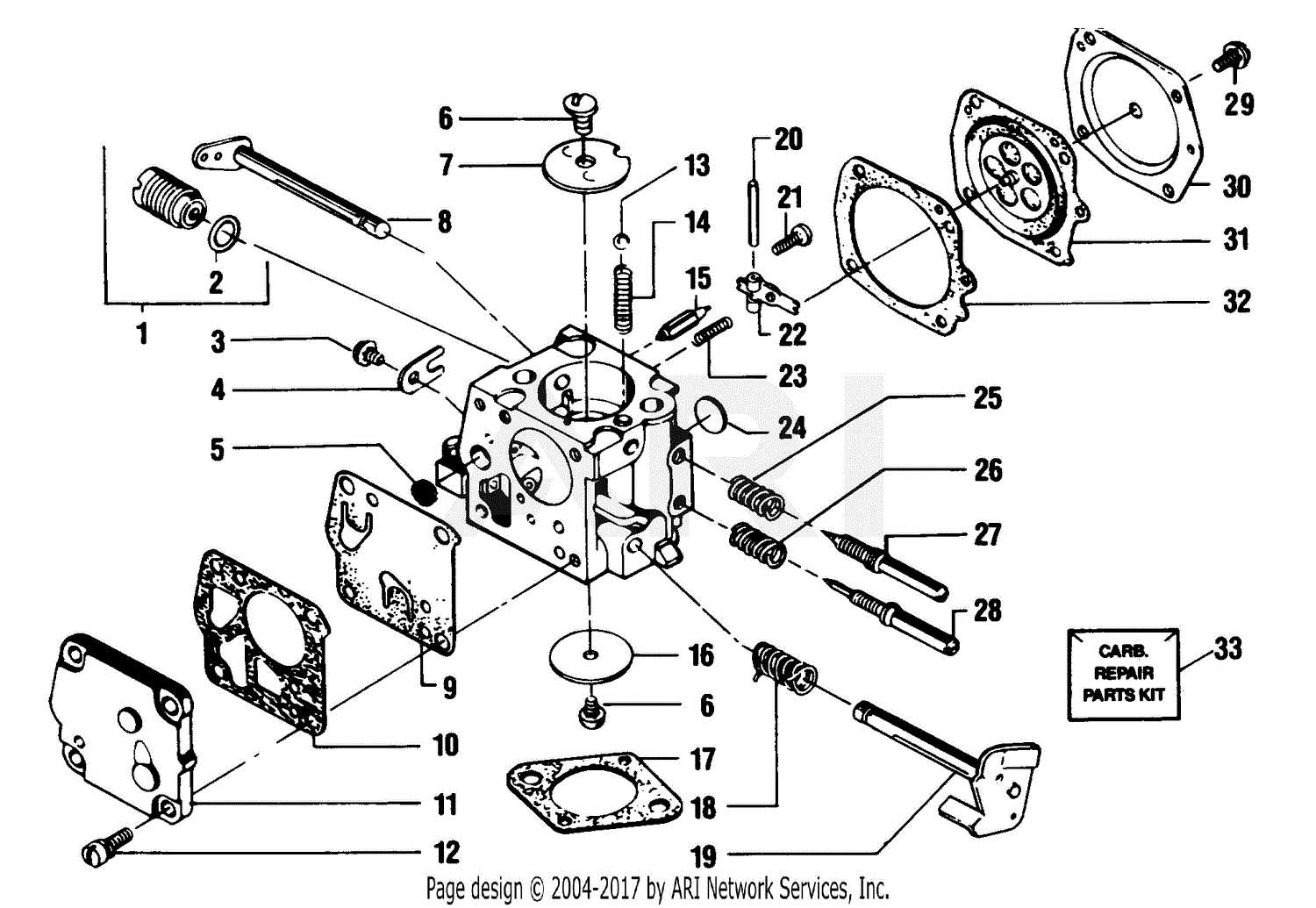

Visual aids can significantly simplify the learning process, providing clarity on how different parts interact. By analyzing detailed representations, users can easily identify, troubleshoot, and replace necessary components. This knowledge empowers owners to maintain their machines effectively, leading to better results in their endeavors.

Understanding the 028 Stihl Chainsaw

This section explores a specific model of a popular cutting tool, focusing on its components and functionality. By examining the intricate design, users can enhance their knowledge and optimize performance.

- History: Developed to meet the needs of professionals and enthusiasts.

- Design Features: Combines durability with ergonomic handling.

- Applications: Ideal for various tasks, from logging to landscaping.

To maximize efficiency, familiarity with the main elements is crucial. Understanding how each component interacts can lead to better maintenance and operational longevity.

- Engine: The heart of the tool, providing power.

- Guide Bar: Essential for directing the cutting action.

- Chain: The element that performs the cutting, requiring regular inspection.

Ultimately, a deeper comprehension of this equipment can lead to improved safety and effectiveness during use.

Key Features of the 028 Model

This model stands out due to its exceptional performance and robust design, making it a favorite among outdoor enthusiasts and professionals alike. The combination of power and efficiency ensures that it can tackle various tasks with ease, whether for cutting firewood or maintaining landscapes.

| Feature | Description |

|---|---|

| Engine Power | Equipped with a high-performance engine that delivers impressive cutting speed. |

| Weight | Lightweight construction for enhanced maneuverability during operation. |

| Durability | Designed with high-quality materials for longevity and resistance to wear. |

| Vibration Control | Features advanced technology to minimize vibrations, improving user comfort. |

| Maintenance | Simple access to key components for hassle-free maintenance and servicing. |

Common Issues with Stihl Chainsaws

When working with power cutting tools, users often encounter various challenges that can affect performance and reliability. Understanding these common complications is essential for effective maintenance and troubleshooting. Recognizing the signs of potential problems can help in prolonging the lifespan of the equipment.

Fuel Problems: One frequent issue arises from the fuel system. Contaminated or stale fuel can lead to starting difficulties or poor engine performance. Regularly replacing the fuel and using fresh mixtures is crucial for optimal function.

Air Filter Blockage: An obstructed air filter can hinder airflow, causing the engine to run inefficiently. It’s important to clean or replace the filter periodically to maintain proper air circulation and enhance performance.

Chain Tension: Improper chain tension can lead to excessive wear and tear or even safety hazards during operation. Ensuring the chain is adequately tightened is vital for effective cutting and user safety.

Spark Plug Issues: A faulty spark plug can prevent ignition or lead to misfiring. Regular inspections and timely replacements can resolve starting issues and improve overall efficiency.

Bar and Chain Wear: Over time, the cutting bar and chain can wear down, affecting cutting performance. Routine checks and replacements will ensure the tool remains effective and safe to use.

By being aware of these common problems and addressing them promptly, users can ensure their equipment operates smoothly and efficiently, reducing downtime and enhancing productivity.

How to Maintain Your Chainsaw

Proper upkeep of your cutting tool is essential for its performance and longevity. Regular maintenance ensures efficiency, safety, and reduces the likelihood of breakdowns, ultimately enhancing your experience during use.

Routine Cleaning

Keeping your equipment clean is vital. After each use, remove any debris and residue from the exterior and air filter. A clean tool not only functions better but also prevents the buildup of harmful substances.

Sharpening the Blade

Regularly check and sharpen the blade to ensure smooth operation. A sharp edge improves cutting performance and minimizes strain on the motor. Use the appropriate sharpening tools to maintain the correct angle for optimal results.

Identifying Replacement Parts Easily

Understanding how to locate and identify components for your outdoor power equipment can significantly enhance its maintenance and longevity. A systematic approach allows users to quickly find the exact items they need, ensuring optimal performance and reducing downtime.

Utilizing Visual References

Visual guides can be invaluable in pinpointing the necessary components. Diagrams and images provide clarity, allowing you to compare and contrast with your existing equipment. This method streamlines the identification process, making it easier to ensure compatibility.

Consulting Reliable Sources

Engaging with trusted online platforms or local retailers can facilitate the search for specific components. Experienced professionals can offer insights, enhancing your understanding of the required items and their functions. This collaboration can lead to more informed purchasing decisions.

Importance of Using Genuine Parts

Utilizing authentic components is crucial for maintaining the performance and longevity of your equipment. Genuine items are specifically designed to fit seamlessly, ensuring optimal functionality and safety. Unlike aftermarket alternatives, which may compromise quality, original pieces provide reliability and peace of mind.

Moreover, employing authentic replacements often preserves the warranty, protecting your investment in the long run. These components undergo rigorous testing, guaranteeing they meet high standards of durability and efficiency. By choosing genuine options, you ultimately enhance the performance and lifespan of your machinery.

Overview of the Parts Diagram

The visual representation of components serves as a crucial resource for understanding the assembly and functionality of mechanical devices. By analyzing this illustrative guide, users can identify individual elements, their placements, and how they interact within the system. This knowledge is essential for maintenance, repairs, and enhancements, ensuring optimal performance and longevity of the equipment.

Key Components

Each element depicted in the illustration plays a vital role in the overall operation. Familiarity with these components not only aids in troubleshooting but also empowers users to make informed decisions during repairs or replacements.

| Component | Description |

|---|---|

| Engine | The core unit that powers the machine. |

| Guide Bar | The elongated piece that supports the cutting tool. |

| Chain | The looped component that performs the cutting action. |

| Handle | The grip used for maneuvering the tool safely. |

| Fuel Tank | Reservoir for the power source needed for operation. |

Importance of Understanding the Diagram

Grasping the layout and function of each part enhances the user’s capability to maintain and optimize performance. It encourages proactive care, leading to improved efficiency and reduced downtime, ultimately prolonging the lifespan of the equipment.

Step-by-Step Repair Process

Repairing outdoor power equipment can seem daunting, but breaking it down into manageable steps simplifies the task. This guide will walk you through the essential phases of restoring functionality, ensuring that each component is addressed systematically. By following these steps, you can effectively troubleshoot and repair your machinery, extending its life and improving performance.

Preparation and Assessment

Begin by gathering the necessary tools and materials for the repair. Carefully inspect the equipment to identify the specific issues affecting its operation. Document any visible damage or wear, and refer to relevant manuals to familiarize yourself with the internal mechanisms. This initial assessment will provide a clear roadmap for the repair process.

Disassembly and Inspection

Once you have assessed the condition, proceed with disassembling the unit. Follow the sequence outlined in the manual to avoid damaging any parts. As you remove each component, inspect them for signs of wear or malfunction. Take notes and photographs to keep track of the assembly process, ensuring a smooth reassembly once repairs are completed.

Tools Needed for Repairs

Effective maintenance and repair of outdoor equipment require specific instruments to ensure optimal performance and safety. Having the right tools on hand can significantly simplify the repair process, making it quicker and more efficient.

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening bolts and nuts. |

| Screwdriver Set | Essential for removing and securing screws. |

| Wrench | Used for gripping and turning fasteners. |

| Pliers | Helpful for holding objects and bending materials. |

| Cleaning Brush | For maintaining cleanliness and preventing debris buildup. |

| Lubricant | Ensures smooth operation and reduces friction. |

Tips for Troubleshooting Problems

Identifying issues in mechanical devices can often be a straightforward process if approached methodically. Understanding the common symptoms and knowing where to look can save time and effort in restoring functionality.

Common Issues to Consider

- Engine won’t start

- Inconsistent power output

- Excessive vibration

- Fuel leakage

Steps for Effective Diagnosis

- Check fuel levels and quality.

- Inspect air filters for clogs.

- Examine spark plugs for wear.

- Look for loose or damaged components.

Best Practices for Chainsaw Storage

Properly storing your cutting tool ensures its longevity and efficiency. Following best practices can prevent damage and maintain optimal performance for future use.

- Clean the tool thoroughly after each use to remove debris and sap.

- Store in a cool, dry place to avoid rust and deterioration.

- Ensure the blade is properly covered or sheathed to prevent accidents and damage.

- Keep it out of reach of children and pets to ensure safety.

Additionally, consider maintaining the fuel in a separate container if your tool uses it, as this can enhance storage safety and efficiency.

Safety Precautions When Operating

When using powerful cutting tools, ensuring personal safety and the well-being of those nearby is paramount. Adopting proper safety measures not only minimizes risks but also enhances the overall effectiveness of the task at hand.

First and foremost, always wear appropriate protective gear. This includes gloves, goggles, and sturdy footwear to shield against potential hazards. Hearing protection is also advisable, as these tools can produce loud noises that may damage your hearing over time.

Additionally, familiarize yourself with the equipment’s operation and maintenance before use. Understanding the various functions can help prevent accidents. Always inspect the tool for any signs of wear or damage before starting.

Moreover, maintain a clear work area. Ensure there are no obstructions that could impede your movement or distract you. It’s crucial to keep bystanders at a safe distance during operation to avoid injuries.

Lastly, never operate the tool while fatigued or under the influence of substances. Staying alert and focused is essential for safe and efficient usage.

Upgrading Components for Better Performance

Enhancing the functionality of your equipment can lead to significant improvements in efficiency and overall performance. By focusing on specific elements that contribute to the machine’s operation, users can achieve more power, better fuel efficiency, and increased longevity. This approach not only optimizes performance but also elevates the user experience, making tasks easier and more enjoyable.

Key Components to Consider

Several critical elements can be upgraded to enhance performance. The air intake system, for example, plays a vital role in ensuring optimal combustion. By replacing standard filters with high-performance options, users can improve airflow, resulting in better power output. Similarly, examining the cutting mechanism can reveal opportunities for enhancements. Upgrading to sharper, more durable blades can increase cutting speed and efficiency.

Benefits of Upgrading

Investing in improved components not only boosts productivity but can also lead to cost savings in the long run. Enhanced fuel efficiency means fewer trips to refuel, while superior materials can reduce the frequency of replacements. Furthermore, users often find that upgraded equipment delivers a more satisfying and effective experience, making challenging tasks feel effortless. Ultimately, thoughtful enhancements can transform standard equipment into high-performance machines that meet and exceed user expectations.