Comprehensive FS45 Stihl Parts Diagram Guide

When it comes to maintaining your outdoor power equipment, having a clear visual representation of its various elements can significantly enhance your repair and service experience. Knowing each component’s role is crucial for effective troubleshooting and ensuring optimal performance.

In this section, we will explore the intricate layout of a popular model, breaking down its essential features. By examining the arrangement and function of each piece, you can easily identify any areas that may require attention or replacement.

Whether you are a seasoned technician or a novice user, understanding the intricate workings of your tool will empower you to keep it running smoothly. Delve into the specifics and discover how each part contributes to the ultimate functionality of your equipment.

Understanding FS45 Stihl Overview

This section provides a comprehensive look into a popular model of outdoor power equipment, focusing on its design, functionality, and key components. Whether for professional landscaping or personal gardening, this tool is designed to meet diverse needs with efficiency and ease of use.

Key Features

- Lightweight construction for easy maneuverability

- Powerful engine for effective trimming and cutting

- User-friendly controls for enhanced handling

- Durable materials ensuring longevity

Applications

- Maintaining residential gardens

- Commercial landscaping services

- Clearing overgrown areas

- Precision edging for a polished look

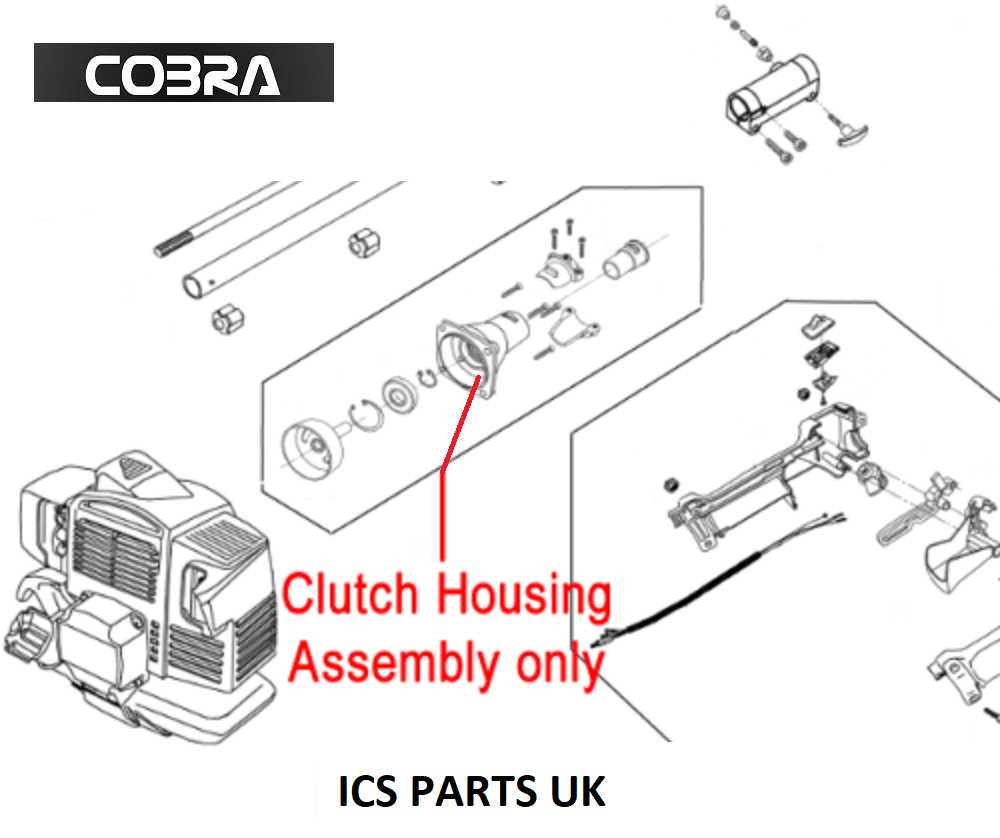

Key Components of FS45 Equipment

Understanding the essential elements of this cutting tool is crucial for effective maintenance and optimal performance. Each component plays a significant role in the overall functionality, ensuring smooth operation and longevity of the equipment.

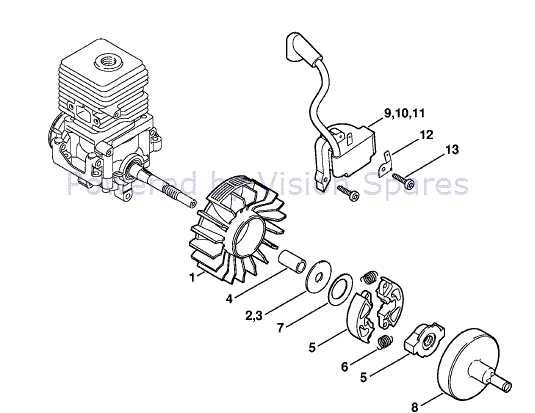

Power Unit

The heart of the machinery, the power unit, provides the necessary energy to drive the cutting mechanisms. Its efficiency directly impacts the tool’s performance, making regular checks essential for reliability.

Cutting Head

The cutting head is responsible for executing the primary task of trimming and clearing. Equipped with various attachments, it allows for versatility in tackling different landscaping jobs. Proper handling and maintenance of this part are vital for achieving the ultimate results.

Benefits of Using Genuine Parts

Opting for authentic components offers numerous advantages that enhance both performance and longevity of equipment. Utilizing original elements ensures compatibility and reliability, minimizing the risk of malfunction and maximizing efficiency.

Quality Assurance

One of the primary benefits of choosing genuine components is the assurance of quality. These products undergo rigorous testing and adhere to strict manufacturing standards, which often surpass those of aftermarket alternatives. This guarantees that each piece is designed to fit perfectly and function optimally within the machinery.

Long-Term Savings

While the initial investment in authentic components may be higher, they often lead to cost savings in the long run. Genuine parts typically have a longer lifespan and reduce the frequency of repairs, which can mitigate the need for replacements and maintenance costs.

| Feature | Genuine Components | Aftermarket Alternatives |

|---|---|---|

| Quality | High | Variable |

| Compatibility | Perfect Fit | Potential Issues |

| Lifespan | Longer | Shorter |

| Warranty | Often Included | Limited |

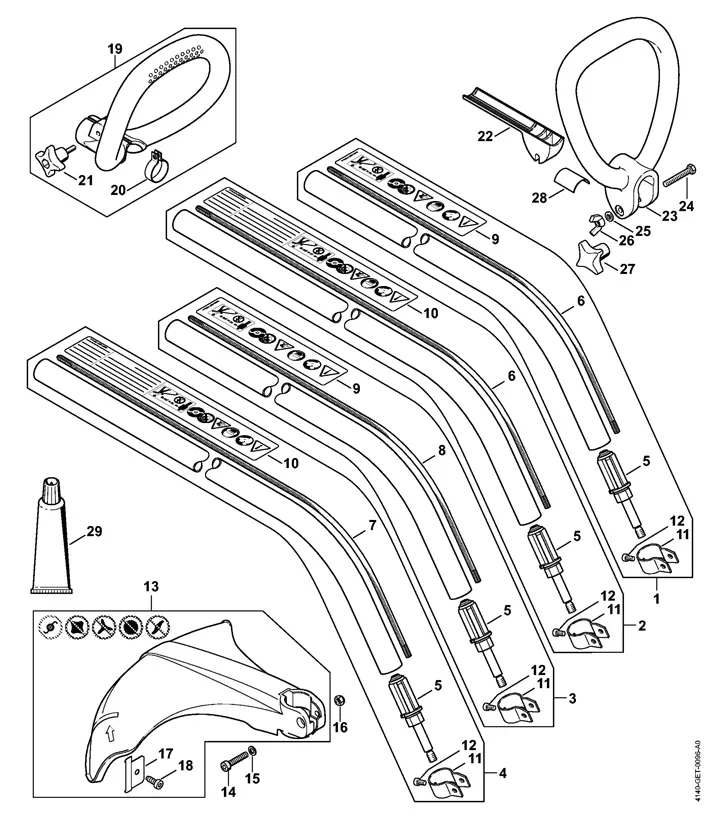

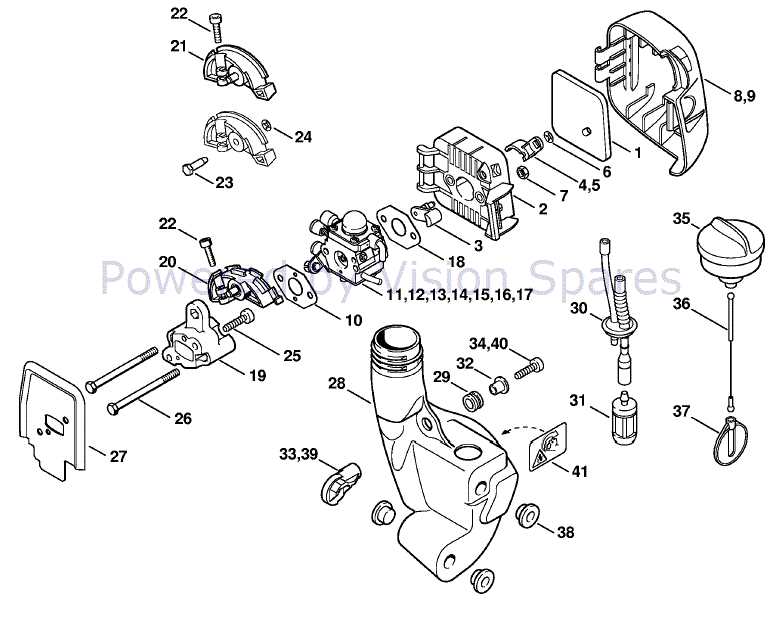

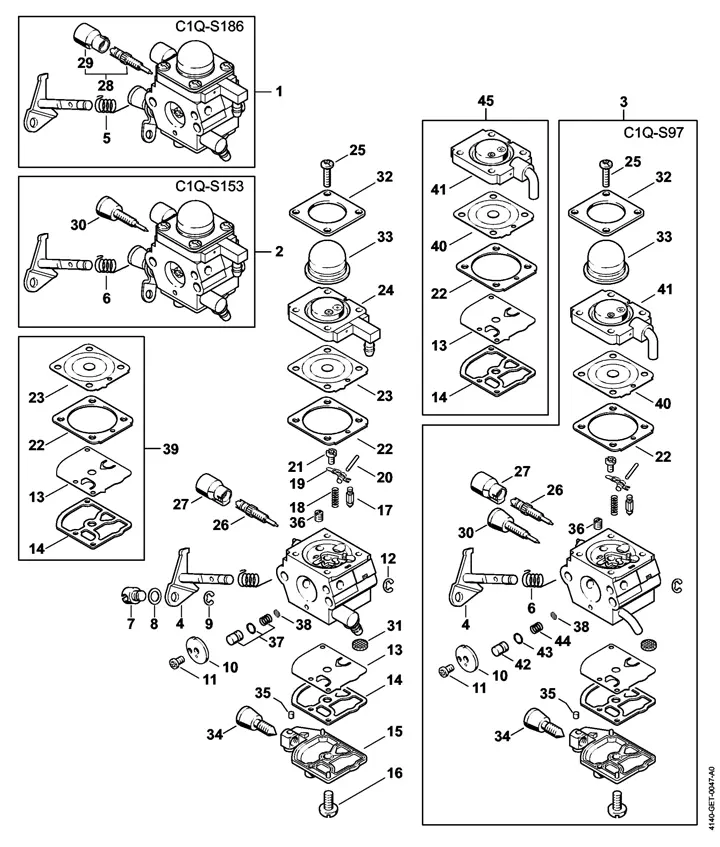

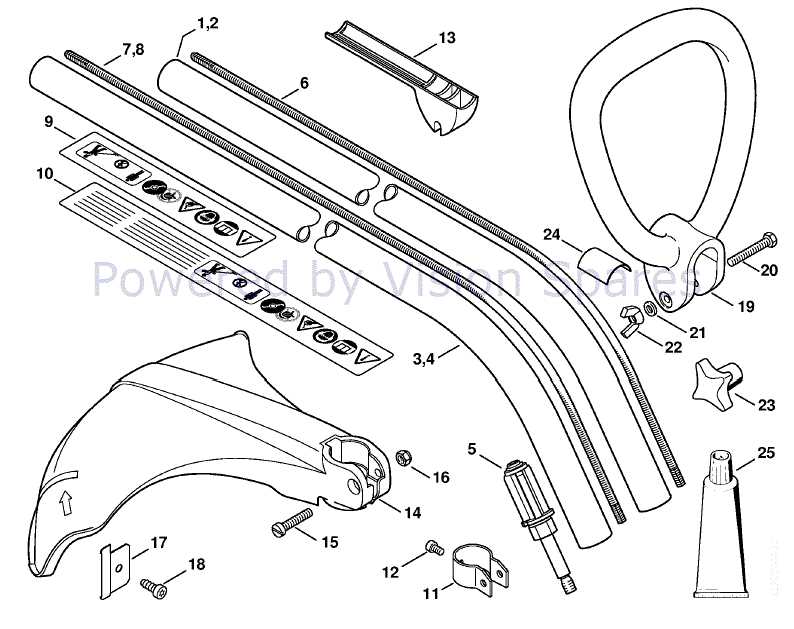

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide a detailed view of various elements, allowing users to identify, locate, and understand each part’s role within a system.

To begin, familiarize yourself with the overall layout of the illustration. Typically, these visuals are organized logically, often following the assembly sequence or functional grouping. This organization helps in grasping how different pieces interact with one another.

Next, pay attention to labels and numbers. Each element is usually accompanied by a unique identifier, which correlates to a list or key. This reference is crucial for finding the exact components you need for replacement or repair.

Additionally, observe the symbols and notations. Different shapes or lines can indicate specific characteristics, such as connections or movement. Understanding these symbols will enhance your ability to interpret the illustration accurately.

Finally, practice makes perfect. The more you engage with these visual guides, the more intuitive reading them will become. Whether you’re troubleshooting or simply exploring, developing this skill is invaluable for anyone working with mechanical systems.

Common Issues with FS45 Models

Understanding frequent challenges encountered with this model can significantly enhance user experience and equipment longevity. Awareness of these issues allows for proactive maintenance and timely repairs.

Common Problems

- Starting difficulties

- Engine stalling

- Overheating

- Inefficient fuel consumption

Potential Causes

- Poor fuel quality

- Clogged air filters

- Defective spark plugs

- Worn-out components

Addressing these issues promptly can lead to improved performance and extend the life of the equipment.

Maintenance Tips for FS45 Users

Proper upkeep of your gardening tool is essential for ensuring optimal performance and longevity. Regular maintenance not only enhances efficiency but also minimizes the risk of unexpected breakdowns. Here are some practical tips to help you keep your equipment in top shape.

1. Regular Cleaning: After each use, it’s important to clean your device thoroughly. Remove debris, dirt, and grass clippings from the exterior and ensure the air filters are free of obstructions. This helps prevent overheating and maintains airflow.

2. Check the Cutting Head: Inspect the cutting head frequently for wear and tear. Replace dull or damaged blades promptly to ensure effective cutting and prevent strain on the motor.

3. Fuel Maintenance: Use fresh, high-quality fuel to avoid engine issues. If your machine will not be used for an extended period, consider using a fuel stabilizer to prevent degradation.

4. Inspect Cables and Connections: Periodically check all cables and connections for signs of wear. Tighten loose screws and replace any damaged parts to avoid operational failures.

5. Follow Manufacturer Guidelines: Always refer to the user manual for specific maintenance recommendations and intervals. Adhering to these guidelines can help you avoid common pitfalls and ensure a long service life for your tool.

By incorporating these maintenance practices, you can enhance the reliability and efficiency of your gardening equipment, making your outdoor tasks more enjoyable and less stressful.

Replacement Parts: When to Buy

Maintaining equipment in optimal condition often requires acquiring new components. Knowing when to invest in these essential items can significantly enhance performance and longevity. Regular inspections play a vital role in identifying wear and tear, which can prevent minor issues from escalating into major problems.

Signs of wear are crucial indicators that it may be time to purchase new items. Look for unusual noises, reduced efficiency, or visible damage. Ignoring these signals can lead to costly repairs down the line.

Additionally, consider the age of your machinery. Older models may need replacements more frequently due to the natural degradation of materials. Investing in quality components can ensure your equipment operates at its best for years to come.

Where to Find FS45 Diagrams

Finding detailed visual guides for your equipment can greatly enhance your understanding and maintenance capabilities. Various resources are available to help you access these essential illustrations, ensuring you can keep your machinery in optimal condition.

Online Resources

- Manufacturer’s Website: Start by checking the official site for comprehensive guides and manuals.

- Forums and Community Groups: Engage with enthusiasts who often share diagrams and troubleshooting tips.

- YouTube: Look for tutorial videos that may include visual aids and breakdowns of components.

Local Options

- Dealerships: Visit authorized dealers who can provide printed manuals and diagrams.

- Repair Shops: Inquire at local repair shops, as they often have resources available for customers.

Assembly Instructions for FS45 Parts

This section provides detailed guidance on how to properly assemble components for efficient operation. Following these instructions will ensure optimal performance and longevity of the equipment.

Required Tools

- Screwdriver

- Wrench

- Pliers

- Torque wrench

Assembly Steps

- Begin by gathering all necessary components.

- Carefully align each part as per the assembly layout.

- Secure the components using the screws provided.

- Ensure all fasteners are tightened to the recommended torque.

- Perform a final inspection to confirm that everything is properly assembled.

Essential Tools for Repairing FS45

Having the right equipment is crucial when it comes to maintaining and fixing your outdoor power tools. Proper tools not only make the process smoother but also ensure that repairs are done effectively and safely. Below is a list of essential instruments and supplies that can help you tackle common issues with your device.

Basic Hand Tools

- Screwdrivers: Both flathead and Phillips types are necessary for loosening and tightening screws.

- Wrenches: A set of adjustable wrenches or specific socket wrenches will help you manage bolts and nuts.

- Pliers: Needle-nose and regular pliers are useful for gripping, twisting, and cutting wires.

- Hex Keys: Often required for securing various components.

Maintenance Supplies

- Lubricants: Essential for reducing friction and wear on moving parts.

- Cleaning Agents: Effective for removing debris and buildup that can affect performance.

- Replacement Filters: Keep the engine running smoothly by replacing air and fuel filters as needed.

- Safety Gear: Always use gloves and goggles to protect yourself during repairs.

Safety Precautions While Operating

Ensuring safety during operation is essential to prevent accidents and injuries. Proper awareness and adherence to guidelines can significantly reduce risks associated with equipment use. This section outlines important measures to consider before and during operation.

Pre-Operation Safety Checks

- Inspect the equipment for any signs of damage or wear.

- Ensure all safety guards and shields are in place.

- Check that all controls function properly.

- Verify that fuel and oil levels are adequate and appropriate.

Personal Protective Equipment

- Wear appropriate eye protection to shield against debris.

- Use hearing protection to guard against noise exposure.

- Don sturdy footwear to protect your feet from falling objects.

- Utilize gloves designed for grip and protection while handling materials.

Following these precautions will help create a safer working environment and promote efficient operation.

Frequently Asked Questions on FS45

This section addresses common inquiries related to a specific type of outdoor power equipment, offering clarity on its functionality, maintenance, and components.

- What is the purpose of this equipment?

This tool is designed for trimming grass and small shrubs, making yard maintenance efficient.

- How often should I perform maintenance?

Regular maintenance should be conducted every 20-25 hours of use, or as recommended by the manufacturer.

- What types of fuel should I use?

It is advisable to use a mixture of gasoline and oil specifically formulated for two-stroke engines.

- Where can I find replacement components?

Replacement parts can typically be sourced from authorized dealers, online retailers, or local hardware stores.

- How do I troubleshoot starting issues?

- Check the fuel mixture.

- Inspect the spark plug for wear.

- Ensure the air filter is clean.