Magnum Stihl BR 800 Parts Overview

Understanding the intricate details of various mechanisms is crucial for maintaining outdoor devices in peak condition. A thorough comprehension of the internal structures allows users to identify how each element contributes to the overall functionality. Such insights ensure smooth operations and extend the life span of the equipment.

Exploring the internal setup of these machines provides valuable information for both novice and seasoned users. It helps in recognizing how to address wear and tear, and ensures that every piece functions optimally. By grasping the layout, one can more easily conduct routine maintenance and address potential issues before they escalate.

For those who rely on these devices for outdoor tasks, knowing the configuration of essential components can significantly impact performance and efficiency. A clear

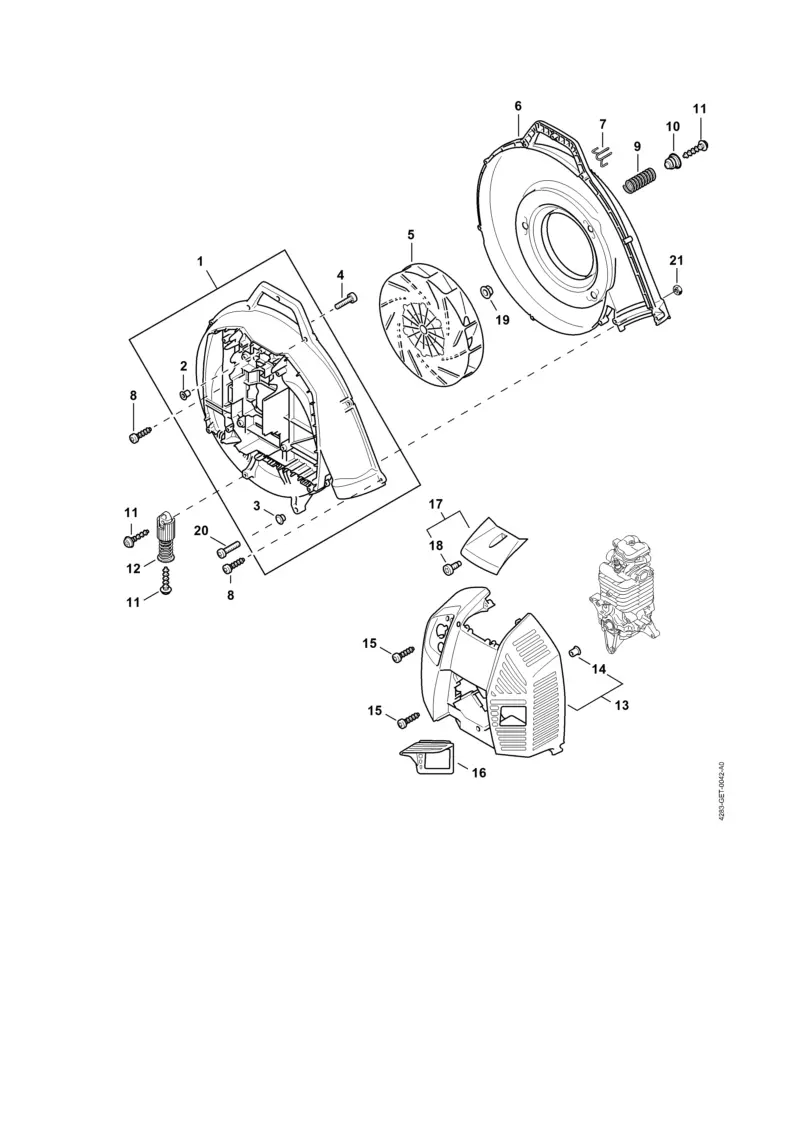

Magnum Stihl BR 800 Parts Diagram

The visual representation of components for this high-powered blower provides a clear understanding of how each element is interconnected. It serves as a guide, offering insight into the structure and function of the various elements. This helps users identify and comprehend the role of each part, ensuring smoother operation and easier maintenance.

Understanding Key Elements

Each component plays a crucial role in the overall efficiency and functionality of the equipment. By analyzing the arrangement of these parts, users can better appreciate the purpose of each element, whether it’s related to airflow management, power distribution, or structural support.

Practical Insights for Maintenance

Having a clear

Main Components Overview

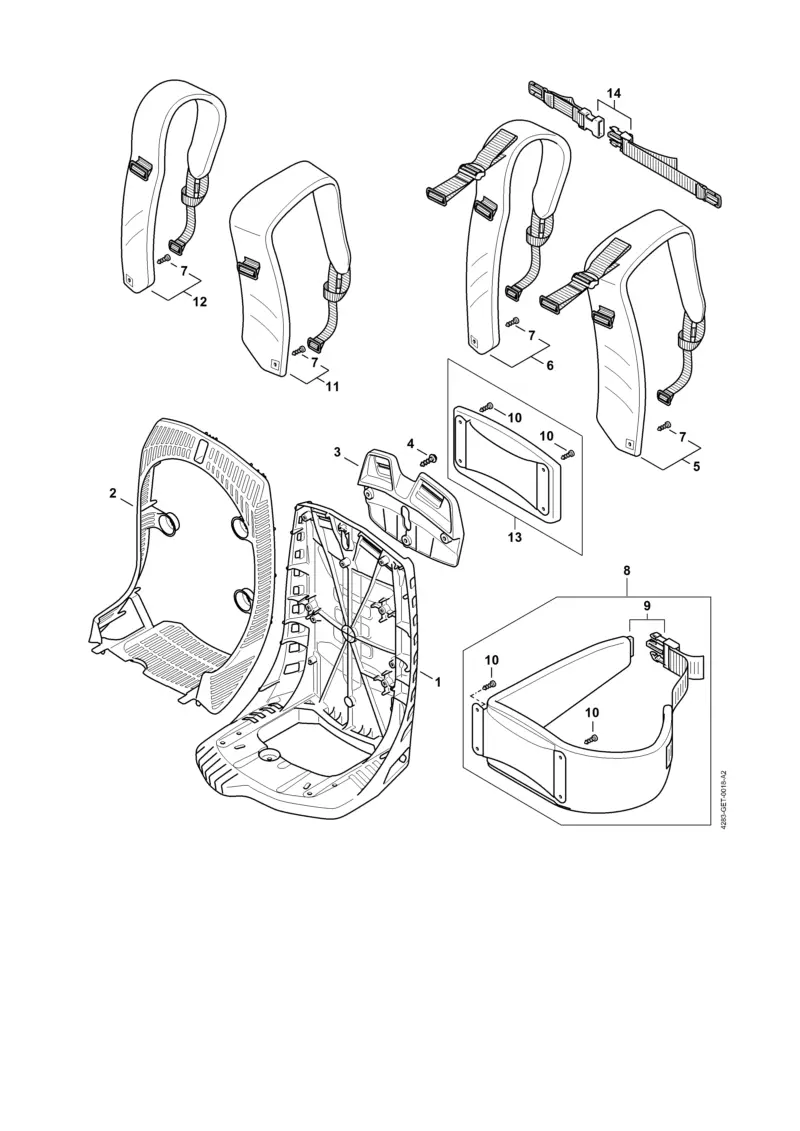

The following section offers a broad understanding of the key elements that make up this powerful equipment. Designed for efficiency and durability, these components work together to deliver high performance in demanding conditions. By examining each part, users can gain insights into the crucial elements that ensure reliable operation.

Engine Unit: The core power source, the engine is built to provide consistent energy output. Its design emphasizes reliability, ensuring smooth operation even during intensive use.

Air Intake System: This component helps to maintain optimal airflow, ensuring that the engine receives a clean and steady supply of air, which is essential for efficient combustion.

Comfort Features: Built with user experience in mind, these features include adjustable straps and ergonomic handles, providing better control and reducing fatigue during prolonged use.

Fuel System:

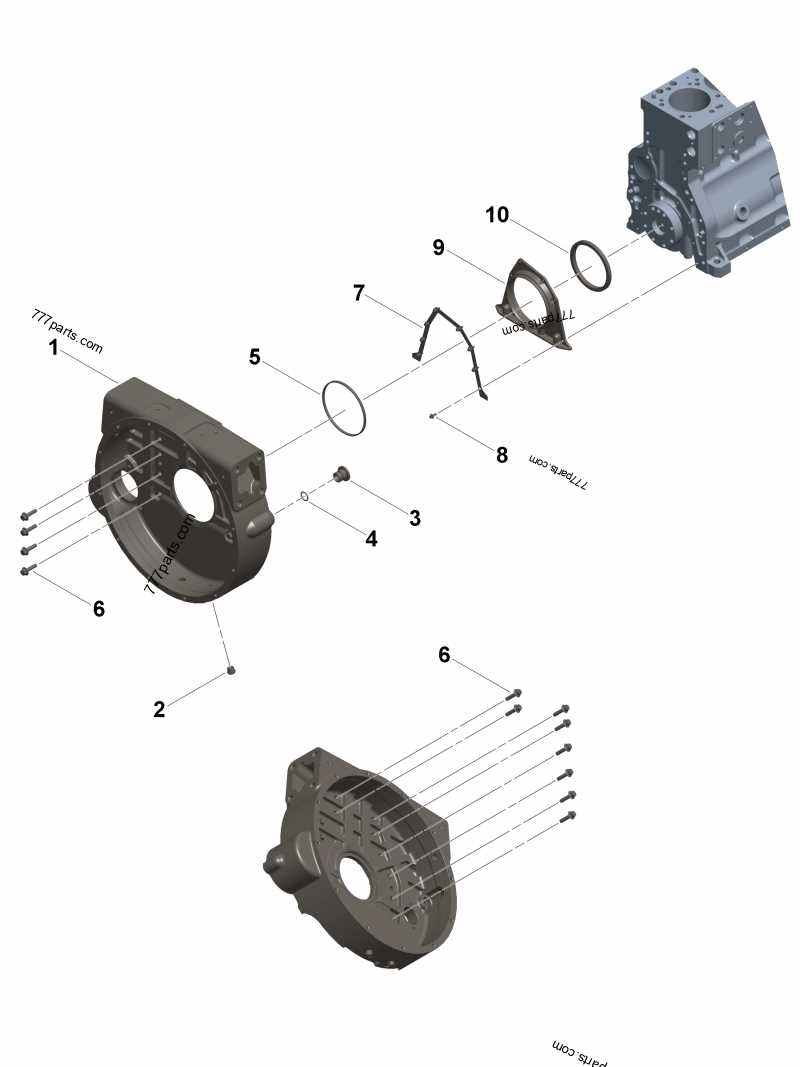

Detailed Breakdown of Engine Parts

A closer look into the components of the motor reveals how each element works together to ensure smooth and efficient operation. Understanding the intricate design and functionality of various elements can help in maintaining and troubleshooting potential issues.

The engine’s cylinder forms the core of the system, where combustion occurs, generating power for the entire mechanism. It is complemented by pistons that move rapidly to convert fuel into energy. Additionally, the crankshaft transfers this motion, creating a rotary force that drives the system.

Supporting these core components is the carburetor, which ensures the precise mixture of air and fuel, while the air filter keeps impurities at bay, ensuring optimal performance. Cooling is handled by fan blades, which disperse heat to prevent overheating, thus ensuring durability during extended use.

Fuel System and Its Elements

The fuel system ensures a smooth and efficient transfer of energy by guiding the combustible mixture through various stages. This network is designed to maintain optimal performance, providing the right balance of air and fuel for consistent operation. It includes several interconnected components that work together to keep the engine running effectively.

Main Components of the Fuel System

The core of this system includes a fuel tank that stores the liquid, delivering it through pipes and hoses to different parts. A carburetor or fuel injection mechanism regulates the mixture, ensuring it is properly atomized before reaching the combustion chamber. The fuel filter is

Air Filtration System Layout

The air filtration system is designed to ensure clean airflow by removing dust and debris before they enter the engine. It consists of multiple components that work together to maintain optimal air quality and protect internal mechanisms from contamination.

The primary element of the system is the air filter, which captures fine particles from the intake air. This filter is positioned strategically to ensure that it can be easily accessed for maintenance and replacement. Adjacent to it, there is a pre-filter that catches larger particles, extending the lifespan of the main filter.

A carefully placed intake duct channels air towards the filtration unit, minimizing turbulence and promoting a smooth flow. Once the air passes through the filter, it moves into a secure housing that directs it towards the engine. The housing is designed to prevent any unfiltered air from bypassing the system, ensuring only purified air reaches the engine.

Regular maintenance of this system is

Starter Assembly and Mechanism

The starter assembly plays a crucial role in initiating the operation of outdoor power equipment. This mechanism is designed to facilitate the effortless ignition of the engine, ensuring a smooth start each time the equipment is in use. Understanding its components and functions is essential for effective maintenance and troubleshooting.

Components of the Starter Mechanism

The starter assembly comprises several key components that work together to initiate the engine’s operation:

- Starter Rope: This flexible cord is pulled to engage the starting process.

- Recoil Spring: This spring provides the necessary tension to retract the starter rope after pulling.

- Starter Pulley: This component houses the rope and is responsible for transferring the pulling force to the engine.

- Starter Handle: The handle is the part that the user grips while pulling the rope to start the engine.

- Mounting Bracket: This secures the starter assembly to the engine casing.

Operational Mechanism

The operational process begins when the user pulls the starter handle, which unwinds the starter rope from the pulley. This action compresses the recoil spring, creating potential energy. As the rope is fully extended, the spring quickly recoils, pulling the rope back and causing the pulley to rotate. This rotation engages the engine flywheel, initiating the combustion cycle and starting the engine.

Ignition System Configuration

The ignition system is a vital component that ensures the effective operation of an engine by generating the necessary spark to ignite the fuel-air mixture. Proper configuration of this system is essential for optimal performance, efficiency, and reliability.

Key Elements: The configuration involves various elements such as the ignition coil, spark plug, and wiring connections. Each part must be precisely aligned and maintained to ensure smooth operation. Regular checks and adjustments can prevent misfires and other performance issues.

Maintenance Tips: It is advisable to inspect the ignition system periodically. Look for any signs of wear or damage, especially in the wiring and connections. Replacing components at the first sign of trouble can save time and enhance overall functionality.

Exhaust System Design and Parts

The exhaust mechanism plays a crucial role in the efficient operation of an engine by directing harmful gases away from the combustion chamber. A well-designed exhaust system not only enhances performance but also minimizes environmental impact. This section delves into the components and layout of the exhaust arrangement, emphasizing their functions and significance.

Key Components of the Exhaust System

Understanding the essential elements of the exhaust mechanism is vital for proper maintenance and performance optimization. Below are the primary components:

| Component | Function |

|---|---|

| Exhaust Manifold | Collects gases from the engine cylinders and directs them to the exhaust pipe. |

| Catalytic Converter | Reduces harmful emissions by converting them into less harmful substances. |

| Muffler | Reduces noise produced by the exhaust gases while maintaining flow efficiency. |

| Exhaust Pipe | Channels gases away from the engine and out of the vehicle. |

Importance of Proper Maintenance

Regular inspection and upkeep of the exhaust arrangement are essential for optimal engine performance and compliance with environmental standards. Neglecting this system can lead to decreased efficiency, increased emissions, and potential engine damage.

Throttle Control and Adjustments

The throttle mechanism plays a vital role in the performance and efficiency of your equipment. Proper control and adjustment of this component ensure optimal operation, allowing the user to manage engine speed effectively. This section explores the fundamental aspects of throttle functionality and provides guidance on how to make necessary adjustments.

Understanding the throttle system is essential for maintaining the device. Regular checks can help identify any issues that may arise due to wear or misalignment, affecting performance. Adjustments should be made carefully to ensure responsiveness and precision during operation.

| Component | Description | Adjustment Procedure |

|---|---|---|

| Throttle Lever | The primary control used to manage engine speed. | Ensure proper range of motion without obstruction. |

| Throttle Cable | Connects the throttle lever to the engine’s throttle body. | Check for tension; adjust if slack is present. |

| Linkage Assembly | Transfers motion from the throttle lever to the engine. | Inspect for wear and ensure secure connections. |

Regular maintenance and adjustments can enhance the longevity of the equipment and improve user experience. It is advisable to consult the operational guidelines for specific details on throttle adjustments tailored to the particular model in use.