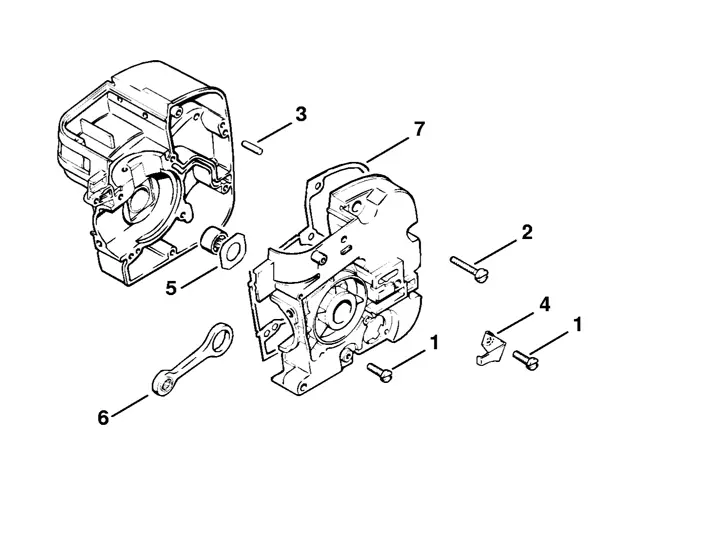

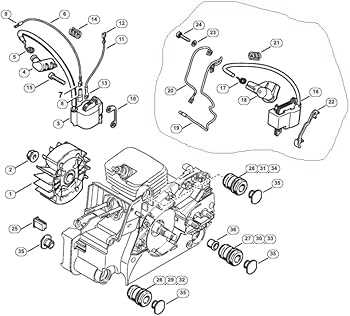

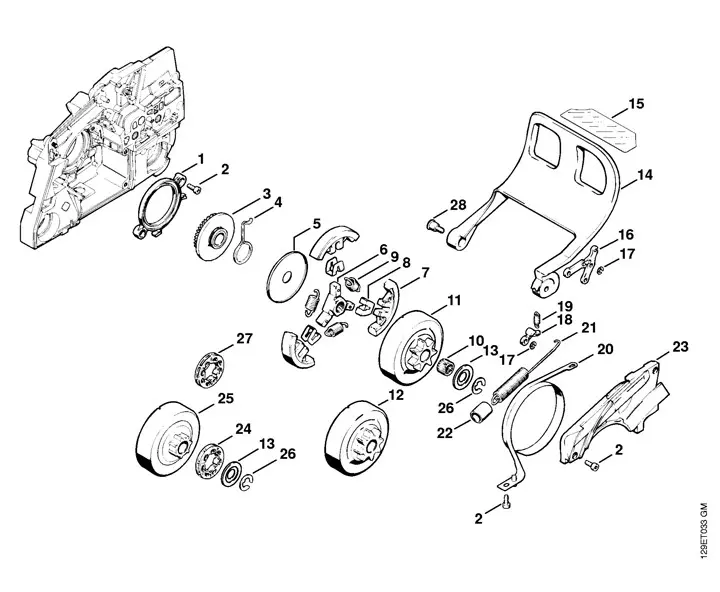

Parts Breakdown for Popular Compact Chainsaw

Understanding the intricate structure of mechanical devices is essential for ensuring optimal performance and longevity. Each element within a tool plays a crucial role in its overall functionality, and knowing how these components work together can help identify potential issues and streamline maintenance.

Exploring the inner workings of various mechanical systems provides valuable insights into their design and operational efficiency. By focusing on specific elements within the assembly, users can gain a deeper appreciation of how individual parts contribute to the smooth operation of the device as a whole.

In the following sections, we will break down the primary components found in this particular machine, offering a clear explanation of each element’s role and how it interacts with the rest of the system. This approach will help users better understand the mechanical makeup, enhancing their ability to troubleshoot or maintain it effectively.

Understanding the Structure of a Chainsaw

The internal layout of a typical cutting tool is designed for efficient operation in various conditions. This tool consists of multiple interconnected components, each playing a crucial role in ensuring smooth performance. By exploring its structural elements, we can gain a better understanding of how these machines function and how their mechanisms work together.

At its core, the machine is built around a central engine that powers the system. This power source is connected to a drive mechanism, which transfers energy to the external blade. Various controls allow the operator to regulate speed and maintain balance, ensuring safety during use.

Another key feature is the lubrication system, which helps reduce friction between moving parts, extending the life of the tool and improving performance. Maintenance of these systems is essential to keep the machine running efficiently, making it important to understand how these sections are interconnected.

Key Components of the MS170 Model

This section highlights the essential elements that make up this versatile tool, emphasizing the importance of each part in ensuring smooth operation and reliability. Understanding these components is crucial for maintaining optimal performance over time.

- Engine Unit: The core of the machine, responsible for generating the power required to drive the cutting mechanism. It’s designed for efficiency and durability, allowing the tool to operate effectively even under tough conditions.

- Cutting Mechanism: This section includes the chain and guide bar, which work together to deliver precise and controlled cutting. The combination ensures that tasks can be completed with minimal effort and maximum accuracy.

- Fuel System: Ensures a consistent supply of fuel to the engine, enabling steady performance. The system includes a fuel tank and related components, all designed to optimize fuel consumption.

- Handle Assembly: Provides the operator with a firm and comfortable grip, enhancing control and safety during use. It’s ergonomically designed to reduce fatigue during extended periods of operation.

- Exhaust System: Manages the release of gases generated by the engine, maintaining efficiency while reducing emissions. It plays a key role in ensuring the tool remains environmentally friendly.

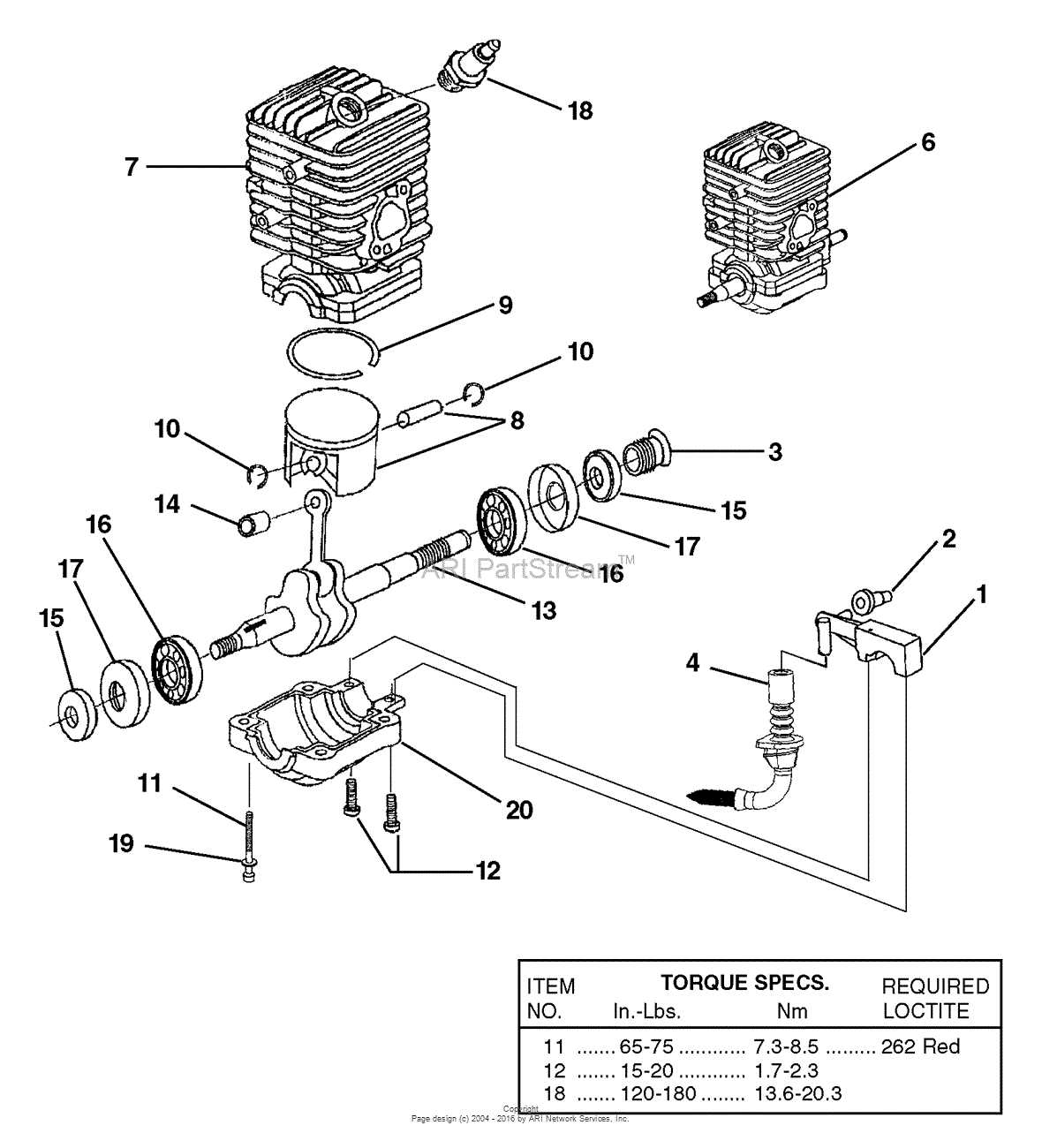

Engine Parts Breakdown for Easy Repairs

Understanding the internal structure of your tool’s motor is crucial for performing efficient and successful maintenance. By breaking down the components, you can more easily identify which elements need attention and how they interact within the overall system. This approach simplifies repairs and reduces downtime, ensuring that your equipment remains in top working condition.

Key Components of the Engine

The core of the motor consists of several interconnected elements that drive performance. The cylinder plays a critical role in housing the combustion process, while the piston moves within the cylinder, converting energy into motion. These two components must function in harmony for the motor to operate smoothly. Alongside these, the crankshaft transfers motion from the piston to the drive system, ensuring effective power distribution.

Regular Maintenance for Longevity

Routine inspections and upkeep of these components are essential for maintaining peak efficiency. Checking for wear on the piston rings and ensuring proper lubrication of the crankshaft can prevent long-term damage. Additionally, inspecting the gaskets for leaks helps maintain consistent pressure, further optimizing engine performance.

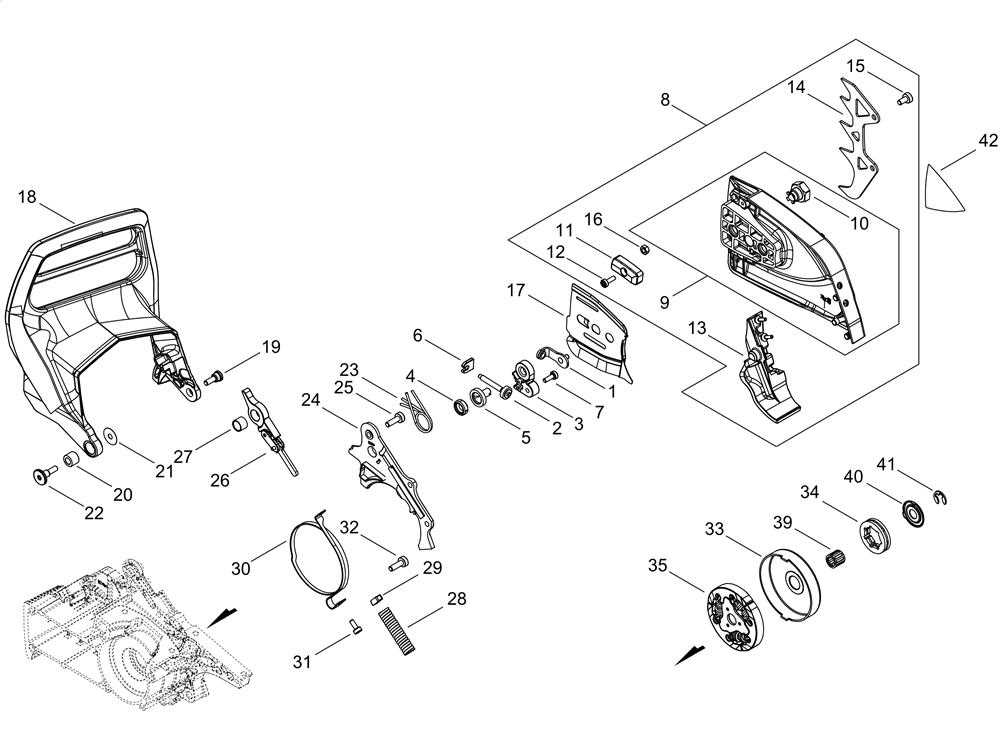

Chainsaw Chain Assembly and Maintenance

Ensuring the proper assembly and care of the cutting chain is essential for efficient operation and long-term reliability. Understanding how to fit the cutting mechanism correctly and maintain its condition will not only enhance performance but also extend the lifespan of the tool.

Assembly Process

When assembling the cutting chain, it is important to follow the correct sequence of steps to ensure it is securely mounted and tensioned. Begin by positioning the bar properly and aligning the drive links with the sprocket.

- Align the chain bar and ensure it is firmly seated in place.

- Wrap the chain around the bar, making sure the teeth face in the correct direction.

- Secure the chain tensioner and adjust it to the appropriate tension.

- Tighten the mounting nuts to secure the assembly.

Maintenance Tips

Regular care of the cutting chain is vital to avoid wear and tear and maintain cutting efficiency. Lubrication and sharpening are the pr

Guide to Handle and Grip Parts

The handle and grip assembly plays a crucial role in ensuring comfortable and safe operation during cutting tasks. These components are designed to provide a firm, ergonomic hold, reducing strain and improving control during extended use. Understanding the function and structure of each part can help maintain better handling performance.

Main Handle Structure

The main handle is designed to offer stability and support, allowing for precise movements. It is often crafted from durable materials that withstand wear while maintaining a comfortable grip. The positioning of this handle is essential to ensure a balanced feel during operation.

Grip Enhancements and Comfort Features

Modern designs often include specialized grips, which may be textured or padded to reduce fatigue and improve comfort. These elements are critical for minimizing vibrations and ensuring a secure hold, especially in challenging conditions. Regular inspection of these features can prevent wear and ensure continued comfort and safety.

Fuel System Overview for MS170 Chainsaw

The fuel system is a crucial component that ensures optimal performance and efficiency of the cutting tool. This system is responsible for delivering the right mixture of fuel and air to the engine, enabling smooth operation. Understanding its elements can help in maintaining and troubleshooting issues that may arise during usage.

Key Components of the Fuel System

The main elements of the fuel delivery system include the fuel tank, fuel lines, and carburetor. The fuel tank stores the necessary liquid, while the fuel lines transport the mixture to the engine. Finally, the carburetor plays a vital role in mixing the fuel and air before it enters the combustion chamber. Each part must function correctly to ensure the device runs efficiently.

Maintenance Tips for Optimal Performance

Regular maintenance of the fuel system is essential to prevent issues. It’s advisable to check the fuel filter for clogs, inspect the lines for leaks, and ensure that the carburetor is clean and adjusted properly. Using the recommended fuel mixture and storing it correctly can also prolong the life of the fuel system.

Bar and Chain Tensioning Mechanism Explained

The mechanism responsible for adjusting the tension of the guide rail and cutting link is crucial for optimal performance and safety. Proper tension ensures efficient cutting action and reduces the risk of damage to the equipment. Understanding this mechanism is essential for maintaining the tool and achieving the best results during operation.

Understanding the Mechanism

This system typically consists of an adjustment screw and a tensioning arm. By turning the screw, the operator can increase or decrease the tension on the cutting link, allowing for precise control. Adequate tension prevents the chain from slipping off the guide rail while also ensuring it is not overly tight, which can lead to premature wear.

Importance of Proper Tension

Maintaining the correct tension not only prolongs the life of the equipment but also enhances safety during use. A loose cutting link may jump off, posing a risk to the operator, while an overly tight chain can cause increased friction and potential overheating. Regular checks and adjustments of the tensioning mechanism are recommended for optimal operation.

Air Filter and Carburetor Connection

The connection between the air filtration system and the fuel delivery component is crucial for optimal engine performance. This relationship ensures that clean air enters the combustion chamber, facilitating efficient combustion and power generation. Proper maintenance and understanding of this connection can significantly enhance the functionality of the equipment.

Importance of Air Filtration

Air filters serve as the first line of defense against contaminants that can affect engine efficiency. A well-maintained air filter allows for:

- Enhanced airflow to the engine

- Improved fuel efficiency

- Reduced emissions

- Extended engine lifespan

Connecting the Components

The correct installation of the air filter and carburetor is essential for seamless operation. Here are key steps to ensure a proper connection:

- Inspect the air filter for any signs of damage or clogging.

- Ensure that the mounting points are clean and free of debris.

- Align the air filter securely with the carburetor intake.

- Fasten the connection using the appropriate screws or clamps.

Regular checks and maintenance of this connection will help maintain the overall health of the engine.

Essential Ignition System Components

The ignition system is a crucial aspect of any engine, responsible for starting and maintaining combustion. Understanding its components can enhance maintenance and troubleshooting efforts, ensuring optimal performance.

Key Components of the Ignition System

- Spark Plug: This device ignites the air-fuel mixture, creating the necessary combustion for the engine to operate. A well-functioning spark plug ensures reliable ignition.

- Ignition Coil: The ignition coil transforms low battery voltage into the high voltage needed to produce a spark at the spark plug. Its efficiency directly affects ignition reliability.

- Flywheel Magnet: This component generates the magnetic field necessary for the ignition coil to function, contributing to the ignition process as the engine turns.

- Electronic Ignition Module: This advanced component regulates the ignition timing, ensuring that the spark occurs at the optimal moment for combustion.

- Wiring Harness: A network of wires connects all ignition components, enabling communication and functionality across the system.

Maintenance Tips

- Regularly inspect and replace spark plugs as needed to maintain optimal combustion.

- Check the ignition coil for signs of wear or damage, ensuring reliable spark generation.

- Ensure all connections in the wiring harness are secure and free from corrosion.

Safety Mechanisms and Their Functions

Ensuring user safety is paramount in any mechanical device designed for cutting or trimming tasks. Various protective features are integrated to prevent accidents and enhance operational security. Understanding these mechanisms can significantly reduce the risk of injury during use.

Primary Safety Features

Among the most critical components are the chain brake and throttle lock. The chain brake is designed to stop the cutting element almost instantly in the event of kickback or loss of control. This feature allows the user to regain stability and prevent potential harm. Meanwhile, the throttle lock prevents unintended acceleration, ensuring that the equipment operates only when intentionally activated by the user.

Additional Protective Mechanisms

Other essential safety elements include vibration dampening systems and protective guards. The vibration dampening system reduces the impact of engine vibrations on the user’s hands, which can cause fatigue and long-term injury. Protective guards are installed to shield users from flying debris and to keep body parts clear of the cutting area, enhancing overall safety during operation.

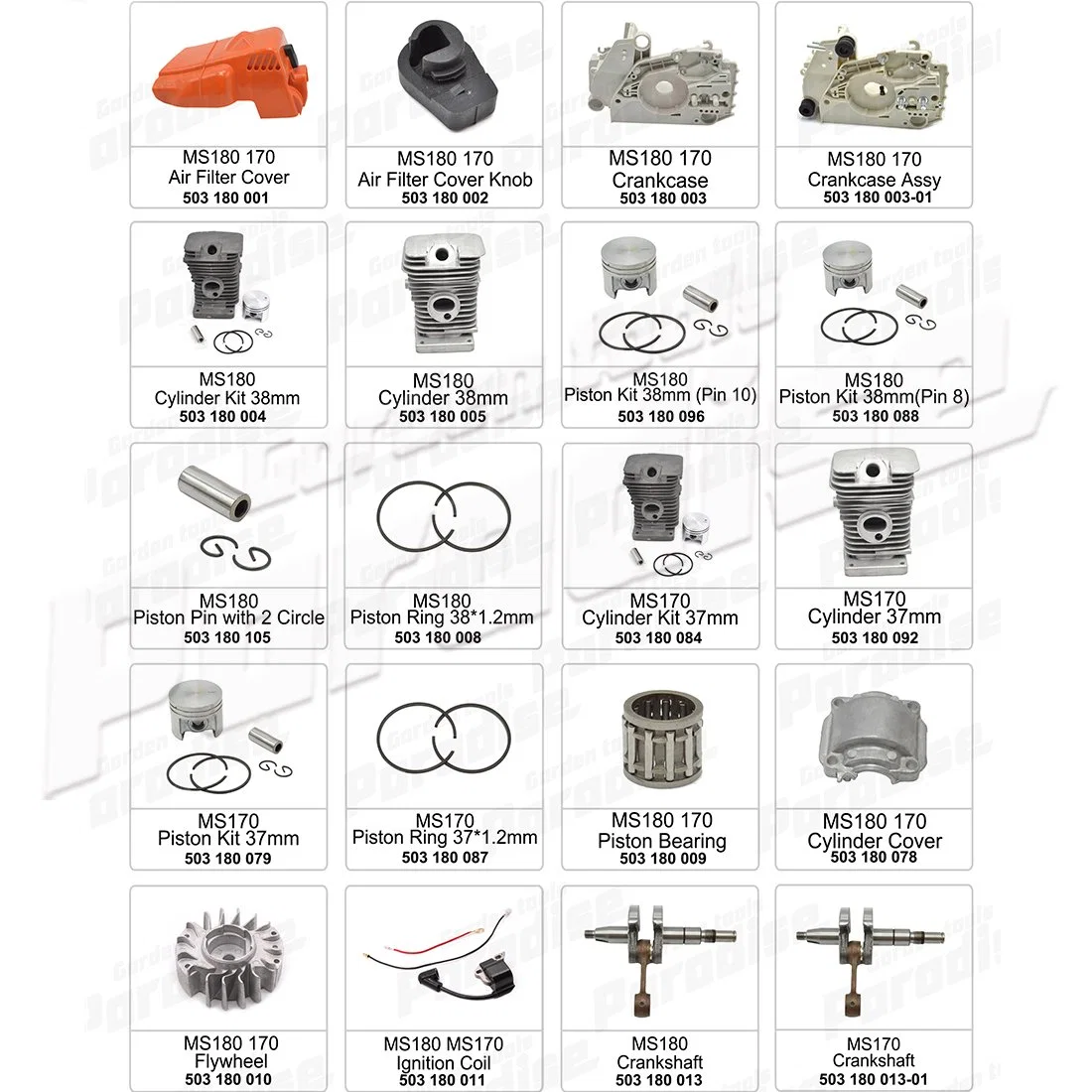

Common Parts Replacement for MS170 Chainsaws

Regular maintenance and timely replacements are essential for keeping outdoor power equipment running smoothly. Understanding which components are most frequently swapped out can enhance the lifespan and efficiency of your tool. This section highlights the commonly replaced items that contribute significantly to optimal performance.

Fuel and Air Filters: These filters play a vital role in ensuring clean airflow and fuel delivery to the engine. Over time, they can become clogged, leading to decreased efficiency. Routine checks and replacements will keep the engine operating at peak performance.

Chain and Bar: The cutting assembly is crucial for effective operation. Chains can dull or break, while bars may wear down from regular use. Regular inspection and timely replacement of these components will ensure smooth cutting and enhance safety.

Spark Plug: A clean and functional spark plug is critical for efficient combustion. If the equipment struggles to start or runs unevenly, checking and replacing the spark plug can often resolve these issues.

Fuel Lines: These lines transport fuel from the tank to the engine. Over time, they can crack or become brittle, leading to leaks. Regular inspection and replacement of fuel lines can prevent operational issues and enhance safety.

Throttle Cable: This component controls the engine’s speed. If the throttle cable becomes frayed or damaged, it can result in poor acceleration or responsiveness. Ensuring this cable is in good condition is essential for proper handling and operation.