Understanding the Schematic Diagram of Stihl 044 Parts

In the world of outdoor power equipment, having a clear grasp of the various elements that make up a chainsaw is essential for both maintenance and repair. This guide aims to provide an insightful overview of the intricate assembly found in one of the leading models, enhancing your ability to identify and troubleshoot any issues that may arise.

By exploring the individual components, you can gain a deeper appreciation of how each piece contributes to the overall functionality of the tool. A thorough examination will empower you to make informed decisions when it comes to servicing or upgrading your equipment.

In this section, we will delve into the specifics, highlighting the ultimate arrangement of these vital elements. Whether you’re a seasoned technician or a novice user, understanding these details will significantly improve your hands-on experience.

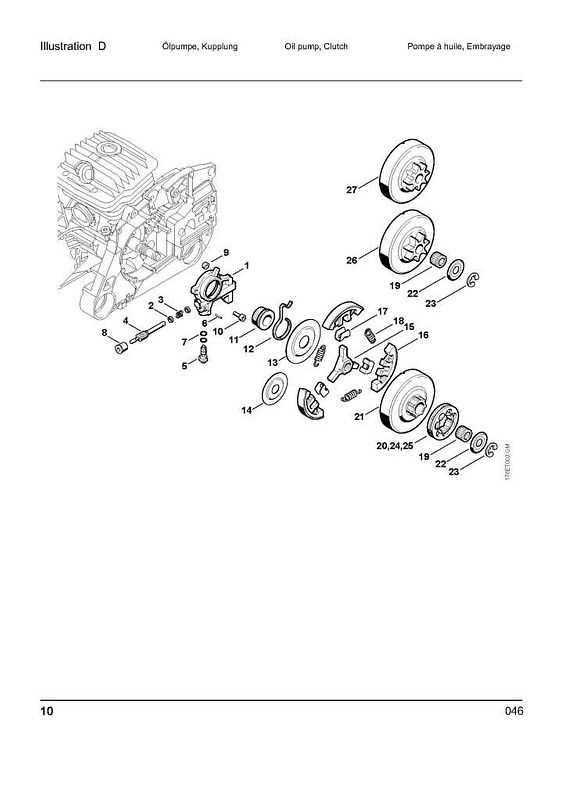

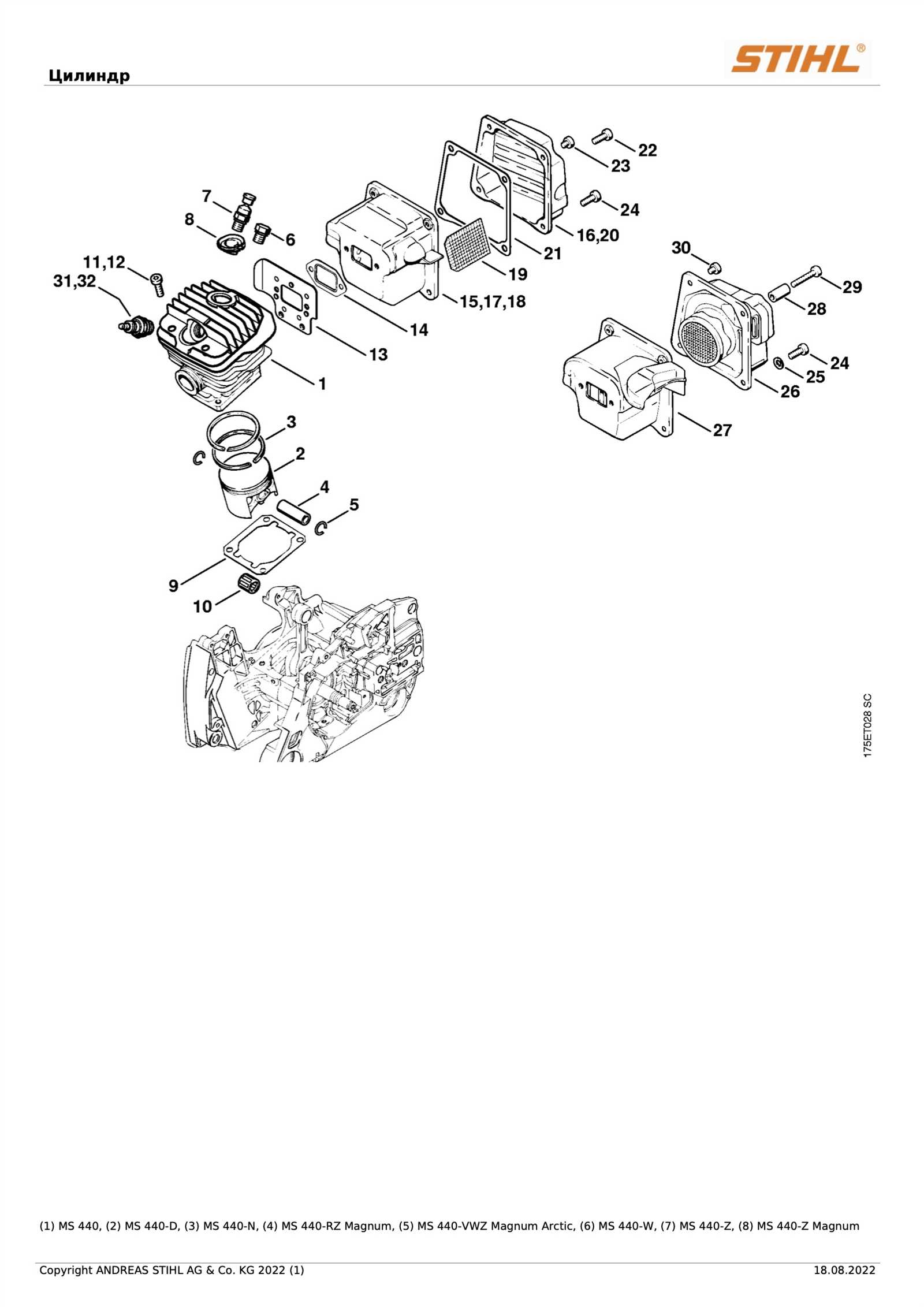

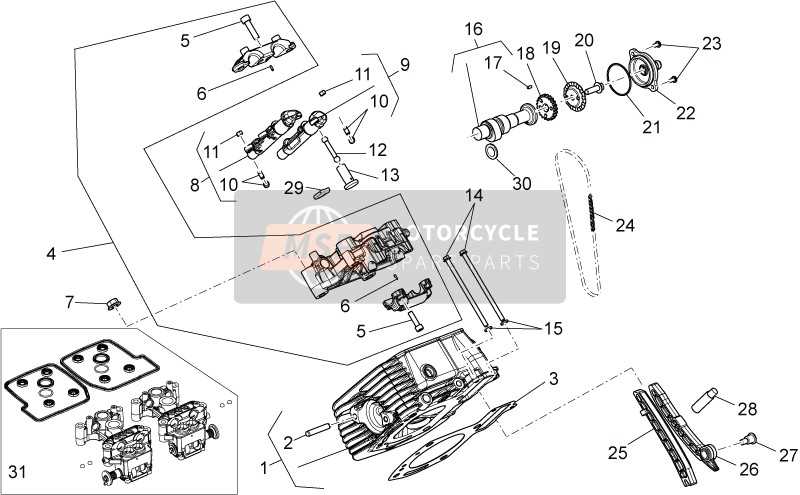

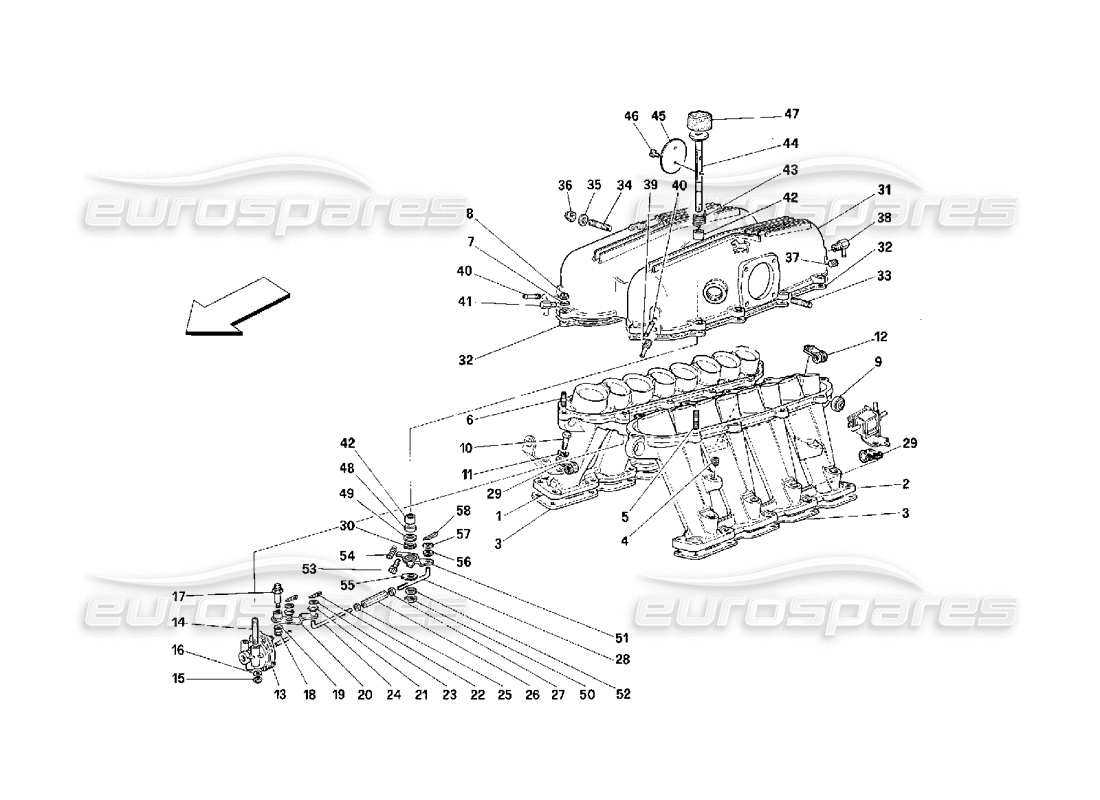

Schematic Overview of Stihl 044

This section provides a comprehensive exploration of the internal components and their functions within a specific model of power equipment. Understanding the arrangement and roles of each element is crucial for effective maintenance and repair.

- Engine Assembly: The heart of the machinery, responsible for power generation.

- Fuel System: Comprising the tank, filter, and lines, this system ensures proper fuel delivery.

- Ignition Unit: This component initiates combustion, crucial for operational efficiency.

- Cutting Mechanism: The blade and associated hardware facilitate the primary function of cutting.

Each component plays an ultimate role in the overall performance, and familiarity with their configuration aids in troubleshooting common issues.

- Regular inspections can prevent major failures.

- Consulting the manual enhances understanding of each part.

- Replacement of worn components ensures longevity.

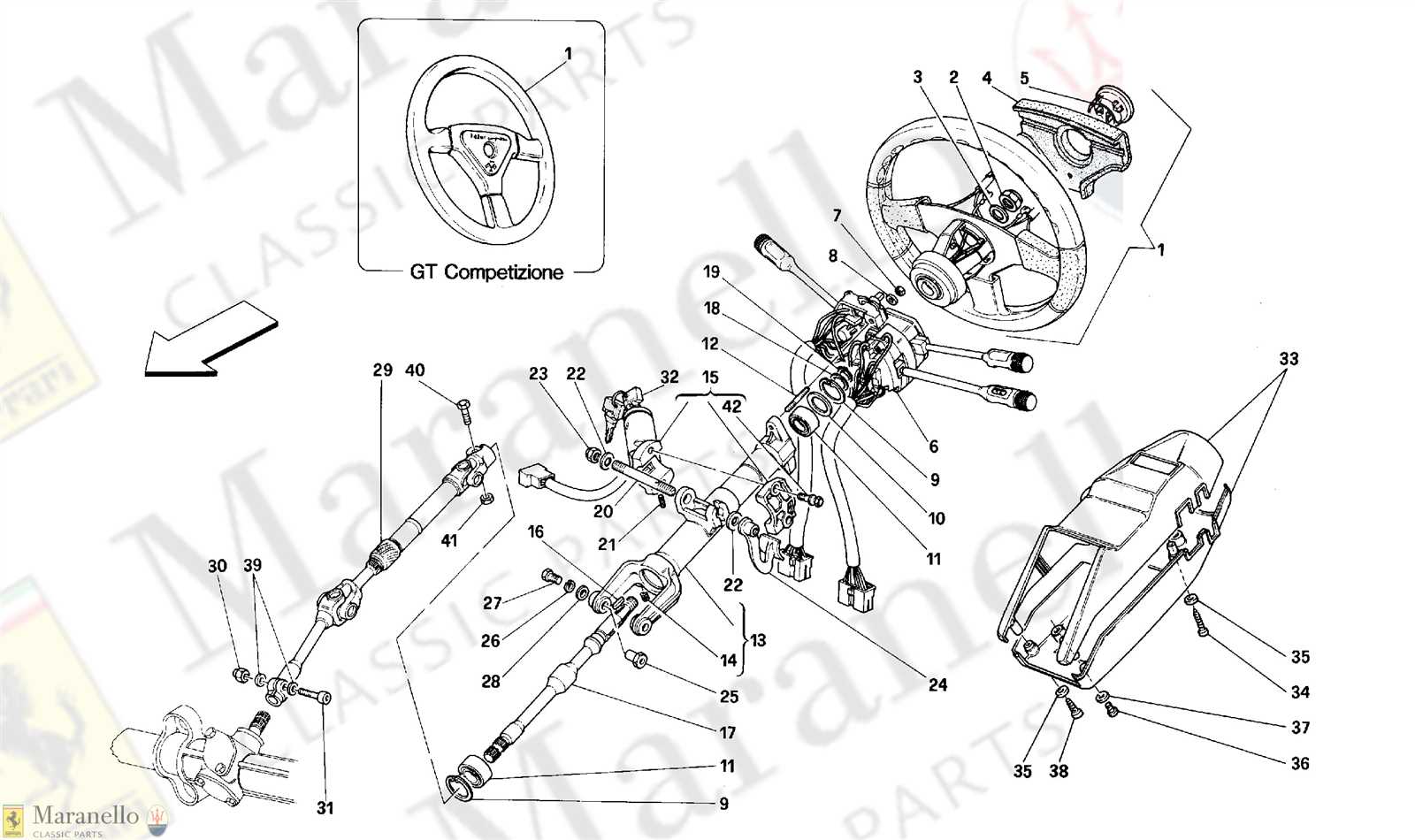

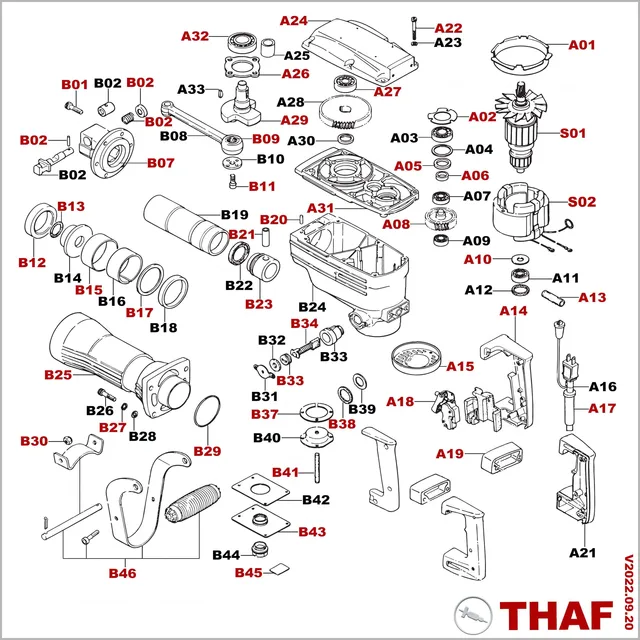

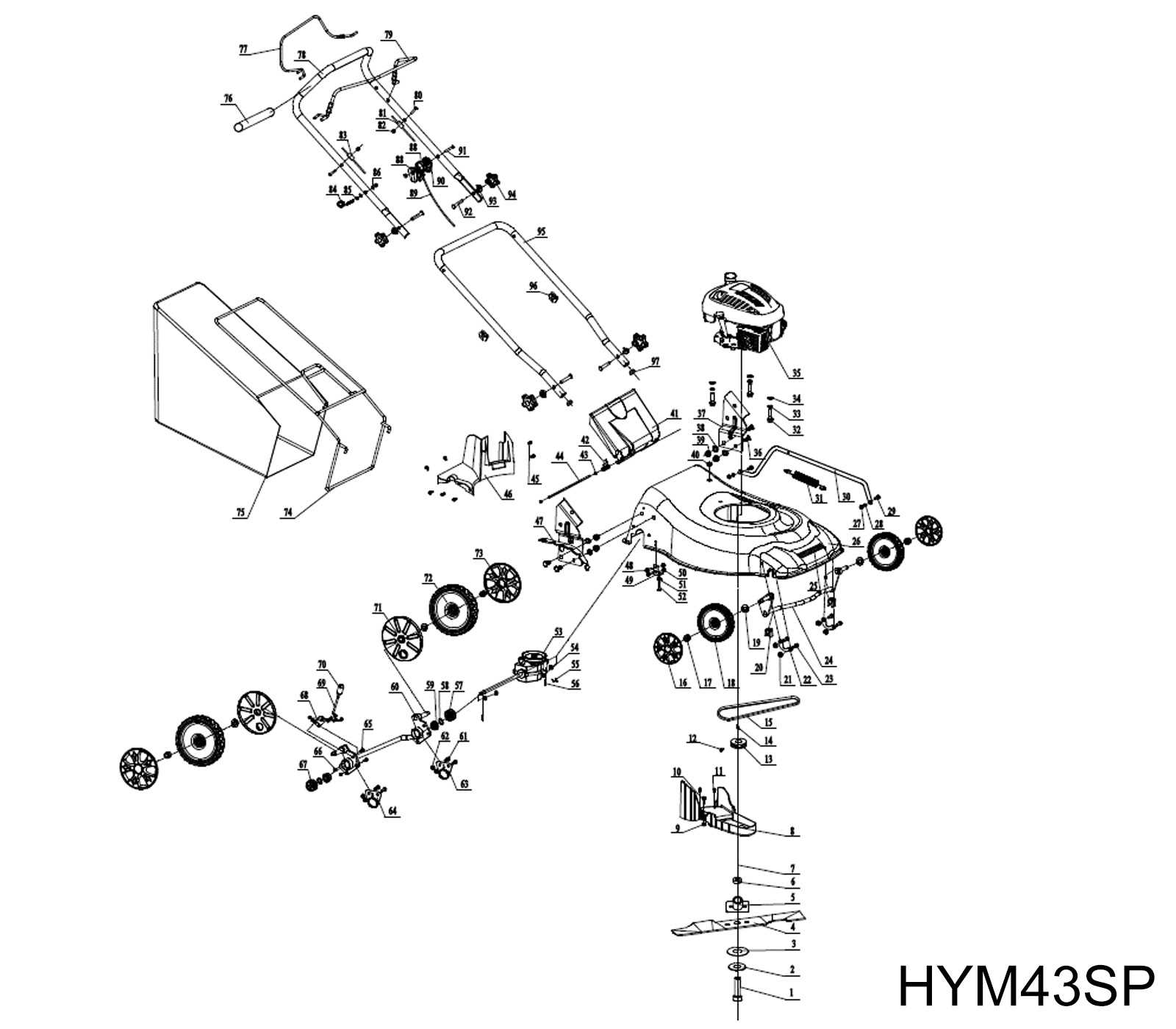

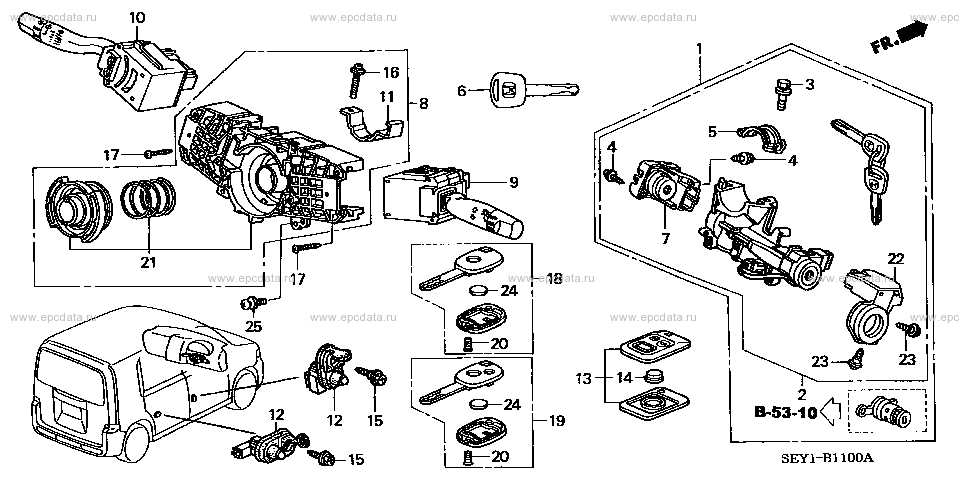

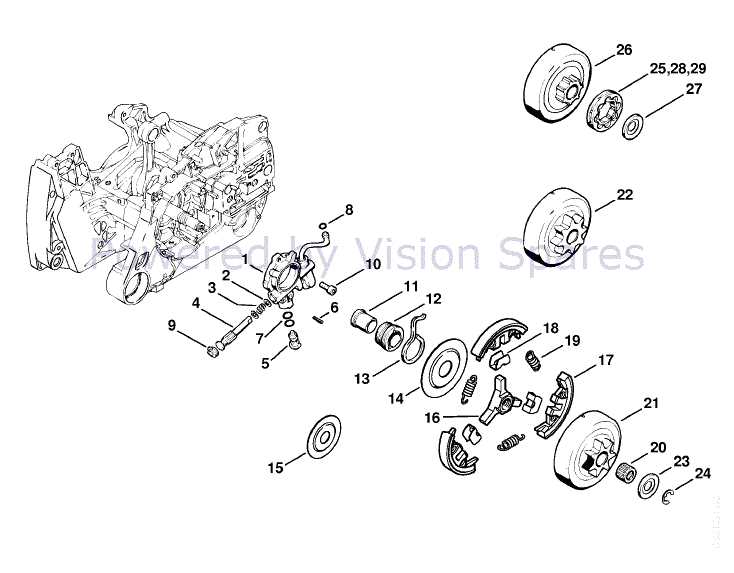

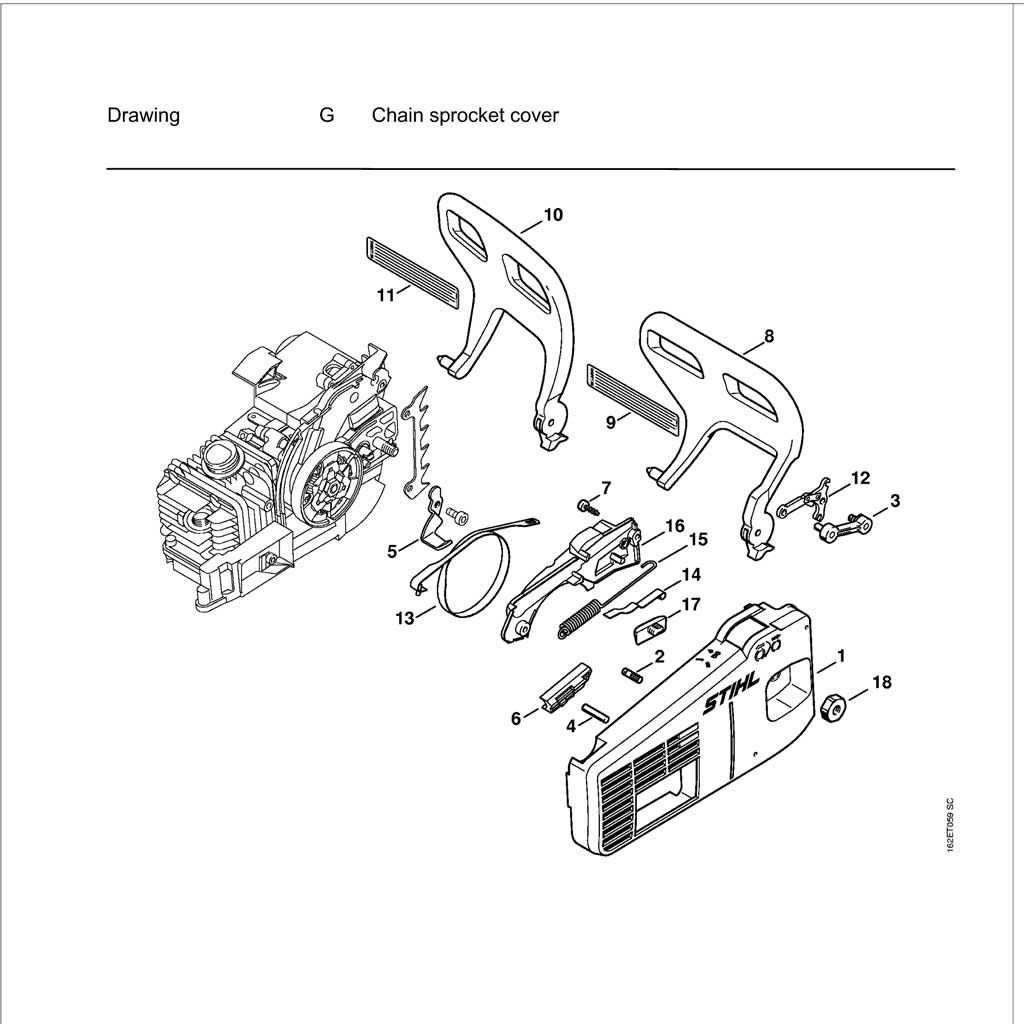

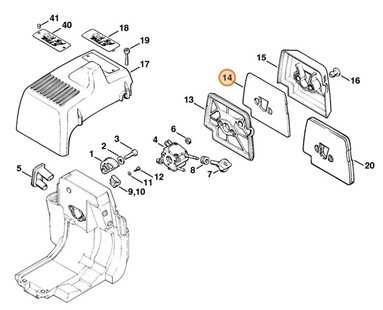

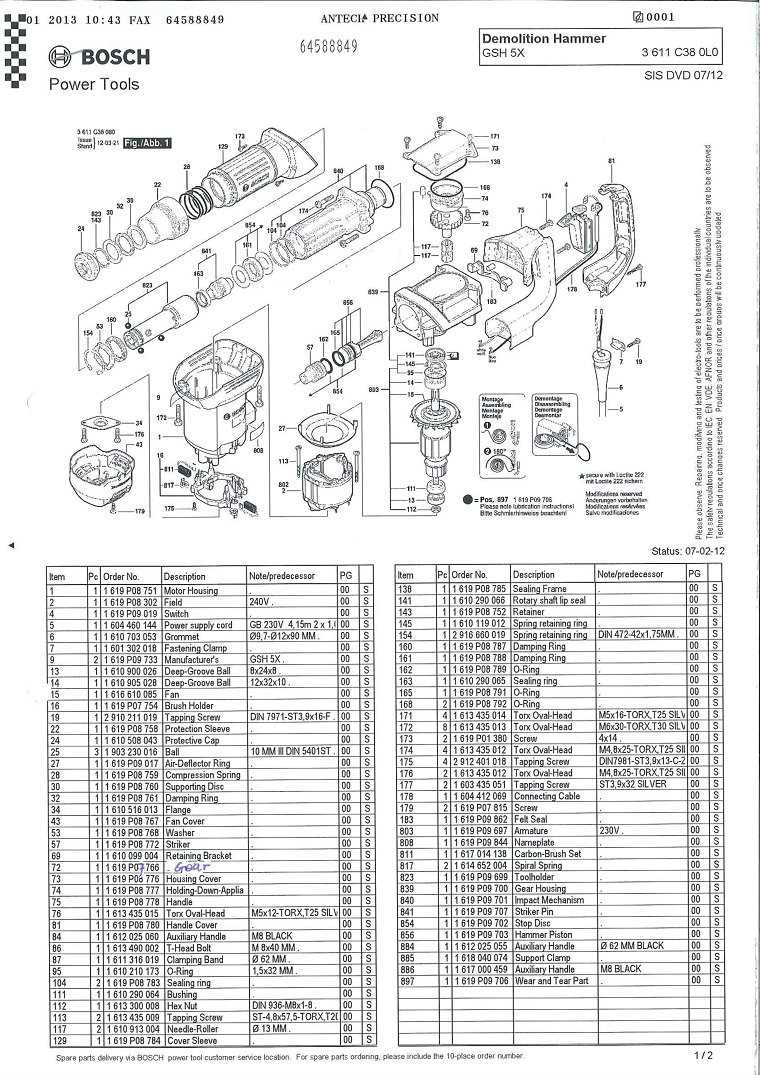

Understanding the Parts Diagram

Gaining insight into the components of a machine is essential for effective maintenance and repair. A visual representation of these elements can significantly aid in identifying each part’s role and function.

When exploring this representation, consider the following key aspects:

- Identification: Each component is labeled, making it easier to recognize and locate specific items.

- Arrangement: The layout often reflects how parts fit together, providing a clearer understanding of assembly.

- Connections: Understanding how different elements interact is crucial for troubleshooting and repairs.

By delving into these illustrations, users can develop a more comprehensive understanding of their equipment, leading to improved functionality and longevity.

Key Components of Stihl 044

Understanding the essential elements of a chainsaw is crucial for optimal performance and maintenance. Each part plays a significant role in the overall functionality, ensuring efficiency and reliability during operation. Knowing these components helps users make informed decisions regarding repairs and upgrades.

One of the primary elements is the engine, which provides the necessary power for cutting. Additionally, the bar and chain work together to enhance cutting precision and speed. The air filter is vital for maintaining engine efficiency, while the fuel system ensures proper combustion. Lastly, the ignition system is crucial for starting the tool reliably.

Common Issues and Repairs

Maintaining outdoor power equipment often involves addressing various challenges that may arise during operation. Identifying these common problems is essential for effective troubleshooting and repair. This section highlights frequent issues encountered with these machines and offers guidance on resolving them to ensure optimal performance.

Engine Performance Problems

One of the most prevalent issues is related to engine performance. Symptoms such as difficulty starting, erratic idling, or a lack of power can indicate underlying problems. Often, these issues stem from fuel contamination, clogged air filters, or faulty spark plugs. Regular maintenance, including cleaning or replacing filters and checking fuel quality, can mitigate these issues.

Chain and Bar Issues

The cutting mechanism can also present challenges. Common signs of trouble include poor cutting performance, excessive vibration, or unusual noises during operation. These may be caused by dull chains, improper tension, or inadequate lubrication. Ensuring that the chain is sharpened regularly and correctly tensioned can significantly improve cutting efficiency and prolong the life of the bar.

Benefits of Using OEM Parts

Choosing original components for maintenance and repair offers numerous advantages that can significantly enhance performance and longevity. These parts are designed specifically for the equipment, ensuring compatibility and reliability that aftermarket alternatives may lack.

Quality Assurance

One of the primary benefits of using original components is the assurance of quality. These components undergo rigorous testing and meet strict manufacturing standards, which often results in:

- Improved durability

- Consistent performance

- Enhanced safety features

Warranty Protection

Utilizing original components can also safeguard your warranty. Many manufacturers require the use of OEM parts to maintain coverage, which means:

- Peace of mind during repairs

- Financial protection against unexpected failures

- Support from the manufacturer in case of issues

In summary, opting for original components not only boosts the efficiency of your equipment but also helps in maintaining its value over time.

Tools Needed for Assembly

Proper assembly of machinery requires a specific set of tools to ensure efficiency and accuracy. Having the right instruments at your disposal not only facilitates a smoother process but also contributes to the longevity and performance of the equipment.

Below is a list of essential tools that you will need for the assembly:

- Wrenches: Various sizes are necessary for tightening bolts and nuts securely.

- Screwdrivers: A set of both flathead and Phillips screwdrivers will be required for different types of screws.

- Torque Wrench: This tool ensures that fasteners are tightened to the manufacturer’s specifications.

- Pliers: Useful for gripping and bending components during assembly.

- Hammers: A rubber mallet can be beneficial for gentle adjustments without damaging parts.

- Measuring Tape: For ensuring correct measurements and alignment of components.

- Safety Gear: Always include gloves and goggles to protect yourself while working.

Having these tools ready will make the assembly process efficient and help achieve optimal results. Always double-check your tool inventory before starting to avoid interruptions during the task.

How to Interpret the Diagram

Understanding the layout of components is essential for effective maintenance and repair. By familiarizing yourself with the visual representation, you can streamline your approach to troubleshooting and assembly. Here are some tips to help you decode the information presented.

Identifying Key Elements

- Labels: Look for marked areas that indicate specific components. These labels often provide valuable information about each part’s function and placement.

- Lines and Arrows: Pay attention to the connections between parts. Lines and arrows typically signify how components interact or link to one another.

- Color Coding: If present, colors can indicate different types of materials or functionalities, helping you to differentiate between similar parts.

Understanding Component Relationships

- Grouping: Components may be grouped based on their functions. Identifying these clusters can simplify the process of understanding how they work together.

- Hierarchy: Recognize the primary components and how they relate to secondary ones. This hierarchical understanding aids in visualizing the overall system.

- Sequence: Follow the sequence of assembly or disassembly indicated in the layout to avoid confusion during repairs.

By carefully examining the visual guide and utilizing these strategies, you can gain a clearer understanding of the relationships and functions of each element within the system.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment requires a proactive approach to care and upkeep. Regular maintenance not only enhances performance but also minimizes the risk of unexpected failures. Below are essential practices to keep your machinery running smoothly for years to come.

Regular Inspections

- Check for any signs of wear and tear on critical components.

- Look for loose or damaged parts that may affect performance.

- Inspect filters and replace them as needed to ensure optimal airflow.

Routine Cleaning

- Keep the exterior clean to prevent dirt buildup that can lead to overheating.

- Clear any debris from vents and cooling systems to maintain efficiency.

- Regularly clean fuel and oil systems to avoid contamination and ensure smooth operation.

By adhering to these maintenance tips, you can significantly enhance the reliability and durability of your equipment, allowing you to focus on the tasks at hand without unnecessary interruptions.

Where to Find Replacement Parts

Locating suitable components for your equipment can be a straightforward process if you know where to look. There are several reliable sources, both online and offline, that offer a wide selection of high-quality items to ensure your machinery operates smoothly.

Authorized Dealers

One of the best options is to visit authorized dealers. These establishments typically carry genuine products and can provide expert advice. They often have knowledgeable staff who can help you identify the right items for your specific model.

Online Marketplaces

The internet is an invaluable resource for sourcing replacement components. Various e-commerce platforms offer a vast range of options, often at competitive prices. Be sure to check customer reviews and ratings to ensure you are purchasing from reputable sellers.

Safety Precautions While Repairing

When undertaking any repair work on machinery, ensuring safety is paramount. Proper precautions can prevent accidents, injuries, and damage to equipment. Familiarizing oneself with potential hazards and implementing protective measures creates a safer working environment.

Personal Protective Equipment

Wearing the appropriate personal protective equipment (PPE) is essential. This includes safety goggles to shield your eyes from debris, gloves to protect your hands from sharp edges, and steel-toed boots to safeguard your feet. A hard hat may also be necessary in environments where falling objects are a risk. Always assess the specific risks associated with the task at hand and equip yourself accordingly.

Work Area Organization

Maintaining an organized workspace contributes significantly to safety. Keep tools and materials neatly stored to minimize tripping hazards. Ensure that the area is well-lit and free from clutter. When working with electrical components, verify that power sources are disconnected to avoid electric shocks. An orderly environment not only enhances safety but also improves efficiency during the repair process.

Comparative Analysis with Other Models

Understanding the nuances between different models is crucial for making informed decisions, particularly when selecting tools for specific tasks. Each model presents unique characteristics and capabilities that can influence performance, durability, and overall user satisfaction. This analysis focuses on how one model stacks up against its peers, highlighting key differences and similarities in functionality and design.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Weight | 10.5 lbs | 11.2 lbs | 9.8 lbs |

| Engine Power | 4.5 HP | 5.0 HP | 4.0 HP |

| Fuel Capacity | 12 oz | 14 oz | 10 oz |

| Bar Length | 20 inches | 18 inches | 22 inches |

| Price | $450 | $500 | $420 |

By comparing these attributes, it becomes evident how each tool is tailored for different user needs. Whether prioritizing weight for ease of handling or engine power for demanding tasks, the choice will ultimately depend on the specific requirements of the user. This analysis serves as a foundation for evaluating options and making a strategic selection based on individual preferences and project demands.

Frequently Asked Questions on Diagrams

This section addresses common inquiries related to visual representations of components and their arrangements. Understanding these illustrations can significantly enhance your ability to assemble or repair equipment effectively.

What are the benefits of using visual representations?

Visual aids simplify complex information, making it easier to identify individual elements and their functions within a system.

How can I interpret these illustrations?

Familiarizing yourself with the symbols and notations commonly used will help you decode the information presented in these visual guides.

Where can I find these visual aids?

Many manufacturers provide them through their websites, user manuals, or dedicated support pages for their products.

Are these resources suitable for beginners?

Yes, they are designed to cater to users at all skill levels, providing a foundational understanding of how components interact.

Can I rely solely on these visuals for repairs?

While they are helpful, it’s recommended to combine them with other resources and hands-on experience for the best results.