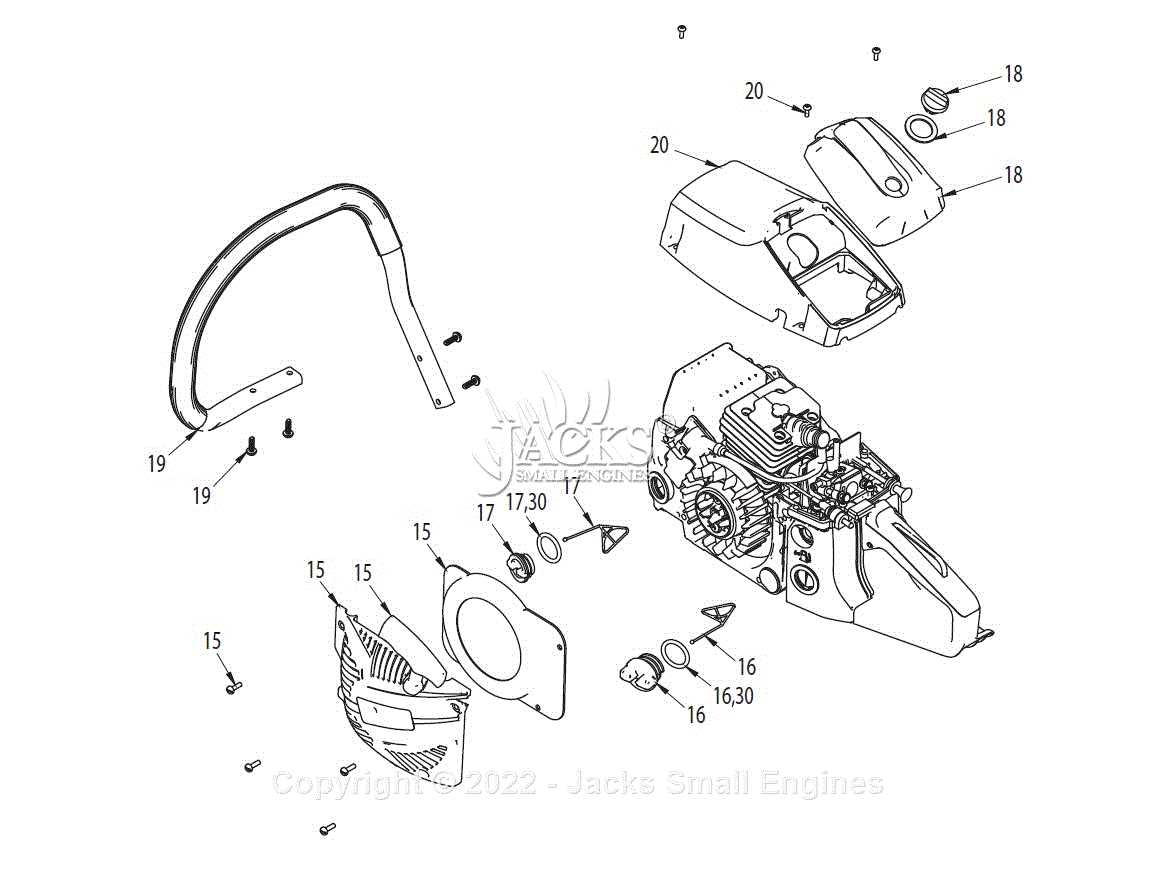

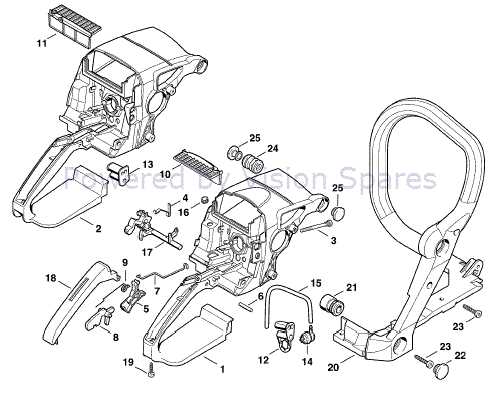

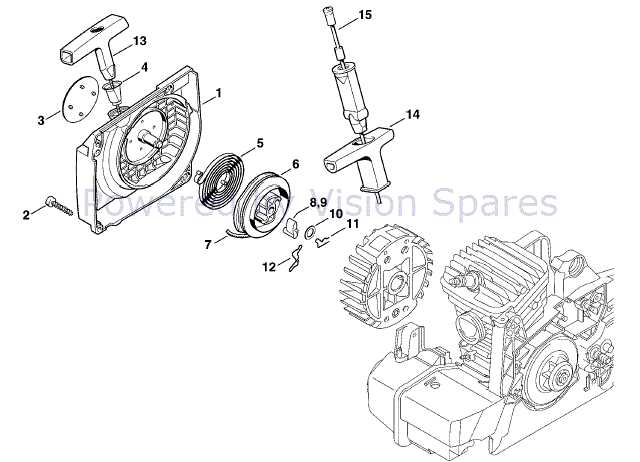

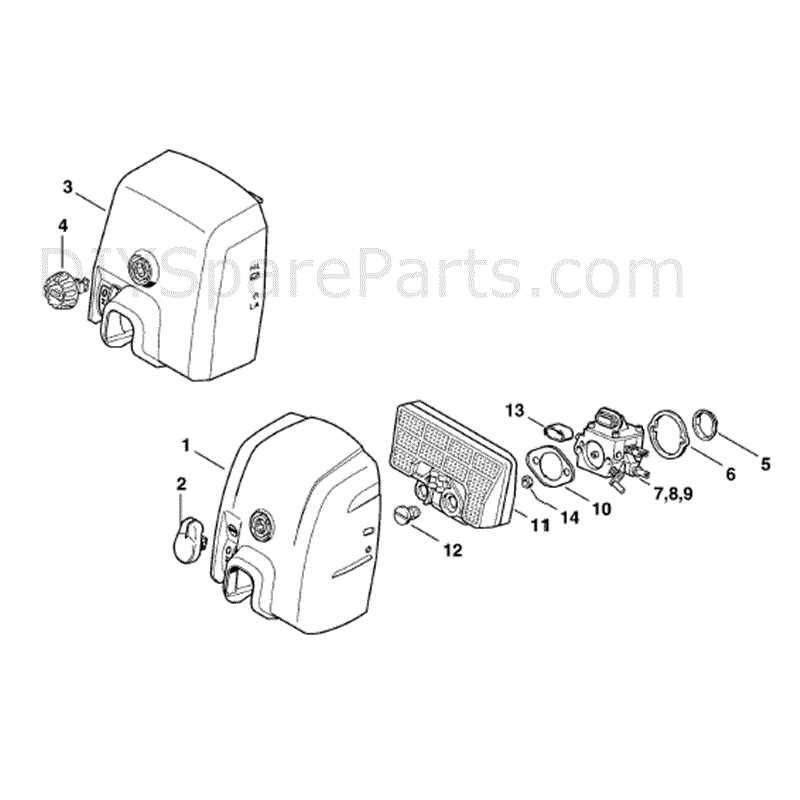

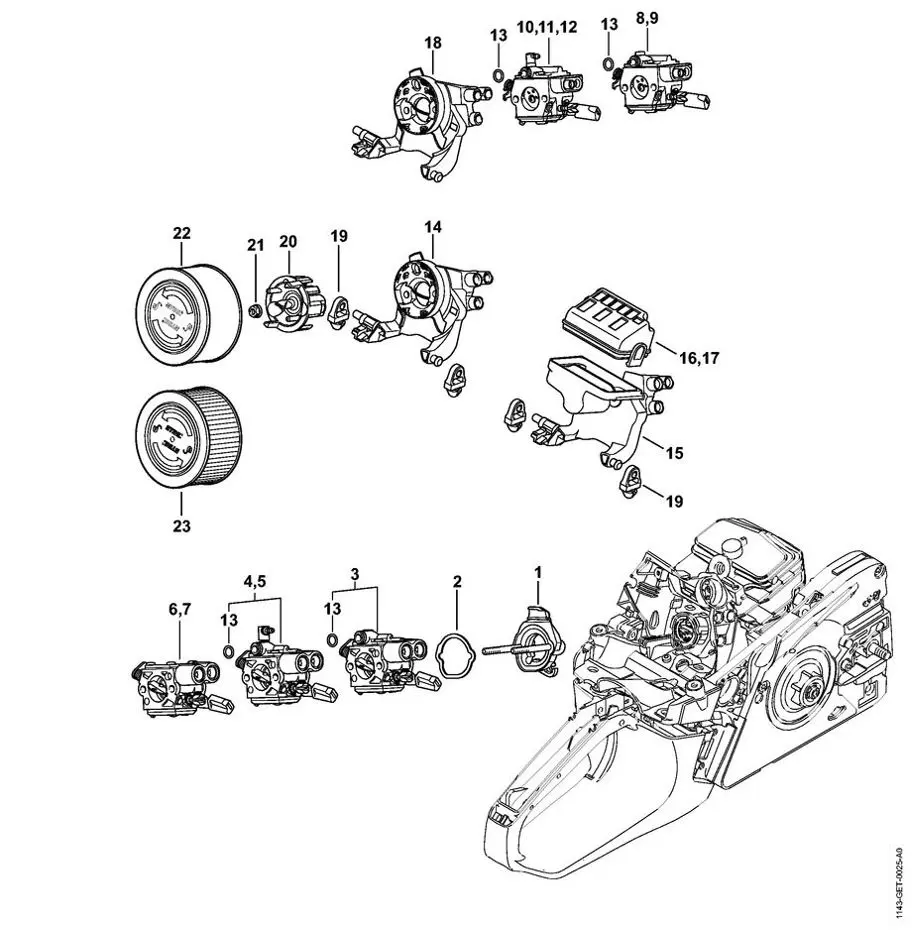

Schematic Diagram of Stihl MS290 Parts

When it comes to maintaining and repairing outdoor power equipment, comprehending the arrangement and function of individual elements is essential. A detailed overview of the internal layout can greatly enhance one’s ability to troubleshoot issues and perform effective maintenance.

Exploring the intricacies of a specific chainsaw model allows enthusiasts and professionals alike to grasp how each component interacts within the machine. This understanding not only aids in identifying potential problems but also supports the optimization of performance and longevity.

In this section, we will delve into the key elements that make up this widely used chainsaw. By analyzing the structure and relationships between various components, users will gain the ultimate insight into the workings of their equipment, ensuring a more efficient and effective operation.

Schematic Overview of Stihl MS290

This section provides a comprehensive exploration of the components that make up the machine, offering insights into their interconnections and functionalities. Understanding these elements is crucial for effective maintenance and troubleshooting.

| Component | Description |

|---|---|

| Engine | Powers the device and drives performance. |

| Bar | Guides the cutting chain for effective operation. |

| Chain | Engages with the bar to perform cutting tasks. |

| Fuel Tank | Holds the fuel necessary for operation. |

| Air Filter | Prevents debris from entering the engine. |

Each component plays a vital role in ensuring optimal performance, allowing users to delve into maintenance routines with confidence.

Understanding Chainsaw Components

Chainsaws are intricate machines designed for various cutting tasks, ranging from tree felling to limb removal. Each element of a chainsaw plays a vital role in its overall functionality, contributing to efficiency and safety. Familiarity with these components is essential for proper maintenance and effective operation.

Key elements of a chainsaw include the power unit, cutting assembly, and safety features. Understanding how these parts work together enables users to operate their tools more effectively and troubleshoot issues that may arise.

| Component | Description |

|---|---|

| Engine | Provides the necessary power to operate the chainsaw, typically a two-stroke gasoline engine. |

| Bar | The long metal strip that guides the chain and supports the cutting process. |

| Chain | A loop of linked metal segments that cuts through wood as it rotates around the bar. |

| Clutch | Engages and disengages the chain from the engine, allowing for safe starting and stopping. |

| Throttle | Controls the engine speed and, consequently, the cutting speed of the chain. |

| Safety Switch | Prevents accidental starts, ensuring the operator’s safety during use. |

By understanding these essential components, users can ensure that their equipment remains in optimal condition, thus enhancing performance and longevity.

Importance of Detailed Diagrams

Clear and comprehensive visual representations are crucial for understanding complex machinery and tools. They provide users with a roadmap, making it easier to identify components, comprehend their relationships, and ensure proper assembly or maintenance.

Enhanced Understanding

Thorough illustrations allow individuals to quickly grasp the inner workings of equipment. This enhanced understanding leads to more effective troubleshooting and repairs, ultimately reducing downtime and increasing productivity.

Accurate Maintenance

Having access to precise visuals ensures that all elements are accounted for during upkeep. This attention to detail minimizes the risk of errors and prolongs the lifespan of the equipment, ensuring optimal performance over time.

Key Parts of Stihl MS290

The efficient functioning of any tool relies on its essential components. Understanding these elements is crucial for effective maintenance and operation. Each part plays a vital role, contributing to the overall performance and longevity of the equipment.

Engine: The powerhouse of the tool, providing the necessary energy for operation. A well-maintained engine ensures optimal performance.

Guide Bar: This component guides the cutting chain, facilitating precision in cutting tasks. Its length and durability are significant factors in the tool’s effectiveness.

Chain: The cutting element that interacts directly with the material. Its sharpness and tension are key to achieving clean cuts.

Air Filter: A crucial part that keeps debris from entering the engine. Regular cleaning or replacement ensures proper airflow and efficiency.

Fuel System: Comprising the tank and lines, this system is essential for delivering fuel to the engine. Any leaks or blockages can affect performance significantly.

Clutch: This mechanism engages and disengages the chain from the engine, allowing for safer operation when not in use.

By familiarizing oneself with these critical components, users can enhance their understanding and care of the tool, ultimately prolonging its life and efficiency.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective assembly, maintenance, or repair of machinery. These illustrations provide a detailed view of each element and its relationships, enabling users to identify parts quickly and efficiently.

Identifying Key Elements

When examining the illustration, start by locating the main components. Each item is often labeled with a unique identifier or number, which corresponds to a list detailing specifications or descriptions. Familiarizing yourself with this labeling system enhances your ability to locate specific parts during your project.

Understanding the Layout

The arrangement of the elements in the visual guide usually follows a logical order, often mirroring the assembly sequence. Pay attention to how components interact with one another, as this will provide insight into how they function collectively. Additionally, note any directional arrows or lines that may indicate movement or connections, as these are crucial for a comprehensive understanding of the assembly.

Common Issues with MS290 Components

Understanding the frequent challenges associated with various components of outdoor power equipment can greatly enhance maintenance and performance. These issues often arise from wear and tear, improper usage, or environmental factors. Recognizing these problems early can prevent further damage and ensure the longevity of the equipment.

One prevalent concern involves the fuel delivery system, which can become clogged or damaged over time. A restricted fuel flow may lead to poor engine performance or difficulty starting. Regular inspection and cleaning of the fuel lines and filter are essential for optimal operation.

Another common problem pertains to the ignition components. Worn spark plugs or faulty ignition coils can result in misfires or failure to start. Ensuring these elements are in good condition is crucial for reliable ignition and overall functionality.

Chain tension issues are also frequent. A loose or overly tight chain can cause safety hazards and affect cutting efficiency. Proper adjustment and routine checks are vital to maintain the correct tension, ensuring smooth operation and reducing wear on both the chain and guide bar.

Lastly, air filtration plays a significant role in the performance of outdoor tools. A clogged air filter can restrict airflow, leading to inefficient combustion and decreased power. Regularly replacing or cleaning the air filter can help maintain optimal engine performance and prevent damage.

Maintenance Tips for Longevity

Proper care and routine upkeep are essential for ensuring that your equipment operates efficiently and lasts for many years. By following a few simple maintenance practices, you can significantly enhance performance and extend the lifespan of your tools. Regular attention to key components can prevent unnecessary wear and potential failures, ultimately saving time and money in the long run.

Start by keeping the machine clean and free from debris. Regularly inspect and remove any dirt or buildup that may accumulate during use. This not only prevents overheating but also allows for better functionality. Additionally, always check the fuel system and use high-quality fuel to avoid clogging and ensure optimal performance.

Lubrication is another crucial aspect of maintenance. Ensure all moving parts are well-greased to reduce friction and prevent premature wear. Pay close attention to bearings and chains, as they often require more frequent servicing. Furthermore, regularly inspect the air filter and replace it when necessary to maintain proper airflow and engine efficiency.

Lastly, be vigilant about monitoring any signs of wear or damage. Addressing small issues promptly can prevent them from escalating into more significant problems. By incorporating these practices into your routine, you will foster a longer and more reliable operational life for your equipment.

Ordering Replacement Parts Online

Acquiring new components for your machinery has never been easier thanks to the convenience of online shopping. This method allows users to access a vast selection of items from the comfort of their homes, ensuring they can find what they need swiftly.

When seeking replacements, consider the following steps:

- Identify the specific component required for your equipment.

- Research reputable online retailers that specialize in machinery supplies.

- Check for availability and compare prices to ensure you’re getting a good deal.

- Read customer reviews to gauge the reliability of the seller.

- Add the selected item to your cart and proceed to checkout, ensuring all details are correct.

By following these guidelines, you can make informed decisions and ultimately enhance the performance of your tools with ease.

Identifying Original vs. Imitation Parts

Understanding the distinctions between authentic and counterfeit components is crucial for maintaining equipment efficiency and longevity. By recognizing key features, users can ensure optimal performance and avoid potential hazards associated with inferior alternatives.

Visual Differences

Original components often showcase superior craftsmanship, including precise measurements and clean finishes. In contrast, imitation parts may exhibit uneven edges, poor quality materials, and inconsistent branding. Always examine logos and markings for authenticity.

Performance and Longevity

Genuine components are designed to meet specific standards, offering enhanced durability and reliability. Imitations may function initially but can lead to premature wear and failure, ultimately costing more in repairs. Investing in original items ensures the ultimate performance of your equipment.

Safety Considerations for Repairs

When undertaking any maintenance or restoration task, prioritizing safety is essential to prevent accidents and injuries. Proper preparation and the right tools can significantly reduce risks during the process. It is crucial to understand the potential hazards associated with handling mechanical equipment.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and sturdy footwear. These items act as a barrier against sharp objects and debris, ensuring that you remain safe while working.

Work Environment

Ensure that your workspace is clean and well-lit. Remove any unnecessary items that could pose a tripping hazard. Keeping your tools organized and within reach not only enhances efficiency but also minimizes distractions that can lead to mistakes.

Tools Required for Maintenance

Proper upkeep of your equipment is essential for optimal performance and longevity. To ensure that your machinery operates smoothly, having the right tools on hand is crucial. This section outlines the essential instruments needed for effective maintenance tasks.

Essential Tools

- Wrench set

- Screwdriver set

- Fuel container

- Oil can

- Cleaning brush

- Protective gloves

Additional Accessories

- Torque wrench

- Feeler gauge

- Spark plug wrench

- Chain sharpening tool

- Safety goggles

Having these tools ready not only simplifies the maintenance process but also enhances safety and efficiency. Regularly checking your equipment with the right instruments can prevent potential issues down the line.

Comparing MS290 with Other Models

This section explores the differences and similarities between various chainsaw models, highlighting their features, performance, and suitability for different tasks. By understanding these variations, users can make informed decisions when selecting a tool that meets their specific needs.

Performance and Power

When evaluating cutting power, some models stand out for their superior engine performance and efficiency. Factors such as torque, speed, and fuel consumption are essential when comparing these machines, as they directly affect usability and overall effectiveness in the field.

Ergonomics and Design

The design and comfort of a chainsaw can significantly impact user experience. Weight distribution, handle design, and vibration control are key elements that can enhance handling and reduce fatigue during prolonged use, making certain models more appealing for extensive jobs.

Community Resources for Stihl Owners

For enthusiasts and users of outdoor power tools, a strong network of resources is essential. These platforms not only provide valuable information but also foster connections among owners, enabling them to share experiences and solutions.

Online Forums and Discussion Groups

Participating in dedicated online forums can significantly enhance your knowledge. Members share tips, troubleshooting advice, and personal insights. Platforms like Reddit and specialized forums offer a wealth of experience from fellow users.

Local Workshops and Meetups

Attending workshops or local meetups is an excellent way to learn hands-on skills and connect with others. These gatherings often feature expert demonstrations and provide a chance to ask questions directly, enriching your understanding and maintenance techniques.