Complete Guide to Stihl 011 AVT Parts Diagram

In the world of outdoor power tools, having a clear grasp of your equipment’s structure is essential for optimal performance and maintenance. A comprehensive overview of essential components not only enhances your understanding but also empowers you to tackle repairs with confidence.

Every machine is a combination of various elements, each serving a specific purpose. Recognizing these elements allows users to identify potential issues and streamline the repair process. This knowledge is ultimately key to ensuring longevity and efficiency in operation.

Whether you’re a seasoned professional or a casual user, delving into the intricacies of your device can make a significant difference. Familiarity with each part equips you with the skills to address malfunctions and keep your equipment running smoothly for years to come.

Understanding Stihl 011 AVT Parts

When it comes to maintaining and repairing outdoor power tools, having a solid grasp of the components involved is essential. Each machine comprises various elements, each serving a specific function to ensure optimal performance. By familiarizing oneself with these constituents, users can better diagnose issues and execute repairs with confidence.

Key Components Overview

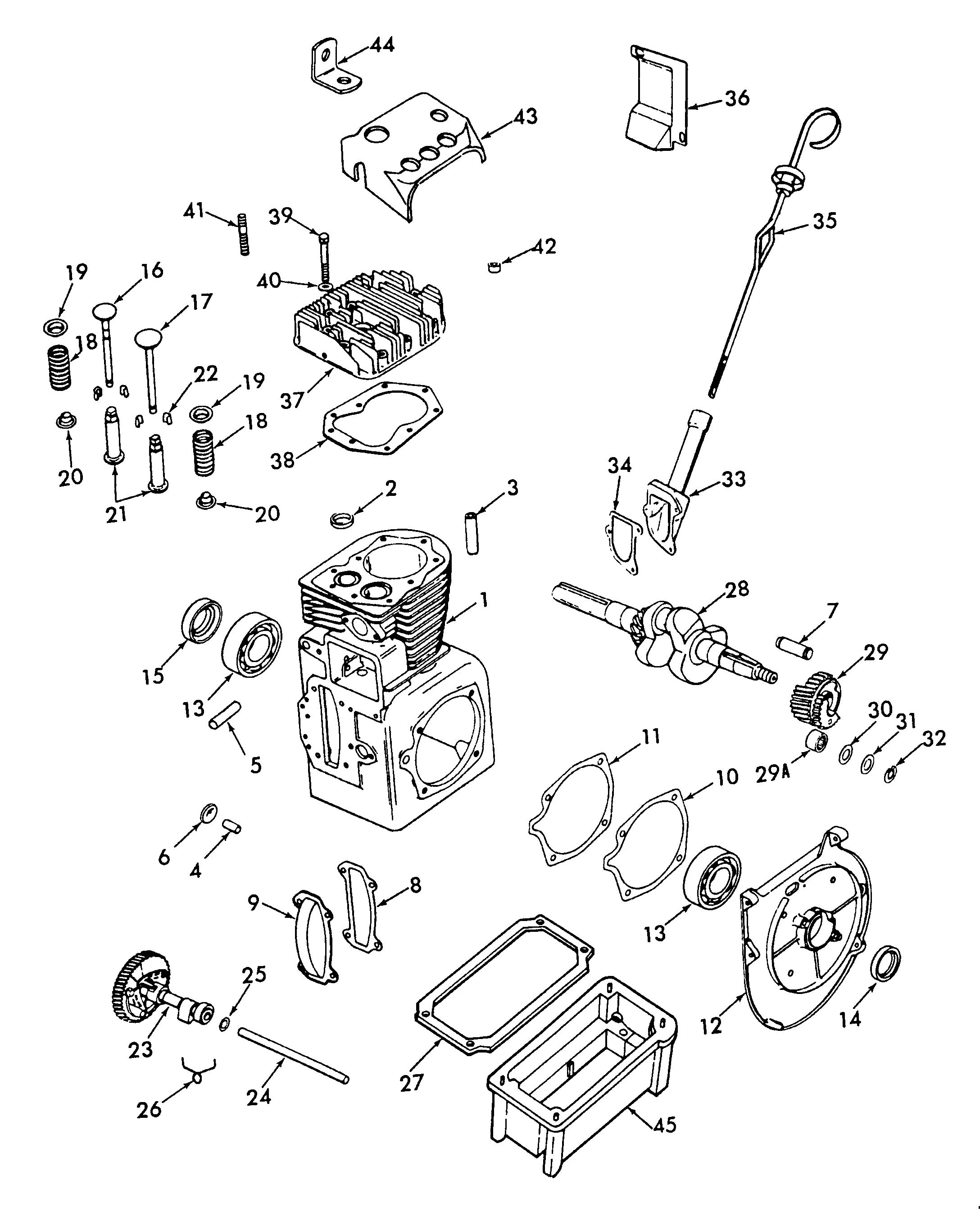

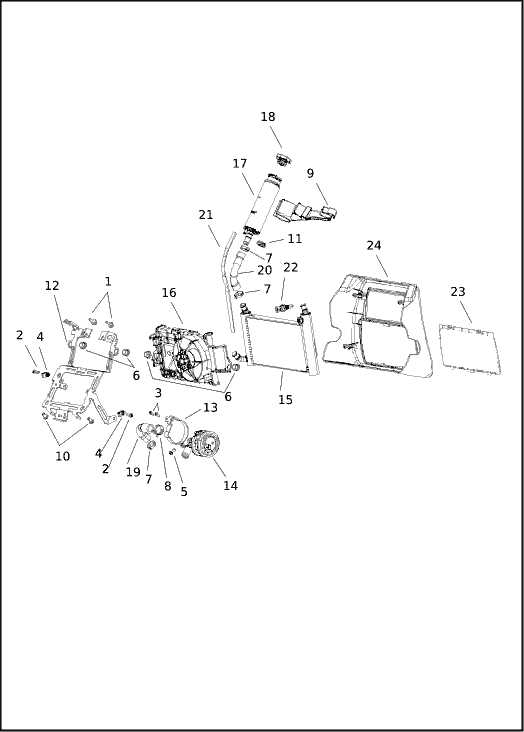

Every piece of equipment includes critical sections such as the engine, cutting mechanism, and ignition system. The engine is the heart of the machine, converting fuel into energy. The cutting mechanism, often the most visible part, is responsible for executing the primary task of the tool, while the ignition system initiates the engine’s operation. Understanding how these components interact is vital for effective troubleshooting.

Maintenance Tips

Regular upkeep is crucial for prolonging the life of any outdoor device. This includes checking filters, replacing worn-out items, and ensuring that moving parts are lubricated. Neglecting these practices can lead to decreased efficiency and increased wear, potentially resulting in costly repairs. By staying proactive with maintenance, users can ensure that their equipment runs smoothly for years to come.

Overview of Stihl 011 AVT Model

The model in question represents a remarkable blend of innovation and functionality, catering to both casual users and professionals alike. Its design reflects a commitment to durability and ease of use, making it a favored choice for various tasks.

Key features include an efficient engine that delivers powerful performance while maintaining fuel economy. The ergonomic design ensures comfort during extended use, reducing user fatigue. Moreover, advanced vibration dampening technology enhances the overall experience, allowing for precise control and improved handling.

In terms of maintenance, this unit offers straightforward accessibility to essential components, promoting hassle-free upkeep. Users appreciate the reliability and longevity that this model provides, making it an ultimate tool for outdoor enthusiasts and professionals seeking quality performance.

Key Features of the Chainsaw

Chainsaws are powerful tools designed for cutting wood with efficiency and precision. Understanding their main attributes can help users make informed decisions about their selection and usage.

- Engine Power: A robust engine provides the necessary strength for heavy-duty tasks.

- Bar Length: Different lengths accommodate various cutting needs, from small branches to large trees.

- Weight: A lighter design enhances maneuverability, making it easier to handle during extended use.

- Safety Features: Built-in safeguards, such as chain brakes and low kickback chains, enhance user protection.

- Fuel Efficiency: Modern models are designed to consume less fuel while maintaining performance.

Each feature contributes to the ultimate effectiveness and user experience, making it essential to choose a model that aligns with specific tasks.

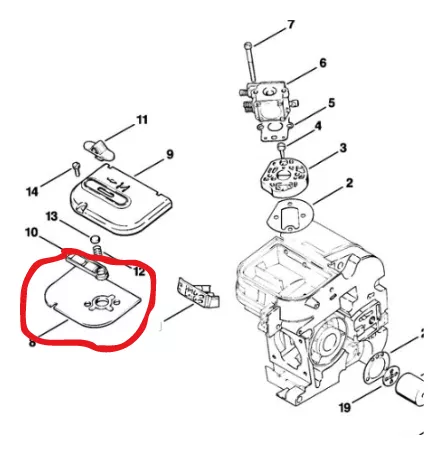

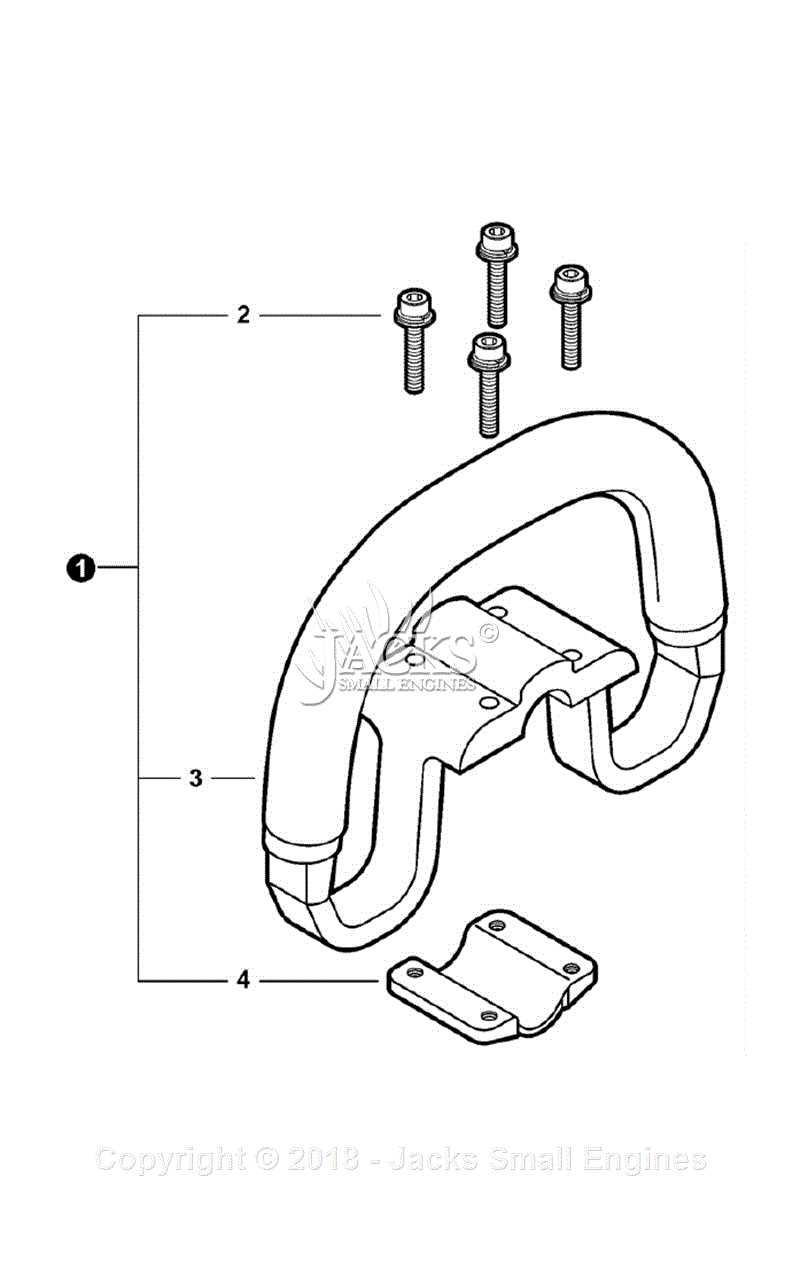

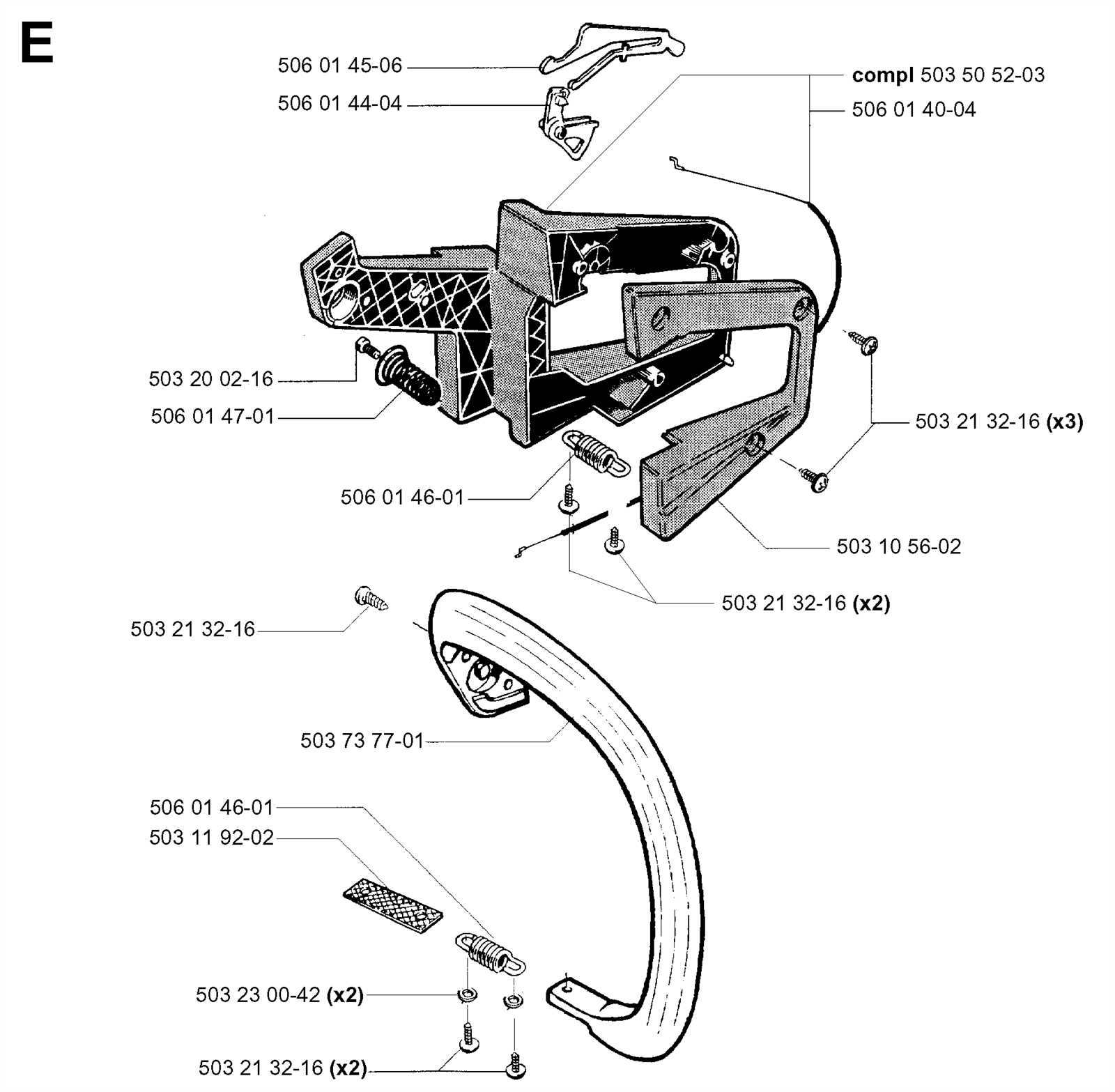

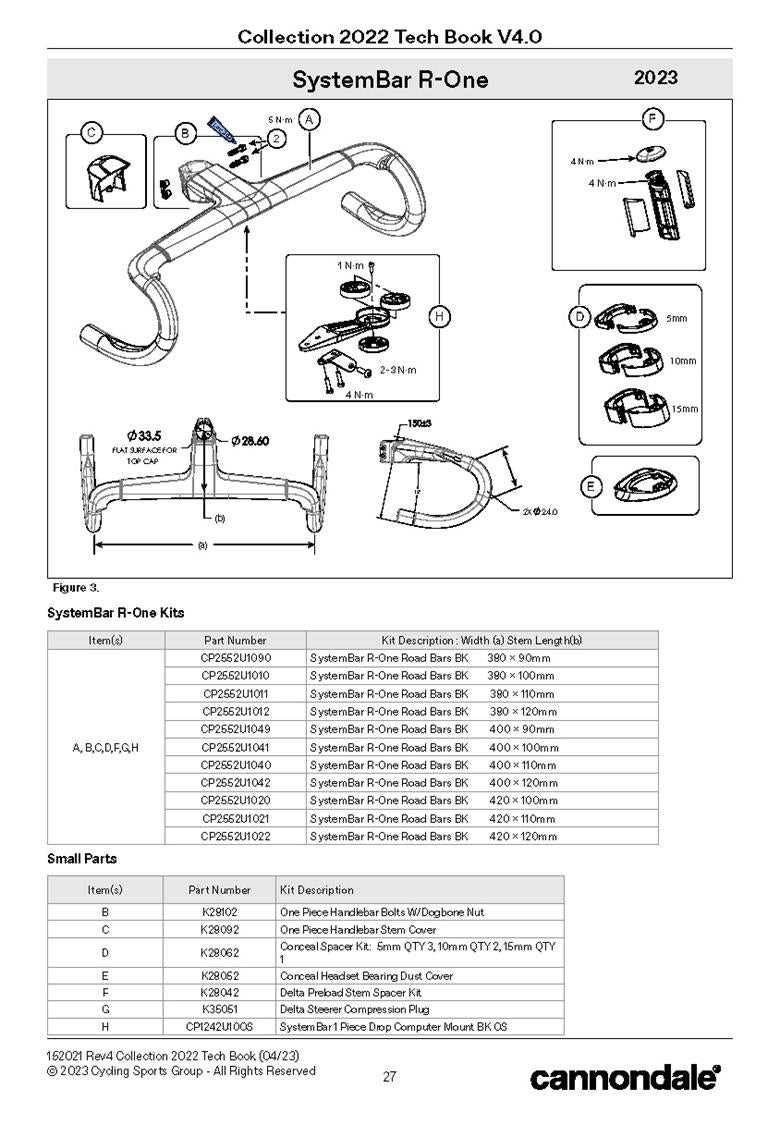

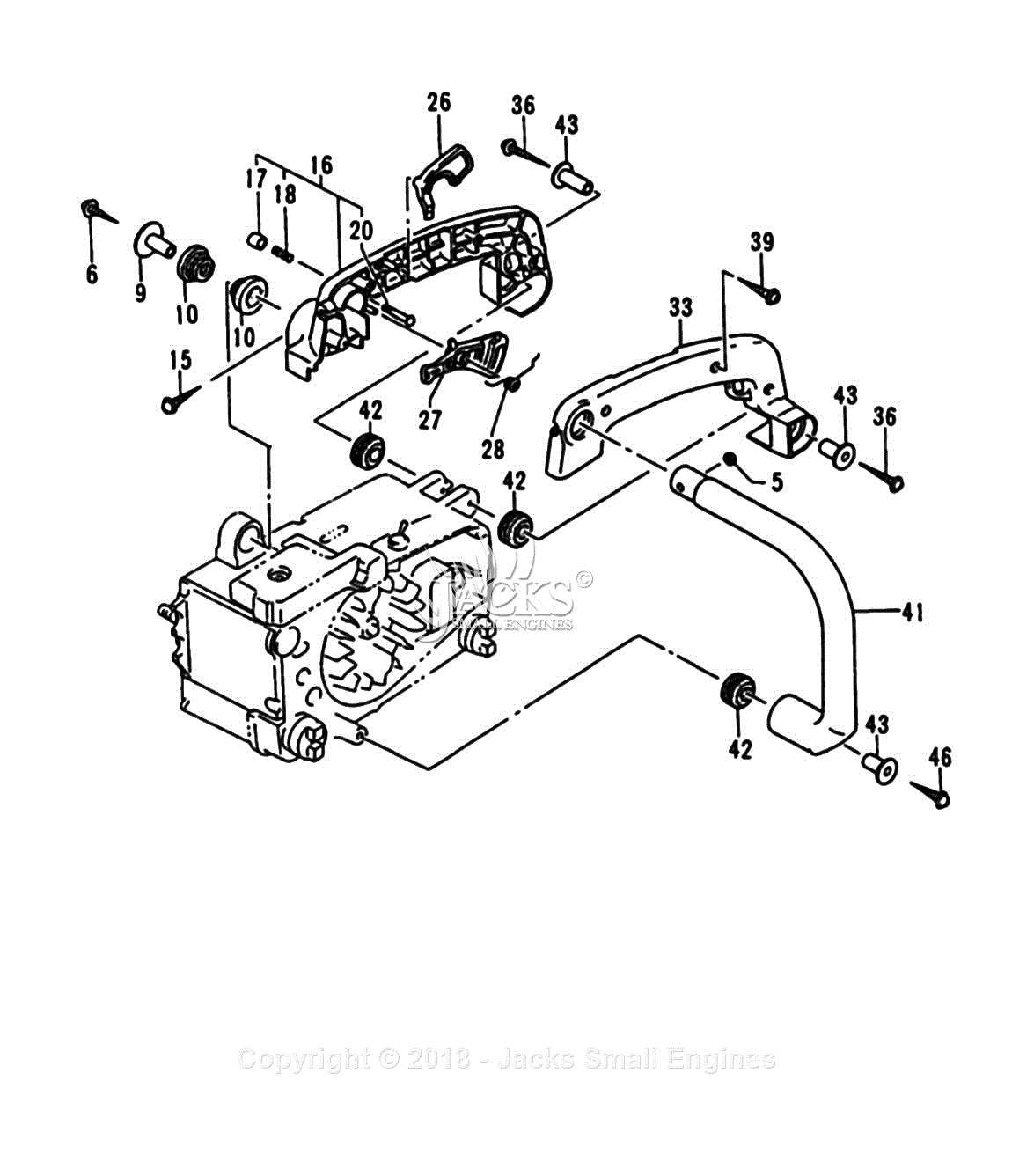

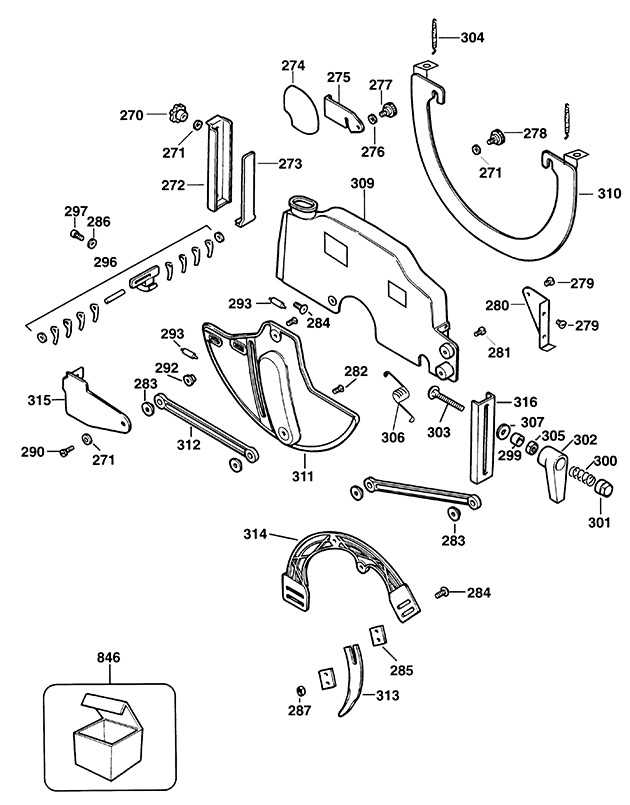

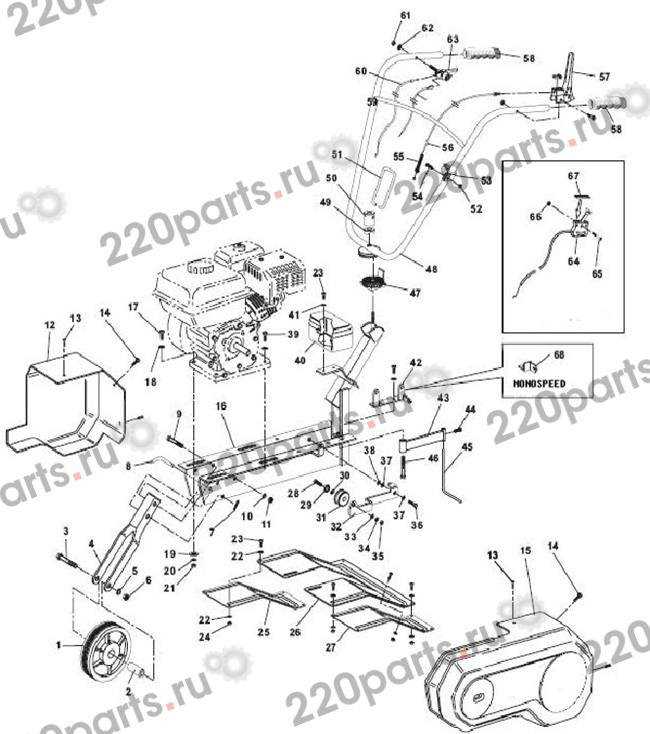

Importance of Parts Diagrams

Understanding the intricate components of machinery is crucial for efficient maintenance and repair. Visual representations serve as valuable tools that facilitate a clearer comprehension of individual elements and their relationships within the overall assembly. This knowledge ultimately enhances the longevity and performance of equipment.

Enhanced Maintenance

Having a visual reference allows users to quickly identify worn or damaged components, streamlining the maintenance process. This can significantly reduce downtime and improve operational efficiency.

Facilitated Repairs

When repairs are necessary, detailed illustrations guide users through disassembly and reassembly, minimizing the risk of error. This approach not only saves time but also ensures that the equipment functions optimally after service.

Where to Find Parts Diagrams

Locating detailed schematics for machinery can be essential for maintenance and repairs. These visual aids provide invaluable insights into the components and assembly of equipment, enabling users to identify the necessary elements for their projects. Understanding where to access these resources can significantly enhance the repair process and ensure that the correct items are sourced efficiently.

Online Resources

The internet is a treasure trove of information, making it one of the most convenient places to search for schematics. Various manufacturer websites offer downloadable resources for their products, including user manuals and visual breakdowns. Additionally, numerous forums and community groups dedicated to machinery often share links to these resources, providing a collaborative environment for enthusiasts and professionals alike.

Local Dealers and Service Centers

Another reliable source for obtaining detailed schematics is local dealerships and authorized service centers. These establishments not only provide access to official resources but also offer expertise from trained professionals who can assist in interpreting the information. Building a relationship with a local dealer can yield ongoing support and insight for future repairs and maintenance needs.

Commonly Replaced Components

In any machinery, certain elements tend to wear out more quickly due to regular use and stress. Understanding these components can help in maintaining optimal performance and extending the lifespan of the equipment.

Critical Elements

Among the vital parts often replaced are the ignition systems, which are essential for reliable operation. Regular checks and timely replacements can prevent significant downtimes and ensure smooth functionality.

Wear and Tear Components

Additionally, components like fuel lines and air filters are subject to deterioration over time. Maintaining these parts not only enhances efficiency but also contributes to a cleaner and safer working environment. Proper care of these elements is crucial for overall equipment health.

Tools Needed for Repairs

When undertaking maintenance or fixing machinery, having the right equipment is crucial for efficiency and effectiveness. Proper tools not only facilitate the repair process but also ensure that tasks are completed safely and accurately.

- Screwdrivers: Essential for loosening and tightening screws, a variety of sizes and types (flathead and Phillips) are necessary.

- Wrenches: Both adjustable and fixed wrenches are important for managing nuts and bolts of various sizes.

- Pliers: Useful for gripping, twisting, and cutting wires or small components, pliers come in handy for various tasks.

- Socket Set: A comprehensive socket set helps tackle a range of fasteners with ease and efficiency.

- Torque Wrench: This tool is vital for applying a specific torque to fasteners, ensuring proper assembly and preventing damage.

Additionally, consider these items for enhanced functionality:

- Multimeter: For checking electrical components and ensuring proper voltage levels.

- Cleaning Brushes: To remove debris and dirt from parts, aiding in better performance.

- Safety Gear: Always prioritize safety by wearing gloves, goggles, and other protective equipment during repairs.

Gathering these essential tools will make any repair task smoother and more manageable, leading to better outcomes and extended equipment lifespan.

Maintenance Tips for Longevity

Ensuring the extended life of your equipment requires regular care and attention. By following essential maintenance practices, you can optimize performance and prevent premature wear and tear. A consistent upkeep routine not only enhances efficiency but also reduces the likelihood of unexpected breakdowns.

Regular Cleaning

Keeping your machinery clean is crucial. After each use, remove debris and residue to prevent buildup. This simple act minimizes the risk of corrosion and promotes smoother operation.

Periodic Inspections

Conducting regular inspections allows you to identify potential issues before they escalate. Check for wear on components and replace any damaged parts promptly. This proactive approach helps maintain peak functionality and safety.

Identifying OEM vs. Aftermarket Parts

Understanding the distinction between original equipment manufacturer components and those produced by third-party vendors is crucial for maintaining optimal performance and longevity of your machinery. Each type has its own advantages and disadvantages that can affect functionality, cost, and reliability.

OEM components are designed specifically for your equipment, ensuring compatibility and adherence to manufacturer standards. They often come with warranties, providing peace of mind. In contrast, aftermarket options can offer cost savings and variety, but their quality may vary significantly, making it essential to research and choose wisely.

When selecting between these options, consider factors such as performance, budget, and intended use. Delving into reviews and manufacturer recommendations can help in making an informed decision, ultimately leading to better maintenance outcomes.

Step-by-Step Repair Guide

This guide provides a comprehensive approach to effectively addressing common issues encountered in machinery maintenance. By following systematic instructions, you can enhance your understanding and skills in the repair process.

Step 1: Begin by gathering all necessary tools and components to ensure a smooth workflow. Having everything at hand will minimize interruptions.

Step 2: Carefully disassemble the unit, taking note of each part’s location. It’s essential to document the arrangement for easier reassembly.

Step 3: Inspect each component for wear and damage. Identify parts that require replacement or repair, ensuring you know the specifications for each item.

Step 4: Clean all accessible areas to remove debris and old lubricants. This step is vital for maintaining optimal performance.

Step 5: Replace damaged components with new ones, following the original layout you documented earlier. Ensure each part is securely fitted.

Step 6: Reassemble the unit, paying close attention to the order of components. Double-check connections to avoid issues during operation.

Step 7: Conduct a thorough test after reassembly. Observe the machinery during operation to ensure everything functions as intended.

Step 8: Finally, document any changes or replacements made for future reference. Keeping a record will aid in upcoming maintenance tasks.

Troubleshooting Common Issues

This section focuses on identifying and resolving frequent problems that may arise during operation. Understanding these challenges can enhance performance and prolong the lifespan of the equipment.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Engine won’t start | Empty fuel tank, clogged filter, faulty spark plug | Refill fuel, clean or replace filter, check and replace spark plug |

| Loss of power | Dirty air filter, improper fuel mixture | Clean or replace air filter, adjust fuel mix |

| Excessive vibration | Loose components, unbalanced cutting tool | Tighten screws, balance or replace cutting tool |

| Smoke emission | Overfilled oil, improper fuel type | Drain excess oil, use correct fuel type |

Safety Precautions While Repairing

When engaging in maintenance or repair work, it is crucial to prioritize safety to prevent accidents and injuries. Understanding the proper protocols can make the process more efficient and secure, ensuring that both the individual and the equipment remain unharmed during the procedure.

Always wear appropriate personal protective equipment, including gloves, goggles, and sturdy footwear. This gear helps protect against potential hazards such as flying debris or sharp components. Additionally, ensure that the workspace is clean and organized to minimize risks associated with clutter.

Before starting any repair tasks, disconnect the power source to eliminate the chance of accidental activation. Familiarize yourself with the equipment’s manual to understand its specific features and safety recommendations. Take your time and avoid rushing through the repairs, as haste can lead to mistakes.

Furthermore, never work alone when dealing with complex machinery. Having a partner can provide assistance in case of emergencies and enhance overall safety. Lastly, ensure proper ventilation if working with substances that emit fumes, maintaining a safe environment throughout the repair process.

Resources for Further Information

Accessing detailed materials related to equipment components can significantly enhance your understanding and maintenance capabilities. Whether you are a professional or an enthusiast, utilizing reliable sources ensures you have the necessary information for effective repairs and enhancements.

Online Communities and Forums

Engaging with online groups can provide valuable insights and advice from fellow users. These platforms often host discussions about troubleshooting, modifications, and best practices, fostering a community of shared knowledge.

Manufacturer Websites and Support

Official manufacturer websites are an excellent starting point for obtaining documentation, including user manuals and service guides. These resources typically offer comprehensive information about specifications and maintenance procedures.

| Resource Type | Examples |

|---|---|

| Online Communities | Reddit, Facebook Groups, Specialty Forums |

| Manufacturer Support | Official Websites, Customer Service, Technical Support |

| Documentation Repositories | Online Libraries, PDF Archives, Instructional Videos |