Stihl 020 AV Parts Diagram Guide

In the world of outdoor power equipment, comprehending the intricate details of your machine can significantly enhance its performance and longevity. Knowing how each element interacts not only aids in maintenance but also empowers users to troubleshoot issues effectively. This section is dedicated to unraveling the various components of a specific model, providing clarity on their arrangement and functionality.

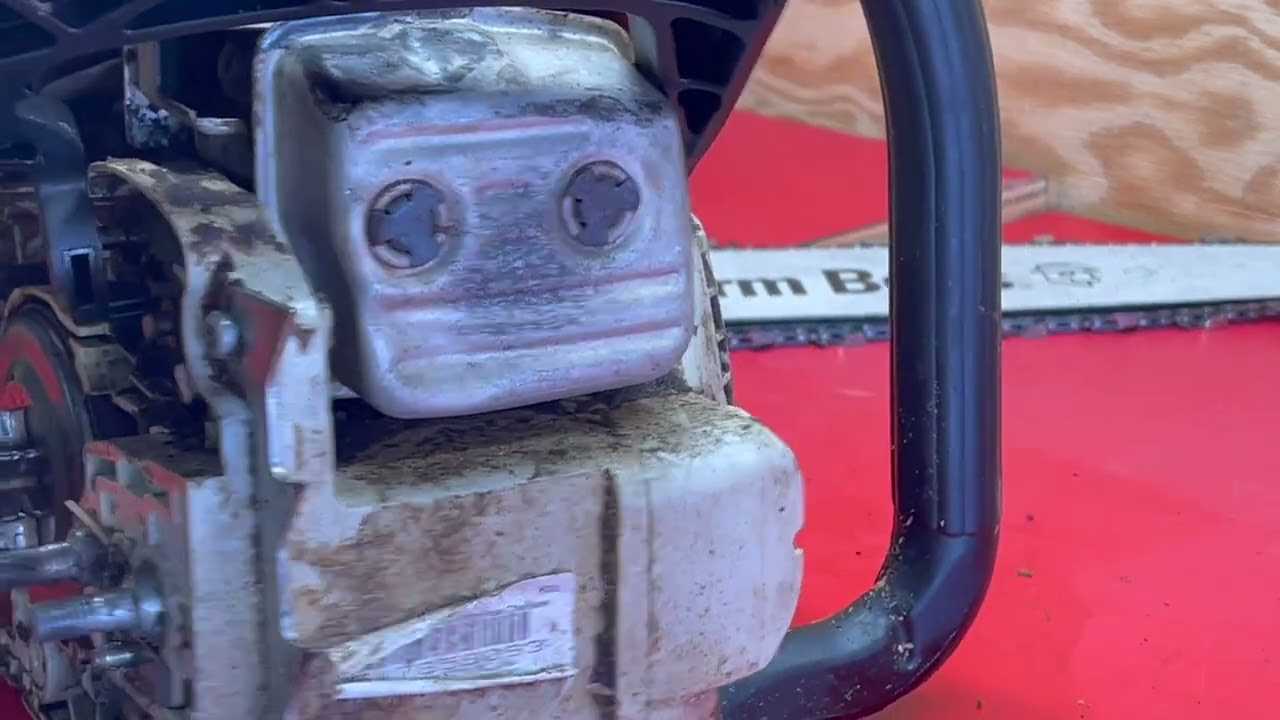

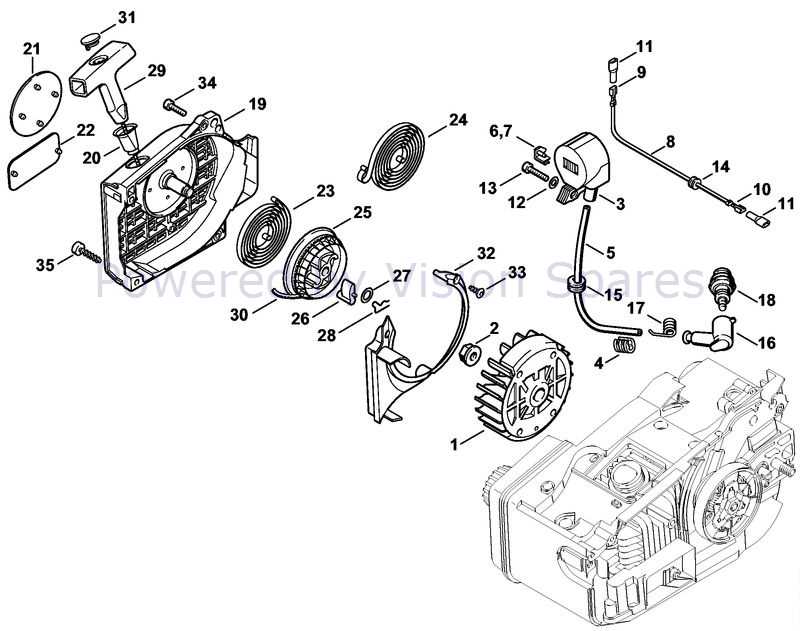

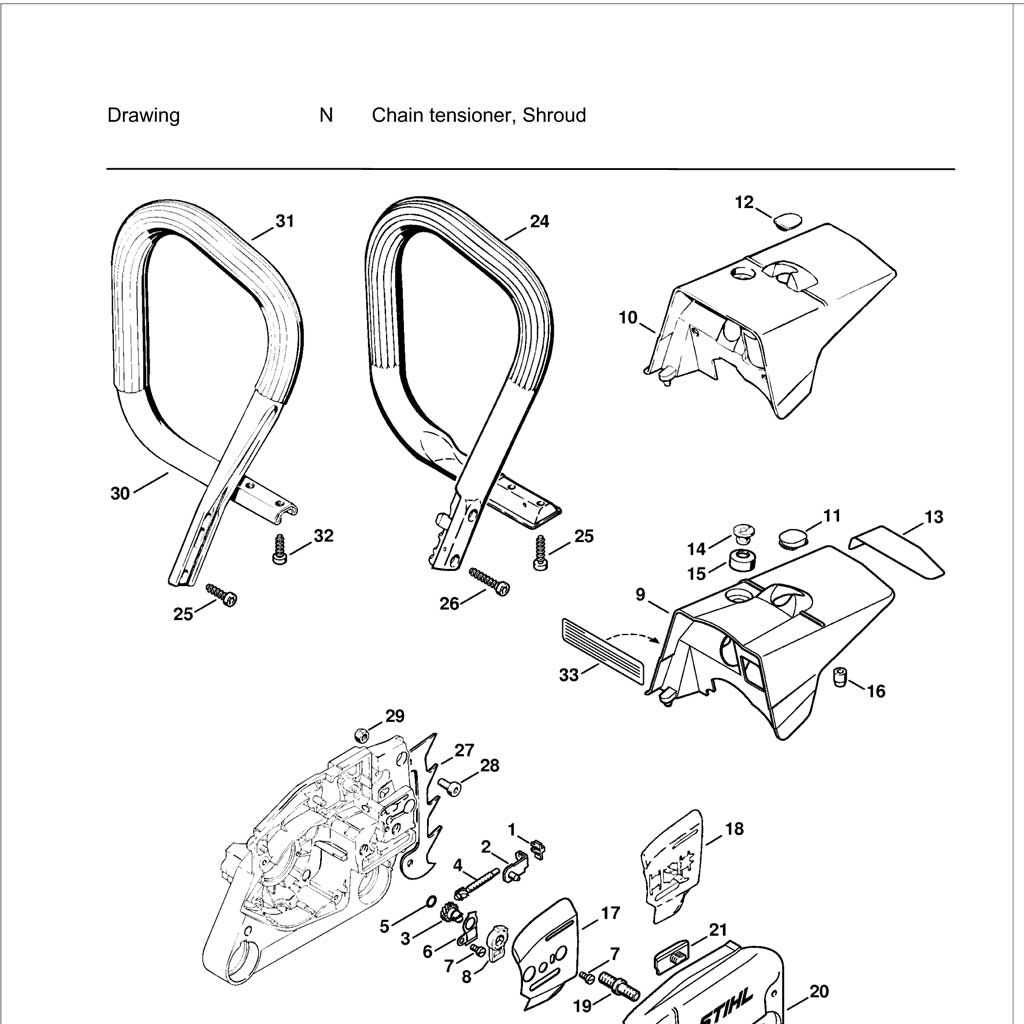

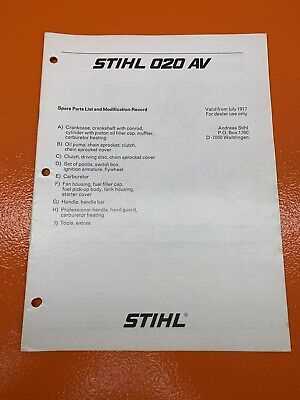

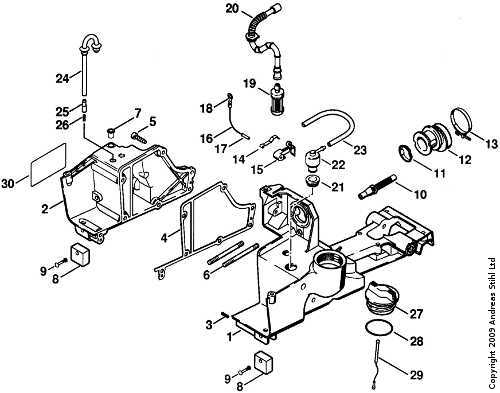

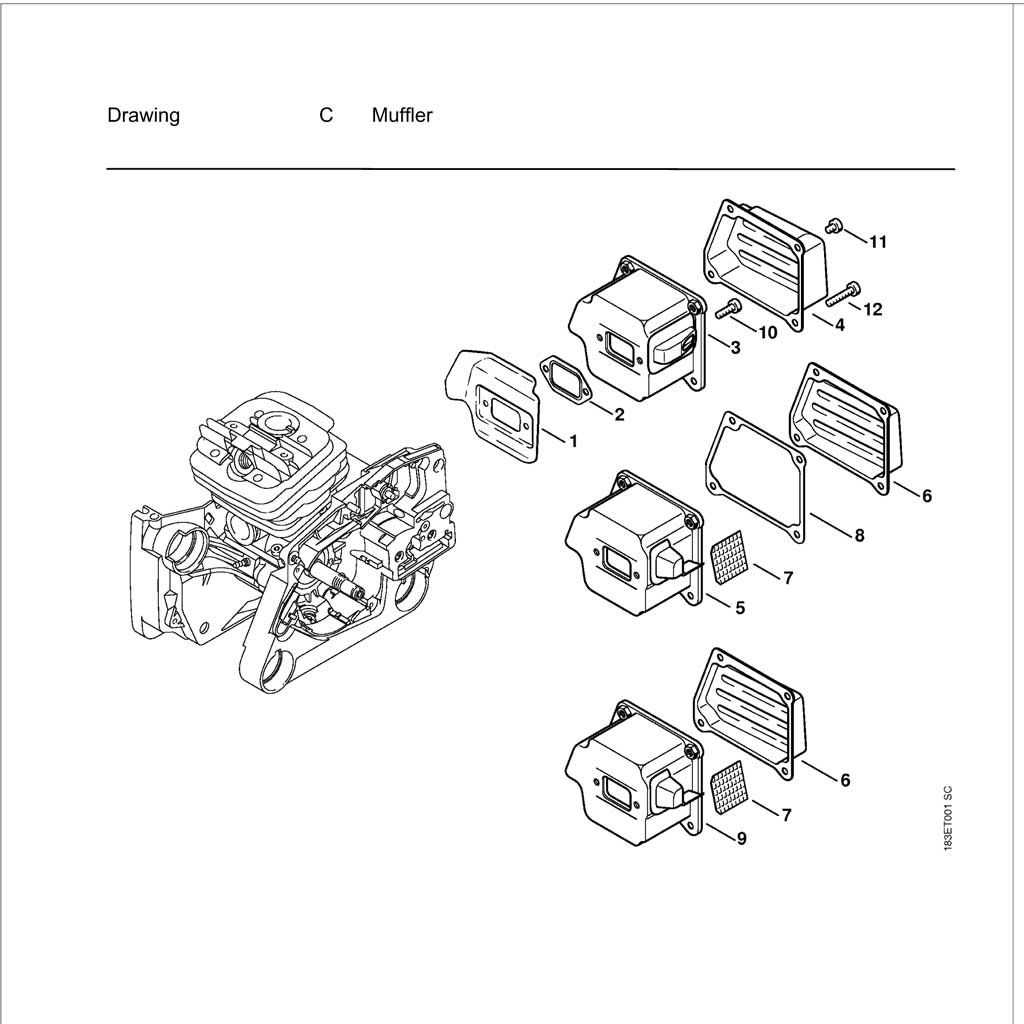

Visual aids play a crucial role in this understanding, allowing users to identify each piece and its respective place within the assembly. By examining the layout of these elements, operators can gain insights into proper assembly, disassembly, and the potential need for replacements. A clear visual representation helps in grasping the complex relationships between parts, ensuring a smoother operational experience.

Moreover, being well-versed in the configuration of your equipment fosters confidence when making repairs or modifications. With this knowledge, one can approach any task with a sense of assurance, ultimately leading to improved efficiency in the field. Whether you’re a seasoned professional or a hobbyist, familiarizing yourself with these intricacies is an invaluable step towards mastery of your tools.

Understanding Stihl 020 AV Parts

This section aims to provide insights into the essential components of a specific model, focusing on their roles and significance. Each element plays a vital part in ensuring optimal functionality and performance, contributing to the overall efficiency of the machine.

Key Components: Identifying the main elements helps users comprehend how they interact with each other. From the engine assembly to the cutting mechanism, understanding these features can enhance maintenance practices.

Maintenance Tips: Regular upkeep of these critical parts is necessary for longevity. Familiarizing oneself with each component will facilitate better care and timely replacements when needed.

Key Components of the Stihl 020

This section explores the essential elements that contribute to the functionality and efficiency of this well-known chainsaw model. Understanding these components can enhance maintenance practices and improve overall performance.

Essential Features

- Engine Assembly

- Fuel System

- Ignition System

- Chain Mechanism

- Bar and Chain Assembly

Maintenance Considerations

- Regularly check the condition of the air filter.

- Ensure the fuel lines are free of leaks and blockages.

- Inspect the spark plug for wear and proper gap.

- Lubricate the chain to minimize wear.

- Monitor tension and sharpness of the cutting chain.

By familiarizing oneself with these vital components, users can ensure a longer lifespan and optimal performance of the equipment.

Importance of a Parts Diagram

Understanding the various components of any machinery is crucial for efficient maintenance and repair. A visual representation of these elements can greatly enhance the user’s ability to identify, troubleshoot, and replace specific parts effectively. This clarity not only saves time but also prevents potential damage caused by incorrect assembly.

Moreover, having access to such visual guides can empower users to delve into repairs with confidence, reducing reliance on professional services. It serves as an ultimate tool for both novice and experienced individuals, ensuring that every element is accounted for during any maintenance task.

Additionally, these illustrations often include important notes and specifications, providing deeper insights into the functionality and compatibility of each component. This information is invaluable in ensuring that repairs are performed correctly and safely.

How to Read Parts Diagrams

Understanding the visual representations of components is essential for effective maintenance and repair. These illustrations serve as a roadmap, guiding you through the various elements and their interconnections. Familiarity with these visuals can greatly enhance your ability to identify specific items and understand how they function together.

When approaching these illustrations, it is crucial to pay attention to the following key features:

| Feature | Description |

|---|---|

| Labels | Each element typically has a corresponding label, which may include a part number or description to facilitate identification. |

| Numbering System | Many visuals use a numbering scheme to correlate with a list of items, making it easier to locate and order necessary components. |

| Groupings | Components are often organized into sections, representing assemblies or related parts, helping to streamline understanding of their function. |

| Orientation | Understanding the orientation of parts can provide insights into assembly and disassembly processes, highlighting how pieces fit together. |

By keeping these elements in mind, you will be better equipped to navigate the intricate details of component visuals and effectively address any repair or maintenance tasks.

Common Repairs for Stihl 020 AV

Regular maintenance and occasional repairs are essential for ensuring optimal performance and longevity of outdoor power equipment. Understanding the most frequent issues can help users address them effectively, minimizing downtime and enhancing reliability. This section highlights some of the typical repairs that may be needed for effective operation.

Fuel System Issues

One common problem arises from fuel system malfunctions, which can lead to difficulties in starting or running the equipment smoothly. Clogged fuel filters, damaged fuel lines, or issues with the carburetor often require attention. Regular inspection and cleaning can prevent these issues, ensuring a steady flow of fuel and maintaining engine performance.

Ignition Problems

Another frequent repair involves ignition system failures. If the engine fails to start or runs inconsistently, it may be due to a faulty spark plug or ignition coil. Replacing these components is often straightforward and can significantly improve starting reliability and overall performance. Regularly checking these parts can help avoid unexpected breakdowns.

Where to Find Replacement Parts

Locating components for your machinery can be a straightforward task if you know where to look. Various sources offer the necessary items to keep your equipment running smoothly. Understanding the options available will help you make informed decisions and ensure you have the right items for your needs.

Authorized Dealers

One of the most reliable sources for acquiring quality components is through authorized dealers. These establishments are recognized for their commitment to genuine products and typically provide expert assistance. Here are some advantages of choosing authorized retailers:

| Advantage | Description |

|---|---|

| Genuine Quality | Products are guaranteed to meet manufacturer standards. |

| Expert Advice | Staff members often possess extensive knowledge to guide you. |

| Warranty Support | Purchasing through authorized channels often includes warranty coverage. |

Online Marketplaces

For those who prefer shopping from home, online marketplaces offer a vast selection of components. Various platforms allow users to compare prices and find specific items. However, it’s essential to check seller ratings and product reviews to ensure quality and reliability.

Maintenance Tips for Longevity

Ensuring the extended life of your equipment requires regular care and attention. Implementing a consistent maintenance routine not only enhances performance but also prevents costly repairs down the line.

Start by regularly inspecting all components for wear and tear. Clean the machine after each use to remove debris that could cause damage over time. Pay particular attention to the air filter and fuel system, as these can significantly impact efficiency.

Additionally, keep all moving parts lubricated to reduce friction and wear. Using the right type of oil and ensuring proper levels is crucial for optimal functioning. Lastly, follow the manufacturer’s guidelines for replacing essential parts to maintain peak performance.

Identifying Faulty Parts Easily

Recognizing malfunctioning components in machinery is crucial for maintaining optimal performance and extending lifespan. A systematic approach can simplify this process, ensuring that issues are identified swiftly and accurately.

Common Indicators of Malfunction

- Unusual noises during operation

- Reduced efficiency or power output

- Frequent stalling or failure to start

- Visible wear or damage on critical elements

Steps for Assessment

- Perform a visual inspection to spot any obvious damage.

- Listen for irregular sounds that could indicate issues.

- Test functionality under controlled conditions to evaluate performance.

- Consult technical resources to verify specifications and tolerances.

Comparison with Other Stihl Models

This section explores the differences and similarities between various chainsaw models from a renowned manufacturer, highlighting their features, performance, and design. By examining these models, we can gain insights into how they cater to different user needs and preferences.

Additionally, ergonomic design and vibration reduction technology vary across models, influencing comfort during prolonged use. Users often find that certain chainsaws are better suited for professional use, while others may appeal to homeowners for occasional projects. Analyzing these aspects helps in determining which model stands out as the ultimate choice for different scenarios.

Tools Needed for Repairs

When undertaking maintenance tasks, having the right instruments is essential for efficiency and effectiveness. The appropriate equipment not only simplifies the process but also ensures that the job is completed correctly, minimizing the risk of damage. Below is a list of essential tools that will aid in the repair process.

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening various bolts and nuts. |

| Screwdriver Set | Necessary for removing and securing screws in different sizes. |

| Pliers | Useful for gripping, twisting, and cutting wires or small parts. |

| Torque Wrench | Ensures that bolts are tightened to the manufacturer’s specifications. |

| File Set | Ideal for smoothing rough edges and surfaces during repairs. |

| Cleaning Brush | Helps to remove debris and dirt from components before inspection. |

| Safety Gear | Includes gloves and goggles to protect against potential hazards. |

Equipping yourself with these tools will greatly enhance your ability to perform repairs efficiently and safely. Having a well-stocked toolkit is a crucial step in ensuring a successful maintenance experience.

Ordering Genuine Stihl Parts Online

When it comes to maintaining your outdoor equipment, securing authentic components is crucial for optimal performance and longevity. Purchasing these items through reliable online platforms can simplify the process, ensuring you receive high-quality replacements tailored for your machine.

| Steps | Description |

|---|---|

| Research | Identify the specific components you need and verify their compatibility with your equipment. |

| Choose a Supplier | Select a reputable online retailer known for offering genuine merchandise. |

| Verify Authenticity | Check for authenticity guarantees or customer reviews to ensure quality. |

| Place Your Order | Add the desired items to your cart and proceed to checkout. |

| Track Shipment | Use tracking options to monitor the delivery status of your order. |

By following these steps, you can delve into a hassle-free shopping experience, ensuring your machinery runs at its ultimate best.

DIY Repair vs. Professional Service

When it comes to fixing equipment, individuals often face the choice between tackling repairs themselves or seeking assistance from experts. Each approach has its own set of advantages and challenges, influencing the decision-making process based on factors like cost, time, and technical skill.

Advantages of DIY Repair

Taking the do-it-yourself route can be rewarding. It allows for greater control over the repair process, often resulting in cost savings. Additionally, acquiring hands-on experience can enhance one’s understanding of the machinery and promote self-sufficiency.

Benefits of Professional Service

On the other hand, relying on professionals ensures that repairs are conducted with expertise and efficiency. Specialists bring a wealth of experience and access to specialized tools, reducing the risk of errors and potentially extending the lifespan of the equipment. This approach can save time and provide peace of mind.

Frequently Asked Questions about Parts

This section addresses common inquiries regarding components and their replacements for specific equipment. Understanding these elements is crucial for maintenance and efficiency, ensuring that users have the necessary knowledge to care for their tools effectively.

Common Inquiries

- What are the signs that a component needs to be replaced?

- How can I identify the correct replacement for my equipment?

- Are aftermarket options as reliable as original ones?

- What is the average lifespan of major components?

Replacement Process

- Always consult the user manual for guidance.

- Gather necessary tools before starting the replacement.

- Ensure the equipment is powered off and cooled down.

- Follow safety precautions during the replacement process.

- Test the equipment after replacing to ensure proper function.