Comprehensive Guide to Stihl 024 Parts Diagram

For anyone involved in the upkeep or repair of power tools, having a comprehensive grasp of the internal structure is essential. This knowledge not only aids in efficient maintenance but also enhances the overall performance of the machine. Familiarity with each element’s role ensures a smoother operation and can significantly prolong the tool’s lifespan.

In this section, we delve into the intricate assembly of a popular model, offering a detailed visual representation of its key components. By exploring the layout and functionality of these individual parts, users can better appreciate the machine’s engineering and design. This understanding empowers owners to tackle repairs with confidence and precision.

Furthermore, recognizing how different elements interact can assist in troubleshooting common issues. Whether you’re a seasoned technician or a casual user, being informed about the essential constituents of your equipment is invaluable. Let’s explore this essential guide to enhance your knowledge and skills in tool maintenance.

Understanding the Stihl 024 Chainsaw

This section aims to provide insights into a popular model of chainsaw known for its reliability and performance. Many users appreciate its robust design and versatility, making it suitable for various cutting tasks. Understanding its components and functionality is essential for both maintenance and effective operation.

Key Features

- Powerful engine that delivers efficient cutting performance

- Lightweight construction for enhanced maneuverability

- User-friendly controls that simplify operation

- Durable materials designed to withstand heavy usage

Essential Components

Familiarity with the critical elements of this chainsaw can enhance its usage and longevity. Here are some fundamental parts to consider:

- Engine: The heart of the machine, providing necessary power.

- Guide bar: Supports the cutting chain, crucial for effective slicing.

- Chain: The component that does the actual cutting work.

- Air filter: Essential for maintaining engine efficiency by preventing debris intake.

- Fuel tank: Holds the fuel mixture required for operation.

Understanding these components helps in recognizing how they work together to ensure optimal performance. Proper care and timely replacements of these parts can significantly extend the lifespan of the machine.

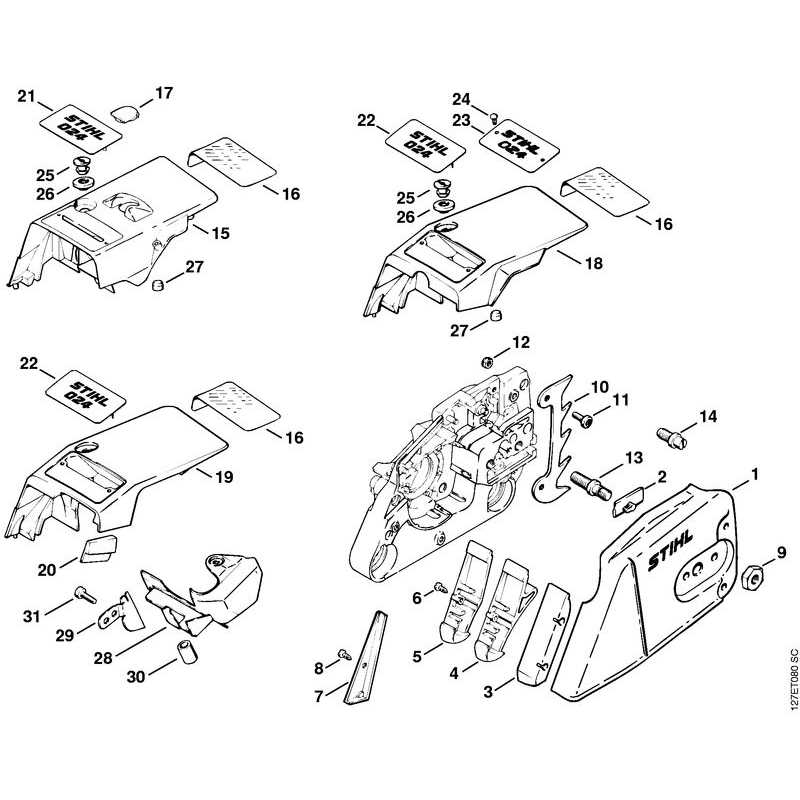

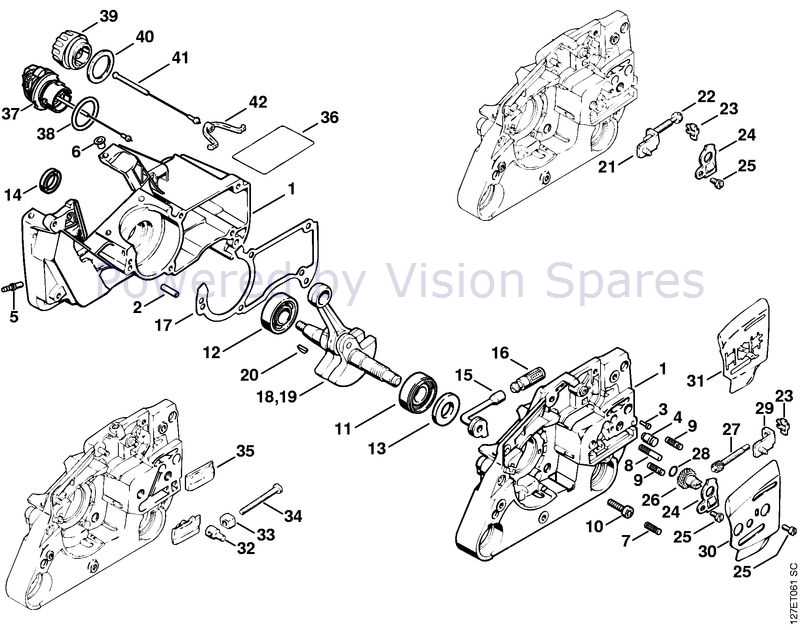

Essential Components of Stihl 024

Understanding the key elements of a powerful cutting tool is crucial for both maintenance and performance. Each part plays a significant role in ensuring the equipment operates efficiently, allowing users to accomplish their tasks with ease.

Core Elements

- Engine: The heart of the machine, providing the necessary power for cutting through various materials.

- Bar and Chain: These components work together to deliver precision cuts. The bar supports the chain, which does the actual cutting.

- Fuel System: Essential for delivering the right mixture of fuel and oil to the engine, ensuring optimal performance.

Supporting Components

- Air Filter: Keeps debris and dust out of the engine, promoting longevity and efficiency.

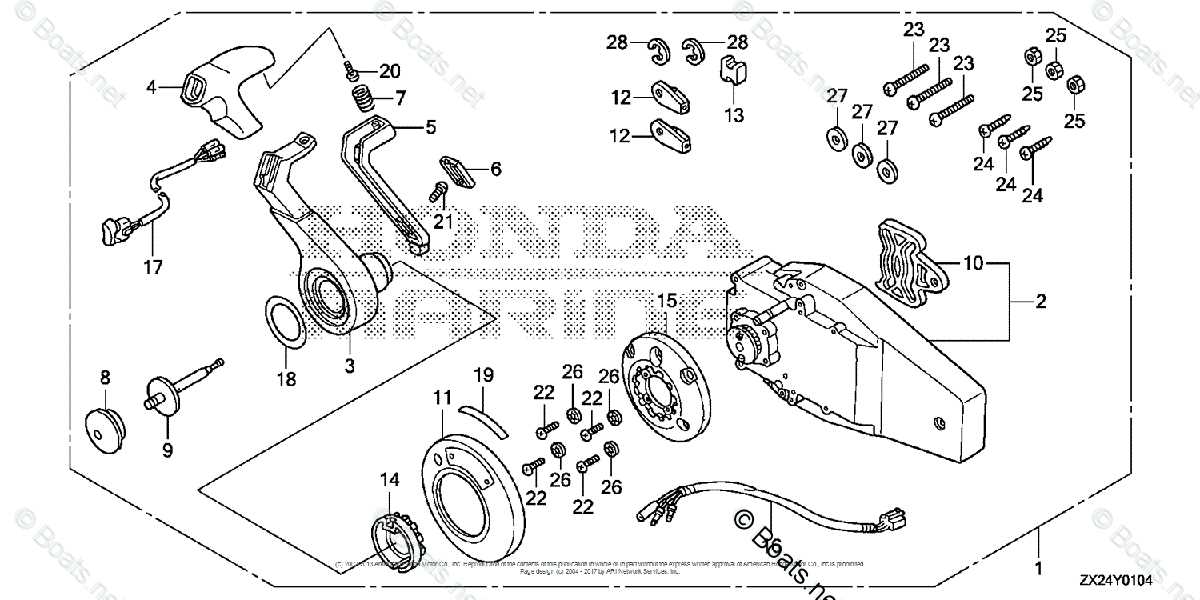

- Ignition System: Responsible for starting the engine and maintaining its operation through electrical spark generation.

- Starter Mechanism: Facilitates easy ignition, allowing users to quickly get to work without hassle.

By familiarizing oneself with these essential components, users can ensure proper maintenance and enhance the overall functionality of their cutting equipment.

Common Issues with Stihl 024 Parts

When working with outdoor power equipment, users often encounter a variety of challenges related to components. These issues can stem from wear and tear, improper maintenance, or simply the passage of time. Understanding these common problems can help users troubleshoot effectively and maintain optimal performance.

Wear and Tear

Over time, various elements may experience deterioration. For instance, the ignition system components can become less effective, leading to starting difficulties. Similarly, fuel lines may degrade, resulting in leaks or fuel delivery problems. Regular inspections can help identify these issues before they escalate.

Improper Maintenance

Lack of proper care can also lead to a range of complications. Neglecting to clean air filters or replace spark plugs can hinder performance and efficiency. Additionally, failing to check the tension on the drive belt may cause premature wear. Adhering to a maintenance schedule is crucial for longevity and reliability.

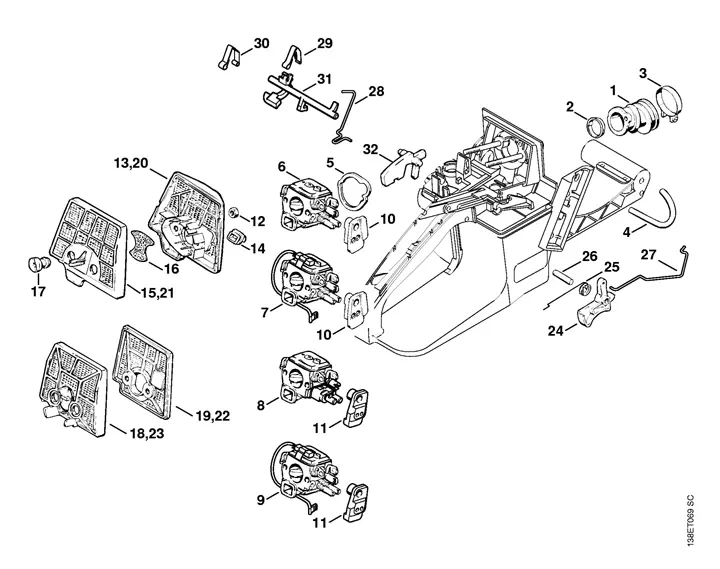

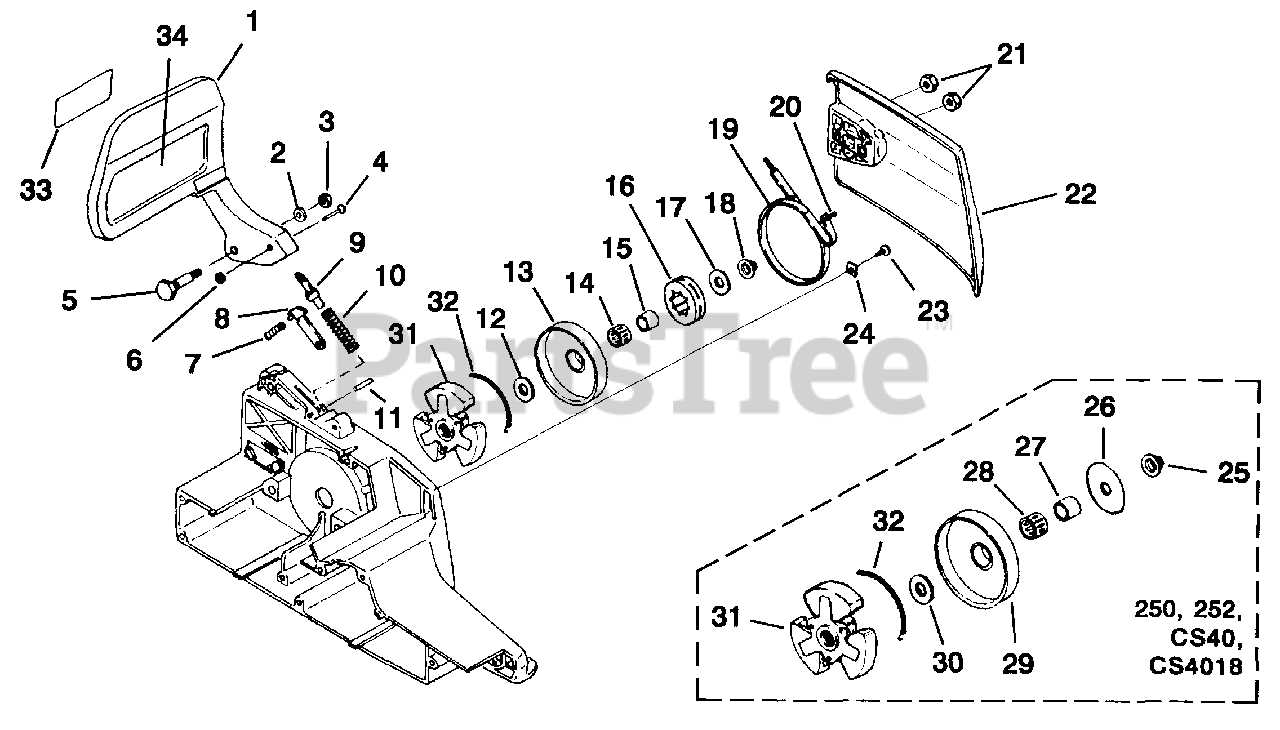

How to Read Parts Diagrams

Understanding visual representations of components is essential for efficient maintenance and repair of various machinery. These illustrations serve as valuable guides, helping users identify individual elements, their relationships, and overall assembly. By mastering the ability to interpret these visuals, one can streamline the process of sourcing replacements and performing repairs effectively.

Key Elements of Visual Representations

When examining these illustrations, focus on several crucial aspects:

| Element | Description |

|---|---|

| Labels | Numerical or alphabetical identifiers corresponding to specific items, often found beside each component. |

| Lines and Arrows | Connectors indicating how parts relate to one another or their orientation within the assembly. |

| Legends | A key or reference guide explaining the symbols used in the illustration, providing clarity on component types. |

Interpreting Component Relationships

Identifying how each piece interacts with others is crucial for a successful repair. Pay attention to the connections indicated by lines and arrows, as these can highlight the order of assembly and any necessary steps for disassembly. Understanding these relationships not only aids in repairs but also enhances overall familiarity with the machinery.

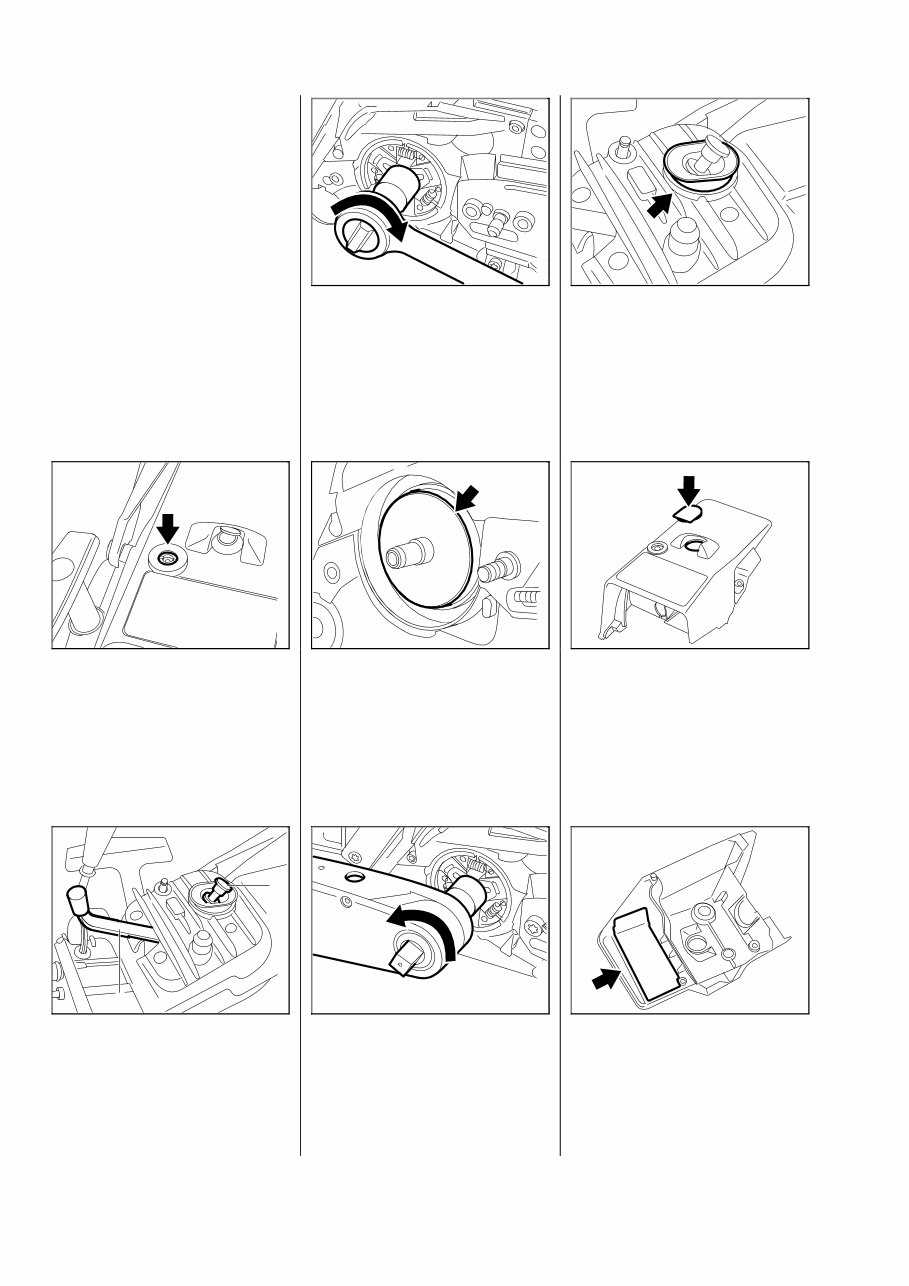

Replacing Parts on Stihl 024

When it comes to maintaining your outdoor power equipment, knowing how to efficiently swap out components is essential for optimal performance. Regular replacements can help ensure longevity and reliability, preventing more significant issues down the line. Understanding the basic process can empower users to tackle repairs confidently.

Common Components to Replace

Several key elements may need attention over time. Being aware of these will help you identify potential problems early and keep your machinery running smoothly.

| Component | Symptoms of Wear | Replacement Frequency |

|---|---|---|

| Fuel Filter | Poor engine performance | Every season |

| Air Filter | Reduced airflow | Every few months |

| Spark Plug | Difficulty starting | Once a year |

| Chain | Excessive wear | As needed |

Steps for Effective Replacement

To ensure a smooth replacement process, follow these steps:

- Gather necessary tools and new components.

- Ensure the equipment is turned off and cool to the touch.

- Refer to the user manual for specific instructions on accessing each part.

- Carefully remove the old component and install the new one, ensuring proper alignment.

- Test the equipment to confirm the replacement was successful.

Maintenance Tips for Stihl 024

Proper upkeep of your equipment ensures longevity and optimal performance. Regular maintenance not only enhances efficiency but also prevents costly repairs down the line. Below are essential tips to keep your tool in excellent condition.

- Regular Cleaning: After each use, clean the exterior and components to prevent buildup of dirt and debris.

- Chain Inspection: Frequently check the cutting chain for wear and damage. Replace it if necessary to maintain effective cutting performance.

- Oil Levels: Ensure that the lubrication system is filled with appropriate oil. Insufficient lubrication can lead to overheating and wear.

- Filter Maintenance: Clean or replace air filters regularly to ensure proper airflow and prevent engine strain.

- Spark Plug Check: Inspect the spark plug for carbon buildup. Replace it if it appears worn or dirty to ensure smooth ignition.

By following these simple guidelines, you can significantly extend the life of your equipment and enhance its performance, making every task easier and more efficient.

Where to Find Replacement Parts

When it comes to maintaining outdoor power equipment, sourcing high-quality components is essential for optimal performance. Whether you need a new blade, filter, or any other essential element, there are several reliable avenues to explore for finding the right items to keep your machinery running smoothly.

Authorized Dealers

Your first stop should be authorized dealers who specialize in equipment sales and service. These retailers often carry a comprehensive selection of original components designed specifically for your model. Additionally, their knowledgeable staff can provide guidance on installation and compatibility, ensuring you make the best choice for your needs.

Online Marketplaces

The internet offers a vast array of options, from well-known e-commerce sites to niche retailers dedicated to outdoor machinery. Searching for components online allows you to compare prices and read reviews from other users. Just be sure to verify the authenticity of the seller and the quality of the products to avoid any issues down the line.

DIY Repairs for Stihl 024

Maintaining outdoor power equipment can often feel daunting, but with a bit of guidance, many tasks can be tackled at home. Performing simple repairs not only saves money but also enhances your understanding of the machinery you use. This section will provide insights into common issues and solutions that can help you keep your tools in top condition.

Common Issues and Solutions

One of the most frequent problems users encounter is difficulty in starting the engine. This may be attributed to fuel issues, a clogged air filter, or spark plug malfunctions. Begin by checking the fuel mixture and ensuring it is fresh. Next, inspect the air filter; cleaning or replacing it can significantly improve airflow. If the problem persists, examining the spark plug for wear or damage is essential, as a faulty plug can hinder ignition.

Regular Maintenance Tips

Routine upkeep can prevent many issues before they arise. Always clean the equipment after each use to remove debris and prevent rust. Additionally, regularly check and tighten all screws and bolts, as vibrations can loosen them over time. Lubricating moving parts can reduce wear and tear, ensuring your machinery operates smoothly. By committing to these simple practices, you can extend the lifespan of your equipment and maintain its performance.

Stihl 024 vs. Other Models

When comparing various models of a popular power tool, it’s essential to analyze their performance, features, and applications. Each variant has unique specifications and capabilities that cater to different user needs, making it vital to understand how they stack up against one another. This exploration provides insights into the advantages and limitations of the tool in question, facilitating informed choices for potential buyers.

Performance and Power

One of the most significant factors to consider is the engine’s output and efficiency. The model in focus often boasts a robust engine that delivers impressive cutting power, making it suitable for both professional and domestic tasks. In contrast, some competitors might offer lighter alternatives with lower power, ideal for occasional use. However, these may lack the durability required for intensive jobs.

Weight and Maneuverability

Weight plays a crucial role in user experience, especially during prolonged operation. The highlighted model strikes a balance between power and weight, ensuring that users can handle it comfortably over extended periods. Meanwhile, other versions may prioritize lightness, providing ease of use but potentially sacrificing power. This trade-off is essential for those considering how they intend to utilize the tool.

Ultimately, evaluating these aspects helps users choose a model that aligns with their specific needs and preferences. Whether prioritizing power or ease of handling, understanding the distinctions among various offerings is key to making an informed decision.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components offers numerous advantages that enhance the performance and longevity of machinery. These high-quality items are specifically designed to meet the exact specifications required for optimal functionality, ensuring that your equipment operates at its best. The reliability and durability of these products can lead to significant cost savings in the long run, as they often require less frequent replacements compared to aftermarket alternatives.

| Advantage | Description |

|---|---|

| Quality Assurance | OEM components undergo rigorous testing to ensure they meet strict quality standards. |

| Perfect Fit | Designed specifically for your equipment, these parts guarantee a seamless fit and functionality. |

| Enhanced Performance | Using original components helps maintain peak performance levels, leading to better efficiency. |

| Warranty Protection | Many manufacturers provide warranties for their equipment, which may be voided if non-original parts are used. |

| Support Availability | OEM parts often come with better customer support and resources, making them easier to acquire and install. |

In summary, choosing original components not only ensures compatibility and performance but also provides peace of mind, knowing that you are investing in the longevity and reliability of your equipment.

Frequently Asked Questions about Stihl 024

This section aims to address common inquiries regarding a popular model known for its reliability and efficiency. Whether you are seeking maintenance tips or troubleshooting advice, you’ll find helpful information here.

General Questions

- What are the primary features of this model?

- How do I ensure optimal performance and longevity?

- What type of fuel is recommended for use?

Troubleshooting and Maintenance

- What should I do if the engine won’t start?

- How can I tell if the chain needs sharpening?

- What are the signs of wear that I should watch for?