Understanding the Parts Diagram of Stihl 026 Pro Chainsaw

When it comes to high-performance equipment designed for rigorous tasks, comprehending the intricacies of its construction is vital. A thorough exploration of the essential elements that make up this robust machine allows users to maximize efficiency and maintain longevity.

In this section, we will delve into the various segments that contribute to the overall functionality of the tool. Each component plays a significant role, and recognizing their specific purposes can enhance your operational expertise.

By examining a detailed representation of these critical pieces, you can gain insights into maintenance and potential upgrades. This ultimate guide will empower you to navigate the complexities of your equipment with confidence.

Understanding Stihl 026 Pro Overview

This section provides a comprehensive look at a popular tool used in various forestry and landscaping tasks. Renowned for its efficiency and reliability, it stands out in its category, making it a preferred choice among professionals and enthusiasts alike.

Key features include:

- Powerful engine performance that enhances cutting capability.

- Lightweight design for improved maneuverability and reduced fatigue during prolonged use.

- Ergonomic handles that promote comfort and control.

- Durable construction materials ensuring longevity and resilience under tough conditions.

Understanding the components and functionalities of this equipment is essential for optimal use. Key aspects to consider include:

- Engine specifications and their impact on performance.

- Maintenance practices that ensure peak functionality.

- Safety features that protect the user during operation.

- Compatibility with various accessories and attachments to enhance versatility.

By familiarizing oneself with these characteristics, users can maximize the effectiveness of their equipment and ensure a safer, more productive experience.

Key Features of the Chainsaw

This segment explores the essential characteristics that define a high-performance cutting tool. Understanding these attributes helps users select the right model for their specific needs, ensuring efficiency and safety during operation.

Power and Performance

The strength of the motor plays a crucial role in determining cutting efficiency. A robust engine not only enhances speed but also contributes to smoother operation, allowing for seamless handling of various tasks.

Durability and Design

Quality construction materials and ergonomic design significantly impact longevity and user experience. Durable components resist wear and tear, while comfortable grips ensure extended use without fatigue.

Importance of Maintenance Parts

Regular upkeep is crucial for ensuring the longevity and efficiency of any mechanical tool. By focusing on essential components that require periodic replacement, users can significantly enhance performance and prevent unexpected failures.

Preventing Breakdowns

Timely replacement of worn components helps avoid major malfunctions. This proactive approach not only saves time but also reduces repair costs, making it a wise investment for users.

Optimizing Performance

Maintaining key elements ensures that the equipment operates at its ultimate efficiency. Properly functioning components contribute to smoother operation, improved safety, and overall user satisfaction.

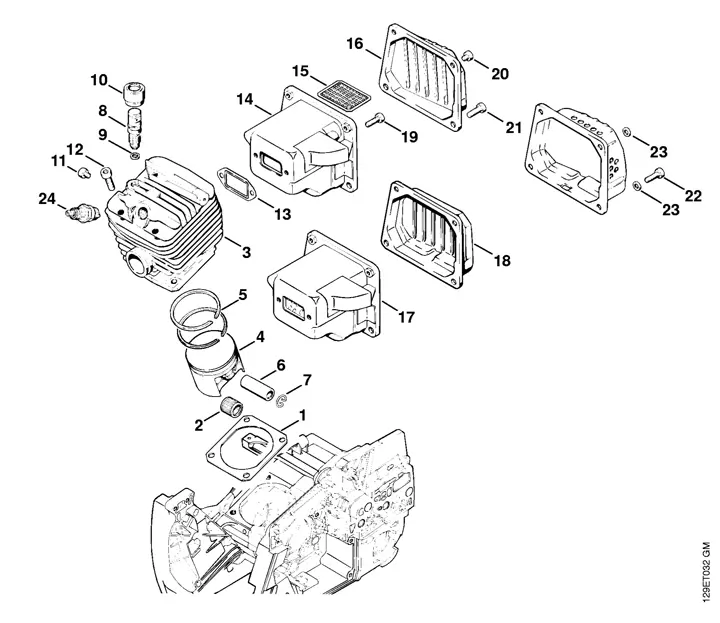

Identifying Essential Components

Understanding the key elements of your cutting tool is crucial for effective maintenance and performance. Each component plays a vital role in ensuring the equipment operates smoothly and efficiently.

- Engine: The heart of the machine, providing power and torque.

- Bar: The guide that supports the cutting chain.

- Chain: The loop of linked segments that performs the cutting action.

- Clutch: Engages and disengages the chain during operation.

- Fuel Tank: Stores the mixture needed for combustion.

- Air Filter: Ensures clean air intake for optimal engine performance.

Familiarizing yourself with these fundamental parts will help you manage repairs and enhance your tool’s longevity.

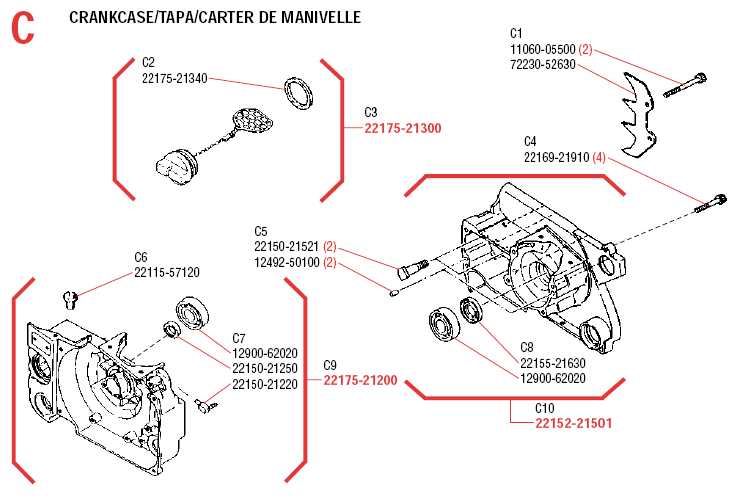

Where to Find Replacement Parts

When seeking components for your equipment, understanding where to look is essential for a smooth repair process. Numerous options are available, each offering unique benefits, whether you prefer online shopping or local stores.

Online Retailers

Many websites specialize in equipment components, providing a wide range of items. Searching for specific names or model numbers can lead you to reputable sites that offer quality goods at competitive prices. Make sure to read reviews and check return policies before making a purchase.

Local Dealers and Shops

Visiting local dealers can also be advantageous, as they often have knowledgeable staff who can assist you in identifying the correct items. Additionally, supporting local businesses helps build community relationships while ensuring you receive expert advice.

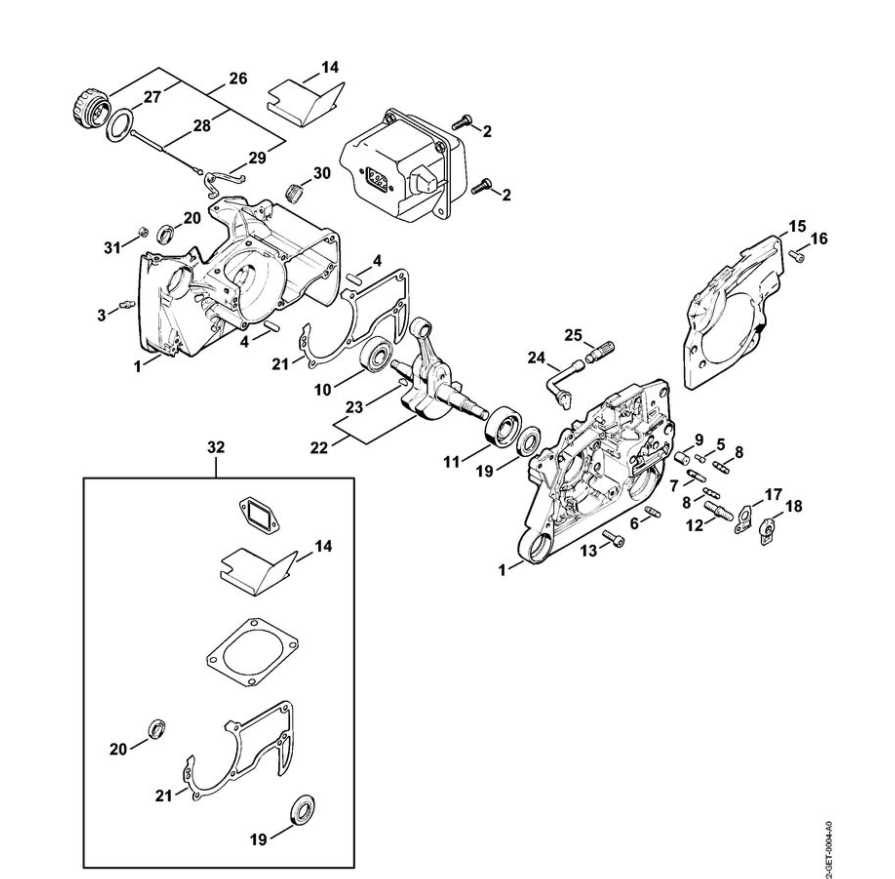

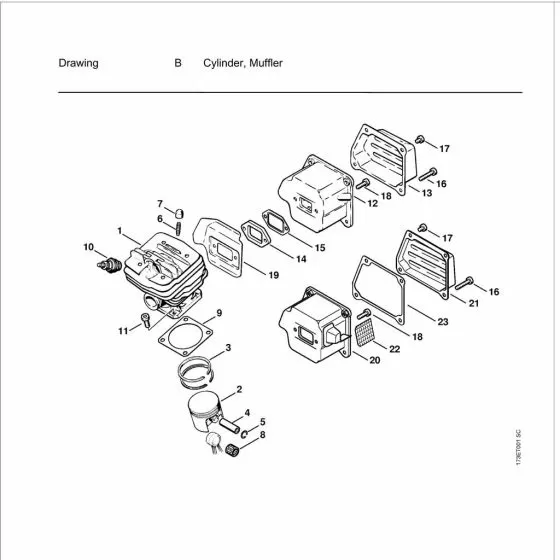

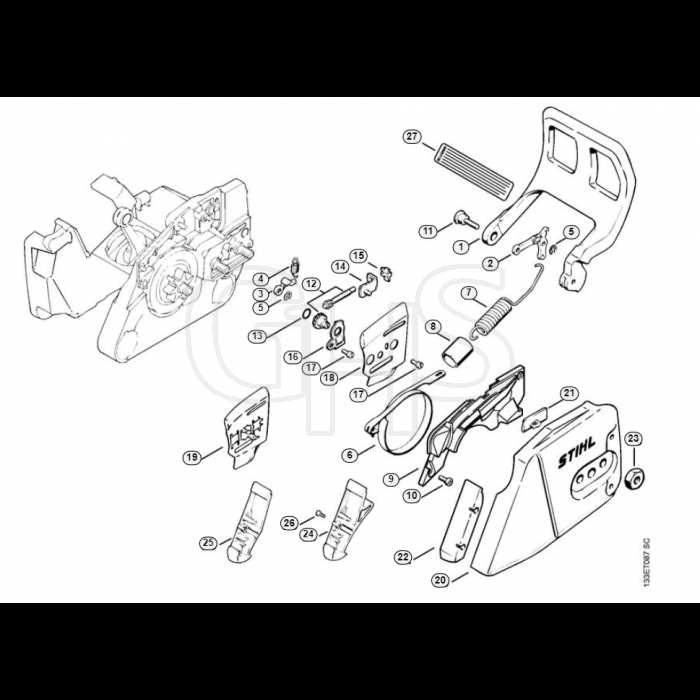

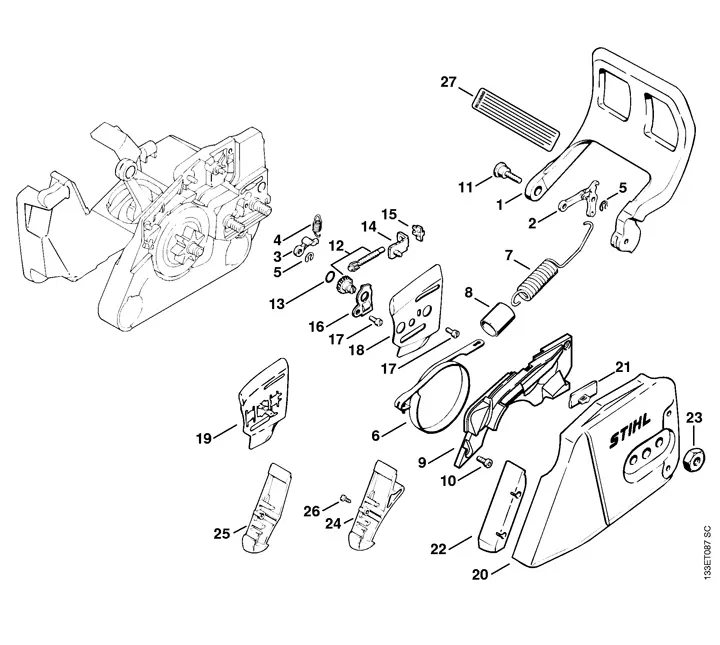

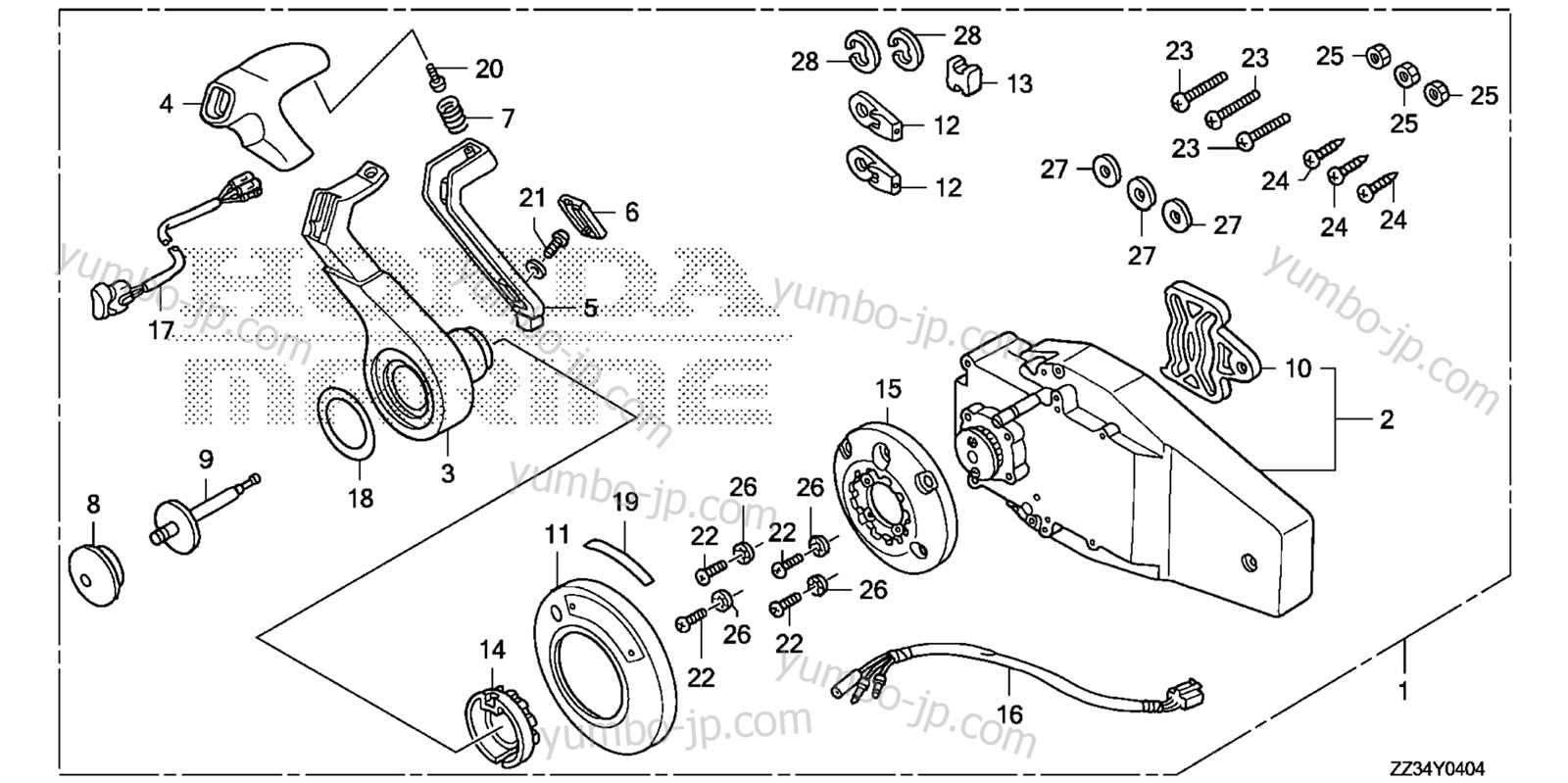

How to Read Parts Diagrams

Understanding assembly illustrations is crucial for effective maintenance and repairs of various machinery. These visual aids provide a comprehensive overview of the components and their arrangement, helping users identify necessary pieces for replacement or servicing.

Key Elements to Focus On

- Labels: Each component is typically labeled with a unique identifier, allowing for easy reference when ordering or discussing parts.

- Exploded View: The layout often displays components in an exploded view, which shows how parts fit together, offering insight into assembly and disassembly processes.

- Numbering System: Many illustrations employ a numbering system that corresponds to a parts list, which can be invaluable when searching for specific items.

Steps for Effective Interpretation

- Begin by familiarizing yourself with the entire layout. Identify the major sections and their purposes.

- Refer to the accompanying list of components, cross-referencing with the illustration for clarity.

- Take note of any special symbols or indicators that may denote specific functions or installation notes.

- Use the visual guide to track the order of disassembly or assembly, ensuring all parts are correctly aligned.

By mastering the art of reading these illustrations, you can significantly enhance your repair skills and maintain your equipment more effectively.

Common Issues and Solutions

Operating a cutting tool can lead to various challenges, often stemming from mechanical wear or improper maintenance. Identifying these issues early can enhance performance and prolong the lifespan of the equipment. This section explores frequent problems and their respective remedies.

| Issue | Solution |

|---|---|

| Tool won’t start | Check fuel levels and spark plug condition. Ensure the choke is set correctly. |

| Poor cutting performance | Sharpen the cutting chain and inspect for tension. Clean the guide bar. |

| Excessive vibration | Inspect for loose bolts and ensure proper chain alignment. Replace worn parts. |

| Overheating | Check oil levels and ensure proper lubrication. Avoid prolonged use without breaks. |

Upgrading Your Chainsaw Efficiency

Enhancing the performance of your cutting tool can significantly improve productivity and ease of use. By focusing on key components and adopting the latest technologies, you can achieve superior results in your tasks. This section explores various methods to elevate the functionality of your equipment.

Essential Upgrades

Consider investing in high-quality cutting attachments and reliable power sources. Upgrading to sharper blades and optimizing fuel systems can drastically enhance cutting speed and precision. Additionally, incorporating advanced filtration systems can prolong the lifespan of your device.

Maintenance Practices

Regular maintenance is crucial for sustaining efficiency. Ensure that you clean and inspect components frequently, replacing worn-out elements promptly. Implementing a scheduled upkeep routine can prevent potential issues and keep your equipment running at its ultimate best.

Tips for Proper Assembly

Ensuring that your tool is assembled correctly is crucial for optimal performance and safety. A systematic approach to putting together components can prevent potential issues and enhance longevity.

Begin by organizing all components in a clean workspace. Familiarize yourself with each element, checking for any damage or wear before assembly. Follow the manufacturer’s guidelines closely, as they provide vital instructions on how each part interacts with others.

Use the right tools for the job to avoid stripping screws or damaging parts. Take your time during the assembly process; rushing can lead to mistakes that might be costly. Once assembled, perform a thorough inspection to ensure everything is securely fitted and functioning correctly.

Lastly, consider keeping a maintenance log to track any repairs or adjustments made, helping you stay on top of performance and safety in the future.

Exploring Aftermarket Options

When it comes to enhancing the performance and longevity of your equipment, considering alternative components can be a wise choice. Aftermarket solutions often provide a cost-effective way to maintain and improve functionality, offering a wide variety of choices that may not be available through original manufacturers. This section delves into the benefits and considerations of selecting non-original parts.

One of the primary advantages of opting for aftermarket components is the potential for significant savings. Many users find that these alternatives can perform just as well, if not better, than their original counterparts. Additionally, the aftermarket market is abundant, catering to diverse needs and preferences.

| Benefits | Considerations |

|---|---|

| Cost-effective options | Quality can vary |

| Wider selection | Compatibility issues |

| Potential performance enhancements | Limited warranty |

| Community support | Research needed |

Before making a purchase, it’s essential to conduct thorough research. User reviews and expert recommendations can provide insight into which aftermarket options are reliable. By carefully weighing the pros and cons, you can make an informed decision that meets your specific requirements.

Safety Equipment for Chainsaw Use

When operating powerful cutting tools, prioritizing safety is essential. Utilizing the appropriate protective gear minimizes the risk of injuries and ensures a secure working environment. This section outlines the necessary equipment to enhance safety during operations.

Essential Protective Gear

- Helmet: A sturdy helmet protects the head from falling debris.

- Eye Protection: Safety goggles or face shields shield the eyes from flying particles.

- Hearing Protection: Earplugs or earmuffs reduce noise exposure from the machinery.

- Gloves: Durable gloves provide grip and protect hands from cuts and abrasions.

- Leg Protection: Chaps or protective trousers safeguard the legs from accidental contact with the blade.

- Footwear: Steel-toed boots offer stability and protect feet from heavy objects.

Additional Safety Measures

- Ensure all protective equipment fits properly for maximum effectiveness.

- Inspect gear before use for any signs of wear or damage.

- Stay hydrated and take regular breaks to maintain focus.

- Familiarize yourself with the operation manual of the equipment being used.

Incorporating these safety measures is vital for a successful and secure cutting experience. Always prioritize personal protection to minimize risks during your tasks.

Frequently Asked Questions

This section addresses common inquiries related to maintenance and repair of cutting tools, providing clarity and guidance for users seeking assistance with their equipment. Below are some of the most frequently posed questions along with detailed answers.

What should I do if my equipment is not starting?

If your tool fails to start, first check the fuel level and ensure the mixture is fresh. Additionally, inspect the ignition system and air filter for any blockages.

How often should I replace the blade?

The blade should be replaced when it shows signs of wear, such as dullness or damage. Regular maintenance can prolong its life and improve performance.

What type of fuel is recommended?

Always use a high-quality fuel mixture suitable for your specific model. Refer to the manufacturer’s guidelines for the correct fuel-to-oil ratio.

Is it necessary to perform regular maintenance?

Yes, regular maintenance is crucial for optimal performance and longevity. It helps prevent breakdowns and ensures safety during operation.

Where can I find replacement components?

Replacement components can typically be found at authorized dealers or reputable online retailers. Always ensure the parts match your equipment specifications.

How can I improve my cutting efficiency?

To enhance cutting efficiency, maintain a sharp blade, use the correct technique, and ensure the tool is well-lubricated and in good condition.