Stihl 034 Chainsaw Parts Diagram Overview

When it comes to maintaining and optimizing your outdoor equipment, having a clear understanding of its components is crucial. This knowledge not only enhances performance but also ensures longevity and efficiency in operations.

Within this section, we will explore a detailed representation of the various elements that make up a specific model of a cutting instrument. By examining each piece, users can better appreciate the intricate design and functionality that contribute to its overall effectiveness.

Additionally, identifying and understanding these components can assist in troubleshooting and repairs. Whether you are an enthusiast or a professional, diving into the specifics will ultimately empower you to keep your tools in peak condition.

Understanding the Stihl 034 Chainsaw

This section explores the intricacies of a powerful cutting tool designed for various outdoor tasks. Understanding its components and functionality can enhance user experience and efficiency.

- Engine: Provides the necessary power for cutting.

- Guide Bar: Directs the chain, ensuring precision in cutting.

- Chain: The primary element that performs the cutting action.

- Fuel System: Supplies energy to the engine, crucial for performance.

- Oiling Mechanism: Ensures smooth operation and reduces wear on the chain.

By delving into these key components, users can achieve ultimate performance and longevity from their equipment.

Overview of Stihl 034 Features

This model is designed to offer a blend of power and efficiency, making it suitable for a variety of cutting tasks. Its robust construction ensures durability, while the carefully engineered components enhance performance and reliability. Users can expect an impressive balance between weight and cutting ability, catering to both professionals and enthusiasts alike.

Powerful Engine

The heart of this machine lies in its engine, which provides substantial output without compromising on fuel efficiency. With advanced technology, it ensures smoother operation and minimizes emissions, making it an environmentally friendly choice for outdoor tasks.

User-Friendly Design

Ergonomics play a significant role in the design, featuring comfortable handles that reduce fatigue during extended use. Additionally, intuitive controls make it easy for users to operate, enhancing safety and control while performing various cutting operations.

Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair of machinery. These illustrations not only simplify the understanding of complex systems but also provide valuable insights into the relationships between various elements. By referring to these visuals, users can enhance their troubleshooting skills and ensure efficient repairs.

Enhanced Understanding

Illustrative guides offer a clear overview of how each component interacts within the overall structure. This clarity aids both novices and experienced technicians in grasping intricate mechanisms. With well-labeled sections, individuals can quickly locate specific elements and comprehend their functions, ultimately facilitating a smoother repair process.

Facilitating Repairs and Maintenance

Having access to these visual guides significantly streamlines the repair and upkeep process. They serve as essential tools for identifying faulty components and determining the necessary replacements. Moreover, these references minimize the risk of errors, ensuring that the machinery operates at optimal performance after maintenance is performed.

Common Replacement Parts for 034

Regular maintenance is essential for optimal performance and longevity of your equipment. Over time, certain components may wear out or require replacement due to regular usage. Understanding which elements are commonly replaced can help ensure smooth operation and enhance the overall efficiency of your machine.

Essential Components to Consider

Among the frequently replaced items, the following stand out:

- Air Filter: A clean air filter is crucial for proper airflow and engine performance. Regular replacement can prevent dust and debris from entering the engine.

- Fuel Filter: This component ensures that impurities in the fuel do not affect engine function. A clogged filter can lead to starting issues and reduced power.

- Bar and Chain: These elements are vital for cutting efficiency. Dull chains can be sharpened, but replacement may be necessary if damage occurs.

Other Important Items

In addition to the core components, consider the following:

- Spark Plug: This is essential for ignition. Regular inspection and replacement help maintain starting reliability.

- Oil Pump: Ensures proper lubrication. A malfunctioning pump can lead to overheating and increased wear.

- Gaskets and Seals: These prevent leaks and maintain pressure within the engine. Regular checks can help avoid performance issues.

Staying proactive with these common replacements will contribute to the efficiency and reliability of your equipment, ensuring it performs at its best for years to come.

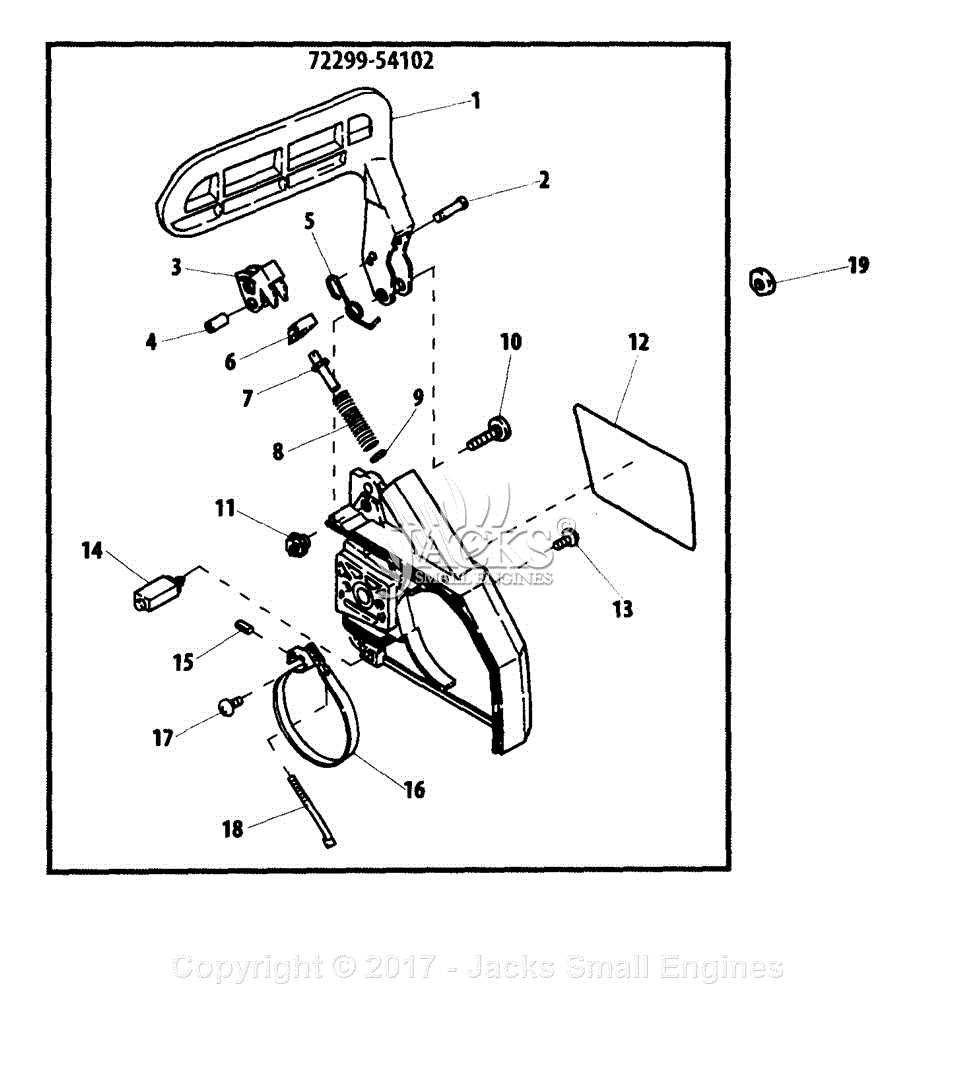

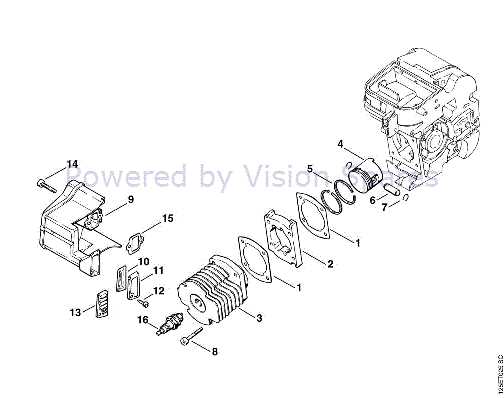

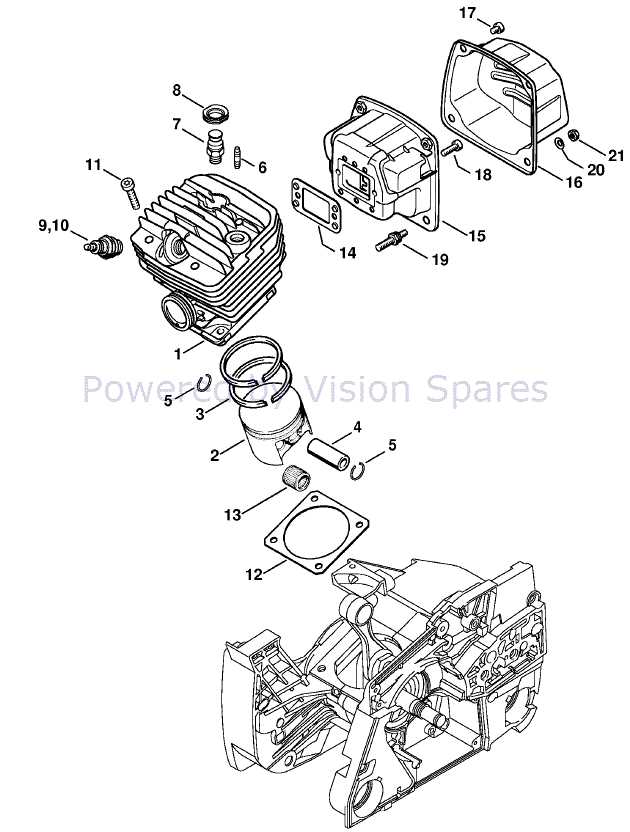

Identifying Parts by Diagram

Understanding the layout of a mechanical tool can greatly enhance maintenance and repair efforts. Visual representations allow users to easily locate components, facilitating a more efficient troubleshooting process. This approach not only aids in identifying individual elements but also helps in grasping their interconnections within the entire system.

Understanding Components

Familiarizing oneself with various elements through illustrations can demystify complex machinery. By studying these visuals, users can quickly learn the function of each piece, empowering them to perform repairs with confidence.

Enhancing Repair Skills

Utilizing visual aids accelerates the learning process and fosters greater competence in maintenance tasks. Recognizing components through clear depictions allows for swift identification, ultimately leading to more effective repairs and increased longevity of the equipment.

Where to Find Diagrams Online

Finding visual guides and schematics for various equipment can significantly enhance your understanding of its components and maintenance. Numerous online resources provide detailed illustrations that can assist in identifying and sourcing the necessary items for repairs or upgrades.

Here are some reliable platforms where you can access these valuable resources:

| Website | Description |

|---|---|

| ManualsLib | A comprehensive library of user manuals and technical documents, featuring extensive collections for various tools and machinery. |

| PartsLookup | An easy-to-navigate site that offers breakdowns of different machines, along with lists of components and their corresponding images. |

| eReplacementParts | This site specializes in replacement components and includes detailed drawings that can help pinpoint the exact parts you need. |

| Schematics.com | A platform dedicated to various equipment diagrams, providing users with easy access to visual references for repairs and assembly. |

Utilizing these resources can streamline your repair process and ensure that you have the right information at your fingertips.

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. These visual guides provide a clear outline of individual elements, their arrangement, and interconnections. Familiarizing yourself with this format enables you to quickly identify and locate the necessary components for any task.

Identifying Components

Start by examining the labels and symbols used in the illustration. Each part will typically have a corresponding number or code, which can be cross-referenced with a list for detailed information. Pay attention to the shapes and sizes, as they often indicate the functionality and compatibility of each piece.

Understanding Relationships

Next, focus on how the elements interact with one another. Arrows and lines may depict connections or flow, indicating how parts fit together or function in unison. Recognizing these relationships is crucial for troubleshooting issues and ensuring everything operates smoothly.

In summary, mastering the interpretation of these visuals not only aids in repairs but also enhances your overall understanding of the machinery, making future tasks more efficient.

Tips for Maintaining Your Chainsaw

Proper upkeep is essential for ensuring the longevity and efficiency of your cutting tool. Regular maintenance not only enhances performance but also prevents potential issues that can arise from neglect.

Regular Checks

- Inspect the chain for wear and tear.

- Ensure the bar is straight and free from damage.

- Check the fuel and oil levels before each use.

Cleaning and Lubrication

- Clean the air filter regularly to improve airflow.

- Lubricate the bar and chain to reduce friction.

- Wipe down the exterior to prevent debris buildup.

Ordering Genuine Stihl Parts

When seeking components for your equipment, it’s crucial to ensure you acquire authentic items for optimal performance and longevity. Genuine articles guarantee compatibility and reliability, helping to maintain the efficiency of your machinery.

To streamline the ordering process, consider the following steps:

| Step | Description |

|---|---|

| 1 | Identify the specific component needed for your equipment. |

| 2 | Consult the official website or an authorized dealer for availability. |

| 3 | Gather the equipment model number and any other relevant details. |

| 4 | Place your order through a trusted source to ensure authenticity. |

Following these guidelines will help you acquire the right items, ensuring your equipment operates at its best.

Aftermarket vs. Original Parts

When it comes to maintaining and repairing power equipment, users often face a choice between original manufacturer components and those produced by third-party companies. This decision can significantly impact performance, reliability, and overall satisfaction.

Original components are designed specifically for a particular model, ensuring compatibility and adherence to strict quality standards. In contrast, aftermarket alternatives may offer cost savings but can vary in quality and fit.

- Quality: Original components typically undergo rigorous testing, while aftermarket options may lack consistent quality control.

- Price: Aftermarket components are often less expensive, appealing to budget-conscious consumers.

- Availability: Aftermarket options may be more readily available, especially for older models.

- Warranty: Using original components often preserves warranty coverage, while aftermarket may void it.

Ultimately, the choice between these two types of components depends on individual needs, budget constraints, and the desired level of performance and reliability. Careful consideration will lead to the best decision for equipment upkeep.

Tools Needed for Repairing 034

When undertaking maintenance on your outdoor power equipment, having the right tools is essential for a successful and efficient repair process. Properly equipped, you can ensure that any adjustments or replacements are handled smoothly, reducing the risk of damage and prolonging the lifespan of your equipment.

Essential Hand Tools

Start with a comprehensive set of hand tools, including screwdrivers, wrenches, and pliers. These basic implements are crucial for loosening and tightening various components. A torque wrench may also be necessary to ensure that fasteners are tightened to the manufacturer’s specifications, preventing future issues.

Specialized Equipment

In addition to standard tools, consider investing in specialized equipment such as a compression tester and a spark plug wrench. These tools can help diagnose performance issues and facilitate quick fixes. A cleaning kit is also important for maintaining optimal functionality, ensuring that fuel lines and air filters are free from debris.

Common Issues and Solutions

Operating machinery can often lead to various challenges that affect performance and efficiency. Understanding these common problems and their respective remedies can significantly enhance the user experience and prolong the lifespan of the equipment.

Frequent Problems

Many users encounter issues such as difficulty in starting, poor cutting performance, or unusual noises during operation. Identifying these symptoms is crucial for timely intervention.

Solutions

| Issue | Solution |

|---|---|

| Hard to start | Check the fuel mixture and inspect the spark plug. |

| Poor cutting | Sharpen or replace the cutting chain and adjust tension. |

| Unusual noise | Examine for loose components and ensure proper lubrication. |

Upgrading Your Stihl Chainsaw

Enhancing your power tool can significantly improve its performance and efficiency. By incorporating advanced components, you can achieve better results and extend the life of your equipment. This guide will explore effective strategies for upgrading your machine.

Benefits of Upgrading

- Improved cutting efficiency

- Increased durability

- Enhanced safety features

- Better fuel efficiency

Key Components to Consider

- Bar and Chain: Upgrading to a high-quality bar and chain can provide smoother operation.

- Engine Tune-up: Regular tuning ensures optimal power output and efficiency.

- Air Filter: A high-performance filter can enhance airflow and improve combustion.

- Anti-Vibration System: Adding or upgrading this feature reduces fatigue during extended use.

Delve into each component to determine the ultimate improvements for your machine. Implementing these upgrades will not only boost performance but also enhance your overall experience.