Understanding the Parts Diagram of Stihl 042 AV Chainsaw

When it comes to maintaining and repairing your cutting tool, having a clear understanding of its internal mechanisms is crucial. A comprehensive overview of the individual elements that make up your machine can significantly enhance your ability to troubleshoot and execute repairs efficiently. By familiarizing yourself with these essential components, you empower yourself to ensure optimal performance and longevity of your equipment.

In this section, we delve into the intricate details of each essential piece, illustrating their interconnections and functions within the overall assembly. This knowledge not only aids in identifying potential issues but also provides insights into the proper assembly and disassembly processes. As you explore these intricate systems, you will gain a deeper appreciation for the craftsmanship behind your tool.

Equipped with this information, you will be better prepared to source replacements and upgrades. Whether you are an avid user or a seasoned technician, understanding these parts will help you make informed decisions regarding maintenance and repairs. Join us as we navigate the essential components of your machine, unlocking the full potential of your cutting equipment.

Understanding Stihl 042 AV Chainsaw Parts

In the world of cutting tools, a thorough comprehension of the individual components is essential for effective operation and maintenance. Each element plays a crucial role in ensuring that the equipment functions smoothly and efficiently. By familiarizing oneself with these elements, users can enhance their experience and prolong the life of their tool.

Key Components

Understanding the main parts involved can simplify troubleshooting and repairs. Here are some of the most important components:

- Engine: The heart of the machine, providing the necessary power.

- Bar: The metal arm that holds the cutting chain, crucial for guiding the cutting action.

- Chain: The cutting mechanism that interacts directly with the wood.

- Air Filter: Prevents debris from entering the engine, maintaining performance.

- Fuel System: Essential for storing and delivering fuel to the engine efficiently.

Maintenance Tips

Regular maintenance can greatly improve the lifespan of your tool. Consider these suggestions:

- Check and clean the air filter regularly to ensure optimal airflow.

- Sharpen the cutting chain frequently to maintain cutting efficiency.

- Inspect the fuel system for leaks or blockages to prevent engine issues.

- Lubricate the bar and chain to reduce wear and tear.

By understanding these components and maintenance practices, users can ensure their cutting tool remains in peak condition, ready for any task at hand.

Importance of a Parts Diagram

Understanding the layout and components of machinery is essential for effective maintenance and repair. A visual representation of individual elements aids in recognizing their functions and interconnections. This familiarity not only enhances repair efficiency but also extends the lifespan of equipment.

Benefits of Visual Representations

- Clarity: Illustrations provide a clear view of how parts fit together, reducing confusion during assembly or disassembly.

- Identification: Easy identification of components helps in locating specific items that require replacement or repair.

- Guidance: Step-by-step visual guides offer instructions that simplify complex tasks, making them accessible even for those with limited experience.

Enhancing Efficiency and Accuracy

- Improved Time Management: Quick reference to visuals can significantly reduce the time spent on repairs.

- Minimized Errors: A detailed visual guide decreases the likelihood of mistakes during the reassembly process.

- Informed Decision Making: Knowing the exact layout aids in assessing what needs attention or replacement, leading to better maintenance choices.

Key Components of the Stihl 042 AV

This section explores the essential elements that make up a high-performance chainsaw model. Understanding these key components is crucial for effective maintenance, repair, and optimal operation of the equipment.

Core Elements

- Engine: The heart of the machine, providing the necessary power for cutting.

- Guide Bar: A critical part that supports the chain and aids in precision cutting.

- Chain: Designed for durability and efficiency, it is responsible for the cutting action.

- Air Filter: Essential for keeping the engine clean and functioning smoothly.

- Fuel System: Includes the tank, lines, and carburetor, ensuring a steady fuel supply to the engine.

Additional Features

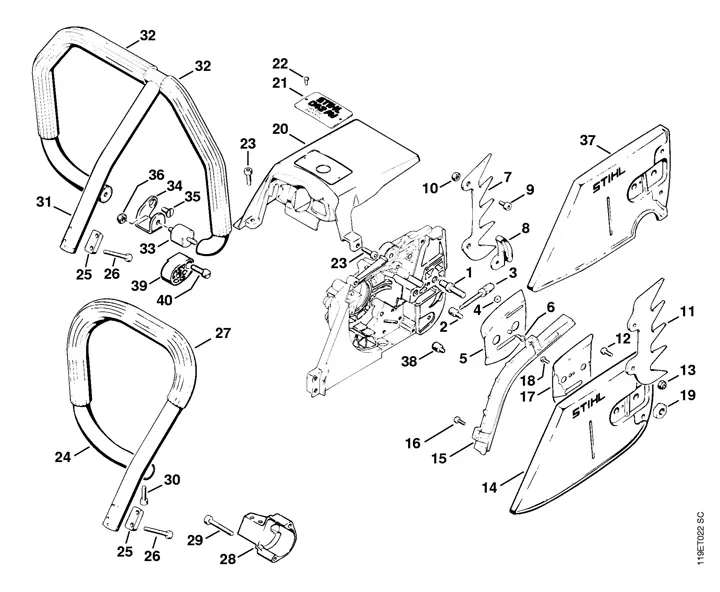

- Handle Assembly: Designed for comfort and control during operation.

- Safety Mechanisms: Incorporates features like chain brakes and throttle locks to enhance user safety.

- Clutch: Enables smooth engagement and disengagement of the chain.

- Starter System: Ensures reliable ignition and quick starts.

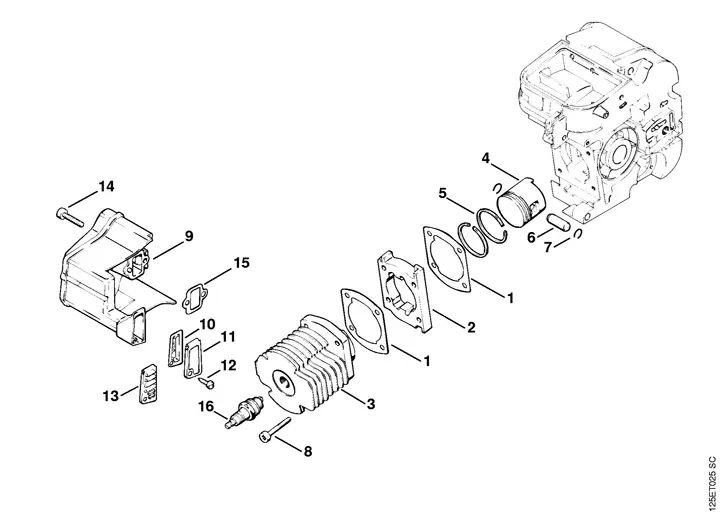

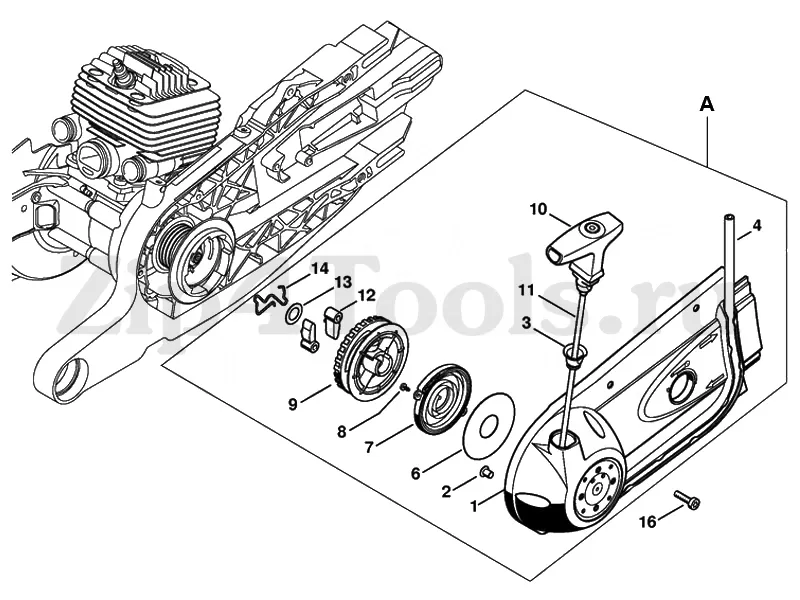

How to Read Parts Diagrams

Understanding visual representations of components is essential for efficient maintenance and repairs. These illustrations provide a clear overview of each element, helping users identify and locate necessary items quickly. Mastering the art of interpreting these visuals can significantly enhance your repair experience.

Familiarize Yourself with the Key

Most illustrations include a legend or key that explains the symbols and lines used. Take the time to review this section, as it will clarify the meaning of various marks and notations. Knowing what each symbol represents is crucial for accurate identification.

Identify the Layout

Components are often arranged in a specific manner, reflecting how they fit together in the actual assembly. Pay attention to the grouping and connections, as this can provide insights into how to disassemble or reassemble the unit. Use colors and numbering to guide you through the various sections and their relationships.

Common Issues and Replacement Parts

In any machinery, wear and tear can lead to various complications that hinder performance. Understanding these common challenges and knowing the appropriate components to substitute can significantly enhance the longevity and functionality of your equipment. This section focuses on prevalent problems faced by users and the essential replacements needed to resolve them.

Typical Problems Encountered

- Engine Starting Difficulties

- Excessive Vibration During Operation

- Loss of Power or Inefficiency

- Fuel Leaks or Contamination

- Wear on Cutting Edges

Essential Components for Replacement

- Air Filter: Regularly replacing this component ensures optimal airflow and engine performance.

- Fuel Filter: A clean filter prevents debris from entering the fuel system, reducing the risk of clogs.

- Spark Plug: A faulty spark plug can lead to ignition issues, making it crucial for smooth starting.

- Blade or Chain: Maintaining sharp cutting edges is vital for effective operation and safety.

- Vibration Dampeners: Replacing worn dampeners can minimize discomfort and enhance control.

By proactively addressing these common issues and replacing the necessary components, users can maintain their equipment’s performance and reliability over time.

Where to Find OEM Parts

Finding original components for your machinery can be crucial for maintaining performance and longevity. Utilizing authentic elements ensures compatibility and reliability, which is essential for optimal operation. Many users seek these original items to avoid the pitfalls associated with inferior substitutes.

One of the best places to start your search is through authorized retailers. These suppliers are often recognized by the manufacturer and provide a wide selection of genuine components. Additionally, online marketplaces specializing in equipment often stock these original items, allowing you to compare prices and availability from the comfort of your home.

Manufacturer Websites are another excellent resource. They typically have a catalog or a parts lookup tool, making it easier to identify and order the exact components you need. Furthermore, local dealers often carry a selection of original items and can offer personalized assistance in finding the right fit for your specific model.

Finally, joining online forums and community groups dedicated to machinery enthusiasts can be beneficial. Members often share experiences and recommend reliable sources for original components, helping you connect with trusted vendors.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended life and optimal performance of your equipment. Regular attention to various components not only enhances functionality but also reduces the likelihood of unexpected failures. By implementing a consistent maintenance routine, you can enjoy reliable operation for years to come.

Regular Cleaning

Keeping your machine clean is crucial. Debris, dirt, and moisture can accumulate and lead to rust or clogging. After each use, wipe down surfaces and remove any residues. Pay special attention to air filters, as a clean filter promotes efficient airflow and prevents engine strain.

Lubrication and Inspection

Frequent lubrication of moving parts is vital to minimize wear and tear. Use appropriate oils to ensure smooth operation. Additionally, inspect components regularly for signs of damage or excessive wear. Promptly addressing any issues can prevent more serious problems in the future.

Comparing Stihl 042 AV Models

When evaluating different variations of a particular chainsaw model, it’s essential to consider their unique features and specifications. Each version often comes with distinct characteristics that can cater to varying needs and preferences of users. Understanding these differences can greatly enhance the decision-making process for both hobbyists and professionals.

Power and Performance: One of the key aspects to compare is the engine power. Variations may exhibit differences in horsepower and torque, influencing cutting efficiency and speed. Users looking for heavy-duty performance might prefer models equipped with higher engine ratings, while those needing a lighter option might opt for less powerful variants.

Weight and Maneuverability: Another crucial factor is the weight of each model. Lighter versions tend to offer better maneuverability, making them ideal for extended use in tight spaces. Conversely, heavier models may provide added stability and durability for tougher tasks. Evaluating the balance between weight and functionality is vital for optimal user experience.

Durability and Design: The construction quality also varies among different editions. Some may feature reinforced components designed to withstand rigorous usage, while others might focus on ease of maintenance. Users should assess how these design elements align with their operational needs to ensure longevity and reliability.

Ergonomics and Comfort: Comfort during operation is paramount, especially for long hours of use. Variations might include ergonomic handles and vibration-dampening technologies that enhance user comfort. Comparing these ergonomic features can help identify the best fit for individual preferences and requirements.

Ultimately, a thorough comparison of these elements will empower users to select the model that best suits their specific tasks and operational environments.

Aftermarket Parts: Pros and Cons

The market for replacement components has grown significantly, offering various options that can enhance or maintain the functionality of equipment. These alternatives often attract users due to their affordability and availability, but they come with both advantages and drawbacks that need to be considered carefully.

On one hand, alternatives can provide a cost-effective solution for those looking to save money. They often come with a wider variety of choices, allowing for customization and tailored performance. However, the quality of these components can vary widely, and some may not meet the same standards as original items. This inconsistency can lead to performance issues or even damage to the equipment.

| Advantages | Disadvantages |

|---|---|

| Cost-effective options | Variable quality |

| Wide variety of choices | Potential compatibility issues |

| Customization possibilities | Limited warranty and support |

| Increased availability | Risk of reduced performance |

Ultimately, users must weigh these factors against their specific needs and circumstances to determine whether these alternatives are a suitable choice for their equipment maintenance and repair strategies.

Repair Techniques for Stihl Chainsaws

Maintaining and fixing cutting tools is essential for ensuring their longevity and optimal performance. Understanding common repair techniques can greatly enhance the efficiency of these machines, allowing users to tackle issues independently. This section delves into various methods and approaches to troubleshooting and repairing popular models of chainsaws.

Common Issues and Solutions

Several frequent problems arise with cutting devices, each requiring specific repair strategies. Below are some common issues along with recommended solutions:

| Issue | Solution |

|---|---|

| Difficulty Starting | Check the spark plug and fuel lines for blockages; replace if necessary. |

| Chain Slippage | Inspect and adjust the tension of the chain; ensure proper alignment. |

| Overheating | Clean the air filter and ensure the oil reservoir is full. |

| Poor Cutting Performance | Sharpen the chain and check for any damaged teeth. |

Preventive Maintenance Tips

Regular maintenance can prevent many issues before they arise. Here are some best practices:

- Regularly clean the air filter and fuel system.

- Inspect the chain tension and bar regularly.

- Store in a dry place to prevent rust.

Resources for Stihl Owners

For enthusiasts and professionals alike, having access to reliable information and tools is essential for maintaining and optimizing outdoor power equipment. A well-rounded selection of resources can enhance the ownership experience, making it easier to tackle repairs, understand functionality, and improve overall performance.

Online Forums and Communities: Engaging with fellow users in dedicated online platforms provides invaluable insights. Sharing experiences, troubleshooting tips, and advice can help users navigate common challenges and enhance their knowledge about their machines.

Official Manuals and Documentation: Comprehensive guides offer essential information regarding maintenance procedures, specifications, and safety protocols. These documents serve as a reliable reference for ensuring that equipment remains in optimal working condition.

Video Tutorials: Visual learning has become increasingly popular, and various platforms host tutorial videos. These resources can simplify complex tasks by providing step-by-step instructions, making repairs and maintenance more accessible for everyone.

Local Dealerships: Authorized retailers not only sell equipment but also provide expert advice and genuine components. Building a relationship with a local dealer can lead to personalized support and access to specialized services.

Parts Suppliers: Reliable suppliers ensure that users can find the necessary components to keep their machines running smoothly. Whether it’s for routine maintenance or unexpected repairs, having a trusted source for parts is crucial.

Blogs and Review Sites: Expert reviews and articles on related topics can help users stay informed about the latest products and innovations. These resources offer valuable perspectives, helping owners make educated decisions when it comes to upgrades or new purchases.

By utilizing these resources, owners can enhance their understanding and ensure their equipment remains reliable and efficient for years to come.