Understanding the Parts Diagram of the Stihl 044 Chainsaw

In the world of power equipment, the efficiency and reliability of a cutting device depend heavily on its internal structure. Each element plays a crucial role in the overall functionality, making it essential for users to grasp how these components interact and contribute to the tool’s performance.

Whether you’re a seasoned professional or a novice enthusiast, familiarizing yourself with the intricacies of this equipment can greatly enhance your maintenance and repair skills. An insightful exploration of the various sections will empower you to troubleshoot issues effectively and ensure the longevity of your device.

By delving into the specifics of each part, you’ll uncover the significance of precise assembly and the impact of wear and tear. Understanding the layout and relationship between different elements will facilitate informed decisions when it comes to servicing and upgrading your equipment.

As you navigate through this exploration, you will not only enhance your knowledge but also develop a deeper appreciation for the craftsmanship that goes into designing and building these powerful tools. Get ready to embark on a journey that uncovers the vital roles of every component in maximizing your device’s potential.

Understanding Stihl 044 Chainsaw Components

In order to effectively operate and maintain a power tool designed for cutting, it is essential to have a comprehensive understanding of its individual elements. Each component plays a crucial role in the overall functionality and performance, ensuring that the tool operates smoothly and efficiently. By familiarizing yourself with these elements, you can enhance your experience and extend the lifespan of the equipment.

Key Elements of the Tool

The primary sections of the equipment include the motor assembly, which provides the necessary power, and the cutting mechanism that interacts with the material being processed. Additionally, the fuel delivery system and air filtration components work together to optimize performance and maintain efficiency. Understanding how these key elements function in tandem is vital for effective usage.

Maintenance and Care

Overview of Stihl 044 Features

This section provides an insight into the distinctive characteristics of a popular power tool designed for cutting and trimming tasks. With its robust design and user-friendly functionalities, this equipment stands out in its category, catering to both professional and amateur users alike.

The tool is engineered for efficiency, offering a blend of power and precision. Key elements include a high-performance engine, ergonomic design, and advanced safety features, ensuring a reliable operation in various conditions. Below is a summary of its main attributes:

| Feature | Description |

|---|---|

| Engine Power | High output for demanding applications, ensuring quick and effective cutting. |

| Weight | Lightweight construction for enhanced maneuverability and reduced fatigue during extended use. |

| Vibration Reduction | Advanced technology to minimize vibrations, improving user comfort and control. |

| Safety Features | Incorporates mechanisms to protect the user, including chain brake and throttle lock. |

| Fuel Efficiency | Designed to optimize fuel consumption while maintaining power output. |

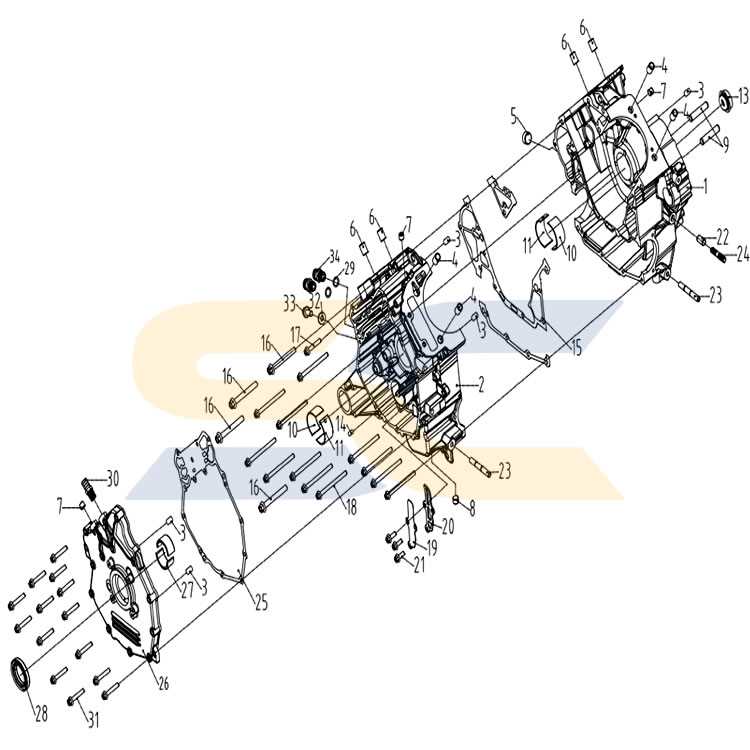

Importance of Parts Diagram

Understanding the components of a mechanical device is crucial for effective maintenance and repair. A visual representation of these elements serves as a valuable tool for both novice and experienced users, enabling them to identify, replace, or repair specific sections efficiently.

Facilitating Repairs

A clear illustration helps in recognizing the interconnections between different segments. This knowledge is essential when troubleshooting issues, as it allows individuals to pinpoint the source of a problem without unnecessary guesswork. By having a comprehensive reference, users can save time and reduce the risk of damaging other components during the repair process.

Enhancing Safety

Familiarity with the layout and function of various elements not only aids in repairs but also contributes to overall safety. Understanding how each part interacts within the machinery ensures that users can operate it correctly and safely. Moreover, a detailed visual guide can highlight areas that require caution, thereby minimizing the likelihood of accidents.

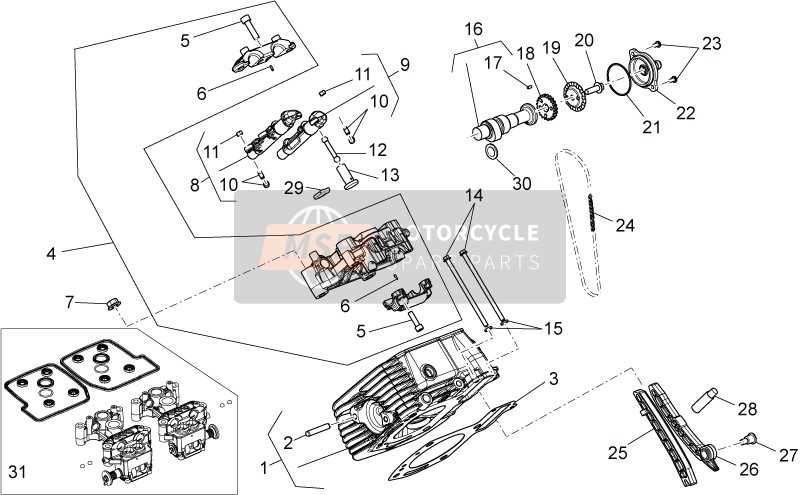

Key Components of Stihl 044

This section will explore the essential elements that contribute to the functionality and performance of a popular model in the field of outdoor power tools. Understanding these components is crucial for both maintenance and efficient operation.

Engine and Power System

The heart of any high-performance tool lies in its engine. The power unit in this model is designed for robust performance, offering reliable power output while maintaining efficiency. It utilizes a two-stroke design that ensures optimal combustion, resulting in high torque and smooth operation. Fuel delivery is managed through a precision system, ensuring that the engine receives the right amount of fuel for peak performance.

Cutting Mechanism

The cutting system is a vital aspect that determines the effectiveness of the tool. This model features a specialized guide bar and chain, meticulously designed to facilitate cutting through various materials with ease. The chain is engineered for durability, with sharp teeth that enhance cutting efficiency. Chain tensioning is adjustable, allowing users to maintain optimal performance and safety during operation. Regular maintenance of the cutting elements is essential to prolong the lifespan of the tool and ensure effective functionality.

Common Issues with Chainsaw Parts

Understanding the frequent challenges associated with power tool components is essential for effective maintenance and longevity. Various elements can encounter issues that may affect performance, safety, and efficiency. Identifying these common problems can lead to timely repairs and optimal functionality.

Wear and Tear

Over time, certain components can experience significant wear. For instance, blades may dull or chip, leading to reduced cutting efficiency. Similarly, filters can become clogged with debris, restricting airflow and compromising engine performance. Regular inspection and timely replacement can help mitigate these issues.

Fuel and Oil Leaks

Leaks can occur in several areas, particularly around gaskets and hoses. This not only leads to loss of essential fluids but can also pose safety hazards. Identifying and addressing leaks promptly is crucial to ensure safe operation and to prevent further damage.

How to Read the Diagram

Understanding technical illustrations is crucial for effective maintenance and repairs. These visual aids provide a comprehensive overview of components and their interconnections, enabling users to identify each element accurately. Mastering the interpretation of these representations can greatly enhance your ability to service the equipment efficiently.

Identifying Components

Start by familiarizing yourself with the symbols and labels used in the illustration. Each part is typically represented by a distinct icon or number, making it easier to locate specific items. Pay attention to the accompanying legend or key, as it often explains the meaning behind each symbol, ensuring clarity in your understanding.

Understanding Relationships

Next, focus on how the elements interact with one another. Arrows or lines may indicate connections, showing how parts fit together and function as a cohesive unit. Analyzing these relationships will help you grasp the overall operation, making it simpler to troubleshoot issues or perform necessary replacements.

With practice, reading these illustrations will become second nature, allowing you to tackle maintenance tasks with confidence.

Identifying Replacement Parts

Understanding the components of your equipment is essential for effective maintenance and repairs. Recognizing individual elements ensures that you can select the correct items when replacements are necessary, contributing to optimal performance and longevity. This section will guide you through the process of identifying and sourcing the right components for your machinery.

Common Components and Their Functions

Familiarizing yourself with the most frequently replaced items will help streamline the repair process. Here are some of the main elements and their roles:

| Component | Description |

|---|---|

| Bar | The long metal piece that guides the cutting mechanism. |

| Chain | The toothed loop that performs the cutting action. |

| Air Filter | A crucial element that prevents dirt and debris from entering the engine. |

| Fuel Filter | Ensures clean fuel reaches the engine for efficient operation. |

Finding the Right Replacements

When searching for new components, it is vital to reference the specific model and details of your device. This information is typically found in the user manual or on the equipment itself. Utilizing reputable suppliers will guarantee the quality and compatibility of the replacements.

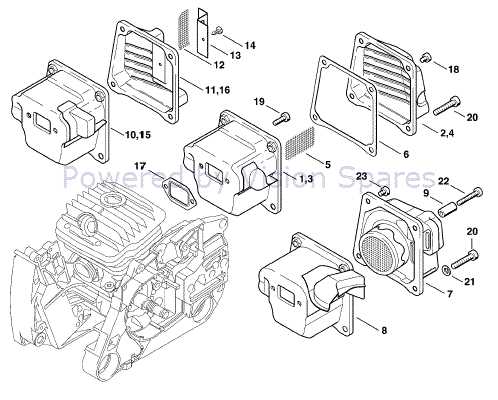

Maintenance Tips for Stihl 044

Proper care and attention are essential for the longevity and performance of your outdoor power tool. Regular maintenance not only ensures smooth operation but also helps prevent unexpected breakdowns and costly repairs. Here are some valuable tips to keep your equipment in optimal condition.

Regular Cleaning

After each use, it is important to clean the exterior thoroughly. Remove any debris, dust, or residue that may have accumulated during operation. Pay special attention to air filters and cooling fins, as these components can significantly impact performance. A clean machine runs more efficiently and has a longer lifespan.

Inspect and Replace Components

Routine inspections of various elements, such as the chain, bar, and tensioning system, are crucial. Look for signs of wear and tear, and replace any damaged parts immediately. Keeping the chain sharp is vital for effective cutting and reduces strain on the engine. Additionally, check fuel and oil levels regularly, ensuring they meet the manufacturer’s recommendations for optimal performance.

By following these maintenance tips, you can enhance the reliability and efficiency of your tool, ensuring it serves you well for many years.

Where to Buy Replacement Parts

Finding high-quality components for your outdoor power equipment is essential for maintaining its performance and longevity. Numerous options are available, catering to different needs and preferences. Whether you prefer shopping online or visiting a local store, understanding where to look can make the process smoother.

Online marketplaces offer a vast selection of options, often featuring competitive prices and customer reviews that can guide your purchase. Websites specializing in equipment supplies provide detailed listings, making it easy to compare items and find exactly what you need. Be sure to verify the seller’s reputation and check for warranties or return policies.

If you prefer a hands-on approach, visiting local dealers or specialty shops can be beneficial. Knowledgeable staff can assist you in finding the correct components and offer advice on installation and maintenance. Additionally, these stores may carry exclusive items that are not available online.

Lastly, consider checking with repair shops that specialize in outdoor machinery. They often have access to various brands and can source components that are difficult to find elsewhere. Plus, they may offer installation services, saving you time and effort.

DIY Repairs with Parts Diagram

Engaging in maintenance and repairs of your outdoor power equipment can be a rewarding experience. Having a visual guide can simplify the process, making it easier to identify components and understand their functions. By following a detailed visual reference, you can ensure that each piece is correctly installed, enhancing the overall performance and longevity of your tools.

Understanding the Components is crucial for effective repairs. When you have a comprehensive visual reference at hand, it helps you familiarize yourself with the individual elements of your equipment. This knowledge empowers you to diagnose issues accurately and select the right replacements when necessary.

Step-by-Step Repair Process can be significantly streamlined with the aid of a visual guide. Start by consulting the reference to locate the specific part you need to work on. Then, follow the outlined steps to disassemble, inspect, and replace any faulty components. This organized approach not only saves time but also minimizes the risk of damaging other parts during the repair process.

Moreover, performing repairs yourself can lead to considerable cost savings. Instead of relying on professional services, you can take matters into your own hands, using the visual guide as your roadmap. This empowers you to maintain your equipment in top condition, ensuring it operates efficiently whenever needed.

In conclusion, utilizing a visual reference for repairs provides clarity and confidence in tackling maintenance tasks. With a bit of patience and the right tools, you can enhance your DIY skills and keep your equipment running smoothly for years to come.

Comparing Stihl 044 with Other Models

This section delves into a comparative analysis of a specific power tool and its counterparts in the market. Understanding the unique features and capabilities of various models can help users make informed decisions based on their specific needs and preferences. By examining the strengths and weaknesses of different options, one can gain insight into which model might be the best fit for a variety of tasks.

Performance: When evaluating these tools, performance is a crucial factor. Some models are designed for heavy-duty use, boasting higher power outputs and faster cutting speeds. Others may prioritize ease of handling and efficiency for lighter tasks, making them more suitable for occasional users or residential projects.

Durability: Another significant aspect is the durability of each tool. Some variations are built with high-quality materials that withstand rigorous use over time, while others may have a more lightweight construction that affects longevity. Understanding the build quality can guide users in selecting a tool that matches their workload and environment.

Maintenance: Maintenance requirements also vary between models. Some might offer user-friendly features that simplify upkeep, while others may necessitate more frequent servicing. This can influence the overall ownership experience, particularly for those who prefer low-maintenance solutions.

Weight and Ergonomics: Weight and ergonomics play vital roles in user comfort and control. Heavier models may provide additional power but can lead to fatigue during extended use. Lighter tools, on the other hand, enhance maneuverability but might compromise on strength. Finding a balance that suits individual preferences is key.

Price: Lastly, cost is an essential consideration. While high-end models may deliver superior performance and features, budget-friendly options can still fulfill many users’ needs without breaking the bank. Analyzing the value offered by each tool relative to its price can help buyers make wise investments.

Tools Needed for Maintenance

Regular upkeep of your equipment is essential for ensuring optimal performance and longevity. Having the right tools on hand simplifies the maintenance process, allowing you to address issues promptly and effectively. Below is a list of essential instruments that will assist you in maintaining your machinery efficiently.

Basic Tools

To start, a set of basic tools is crucial. This includes a screwdriver for adjusting components, a wrench for tightening nuts and bolts, and a torque wrench to ensure proper tightness without damage. Additionally, a cleaning brush and compressed air can help clear debris from hard-to-reach areas, promoting better airflow and performance.

Specialized Equipment

For more thorough maintenance, certain specialized tools are recommended. A file is essential for sharpening cutting edges, while a maintenance kit often includes necessary oils and lubricants that keep moving parts functioning smoothly. Finally, a protective gear such as gloves and goggles should always be worn to ensure safety during any maintenance work.

Safety Precautions When Repairing

Engaging in maintenance and repairs of power equipment requires a careful approach to ensure personal safety and prevent accidents. Understanding the inherent risks and implementing effective safety measures is crucial for anyone undertaking these tasks. Prioritizing safety not only protects the individual but also extends the lifespan of the equipment.

Personal Protective Equipment

Always wear appropriate personal protective gear during any repair activity. This includes safety goggles to shield your eyes from debris, gloves to protect your hands from sharp objects, and sturdy footwear to guard against heavy items that may drop. Additionally, consider using hearing protection if working with machinery that produces significant noise.

Workspace Organization

A well-organized workspace can significantly reduce the risk of accidents. Ensure that your area is clean and free from clutter. Keep tools and parts in designated places to avoid tripping hazards and make it easier to find necessary items. Moreover, proper lighting is essential; work in a well-lit environment to enhance visibility and facilitate detailed inspections.