Understanding the Stihl 066 Magnum Parts Diagram

In the realm of outdoor equipment, particularly when it comes to high-performance cutting tools, comprehending the individual elements that contribute to their efficiency is essential. This knowledge not only enhances maintenance practices but also empowers users to make informed decisions regarding repairs and upgrades. A well-structured overview of these components provides clarity and insight into the intricate workings of these machines.

Each element plays a pivotal role in the overall functionality, ensuring that the device operates at its peak performance. From the motor to the chain mechanism, understanding the interplay between these parts can lead to better troubleshooting and enhanced longevity of the equipment. Users can benefit significantly from familiarizing themselves with how each section interacts, which ultimately results in a more effective cutting experience.

Delving into a detailed representation of these crucial components allows enthusiasts and professionals alike to navigate the complexities of maintenance. By examining the specific arrangements and connections, one can identify potential issues before they escalate. This proactive approach not only saves time and resources but also maximizes the efficiency and reliability of the chainsaw, making it a valuable asset for any user.

Understanding Stihl 066 Magnum Overview

This section aims to provide an insightful overview of a powerful tool known for its efficiency and reliability in demanding tasks. With a robust design and a focus on performance, this equipment stands out in the realm of outdoor machinery. Understanding its components and functionality can enhance user experience and maintenance practices.

Key Features

Recognizing the essential attributes of this machine is crucial for both novices and seasoned users. Its engine power, weight distribution, and ergonomic design contribute to its popularity. Below are some prominent features:

| Feature | Description |

|---|---|

| Engine Power | High output for demanding applications, ensuring efficient operation. |

| Weight | Balanced design for improved maneuverability during use. |

| Ergonomics | Comfortable grip and user-friendly controls for extended usage. |

Maintenance Considerations

Proper upkeep is vital for longevity and performance. Regular checks on essential components can prevent unexpected failures. Key maintenance tasks include monitoring fuel levels, cleaning air filters, and inspecting cutting elements for wear. Understanding these aspects ensures optimal functionality and safety.

Key Features of Stihl 066 Magnum

This powerful tool is designed for heavy-duty tasks, making it a favorite among professionals and enthusiasts alike. Its robust construction and advanced engineering provide an excellent balance of performance and reliability.

Powerful Engine: The high-performance engine delivers exceptional torque, ensuring efficient cutting through dense materials with ease. This feature allows users to tackle larger projects without compromising on speed.

Lightweight Design: Despite its strength, the unit boasts a lightweight design that enhances maneuverability. This allows for prolonged use without causing fatigue, making it ideal for extended work sessions.

Durability: Constructed with high-quality materials, this tool is built to withstand the rigors of demanding tasks. Its longevity is a significant advantage, reducing the need for frequent replacements.

Ease of Maintenance: The thoughtful design includes accessible components, simplifying routine maintenance and repairs. This feature ensures that users can keep their equipment in optimal condition with minimal effort.

Advanced Safety Features: Equipped with multiple safety mechanisms, it prioritizes user protection during operation. These features help prevent accidents, making it a safer choice for both novice and experienced operators.

Versatility: Suitable for a variety of applications, this tool can handle everything from tree felling to firewood cutting. Its adaptability makes it a valuable addition to any toolkit.

Importance of Replacement Parts

Ensuring the longevity and optimal performance of machinery relies heavily on the timely replacement of essential components. Over time, wear and tear can compromise efficiency, leading to potential breakdowns and costly repairs. Regularly updating these vital elements is crucial for maintaining the functionality and safety of equipment.

Enhancing Performance

Utilizing new components can significantly improve the overall operation of machinery. Fresh elements help restore the original capabilities, enabling the equipment to perform at its best. This enhancement not only boosts productivity but also minimizes the risk of malfunction during critical tasks.

Cost-Effectiveness

Investing in quality replacements can save money in the long run. While initial costs may seem high, neglecting necessary updates can lead to more severe issues that require expensive repairs or even complete equipment replacement. Regular maintenance and timely upgrades are key to avoiding unexpected expenses.

| Benefit | Description |

|---|---|

| Increased Efficiency | New components restore optimal functionality, ensuring smoother operation. |

| Reduced Downtime | Regular updates minimize the risk of breakdowns, allowing for uninterrupted work. |

| Enhanced Safety | Replacing worn parts helps maintain safety standards, protecting users and equipment. |

| Longevity | Investing in new elements extends the overall lifespan of the machinery. |

Identifying Common Parts of the Saw

Understanding the key components of a cutting tool is essential for effective maintenance and operation. Each element plays a vital role in ensuring optimal performance, longevity, and safety during use. By familiarizing oneself with these critical parts, users can troubleshoot issues and make informed decisions when replacements or repairs are necessary.

Essential Components

The engine serves as the heart of the machine, providing the necessary power to drive the blade. Coupled with the ignition system, it ensures reliable starting and smooth operation. The cutting mechanism itself, including the guide bar and chain, is designed for precision and efficiency, allowing for clean cuts through various materials.

Support Systems

Additional elements, such as the air filter and fuel system, are crucial for maintaining performance. The air filter prevents debris from entering the engine, while the fuel system ensures a steady flow of energy. Moreover, the vibration dampening system enhances user comfort, reducing fatigue during extended use.

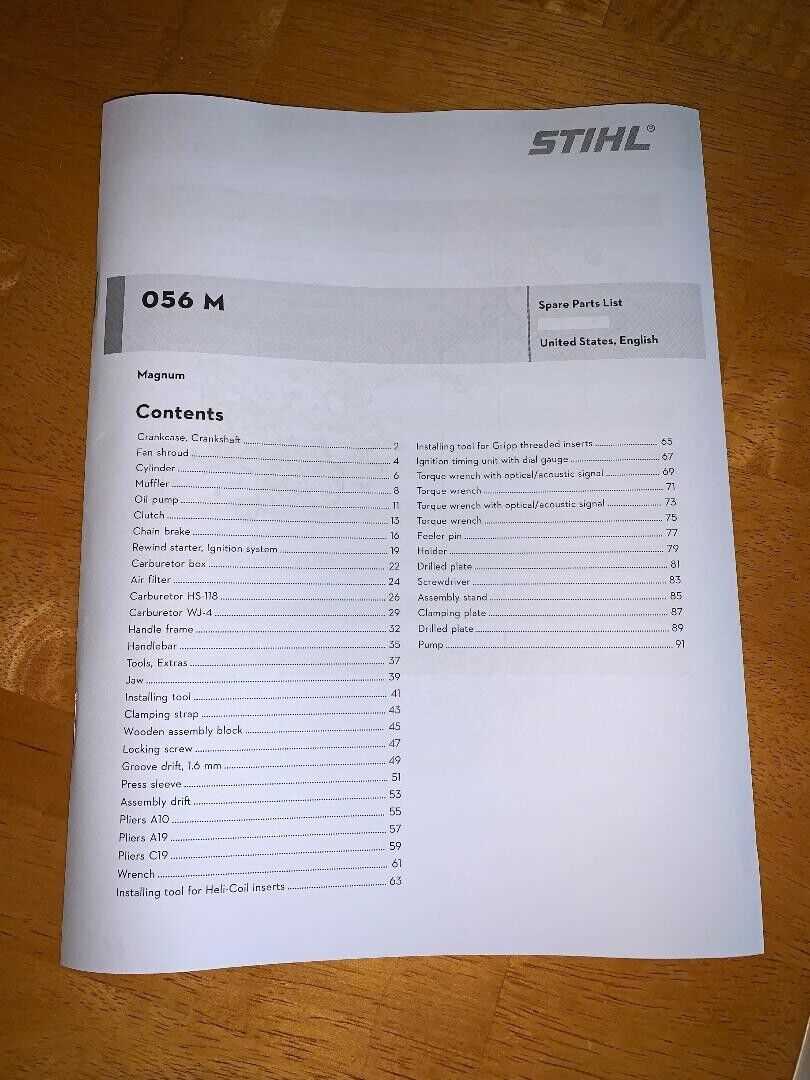

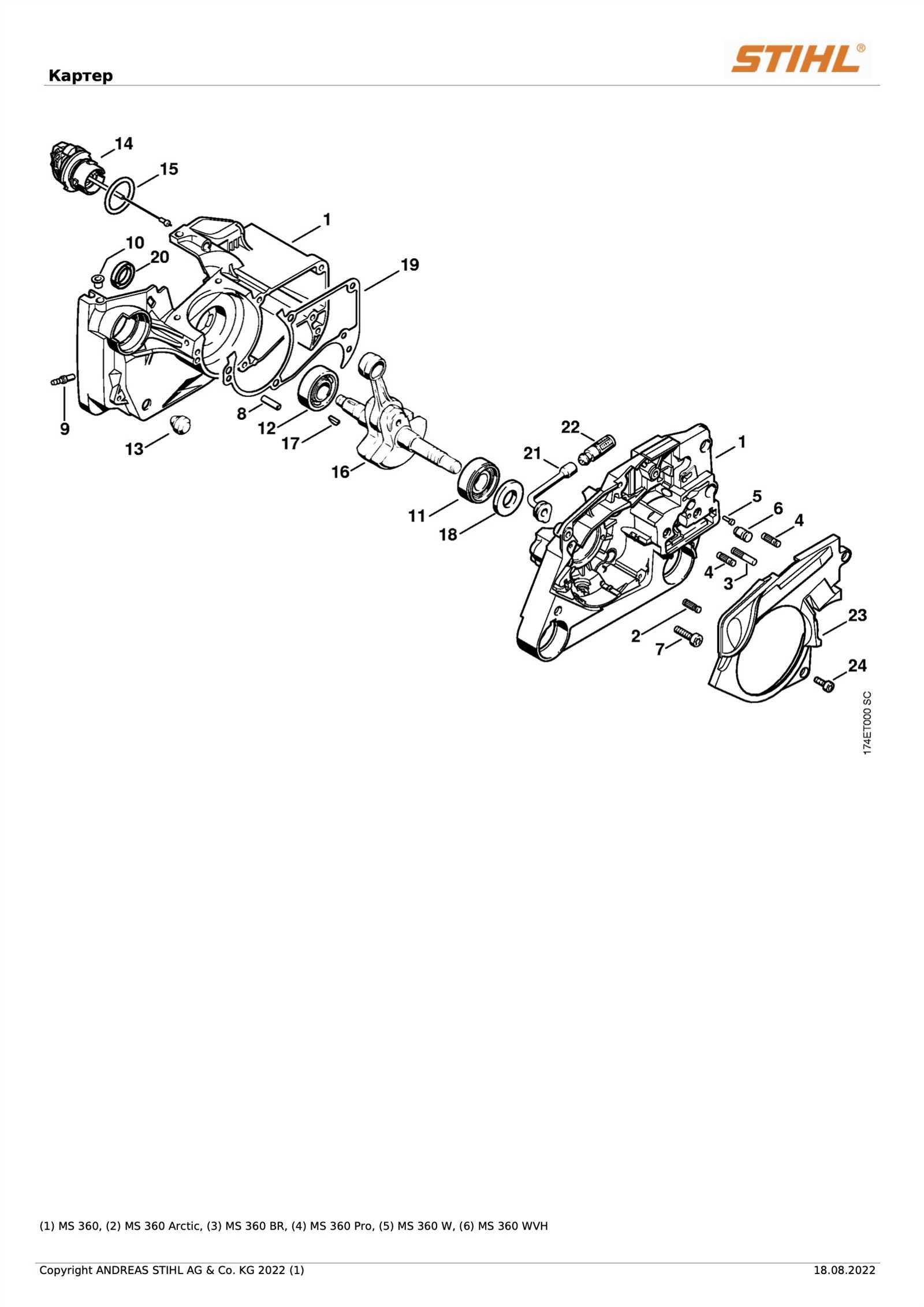

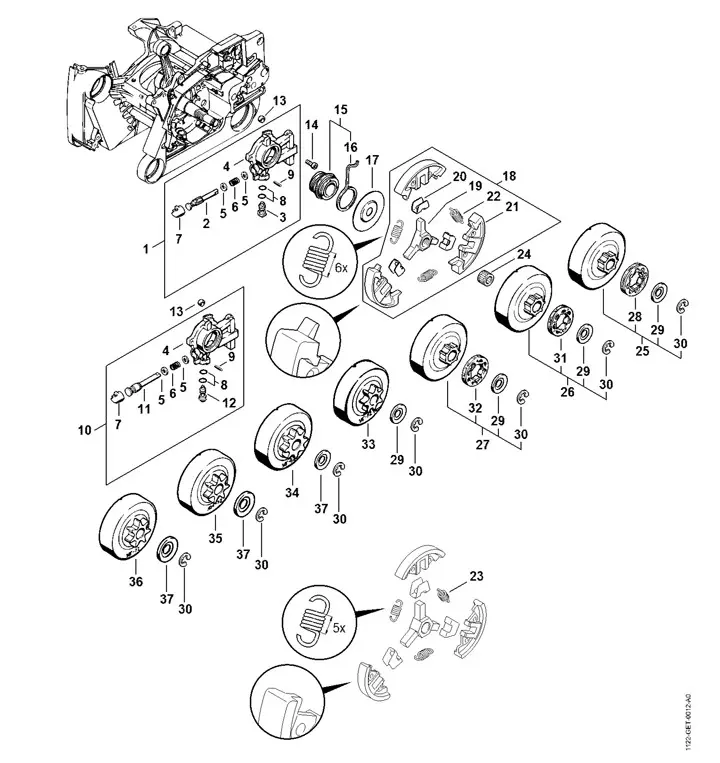

Detailed Parts Diagram Explanation

Understanding the intricate components of a machine is crucial for effective maintenance and repair. A visual representation showcasing the various elements helps users identify, locate, and comprehend the function of each part. This knowledge ensures efficient troubleshooting and enhances the longevity of the equipment.

Key Components Overview

The visual aid typically includes several essential segments that can be categorized as follows:

- Engine Assembly: Central to the machine’s operation, this section encompasses the main power unit.

- Fuel System: This includes components like the fuel tank, lines, and filter, which are vital for proper fuel delivery.

- Cutting Mechanism: The blades and related attachments fall under this category, crucial for the machine’s primary function.

- Body and Housing: The external shell that protects internal parts and supports overall structure.

Benefits of Using Visual Guides

Employing these illustrations offers numerous advantages:

- Enhanced clarity in identifying specific components.

- Streamlined assembly and disassembly processes.

- Improved understanding of the machine’s functionality.

- Facilitation of accurate replacement and repair procedures.

By utilizing these comprehensive visuals, users can better navigate the complexities of their equipment, ensuring efficient performance and maintenance.

How to Use the Diagram Effectively

Understanding the layout of a complex assembly can significantly enhance your maintenance and repair skills. Utilizing a visual reference allows you to identify components and their connections clearly, leading to more efficient troubleshooting and repairs. This guide will help you make the most of such illustrations in your projects.

Familiarize Yourself with the Components

Before diving into any repair or assembly task, take time to study the illustration thoroughly. Identify the various elements and their functions within the system. This will not only help you recognize parts during your work but also give you insight into how they interact with one another. Pay attention to labels and numbering systems that indicate the sequence or hierarchy of components.

Plan Your Approach

Once you have a good understanding of the parts, outline your repair strategy. Refer to the illustration to determine which components require attention. Map out a step-by-step process based on the visual aid, ensuring you have all necessary tools and replacement items at hand. This preparation will streamline your workflow and minimize the risk of overlooking critical steps.

Ordering Genuine Stihl Parts

Acquiring authentic components for your outdoor power equipment is essential for maintaining performance and longevity. By opting for original pieces, you ensure compatibility and reliability, ultimately enhancing your machinery’s efficiency. This section outlines the process of sourcing these quality items, emphasizing the benefits and methods involved.

When seeking original replacements, consider the following steps to ensure a seamless experience:

| Step | Description |

|---|---|

| 1 | Identify the specific component needed by consulting your user manual or equipment specifications. |

| 2 | Visit authorized dealers or reputable online retailers specializing in outdoor machinery. |

| 3 | Provide the model number and any additional details to ensure you receive the correct item. |

| 4 | Review shipping options and confirm your order before finalizing the purchase. |

By following these steps, you can confidently acquire the necessary elements to keep your equipment running smoothly and efficiently, ensuring long-lasting performance.

Tips for Finding Compatible Components

When seeking components for your equipment, it’s essential to ensure they align perfectly with your model. Compatibility not only enhances performance but also ensures safety and longevity. Here are some strategies to guide you in identifying suitable alternatives.

Research Manufacturer Specifications

Always start by consulting the manufacturer’s specifications for your equipment. These documents often detail the required dimensions, materials, and performance standards for each component. By understanding these parameters, you can better assess whether a potential replacement will meet your needs.

Consult User Communities and Forums

Engaging with user communities can provide invaluable insights. Online forums and social media groups dedicated to similar equipment often share experiences, recommendations, and warnings about specific components. Such collective knowledge can help you avoid costly mistakes and lead you to reliable options.

Remember, verifying compatibility through multiple sources will increase your confidence in the components you choose. Taking the time to research will ultimately pay off in performance and durability.

Common Issues and Solutions

Every mechanical device can encounter challenges during its operation. Understanding these common problems and their corresponding solutions can significantly enhance performance and longevity. Below are typical issues faced and effective remedies to address them.

Frequent Problems

- Engine Difficulties

- Fuel Leaks

- Chain Malfunction

- Air Filter Blockage

Effective Solutions

-

Engine Difficulties:

If the engine fails to start or runs inconsistently, check the spark plug for wear and replace it if necessary. Ensure that fuel is reaching the engine by inspecting the fuel lines for clogs.

-

Fuel Leaks:

Inspect fuel lines and connections for cracks or loose fittings. Tighten any loose screws and replace damaged hoses to prevent leaks.

-

Chain Malfunction:

If the cutting chain does not rotate smoothly, verify that it is properly tensioned and lubricated. Adjust the tension as needed and apply adequate chain oil.

-

Air Filter Blockage:

A blocked air filter can hinder performance. Remove the filter and clean it according to the manufacturer’s instructions or replace it if it is excessively dirty.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your outdoor power equipment requires consistent care and attention. Regular maintenance not only enhances performance but also extends the lifespan of your tools. Here are some essential practices to keep your machinery in optimal condition.

- Regular Cleaning: Remove dirt, debris, and residues after each use. This prevents corrosion and helps maintain airflow.

- Inspect Components: Periodically check all essential parts for wear and tear. Look for cracks, fraying, or any signs of damage.

- Lubrication: Apply the appropriate lubricant to moving parts. This reduces friction and prevents premature wear.

- Sharpen Cutting Edges: Keep blades and cutting tools sharp for efficient operation and reduced strain on the engine.

In addition to these basic practices, consider following a structured maintenance schedule:

- Daily Checks: Inspect fuel levels, oil condition, and any visible damages.

- Weekly Maintenance: Clean air filters and check spark plugs to ensure optimal performance.

- Seasonal Overhaul: At the start of each season, conduct a thorough inspection and replace any worn-out parts.

By following these guidelines, you can enhance the performance and lifespan of your equipment, ensuring it remains a reliable tool for years to come.

Aftermarket Parts: Pros and Cons

When considering alternatives to original components for machinery, it’s essential to weigh the benefits and drawbacks. These substitutes can offer a cost-effective solution, but they may also come with varying levels of quality and performance. Understanding these aspects is crucial for making an informed decision.

The following table outlines the primary advantages and disadvantages of opting for alternative components:

| Advantages | Disadvantages |

|---|---|

| Lower cost, making repairs more affordable | Potential variability in quality and reliability |

| Increased availability, often found in multiple outlets | May not fit perfectly or perform as expected |

| Wider range of options for customization | Possible impact on warranty or service agreements |

| Encouragement of competition among manufacturers | Limited customer support or documentation |

In summary, while alternatives can provide significant savings and flexibility, users must be cautious about potential downsides. Assessing the specific needs and quality of these components will lead to a more satisfactory outcome.

Customer Experiences with Stihl 066 Magnum

This section delves into the feedback and insights shared by users of a well-known high-performance chainsaw. Owners often express their satisfaction with its reliability and robust features, which contribute to efficient cutting and overall performance in various applications.

Positive Feedback

Many users highlight the powerful engine and smooth operation, allowing for seamless handling during prolonged tasks. The ease of maintenance is frequently mentioned, as individuals appreciate how simple it is to access critical components for upkeep. Additionally, the lightweight design enhances maneuverability, making it a favorite among professionals and hobbyists alike.

Common Concerns

Despite the generally favorable reviews, some users report challenges with weight when used for extended periods. A few have also noted that the initial cost can be a barrier, although they often agree that the long-term benefits justify the investment. Overall, the collective experiences reflect a balance of enthusiasm and practical considerations.