Understanding the Stihl 201 TC Parts Diagram for Efficient Maintenance

When it comes to maintaining outdoor machinery, having a clear visual representation of its elements is essential for effective repairs and servicing. A comprehensive illustration serves as a roadmap, guiding users through the intricate network of mechanical parts and their respective functions.

Familiarity with each segment of your tool can enhance performance and longevity. By examining these detailed visuals, enthusiasts and professionals alike can delve into the specifics, ensuring that every component is well-understood and correctly addressed during maintenance tasks.

Ultimately, a thorough grasp of the mechanical layout not only simplifies troubleshooting but also empowers users to make informed decisions regarding replacements and upgrades, leading to a more efficient working experience.

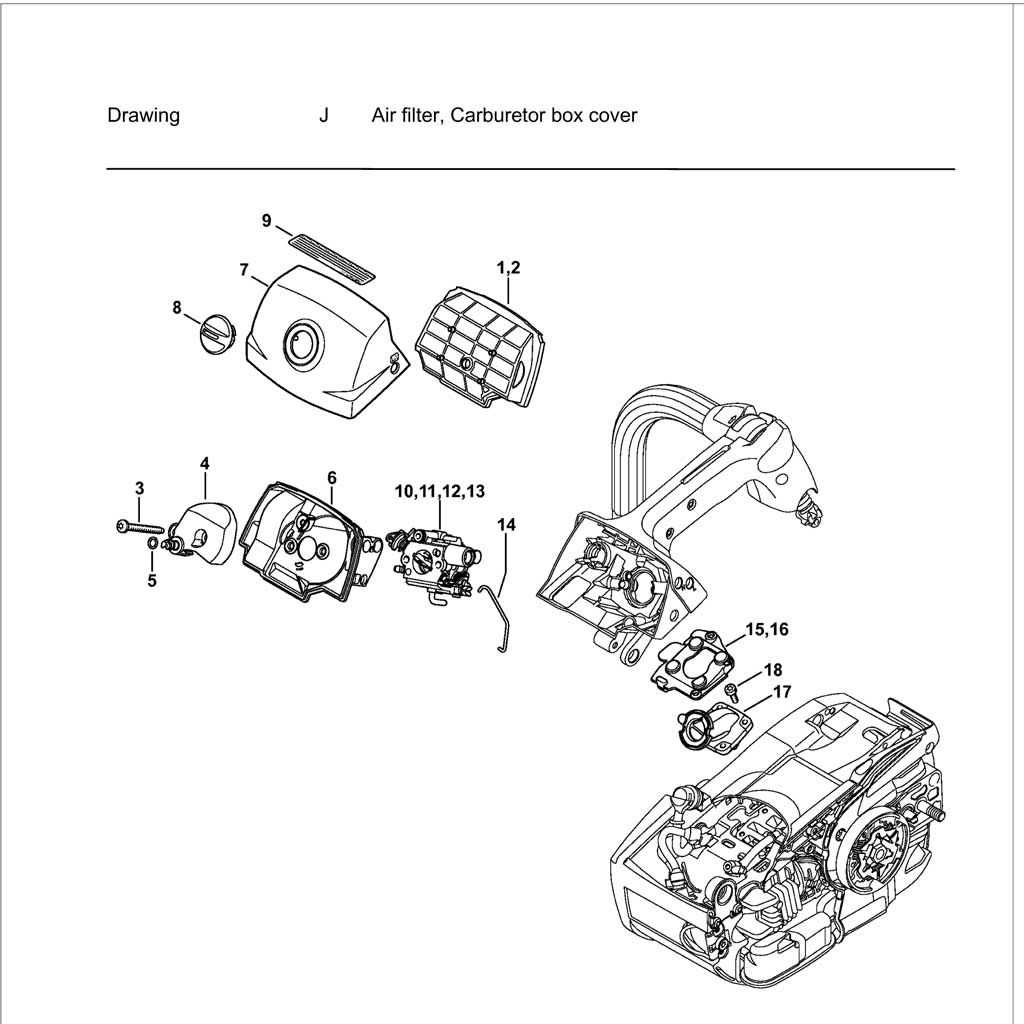

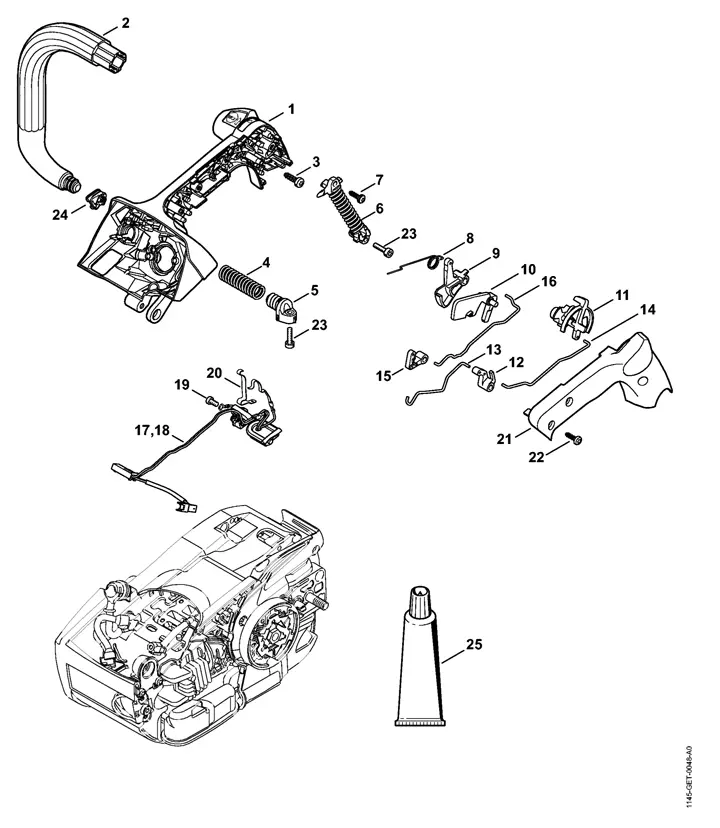

Understanding the Stihl 201 TC Diagram

Grasping the intricacies of a specific equipment schematic is essential for effective maintenance and troubleshooting. This visual representation provides a comprehensive overview of the various components and their interconnections, enabling users to identify parts and understand their functions. By familiarizing oneself with this schematic, one can enhance their repair skills and ensure optimal performance of the tool.

Components and Their Functions

Each element in the schematic plays a crucial role in the overall operation of the machine. From the engine to the cutting mechanism, understanding how these pieces fit together is vital. Familiarity with the functionality of individual components not only aids in repairs but also helps in anticipating potential issues before they escalate.

Utilizing the Schematic for Repairs

When faced with a malfunction, the schematic serves as a roadmap for troubleshooting. Identifying the location and role of each part allows for efficient diagnostics. By following the connections illustrated, users can systematically address problems, ensuring a thorough and informed approach to maintenance.

Key Components of Stihl 201 TC

Understanding the essential elements of a chainsaw can greatly enhance its functionality and ensure optimal performance. Each component plays a crucial role in the overall operation, contributing to efficiency, safety, and ease of use. This overview highlights some of the most important parts that make up this powerful tool.

Engine and Power System

The heart of any chainsaw lies in its engine, which powers the entire mechanism. The power system is designed to deliver a reliable output, allowing for smooth operation during various cutting tasks. A well-maintained engine not only improves performance but also extends the lifespan of the tool.

Cutting Mechanism

The cutting assembly, which includes the chain and bar, is critical for effective wood processing. The design of the chain influences cutting speed and precision, while the bar length affects maneuverability. Regular inspection and maintenance of these elements are essential to ensure they function optimally, providing clean and efficient cuts.

How to Read the Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair of equipment. These visual aids provide a clear view of individual elements, their arrangement, and how they interact within the system. Familiarity with this format can greatly enhance your ability to troubleshoot issues and identify necessary replacements.

Identifying Key Components

When examining the schematic, it is important to recognize the primary features:

- Labels: Each element typically has a unique identifier, often in the form of numbers or letters, which correspond to a list of components.

- Connections: Lines or arrows illustrate how parts connect to each other, indicating flow and interaction.

- Groupings: Components may be clustered by function, helping to visualize how systems work together.

Utilizing Reference Lists

In addition to the visual representation, reference lists are crucial:

- Locate the identification numbers from the schematic.

- Cross-reference these numbers with the accompanying list to find specific details about each item.

- Use this information to determine availability and compatibility when sourcing replacements.

By mastering these elements, you can navigate the schematic effectively, ensuring a thorough understanding of your equipment’s construction and functionality.

Common Repairs for Stihl 201 TC

Regular maintenance and timely repairs are essential for the longevity and efficiency of any outdoor power equipment. Understanding common issues that may arise can help users troubleshoot effectively and minimize downtime. This section explores frequent repair tasks that are often needed for optimal performance.

Engine Troubleshooting

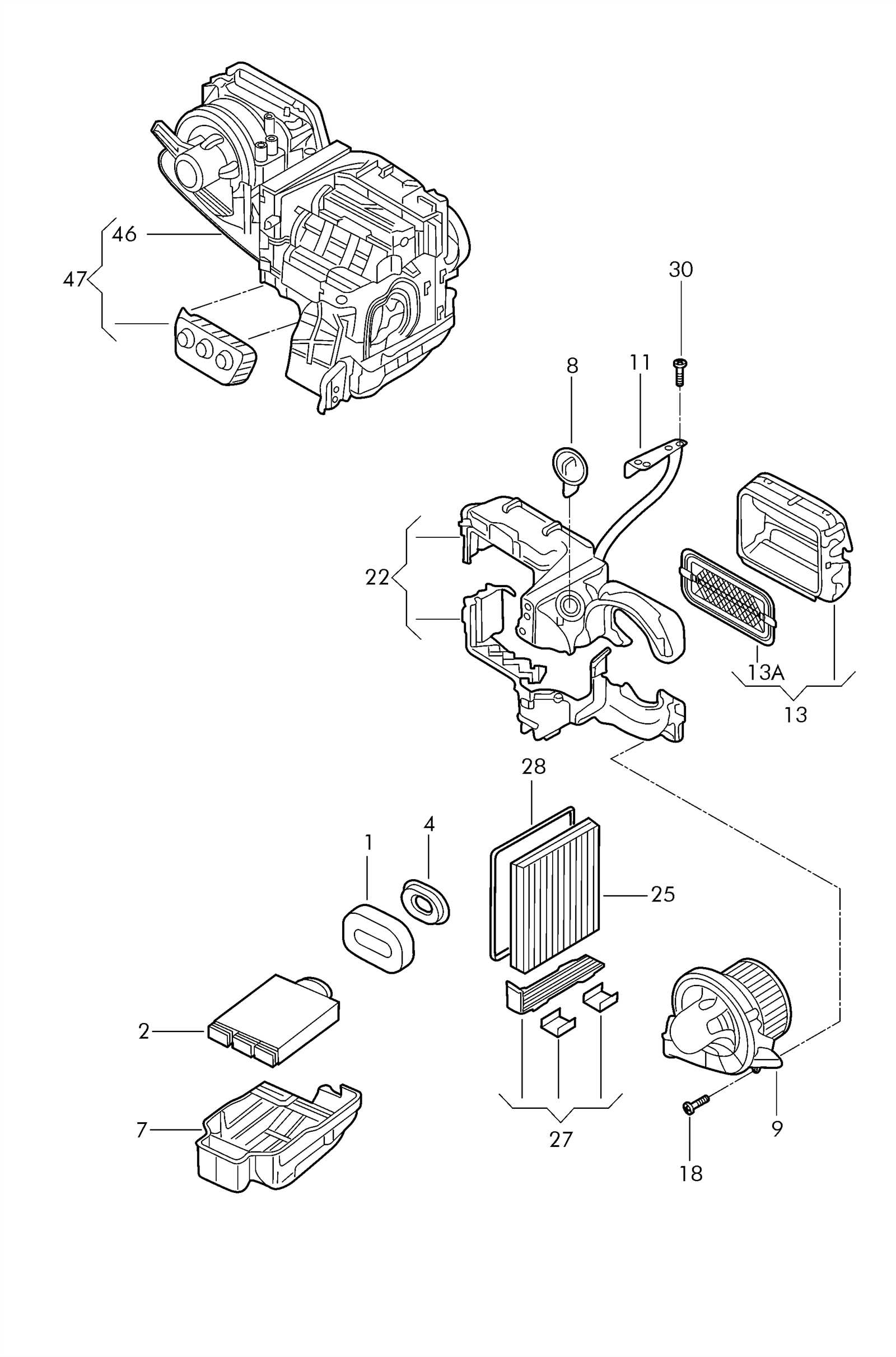

One of the most common challenges involves the engine. Symptoms like difficulty starting or unexpected stalling can be attributed to various factors, including fuel issues, air filter blockages, or spark plug malfunctions. Checking the fuel mixture, replacing the air filter, or installing a new spark plug can often resolve these problems and restore proper functionality.

Chain and Bar Maintenance

Another frequent area of concern is the cutting mechanism. Dull chains or worn bars can lead to inefficient cutting and increased strain on the machine. Regularly inspecting the chain for wear, sharpening it when necessary, and ensuring proper lubrication can enhance performance and extend the life of these components. Neglecting this aspect can result in more significant repairs down the line.

Essential Tools for Maintenance

Proper upkeep of equipment is crucial for optimal performance and longevity. Utilizing the right tools not only facilitates this process but also enhances efficiency, ensuring that every task is completed to the highest standard.

Basic Tools Required

- Wrenches

- Screwdrivers

- Socket set

- Adjustable pliers

Specialized Instruments

- Torque wrench

- Compression tester

- Fuel system cleaner

- Chain sharpening tool

Equipping yourself with these essential instruments will ensure your machinery remains in peak condition, ready for any task at hand.

Finding Genuine Stihl Parts

When it comes to maintaining your outdoor power equipment, sourcing authentic components is crucial for ensuring optimal performance and longevity. Using genuine items not only enhances the reliability of your tools but also protects your investment over time.

One of the best ways to identify original components is by consulting authorized dealers or official websites. These sources guarantee that you receive items that meet the manufacturer’s standards and specifications. Additionally, they often provide support and guidance in selecting the correct items for your specific model.

Another effective approach is to examine the packaging and labeling of the components. Authentic items typically feature clear branding and product information, which helps differentiate them from counterfeit alternatives. It’s important to be cautious of significantly lower prices, as they can indicate inferior quality.

Lastly, engaging with community forums or user groups can provide valuable insights. Fellow enthusiasts often share their experiences and can recommend reliable suppliers. This not only aids in finding genuine components but also fosters a sense of community among users.

Tips for Assembly and Disassembly

When working on equipment, proper assembly and disassembly techniques are crucial for efficiency and safety. Understanding how to carefully approach these tasks can prevent damage and ensure that everything functions optimally once reassembled. Below are some essential strategies to keep in mind during these processes.

Preparation

- Gather all necessary tools and components before starting.

- Read the manufacturer’s guidelines to familiarize yourself with the assembly steps.

- Clear your workspace to ensure easy access to parts and prevent misplacement.

Disassembly Steps

- Begin by disconnecting any power sources to ensure safety.

- Carefully remove outer coverings to expose internal components.

- Take pictures or make notes of the arrangement of parts for reference during reassembly.

- Use the appropriate tools to avoid stripping screws or damaging components.

- Organize removed parts in a systematic manner to facilitate easy identification later.

By following these guidelines, you can streamline both the disassembly and reassembly processes, making the task more manageable and less prone to errors.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is essential to prevent accidents and injuries. Following proper protocols helps create a secure working environment.

- Always wear appropriate personal protective equipment (PPE), such as gloves and goggles.

- Ensure your workspace is clean and organized to minimize hazards.

- Disconnect power sources before beginning any repair work.

Prioritize awareness of your surroundings and potential risks.

- Read the manufacturer’s guidelines thoroughly before starting.

- Use tools properly and inspect them for damage before use.

- Never rush through repairs; take your time to avoid mistakes.

By adhering to these practices, you can significantly reduce the likelihood of mishaps during repair processes.

Upgrading Your Stihl 201 TC

Enhancing your chainsaw can significantly improve its performance and longevity. By carefully selecting compatible components and accessories, you can optimize efficiency, reduce wear, and even elevate safety during operation. This section will guide you through some effective upgrades that can transform your tool into a more powerful and user-friendly machine.

| Upgrade Component | Benefits |

|---|---|

| High-Performance Chain | Increased cutting speed and smoother operation. |

| Upgraded Bar | Improved durability and better handling for larger tasks. |

| Vibration Dampening Handle | Enhanced comfort and reduced fatigue during extended use. |

| Advanced Air Filter | Longer engine life and improved performance in dusty conditions. |

| Fuel Additives | Increased efficiency and reduced emissions. |

Choosing the right upgrades can make a significant difference in how your machine performs. By investing in quality components, you can enjoy a more efficient and effective experience, whether you’re cutting firewood, clearing brush, or tackling other outdoor projects.

Frequently Asked Questions on Parts

This section addresses common inquiries regarding components and their functionality. Understanding these elements is crucial for maintaining equipment and ensuring optimal performance. Below, we provide answers to frequently posed questions to help clarify any uncertainties.

| Question | Answer |

|---|---|

| What should I do if I can’t find a specific component? | Check with authorized dealers or online resources that specialize in equipment parts to locate the item. |

| How can I ensure that I am purchasing the correct item? | Refer to the model number and specifications provided in the user manual to match the required component accurately. |

| Are aftermarket components reliable? | While some aftermarket options can be of good quality, it is advisable to research and read reviews to ensure reliability. |

| How often should I replace worn-out elements? | Regular inspections should be conducted, and replacements should be made as necessary, typically based on usage frequency. |

| Can I install components myself? | Many users can perform basic installations; however, complex repairs may require professional assistance. |

Where to Get Professional Help

When it comes to maintaining and repairing equipment, seeking expert assistance can be crucial for ensuring optimal performance and longevity. Relying on skilled technicians can save time and prevent potential issues that may arise from DIY approaches. Here are some reliable options to consider when looking for professional support.

- Authorized Service Centers: These facilities employ certified specialists familiar with specific models and can provide quality repairs and maintenance.

- Local Repair Shops: Many independent mechanics have extensive experience with various machinery and can offer personalized service tailored to your needs.

- Online Support Communities: Forums and social media groups can be excellent resources for advice from experienced users and professionals who share tips and troubleshooting strategies.

- Manufacturer Support: Reaching out to the manufacturer’s customer service can connect you with knowledgeable representatives who can guide you through specific issues or direct you to nearby service locations.

Choosing the right source for professional assistance ensures that your equipment operates smoothly and remains in excellent condition.