Understanding the Stihl 250 Parts Diagram for Efficient Maintenance

The intricacies of machinery often require a closer look to fully appreciate their functionality. By exploring the individual elements that make up a specific model, one can gain valuable insights into its operation and maintenance.

In this section, we will examine the layout of essential components, enabling users to identify and comprehend the roles each part plays. This knowledge not only aids in troubleshooting but also enhances overall performance.

Whether you are a seasoned professional or a novice user, understanding the arrangement of these vital elements is key to ensuring your equipment runs smoothly. Let’s delve into the ultimate guide for navigating through these components.

Understanding the Stihl 250 Chainsaw

This section aims to explore the essential features and components of a popular cutting tool used for various applications. Understanding its functionality and design can enhance maintenance and efficiency, ensuring optimal performance during use.

Key Features

- Powerful engine designed for heavy-duty tasks

- Lightweight body for easy maneuverability

- Safety mechanisms to protect the user

Maintenance Tips

- Regularly clean the air filter to maintain airflow.

- Check and sharpen the chain frequently for smooth cutting.

- Inspect fuel lines for wear and tear to prevent leaks.

Key Components of the Stihl 250

This section explores the essential elements that contribute to the functionality and efficiency of a specific model in the power tool category. Understanding these components is crucial for maintenance, repair, and optimal performance.

Engine: The heart of the machine, providing the necessary power for operation. Its design ensures durability and efficiency.

Bar and Chain: These components work together to facilitate cutting. The quality and compatibility are vital for achieving desired results.

Air Filter: A critical element that protects the engine from dust and debris, ensuring smooth operation and longevity.

Fuel System: Comprising the fuel tank and lines, this system delivers energy to the engine. Proper maintenance prevents clogs and ensures efficient performance.

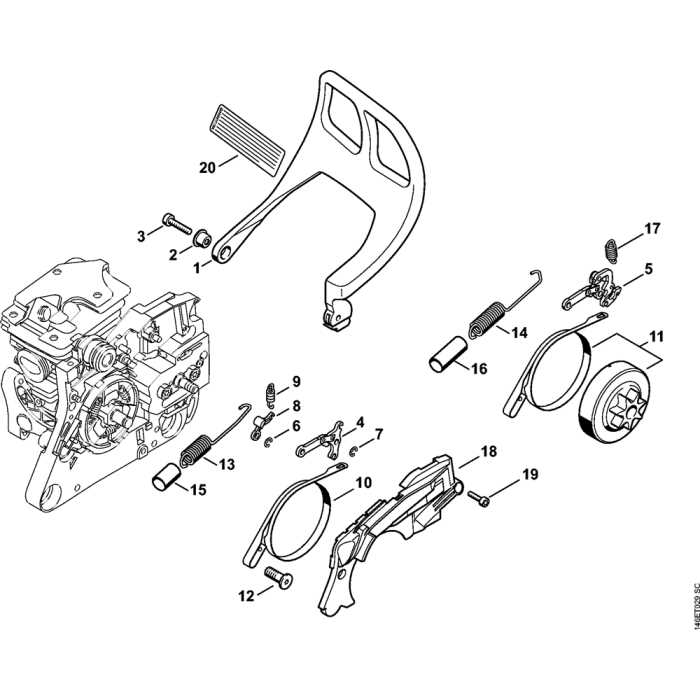

Starter Mechanism: This component initiates the engine’s operation. A reliable starter is essential for ease of use, especially in challenging conditions.

Safety Features: Various mechanisms are in place to protect the user, including chain brakes and throttle locks, enhancing operational safety.

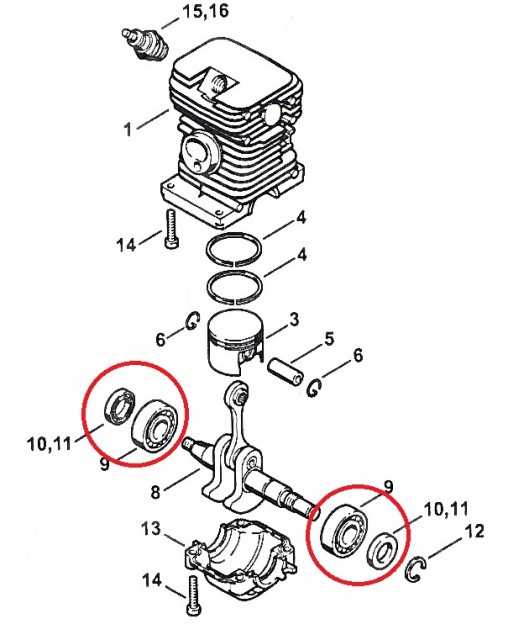

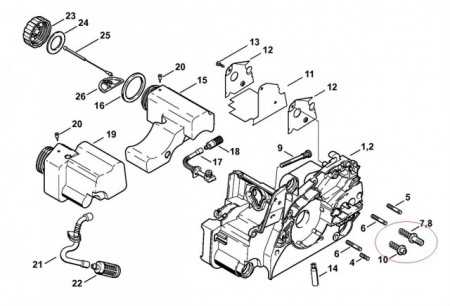

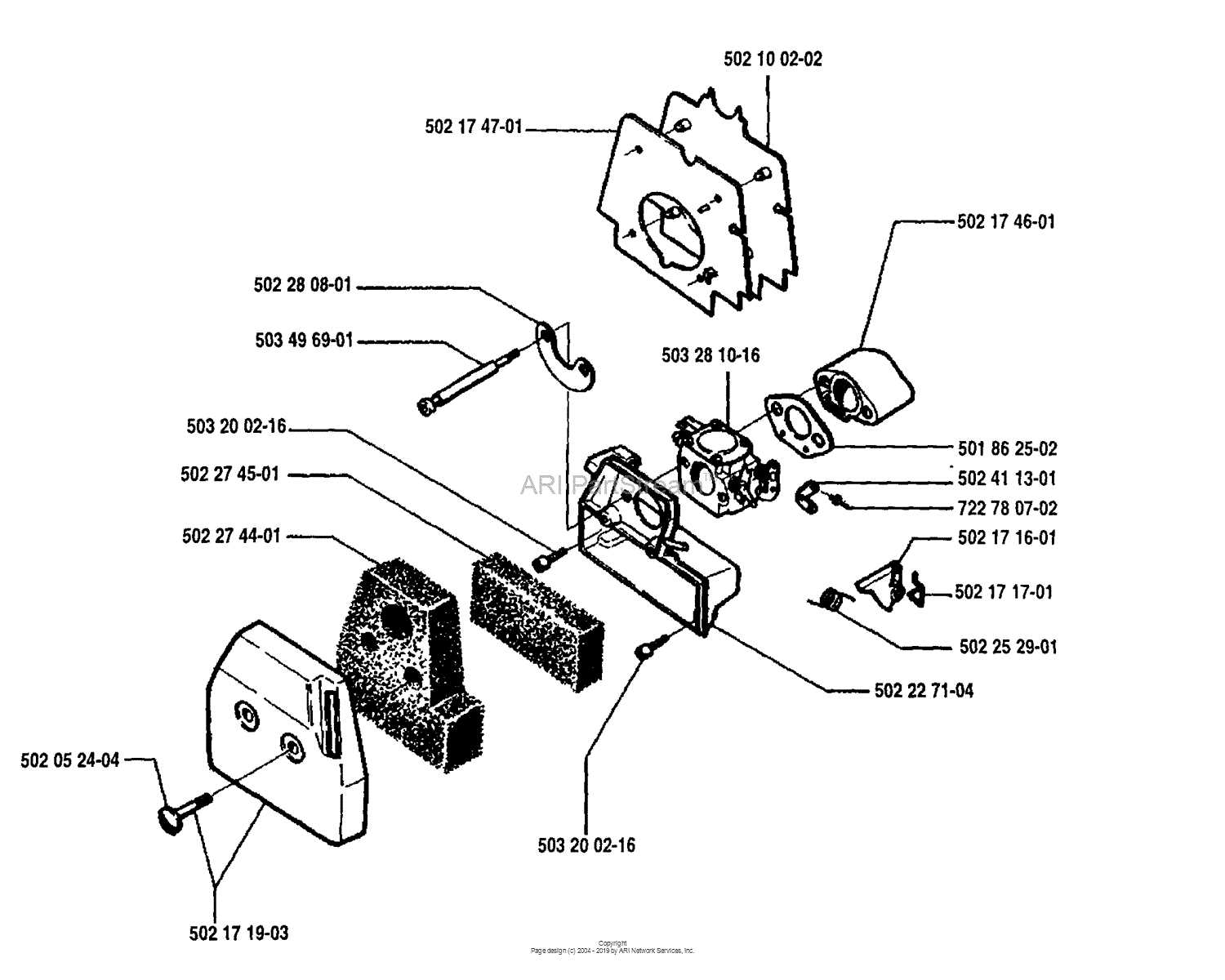

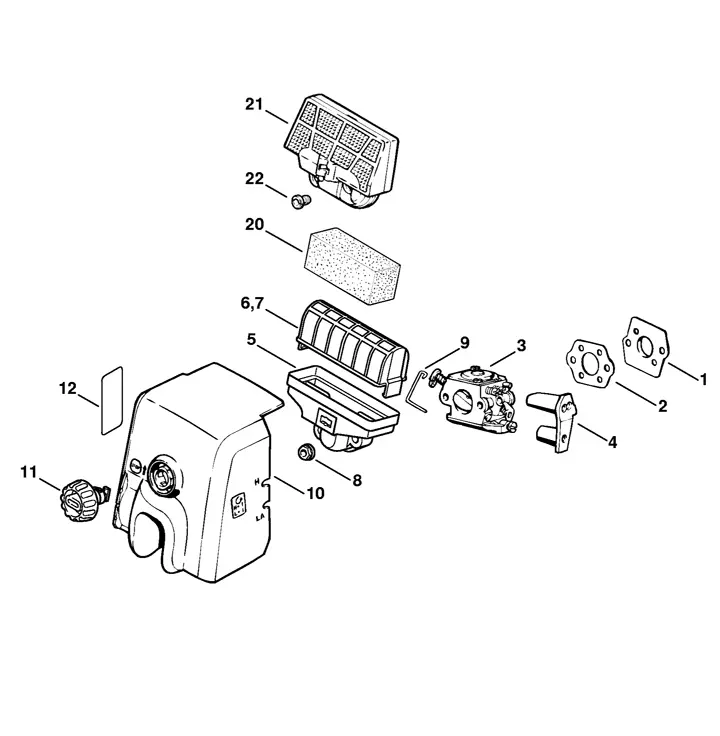

Importance of Parts Diagrams

Understanding the intricate details of mechanical devices is crucial for effective maintenance and repair. Visual representations provide clarity, allowing users to easily identify components and their relationships within a system. This knowledge fosters efficient troubleshooting and ensures that replacements are accurate, reducing downtime.

These visual aids serve as essential tools for technicians and hobbyists alike, enabling them to delve into the assembly and functionality of machinery. By having a clear overview, one can make informed decisions regarding repairs or upgrades. Ultimately, this leads to enhanced performance and longevity of the equipment.

How to Read the Diagram

Understanding technical illustrations is essential for effective maintenance and repairs. These visual aids provide a comprehensive overview of components and their relationships, enabling users to identify parts and their functions accurately. Familiarizing yourself with the layout and symbols used will greatly enhance your ability to navigate through the information presented.

Start by observing the overall structure of the illustration. Components are usually organized logically, often grouped by their functions. Pay attention to labels, as they often indicate part numbers or descriptions that are crucial for identification. Additionally, arrows and lines typically demonstrate connections and relationships, guiding you through assembly or disassembly processes.

Next, focus on the legend or key, if available. This section clarifies symbols and markings that may not be immediately obvious. By cross-referencing these with the illustration, you can gain deeper insights into how each component interacts within the assembly.

Lastly, practice makes perfect. The more you engage with these visuals, the better you’ll become at interpreting them. Whether for troubleshooting or upgrades, mastering this skill will ultimately empower you in your maintenance endeavors.

Common Replacement Parts Overview

When maintaining outdoor power equipment, understanding essential components that often require substitution is crucial. These elements can significantly affect the machine’s performance and longevity. Properly identifying and replacing these parts ensures optimal operation and enhances overall efficiency.

Fuel Filters: Regularly changing these filters is vital to prevent clogging and maintain smooth fuel flow.

Chains: Over time, chains can wear down or become damaged, necessitating prompt replacement for safety and functionality.

Air Filters: Clean air filters are essential for proper airflow, affecting engine performance and fuel consumption.

Spark Plugs: Worn or fouled spark plugs can lead to starting issues and reduced power; timely replacement is recommended.

Guide Bars: These components can become worn or bent, requiring replacement to ensure safe operation and cutting precision.

By proactively addressing these common components, users can significantly extend the lifespan of their machinery and maintain peak performance levels.

Where to Find Genuine Parts

Locating authentic components for your equipment is essential for maintaining its performance and longevity. Using genuine replacements ensures compatibility and reliability, which can significantly affect the overall efficiency of your machine.

Authorized Dealers are the most reliable source for original components. These retailers are certified to sell and distribute genuine items, ensuring you receive the correct parts tailored for your specific model. You can often find a list of authorized dealers on the manufacturer’s official website.

Online Marketplaces also provide a convenient way to purchase authentic components. However, it’s crucial to verify the seller’s reputation and read reviews to avoid counterfeit products. Look for platforms that specialize in equipment parts, as they tend to have a better selection of genuine items.

Another excellent option is Local Repair Shops. Many shops that service your type of equipment will stock original components or can order them for you. Building a relationship with a trusted technician can also provide insights into maintaining your machine effectively.

Always prioritize quality over cost when sourcing replacements. Investing in genuine components may save you money in the long run by preventing potential issues caused by inferior substitutes.

Maintenance Tips for Longevity

Ensuring the enduring performance of your equipment requires a consistent approach to care and upkeep. Regular attention to key components can significantly extend its operational life, prevent unexpected breakdowns, and enhance overall efficiency. By following a few essential practices, you can maximize both reliability and functionality.

| Tip | Description |

|---|---|

| Regular Cleaning | Remove debris and buildup to prevent overheating and ensure optimal performance. |

| Inspect Components | Check for wear and tear on essential parts to address issues before they escalate. |

| Lubrication | Apply appropriate lubricants to moving parts to minimize friction and wear. |

| Storage Practices | Store equipment in a dry, sheltered location to protect it from environmental damage. |

| Routine Servicing | Schedule regular professional maintenance to keep your equipment in top condition. |

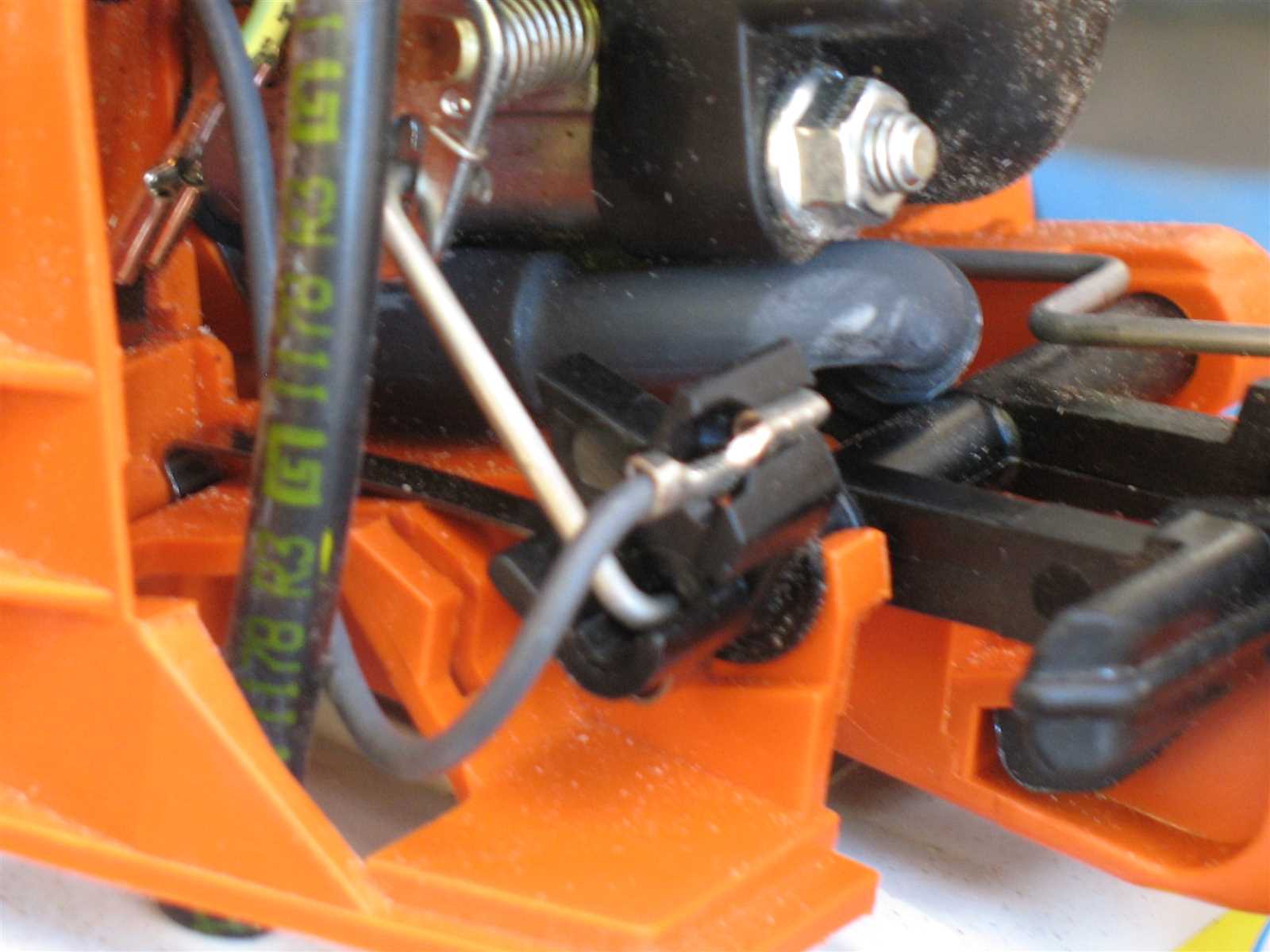

Troubleshooting Common Issues

When operating outdoor power equipment, encountering issues can be frustrating. Understanding the common problems and their solutions can enhance performance and extend the lifespan of the machinery. This section aims to provide guidance on identifying and addressing frequent malfunctions.

Engine Won’t Start

If the engine fails to ignite, first check the fuel level and ensure it’s fresh. Inspect the spark plug for damage or carbon buildup, and replace it if necessary. Additionally, examine the air filter for clogs that could restrict airflow.

Overheating

Overheating can be caused by debris obstructing the cooling fins or insufficient lubrication. Regularly clean the cooling system and ensure proper oil levels. If overheating persists, it may indicate internal damage that requires professional attention.

Using Aftermarket Components Safely

When it comes to enhancing the performance and longevity of your equipment, utilizing alternative components can be a viable option. However, ensuring safety and reliability is paramount. It’s essential to understand the implications of using these substitutes, as they may not always meet the original manufacturer’s standards.

First and foremost, research is crucial. Look for reputable brands that are known for their quality and compatibility with your equipment. Reading reviews and consulting with experienced users can provide valuable insights into the reliability of these alternatives.

Moreover, always verify the specifications and ensure that the aftermarket parts match the original equipment in terms of fit and function. Incorrectly fitted components can lead to operational failures and potential safety hazards.

Lastly, regular maintenance and inspections are vital. Keep an eye on the performance of your equipment and replace any components that show signs of wear or damage. Prioritizing safety will help you make the most of alternative parts while minimizing risks.

Assembly Instructions for Beginners

Understanding the assembly process of various equipment can seem daunting for newcomers. This guide aims to simplify the steps involved, making it accessible for those with limited experience. By following clear instructions, even a novice can successfully piece together complex tools and machinery.

Preparation Steps

Before starting the assembly, gather all necessary components and tools. This preparation ensures a smooth process and minimizes the risk of losing any parts. Additionally, reviewing the assembly guide in advance can provide a clearer overview of the task ahead.

Assembly Process

Follow these fundamental steps for effective assembly:

| Step | Description |

|---|---|

| 1 | Identify and organize all components according to the provided list. |

| 2 | Begin with the main body, ensuring that all necessary screws and connectors are at hand. |

| 3 | Attach smaller parts, paying attention to the alignment and secure fitting. |

| 4 | Double-check each connection before moving on to ensure stability. |

| 5 | Finalize by testing the assembled unit for proper functionality. |

By adhering to these straightforward guidelines, beginners can confidently tackle assembly tasks and gain valuable skills for future projects.

Frequently Asked Questions

This section addresses common inquiries related to maintenance and component identification for specific outdoor equipment. Understanding these elements can enhance the performance and longevity of your tools.

What should I do if I can’t find a specific component?

If you’re having trouble locating a particular part, consider checking with authorized dealers or online retailers specializing in outdoor machinery. Often, diagrams and catalogs can assist in pinpointing the exact item needed.

How often should I perform maintenance checks?

Customer Reviews on Parts Quality

Feedback from users plays a crucial role in assessing the durability and performance of replacement components. Many enthusiasts and professionals share their experiences, providing valuable insights into the reliability and longevity of various items.

Overall, reviews highlight a range of opinions regarding the quality of these components. Here are some common themes found in customer feedback:

- Durability: Many users praise the longevity of certain components, stating they have performed well even under heavy use.

- Fit and Compatibility: Several reviews emphasize the importance of ensuring proper fit, with some users reporting excellent compatibility while others encountered issues.

- Performance Improvement: Users often note noticeable enhancements in performance after replacing old components with new ones, citing improved efficiency and functionality.

In addition, many customers express their satisfaction with the overall value for money:

- Cost-effective options are frequently highlighted, with users appreciating the balance between price and quality.

- Some reviews mention that investing in higher-quality items can save money in the long run due to reduced maintenance needs.

Overall, the shared experiences offer potential buyers a wealth of information, helping them make informed decisions about their purchases. With a blend of praise and constructive criticism, users contribute to a better understanding of what to expect from replacement components in terms of quality and performance.