Understanding the Stihl 420 Concrete Saw Parts Diagram

When it comes to mastering the intricacies of heavy-duty machinery, having a clear understanding of the components and their functions is essential. This guide aims to provide valuable insights into the layout and assembly of a specific model known for its robust performance in various construction tasks. By familiarizing yourself with the essential elements, you can enhance both the maintenance and operational efficiency of your equipment.

The intricacies of a high-performance cutting device can often be overwhelming. However, breaking down its structure into manageable sections allows for a more straightforward approach to troubleshooting and repairs. Each component plays a vital role in the overall functionality, and recognizing how they interconnect can save both time and resources in the long run.

In this article, we will explore an illustrative representation that highlights the various segments of this powerful tool. By detailing the arrangement and purpose of each part, we hope to empower users with the knowledge needed for effective operation and care. With this understanding, you can ensure that your equipment remains in optimal condition, ready to tackle any challenge that comes your way.

Understanding Stihl 420 Concrete Saw

This section delves into the intricacies of a specific power tool designed for precision cutting tasks. By examining its components and functionality, users can gain insights into how to optimize performance and maintenance practices.

Key Features and Functionality

This tool is engineered to deliver efficiency and reliability in various cutting applications. Its robust design allows for deep cuts in hard materials, making it an essential choice for professionals in construction and renovation. Understanding the essential features aids in maximizing its utility.

Maintenance and Care

Proper upkeep of this equipment is vital for ensuring longevity and peak performance. Regular inspection of components, along with timely replacements, can prevent malfunctions and enhance cutting precision.

| Component | Function |

|---|---|

| Blade | Designed for optimal cutting efficiency |

| Engine | Provides power for operation |

| Handle | Ensures user comfort and control |

| Cooling System | Prevents overheating during use |

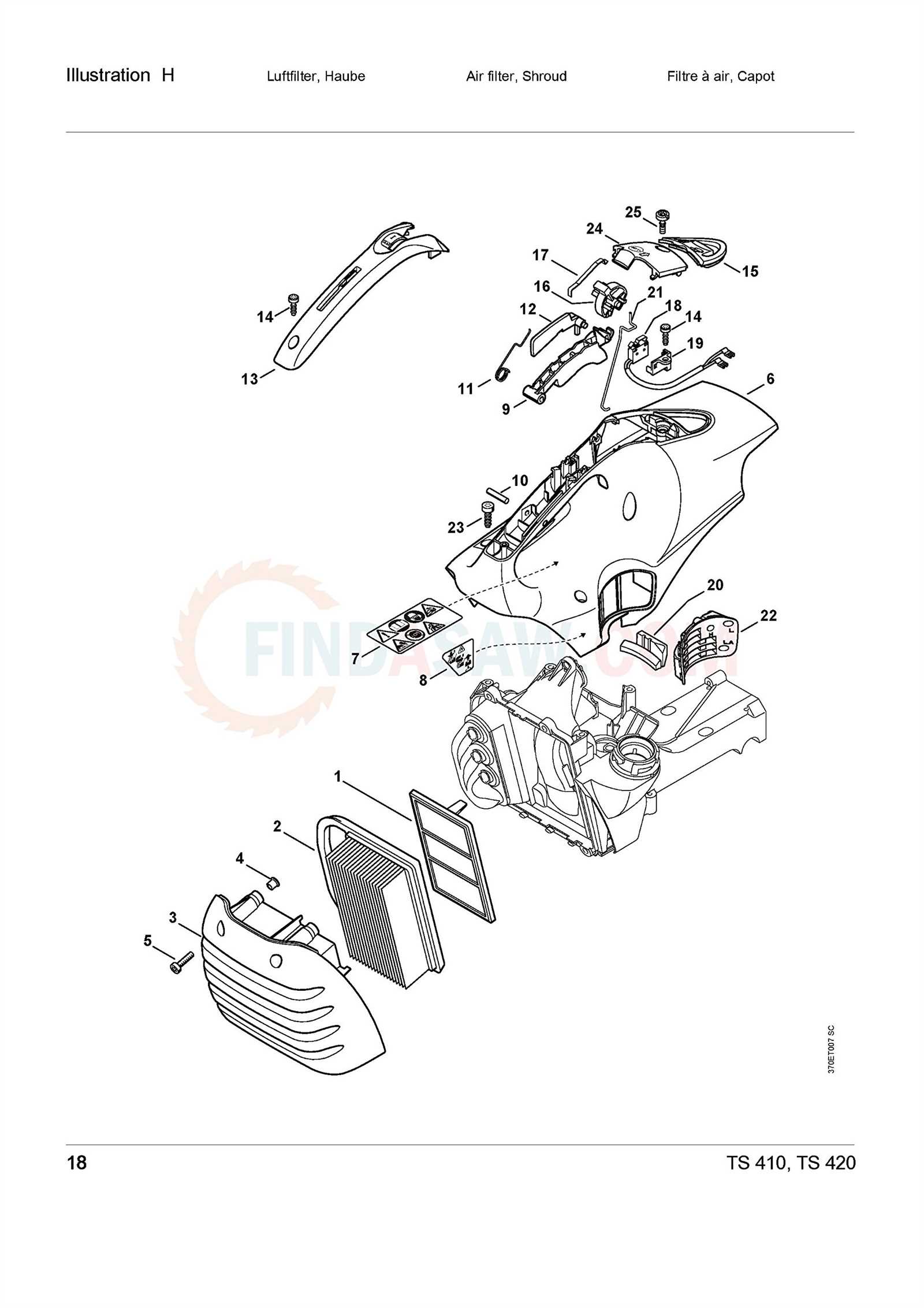

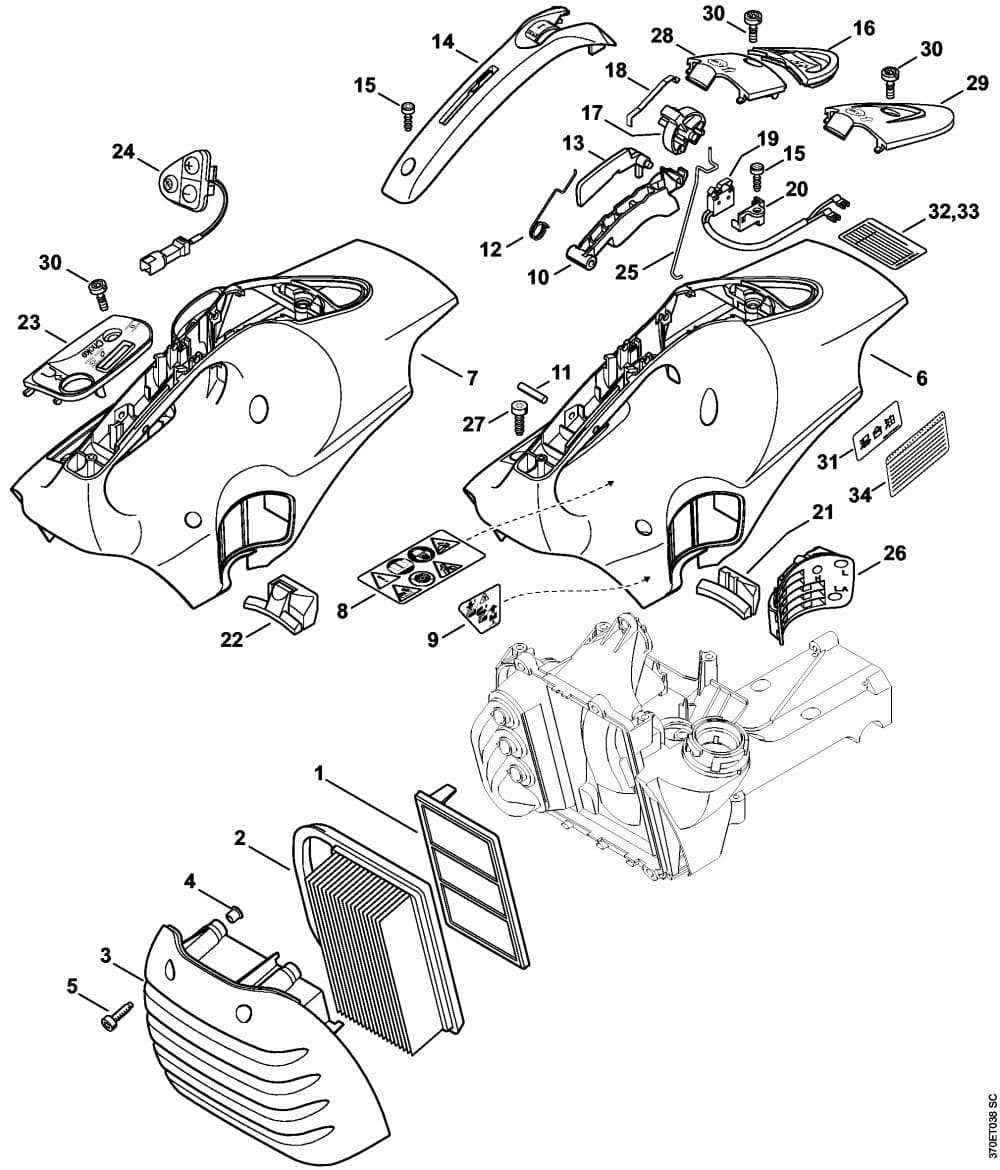

Key Components of the Stihl 420

This section explores the essential elements that contribute to the functionality and performance of a high-quality cutting tool. Understanding these components is vital for maintenance and optimal operation, ensuring the longevity of the equipment.

| Component | Description |

|---|---|

| Engine | Drives the cutting mechanism, providing the necessary power for efficient operation. |

| Blade | The primary tool for cutting, designed for durability and precision across various materials. |

| Guard | Protects the operator from debris and enhances safety during operation. |

| Handle | Ensures a secure grip, allowing for better control and maneuverability. |

| Fuel System | Delivers power by supplying the engine with the required fuel mixture for combustion. |

| Cooling System | Prevents overheating, maintaining optimal performance during prolonged use. |

| Starter Mechanism | Facilitates easy ignition of the engine, ensuring quick readiness for use. |

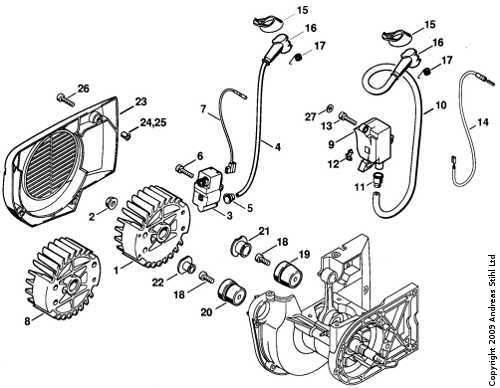

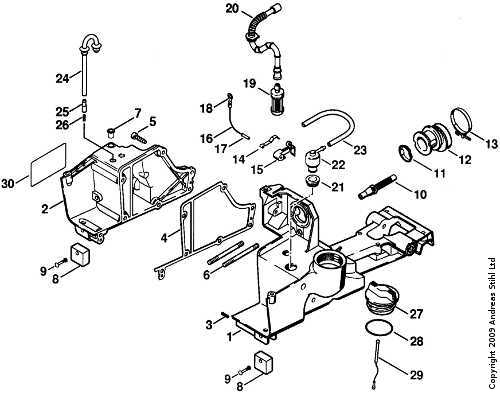

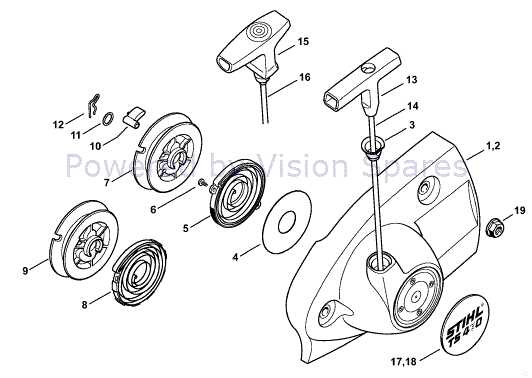

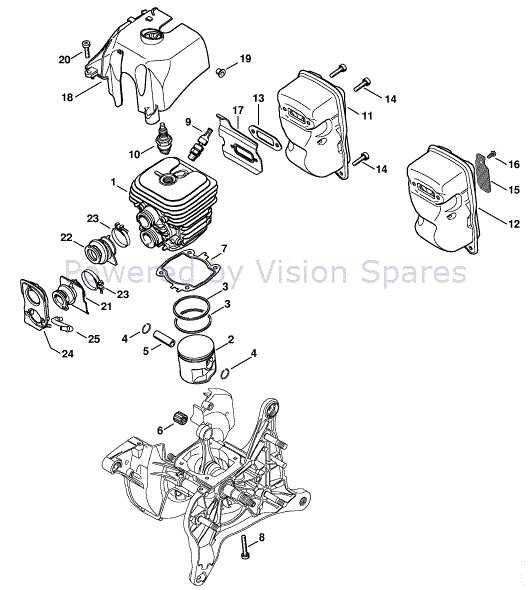

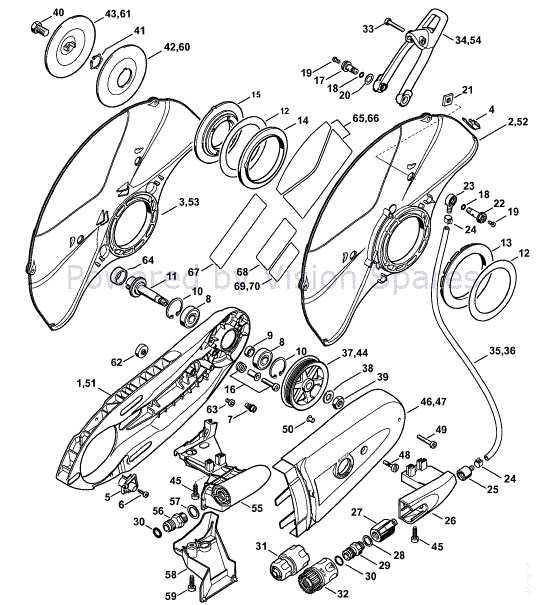

Importance of a Parts Diagram

A visual representation of components is essential for understanding the intricate design of any machine. Such illustrations provide clarity, allowing users to identify various elements and their specific roles within the overall system. This is particularly useful when performing maintenance or repairs, as it streamlines the process and reduces the likelihood of errors.

Facilitating Maintenance and Repairs

Having access to a clear schematic aids technicians in efficiently addressing issues. When every component is labeled and organized, identifying the source of a problem becomes simpler. This not only saves time but also minimizes the risk of further damage during repair work.

Enhancing User Knowledge

Beyond practical applications, these visual guides serve an educational purpose. They empower users to become more familiar with their equipment, fostering a deeper understanding of how each part contributes to the overall functionality. This knowledge can lead to more informed decision-making regarding upgrades and replacements.

Common Issues with Stihl 420 Parts

When working with machinery, certain components can often lead to challenges that affect performance and efficiency. Understanding these common problems is crucial for maintaining optimal functionality. This section explores frequent issues encountered with specific elements of a cutting tool, providing insights into their impact and solutions.

| Issue | Description | Potential Solutions |

|---|---|---|

| Wear and Tear | Components may experience degradation over time, leading to reduced efficiency. | Regular inspection and timely replacement of worn parts. |

| Overheating | Excessive heat can damage critical elements, causing failures. | Ensure proper cooling and lubrication; avoid prolonged usage. |

| Fuel System Issues | Clogs or leaks in the fuel delivery system can impair operation. | Regularly check and clean the fuel lines; replace damaged components. |

| Vibration Problems | Excessive vibrations can lead to loosening of components and discomfort during use. | Inspect and tighten connections; consider using vibration-dampening accessories. |

| Starting Difficulties | Challenges in initiating operation may stem from various mechanical issues. | Check spark plugs, ignition systems, and fuel quality. |

How to Read a Parts Diagram

Understanding a visual representation of components can significantly enhance your ability to identify and manage various elements of equipment. A well-structured illustration serves as a guide, offering clarity on how parts fit together and function as a whole.

Here are some key points to help you interpret these visuals effectively:

- Familiarize Yourself with the Layout: Typically, these representations are organized in a logical sequence, often mirroring the assembly process.

- Identify Labels and Numbers: Each part is usually accompanied by a label or number that corresponds to a list, providing essential information about the component.

- Look for Groupings: Components are often grouped by function or location, making it easier to understand their roles within the system.

To deepen your comprehension, consider the following steps:

- Cross-reference with Documentation: Use the accompanying textual materials to get detailed descriptions of each element.

- Study the Connections: Pay attention to how different components connect or interact with each other.

- Practice with Real Examples: If possible, reference actual units to see how the illustration translates to physical parts.

By applying these strategies, you will gain greater insight into the structure and functionality of your equipment, leading to more informed maintenance and repair decisions.

Maintenance Tips for Longevity

Proper upkeep of your equipment is essential for ensuring its durability and efficiency over time. Regular maintenance not only enhances performance but also prevents unexpected breakdowns and costly repairs. By following a few simple guidelines, you can extend the lifespan of your machinery significantly.

Regular Inspections

Conduct routine checks to identify any signs of wear and tear. Pay close attention to moving parts, ensuring they are free of debris and properly lubricated. A proactive approach helps catch potential issues early, preventing larger problems down the line.

Cleaning and Care

Keep your equipment clean to maintain optimal function. After each use, remove dust, dirt, and any material residue. Using a soft brush or compressed air can effectively clear hard-to-reach areas. Additionally, consider using protective covers when the machinery is not in use to shield it from environmental factors.

By implementing these practices, you can promote a longer service life and reliable performance, ensuring your investment remains productive for years to come.

Where to Find Replacement Parts

Locating components for your equipment can sometimes feel like a daunting task, but with the right resources, it becomes much more manageable. Whether you’re looking for specific elements or general supplies, understanding where to search can save you time and effort.

Authorized Dealers are often the most reliable source. These retailers are equipped with the knowledge and inventory to provide genuine items tailored for your machinery. Visiting their websites or physical stores can yield a variety of options suited to your needs.

Another great option is online marketplaces. Platforms like eBay, Amazon, and specialized websites host a wide range of products, often at competitive prices. Just be sure to check seller ratings and product reviews to ensure you’re getting quality items.

For those who prefer a more hands-on approach, local hardware stores can also be valuable. Many shops carry a selection of components and may even offer advice on compatibility and installation.

Finally, consider community forums and social media groups. Enthusiasts often share their experiences and recommendations on where to find specific items, making these platforms an excellent resource for tips and leads on hard-to-find components.

Comparing Stihl 420 with Other Models

When evaluating different cutting tools, it’s essential to understand the nuances that set each model apart. This comparison will focus on performance, durability, and user-friendliness among various devices in the market.

Key factors to consider include:

- Power and Efficiency: Examine the engine specifications and cutting capabilities, which can significantly impact performance.

- Weight and Portability: Lighter models may offer better maneuverability, which is crucial for extended use in various environments.

- Durability and Build Quality: Assess materials used in construction, as this affects longevity and resistance to wear and tear.

- User Features: Consider ergonomic designs, vibration reduction, and ease of starting mechanisms that enhance user experience.

- Maintenance and Parts Availability: Look into the ease of servicing the tool and the accessibility of replacement components.

To illustrate these points, here’s a brief overview of how different models compare:

- Model A: Known for its lightweight design, it excels in portability but may lack in power compared to heavier counterparts.

- Model B: Offers superior engine performance, making it ideal for heavy-duty tasks but can be cumbersome to handle for longer periods.

- Model C: Balances power and weight well, featuring user-friendly adjustments that appeal to both novice and experienced operators.

In summary, understanding the unique characteristics of each tool enables users to make informed decisions that align with their specific cutting needs.

Tools Needed for Repairs

When it comes to maintaining and fixing machinery, having the right tools is essential for efficient and effective work. Proper equipment not only ensures that repairs are completed safely but also extends the lifespan of the machine. Below is a guide on the necessary instruments to keep on hand for any repair tasks.

Essential Tools

- Wrenches: Various sizes to accommodate different fasteners.

- Screwdrivers: A selection of flathead and Phillips for versatility.

- Socket Set: For easier access to nuts and bolts in tight spaces.

- Pliers: Needle-nose and standard types for gripping and bending.

- Hammer: Useful for tapping and aligning components.

Safety Equipment

- Gloves: Protects hands from sharp edges and debris.

- Safety Goggles: Shields eyes from dust and particles.

- Ear Protection: Important when working with loud machinery.

Having these tools readily available will greatly enhance your ability to perform repairs efficiently and safely. Always ensure that your tools are in good condition and organized for easy access during maintenance tasks.

Identifying Genuine Stihl Parts

When it comes to maintaining and repairing your equipment, recognizing authentic components is crucial for ensuring optimal performance and longevity. Genuine items are crafted with precision and adhere to strict quality standards, unlike their counterfeit counterparts, which may compromise functionality and safety.

To distinguish original products from imitations, examine the packaging and labeling carefully. Authentic components typically feature high-quality packaging, clear branding, and detailed product information. Additionally, checking for serial numbers or specific identifiers on the item itself can provide further verification of authenticity.

Another effective method is to purchase from authorized dealers or trusted retailers. These sources are more likely to offer genuine items, reducing the risk of acquiring subpar replacements. Researching the manufacturer’s website can also provide insights into authorized sellers and the features that distinguish authentic products.

Lastly, familiarize yourself with the typical characteristics of original components, such as weight, color, and finish. This knowledge can help you identify discrepancies that may indicate a counterfeit product. By taking these steps, you can ensure that your equipment remains reliable and efficient for years to come.

Customer Reviews on 420 Performance

Feedback from users highlights the effectiveness and reliability of this powerful tool in demanding tasks. Many appreciate its ability to handle tough materials with precision, making it a popular choice among professionals and DIY enthusiasts alike. The combination of power, ease of use, and durability has led to numerous positive testimonials from satisfied customers.

Strengths Highlighted by Users

Customers frequently mention the robust design and efficient performance as key advantages. Users have noted that the tool operates smoothly even under heavy load, showcasing its capability in various environments. Additionally, the ergonomic features have received acclaim, with many stating that they provide comfort during prolonged usage.

Areas for Improvement

While most reviews are favorable, some users have pointed out a few areas for improvement. A common theme in feedback is the need for more detailed instructions for maintenance. Additionally, some have suggested that the weight can be a challenge for extended tasks, which might affect maneuverability for less experienced operators.

DIY Repair vs. Professional Service

When it comes to fixing equipment, enthusiasts often find themselves at a crossroads between tackling repairs themselves and seeking help from experts. Each approach has its own set of advantages and challenges, making the decision a nuanced one that depends on various factors such as skill level, time availability, and the complexity of the issue at hand.

Advantages of DIY Repairs

Taking on repairs independently can be incredibly rewarding. It fosters a sense of accomplishment and allows individuals to learn new skills. Additionally, DIY solutions often come at a lower cost, as there are no labor fees involved. For those who enjoy hands-on work, it can also be a therapeutic activity, providing a break from daily routines.

Benefits of Professional Assistance

On the other hand, opting for professional service ensures that repairs are performed by trained technicians with expertise in handling specific issues. This can lead to quicker resolutions and often guarantees high-quality work. For complex problems or those requiring specialized tools, relying on professionals can save time and prevent further damage, ultimately offering peace of mind.

In conclusion, weighing the pros and cons of each option is crucial. Whether choosing to repair equipment oneself or hiring a professional, understanding personal capabilities and the nature of the task is essential for making the right decision.