Understanding the Parts Diagram for Stihl BG55 Blower

Maintaining outdoor machinery is crucial for optimal performance and longevity. Familiarizing oneself with the various components of such tools can greatly enhance user experience and efficiency. This section aims to provide insights into the intricacies of a specific model, ensuring that you have the knowledge needed for effective upkeep.

Detailed exploration of machinery components not only assists in troubleshooting issues but also empowers users to undertake repairs with confidence. By examining each element closely, one can delve into the essential functions and interrelationships that make up the entire system.

Whether you are a seasoned professional or a novice, understanding the layout and functionality of each part will serve as the ultimate guide to maximizing your equipment’s capabilities. Prepare to unlock the full potential of your machinery as we dissect the critical aspects of its design and operation.

Understanding Stihl BG55 Components

In the realm of outdoor power tools, a thorough comprehension of the various elements that make up a device is crucial for effective operation and maintenance. Each component plays a significant role in ensuring the overall functionality and performance of the machine. By familiarizing oneself with these individual parts, users can enhance their experience and prolong the lifespan of their equipment.

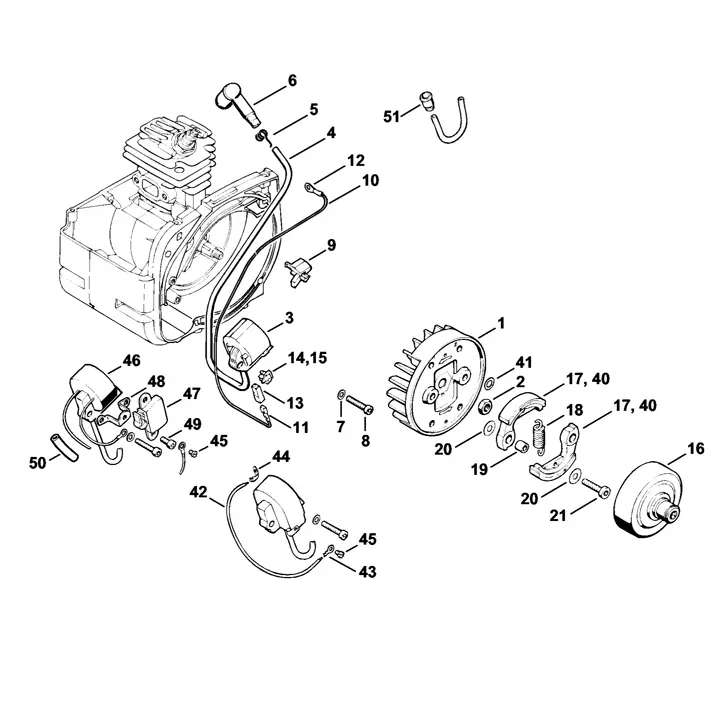

Essential Elements include the engine, which serves as the heart of the machine, providing the necessary power for operation. Coupled with this is the air intake system, which is vital for optimal performance, ensuring that the right amount of air reaches the combustion chamber. The fuel delivery system also deserves attention, as it is responsible for supplying the engine with the required fuel mixture.

Additionally, understanding the significance of the fan assembly is important, as it generates airflow, allowing the device to effectively accomplish its intended tasks. Other critical components include the throttle control, which enables users to adjust the speed, and the nozzle, designed for directing the airflow with precision. Each of these parts contributes to the overall efficiency and effectiveness of the tool, making it essential to be aware of their functions and how they work together.

Importance of Blower Maintenance

Regular upkeep of your outdoor equipment is crucial for optimal performance and longevity. Neglecting maintenance can lead to inefficiencies, increased wear and tear, and ultimately, costly repairs. By prioritizing care, users can ensure reliable operation and enhance the lifespan of their tools.

Key aspects of maintenance include cleaning, inspecting, and replacing worn components. This not only maximizes efficiency but also improves safety during use. A well-maintained machine can significantly reduce the risk of unexpected breakdowns.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Clean Air Filters | Every use | Improved airflow and efficiency |

| Inspect Spark Plug | Monthly | Better ignition and performance |

| Check Fuel System | Seasonally | Prevention of fuel-related issues |

| Lubricate Moving Parts | Every 5 uses | Reduced friction and wear |

Investing time in maintenance is the ultimate way to ensure that your outdoor equipment remains efficient, safe, and reliable throughout its lifespan.

Key Parts of the BG55 Blower

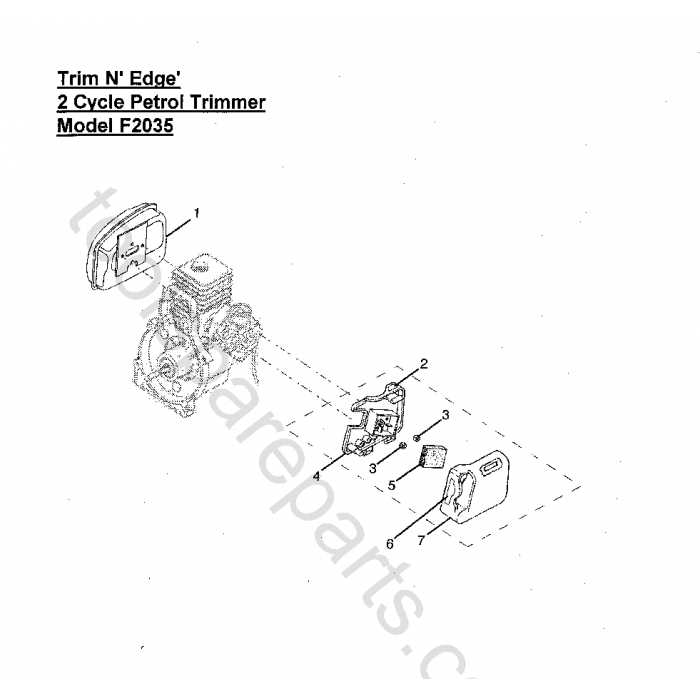

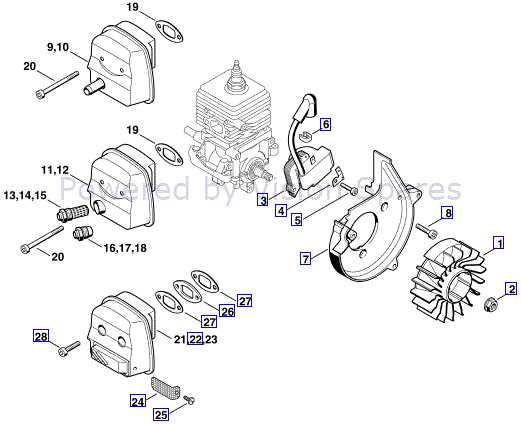

This section delves into the essential components of a popular outdoor tool designed for clearing debris. Understanding these elements is crucial for effective operation and maintenance, ensuring that the machine performs optimally for years to come.

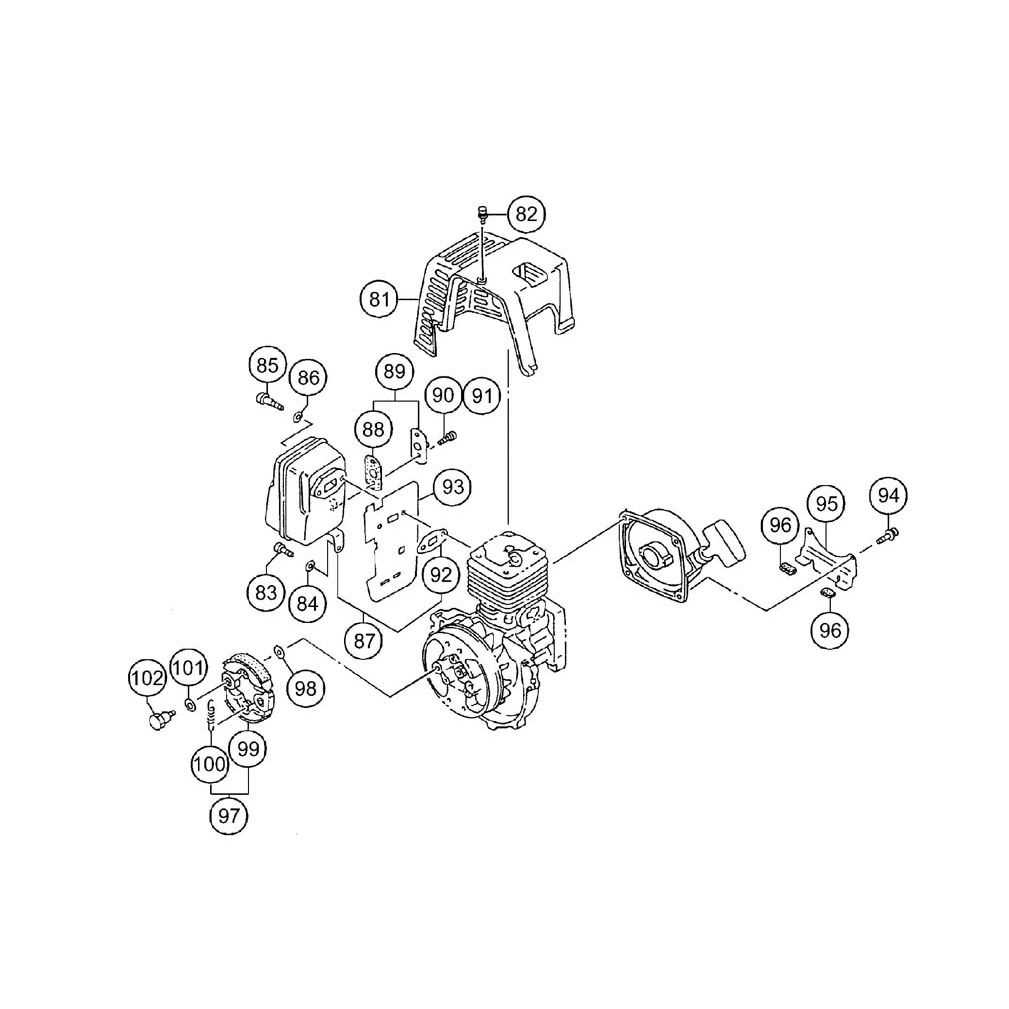

Engine Assembly

The heart of the unit is its engine assembly, which provides the necessary power to generate airflow. This section includes the cylinder, piston, and spark plug. A well-functioning engine is vital for reliable performance, making regular checks and maintenance a priority.

Air Intake System

The air intake system plays a pivotal role in ensuring that the engine receives the right amount of air. This includes components like the air filter and intake manifold. Keeping these parts clean and in good condition can significantly enhance the efficiency and longevity of the tool.

Proper maintenance and understanding of these fundamental components will lead to improved functionality and a better user experience. Regular inspections and timely replacements of worn-out elements are key to maintaining peak performance.

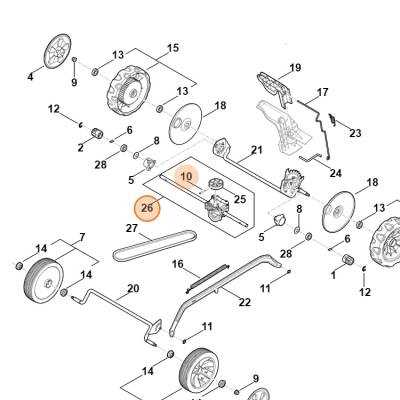

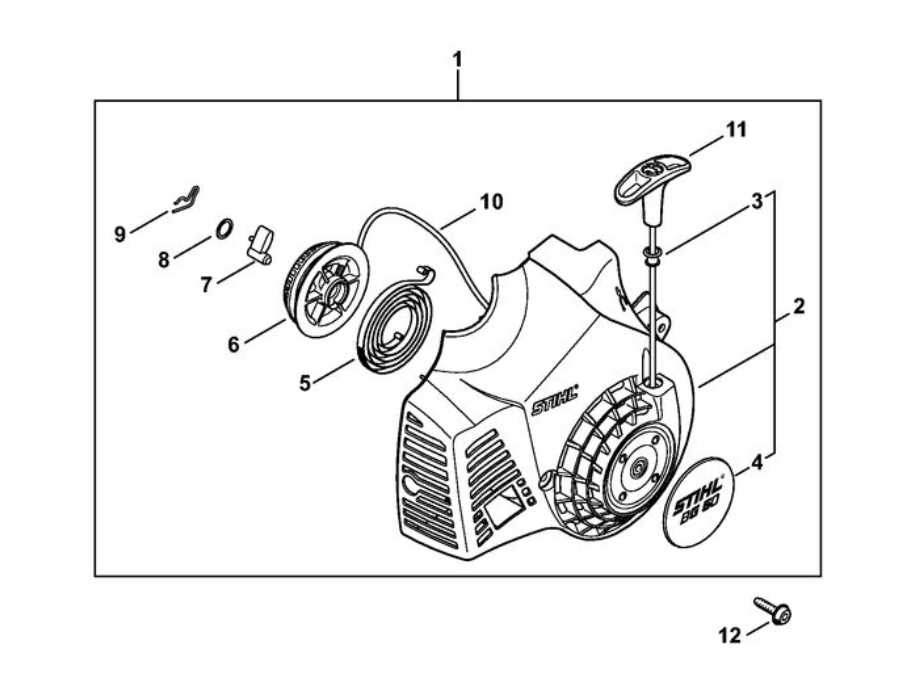

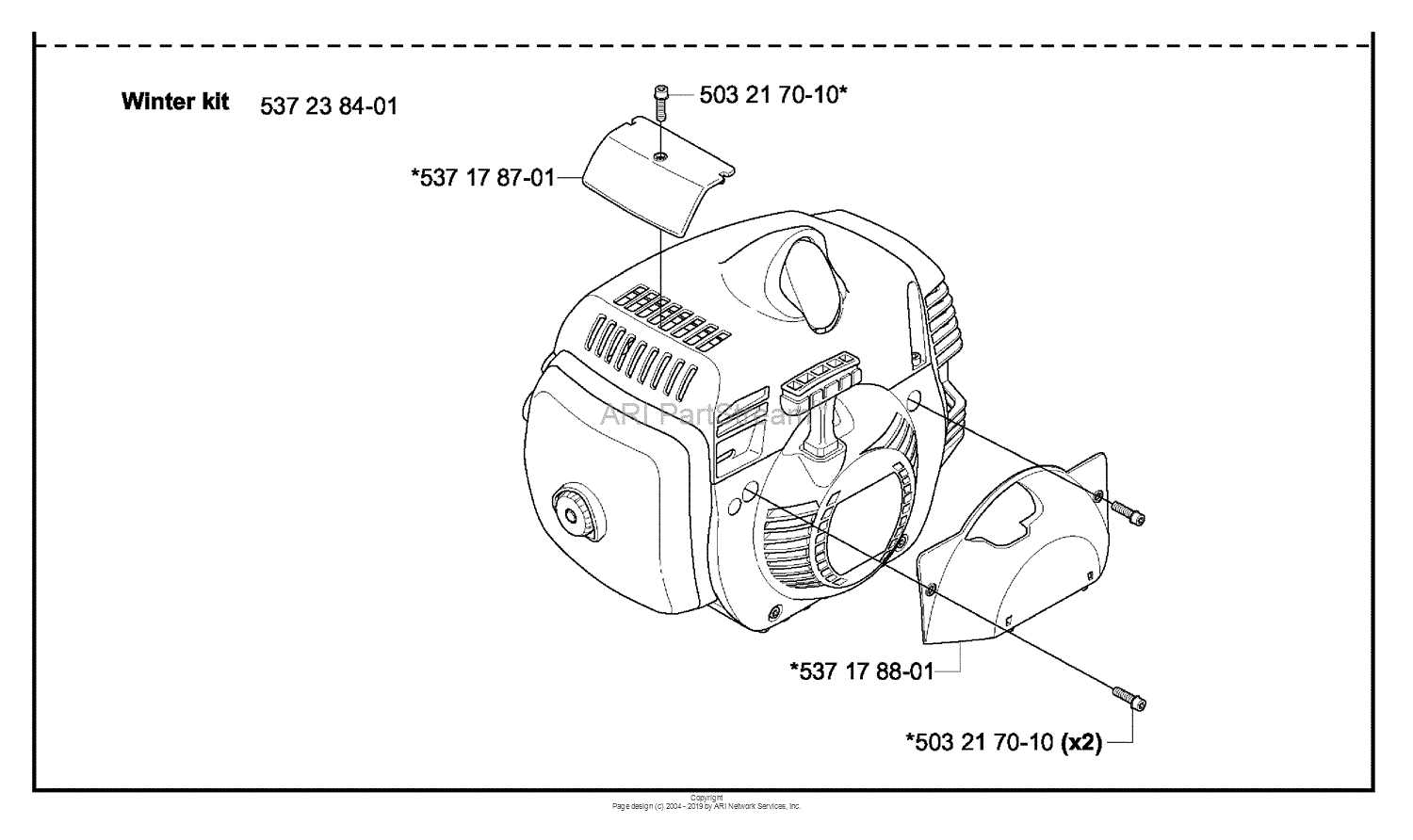

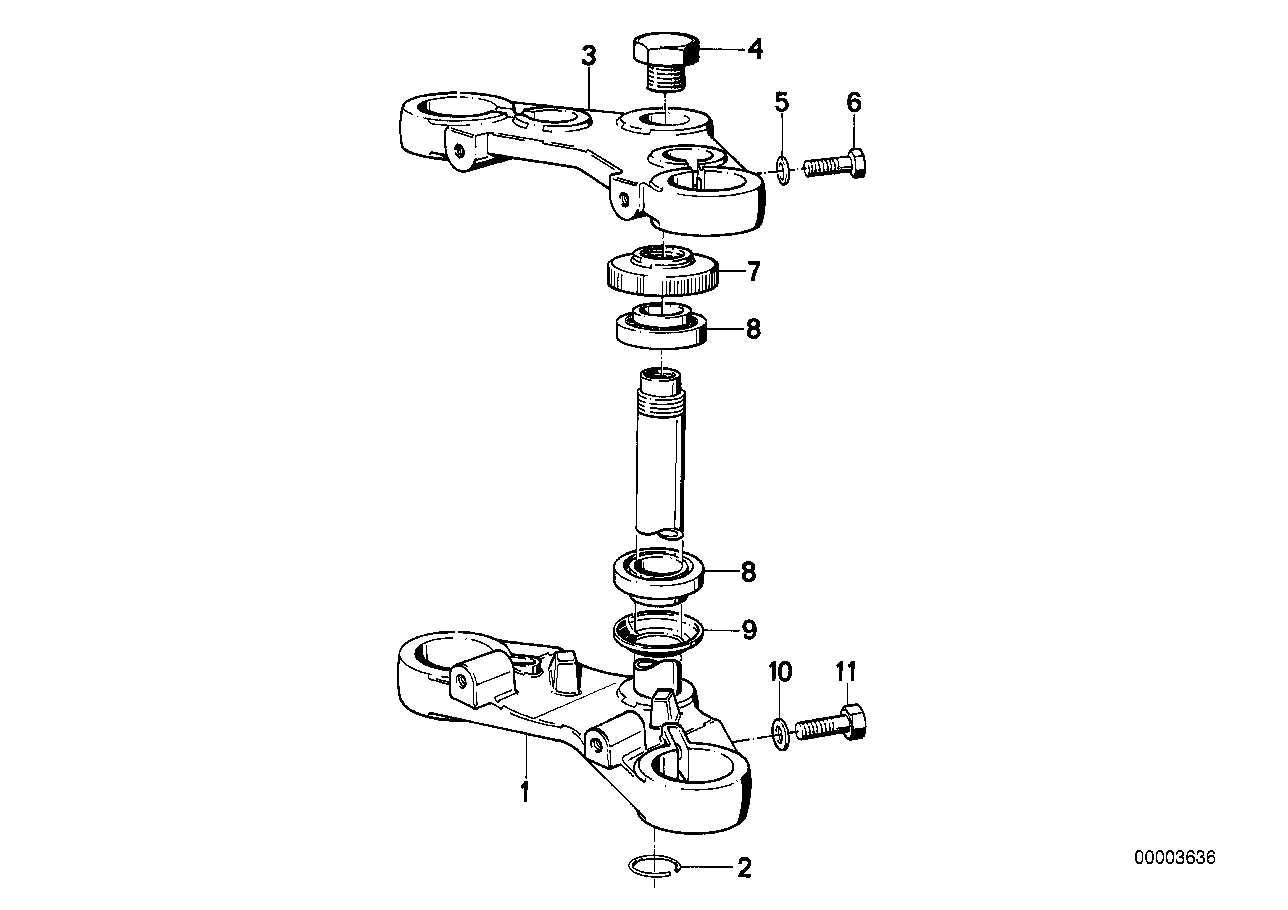

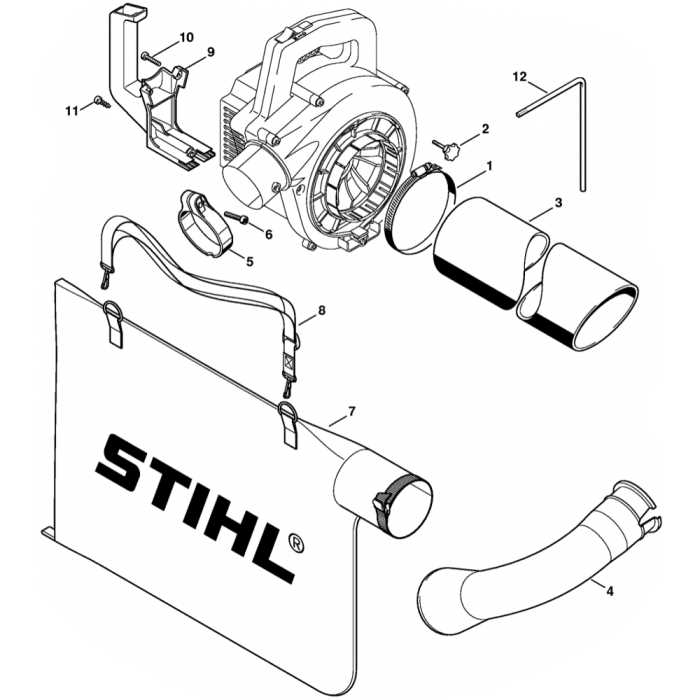

How to Read Parts Diagrams

Understanding the visual representations of components is crucial for effective maintenance and repair. These illustrations serve as guides, detailing how different elements fit together and function within the overall assembly. By familiarizing yourself with these visuals, you can streamline your repair process and enhance your troubleshooting skills.

Key Elements to Identify

When examining a visual representation, there are several key aspects to focus on:

- Labels: Each component is usually marked with a unique identifier. Pay attention to these labels, as they correspond to the listed parts.

- Connections: Observe how different pieces are linked. Understanding these connections will help you recognize how to disassemble and reassemble the unit.

- Numbers: Often, components will be numbered to correspond with a list of parts. Ensure you have access to this list for easy reference.

Reading Techniques

Here are some strategies to effectively interpret these visuals:

- Start with the Overview: Begin by examining the entire layout to grasp the general structure before diving into details.

- Focus on Sections: Break the image into manageable sections, concentrating on one area at a time to avoid feeling overwhelmed.

- Cross-reference: Use the list of components alongside the visual to ensure you understand each part’s role.

By applying these techniques, you will gain confidence in interpreting these valuable resources, ultimately improving your repair capabilities.

Common Issues with Stihl BG55

When operating outdoor equipment, users often encounter several recurring challenges that can affect performance and efficiency. Understanding these common problems can help in troubleshooting and maintaining optimal functionality.

Performance Problems

One frequent issue relates to inconsistent power output. Users may notice a lack of airflow or a decrease in effectiveness, which can stem from various factors such as fuel quality or blockages in the air intake system.

Starting Difficulties

Another common concern is difficulty in starting the machine. This can be attributed to several reasons, including issues with the ignition system or improper fuel mixture. Regular maintenance and checks can alleviate many of these starting problems.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Inconsistent Power | Poor fuel quality, air intake blockage | Use fresh fuel, clean air filters |

| Starting Problems | Ignition failure, incorrect fuel mixture | Inspect spark plug, adjust fuel ratio |

| Excessive Noise | Loose components, worn parts | Tighten screws, replace damaged parts |

Where to Find Replacement Parts

Finding components for outdoor equipment can be a straightforward task if you know where to look. Numerous sources are available to help you acquire the necessary items efficiently.

- Authorized Dealers: Visit local retailers who specialize in outdoor tools. They often have a wide range of components and can assist with specific needs.

- Online Retailers: Websites dedicated to tool supplies offer convenience and a vast selection. Check customer reviews for reliability.

- Manufacturer’s Website: Official sites frequently provide a catalog of items tailored for their equipment, ensuring compatibility.

- Repair Shops: Local mechanics may have spare components or can order them directly for you.

- Forums and Community Groups: Online communities often share resources and recommendations for sourcing components.

By exploring these options, you can ensure that your equipment remains in optimal working condition.

Tools Needed for Repairs

When undertaking maintenance or restoration tasks on your equipment, having the right instruments at hand is crucial for a successful outcome. A well-equipped workspace not only simplifies the process but also enhances safety and efficiency. Here, we outline essential tools that can aid in the repair process.

1. Screwdrivers: A variety of screwdrivers, including flathead and Phillips, are essential for loosening and tightening screws found in the assembly. The right size ensures a snug fit, preventing damage to the screws.

2. Wrenches: Adjustable and socket wrenches are necessary for dealing with nuts and bolts. These tools provide leverage and control, making it easier to handle different sizes.

3. Pliers: Needle-nose and standard pliers are helpful for gripping small components and making precise adjustments. They also assist in bending or cutting wires as needed.

4. Torque Wrench: This tool is vital for applying the correct amount of torque to fasteners, ensuring that everything is securely tightened without overdoing it.

5. Cleaning Supplies: Brushes, cloths, and solvents are important for maintaining cleanliness. Regular cleaning prevents dirt accumulation, which can lead to performance issues.

6. Safety Gear: Always prioritize safety by wearing protective eyewear and gloves. This precaution protects against injuries during repairs.

Equipping yourself with these essential tools will streamline your repair process and contribute to the longevity of your equipment.

Step-by-Step Repair Guide

This guide offers a systematic approach to restoring your equipment, ensuring it runs efficiently. By following these steps, you can identify issues, replace components, and enhance performance without professional assistance.

Identifying the Problem

Start by diagnosing the symptoms. Listen for unusual sounds, check for leaks, or observe any performance drops. Document these observations, as they will guide your repair process.

Disassembly and Replacement

Carefully disassemble the unit, taking care to keep track of each component. Use a diagram if available to ensure proper reassembly. Replace any damaged parts with high-quality alternatives, and always secure connections tightly to avoid future issues.

Safety Tips for Using Blowers

Operating yard care equipment requires attention to safety to prevent accidents and injuries. Understanding the proper usage and precautions can ensure a more secure and efficient experience. Following specific guidelines can help users maximize performance while minimizing risks.

Personal Protective Equipment

Always wear appropriate protective gear when handling equipment. This includes gloves, ear protection, and safety glasses. These items help shield against debris and excessive noise, enhancing overall safety during operation.

Environmental Awareness

Be mindful of your surroundings while in use. Check for children, pets, and obstacles that could interfere with your work. Additionally, consider weather conditions, as wind can affect debris direction and control.

Upgrades for Enhanced Performance

Improving the functionality of your outdoor equipment can significantly boost its efficiency and longevity. By exploring various enhancements, users can ensure optimal operation and tailored performance to meet specific needs. This section delves into several modifications that can elevate your tool’s effectiveness.

Air Filter Enhancement

Upgrading the air intake system is crucial for maximizing airflow and engine performance. A high-quality air filter can prevent debris from entering the engine, ensuring smooth operation. Regular maintenance of this component can lead to improved fuel efficiency and power output.

Exhaust System Optimization

Another vital area for enhancement is the exhaust setup. By installing a more efficient exhaust system, users can reduce back pressure, which allows the engine to breathe better. This can result in a noticeable increase in power and responsiveness, making tasks easier and faster.

Comparing Stihl BG55 to Other Models

This section explores the differences and similarities among various models of handheld outdoor equipment designed for clearing debris. By examining performance, features, and usability, users can determine which option best suits their needs.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Engine Power | 25 cc | 27 cc | 24 cc |

| Weight | 9.5 lbs | 8.8 lbs | 10.2 lbs |

| Air Speed | 150 mph | 180 mph | 160 mph |

| Fuel Capacity | 16 oz | 14 oz | 15 oz |

Ultimately, understanding these variations helps potential buyers make informed choices based on their specific requirements and preferences.

Customer Reviews and Feedback

This section aims to capture the sentiments and opinions of users regarding their experiences with the equipment. Insights from customers help prospective buyers make informed decisions, highlighting the effectiveness and reliability of various components.

| Rating | Comment | Reviewer |

|---|---|---|

| 5/5 | Exceptional performance; easy to handle and powerful. | John D. |

| 4/5 | Great value for the price, though a bit noisy. | Sarah K. |

| 3/5 | Good for light tasks, but struggles with heavy debris. | Mike L. |

| 5/5 | Reliable and durable; a must-have for my garden. | Linda S. |

| 4/5 | Impressive power; lightweight and easy to maneuver. | James R. |