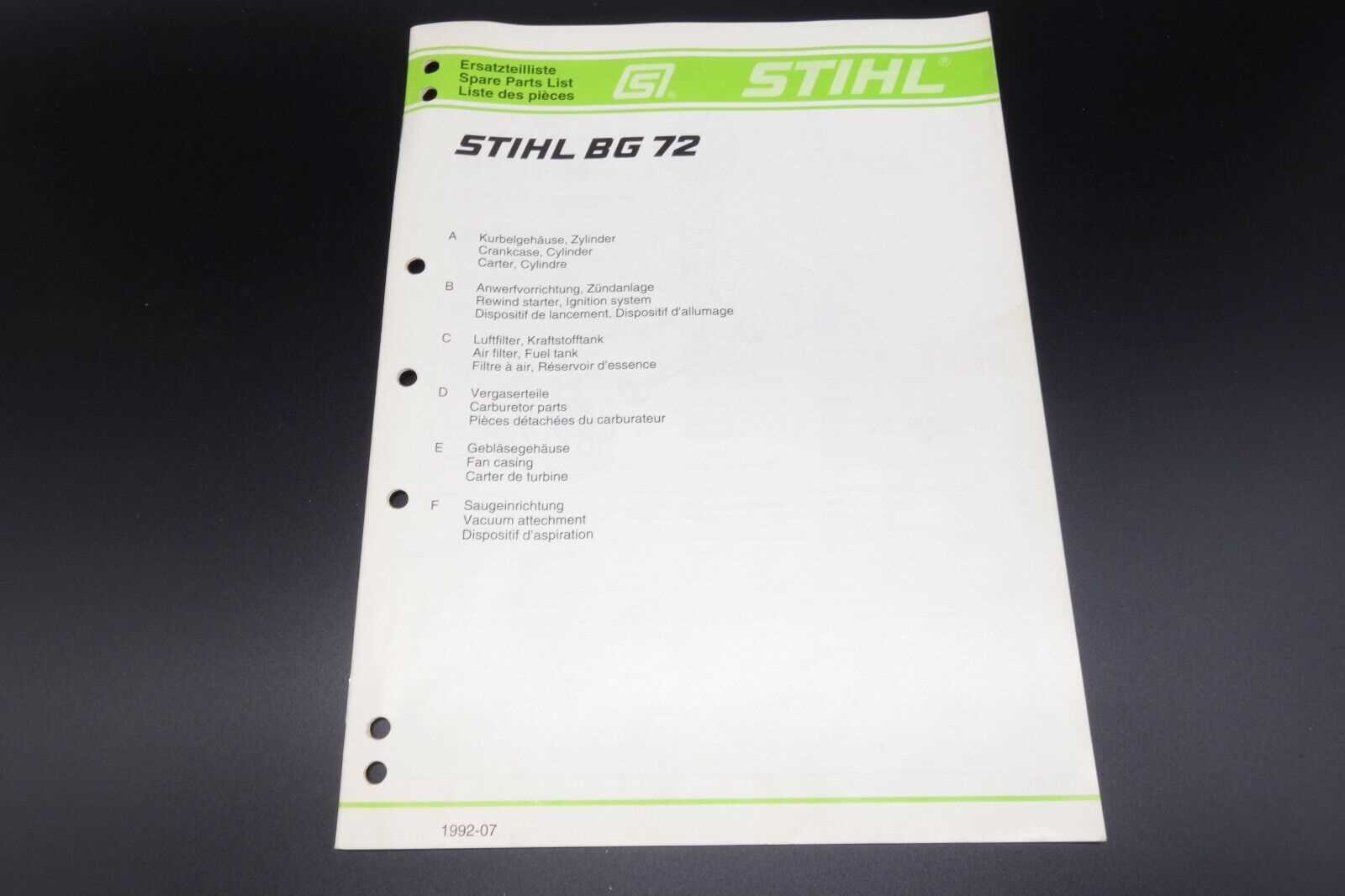

Comprehensive Guide to Stihl BG72 Parts Diagram

When it comes to maintaining and repairing outdoor machinery, having a clear visual representation of its components is essential. Such illustrations provide invaluable assistance in identifying individual parts and their respective functions, allowing for more efficient troubleshooting and repair processes. This knowledge is crucial for both novice users and seasoned technicians alike.

These schematics serve not only as guides but also as educational tools, helping users to familiarize themselves with the intricacies of their equipment. By analyzing the layout, one can quickly pinpoint wear and tear or potential issues that may arise during operation. Furthermore, understanding how each element fits together enhances the ability to perform regular maintenance and upgrades effectively.

Equipped with this information, users can ensure their machinery operates at peak performance. Whether it’s for routine checks or in the event of a malfunction, having access to comprehensive illustrations can simplify the complexities involved in handling outdoor tools. Thus, a detailed visual guide becomes an indispensable asset for anyone invested in maintaining their equipment efficiently.

Understanding Stihl BG72 Parts

When dealing with outdoor power equipment, having a solid grasp of its components is essential for maintenance and repair. Each element plays a critical role in the overall functionality, ensuring optimal performance and longevity. Familiarizing oneself with these individual elements allows for better troubleshooting and efficient upkeep, ultimately enhancing the user experience.

Key Components Overview

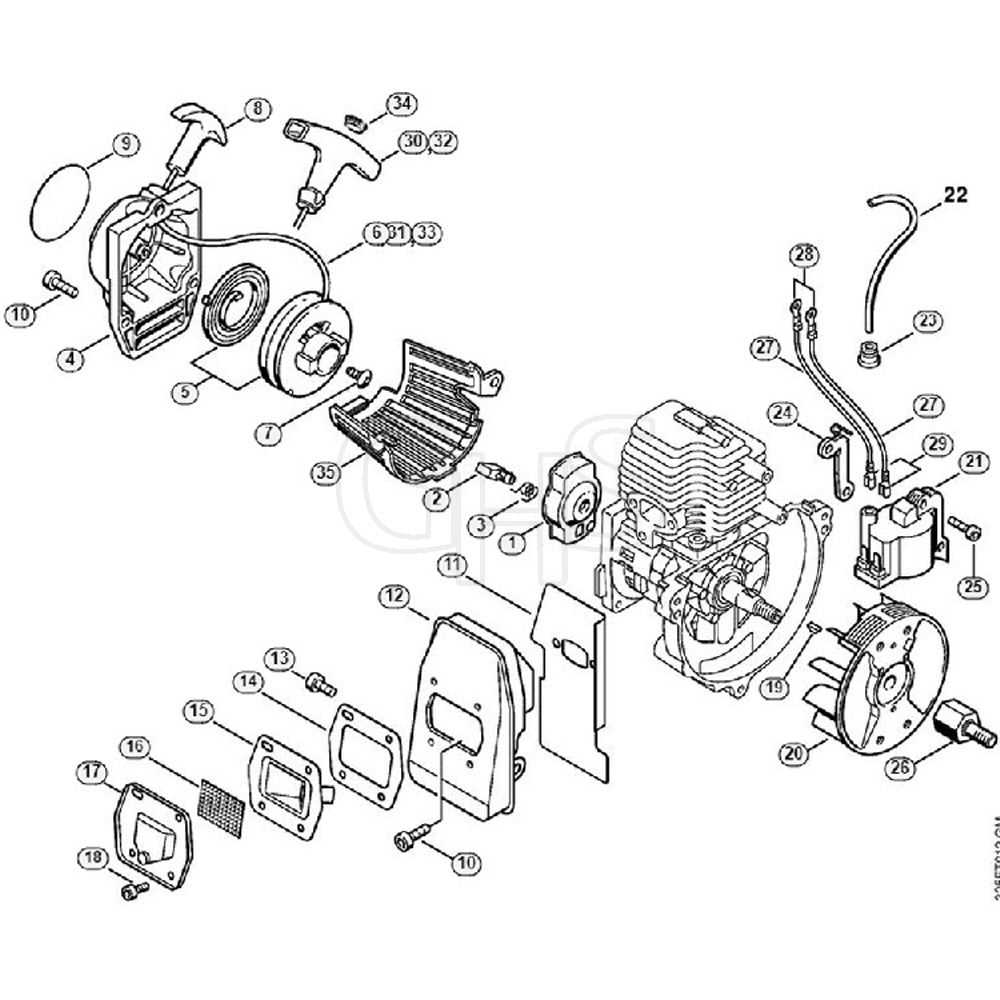

The core elements include the motor, air filter, and fuel system, each contributing to the unit’s efficiency. The motor drives the entire mechanism, while the air filter ensures a clean airflow for combustion. Additionally, the fuel system is responsible for the proper mixture of fuel and air, crucial for peak performance. Understanding how these components interact can aid in diagnosing issues and planning maintenance tasks.

Maintenance and Repair Tips

Regular inspections of these vital components can prevent larger issues down the line. Cleaning the air filter and ensuring the fuel system is free of blockages are simple yet effective practices. Furthermore, keeping an eye on wear and tear can lead to timely replacements, ensuring that the equipment remains in top shape for years to come.

Overview of Stihl BG72 Components

This section provides a comprehensive look at the essential elements that comprise the equipment, focusing on their functions and interrelationships. Understanding these components is crucial for effective maintenance and optimal performance.

| Component | Description |

|---|---|

| Engine | The heart of the machine, responsible for generating power. |

| Fan | Plays a key role in air circulation and debris movement. |

| Fuel Tank | Holds the necessary liquid for operation, ensuring efficiency. |

| Throttle Control | Allows the user to manage engine speed and power output. |

| Housing | Encases the internal mechanisms, providing protection and durability. |

| Exhaust System | Responsible for directing emissions away from the operator. |

| Handle | Facilitates control and maneuverability during operation. |

Importance of a Parts Diagram

Understanding the components of machinery is crucial for effective maintenance and repair. A visual representation of the various elements not only aids in identifying specific parts but also facilitates a deeper comprehension of how they interact within the overall system. This knowledge empowers users to troubleshoot issues efficiently and ensures the longevity of the equipment.

Benefits of Visual Representation

A visual guide serves multiple purposes, enhancing both learning and practical application. It simplifies the process of locating components, thus saving time and reducing frustration during repairs. Additionally, such an illustration can be an invaluable resource for training new technicians, providing them with a clear reference point.

Streamlining Repair Processes

Having access to a comprehensive visual guide allows for more streamlined repair processes. It encourages systematic approaches, reducing the likelihood of overlooking essential parts. Furthermore, a well-organized depiction aids in inventory management, ensuring that the necessary components are readily available for replacements.

| Aspect | Importance |

|---|---|

| Identification | Facilitates quick location of parts |

| Training | Assists in educating new users |

| Efficiency | Reduces downtime during repairs |

| Inventory | Aids in managing spare parts |

Common Issues with Stihl BG72

When it comes to handheld blowers, several challenges may arise during their operation. Understanding these common problems can help users maintain optimal performance and longevity of the equipment.

Frequent Problems Encountered

- Difficulty Starting: Many users report issues when attempting to start the engine. This can be due to a variety of factors, including fuel quality, spark plug condition, or air filter blockages.

- Power Loss: A noticeable decrease in power can occur, often linked to fuel delivery problems, clogged filters, or worn-out components.

- Excessive Vibration: If the device vibrates more than usual, it may indicate imbalances in the rotor or wear on the mounting hardware.

- Fuel Leaks: Leaking fuel can lead to dangerous situations and is often a result of damaged hoses or loose connections.

Troubleshooting Tips

- Check the Fuel: Always use fresh, appropriate fuel and ensure it is correctly mixed if using a two-stroke engine.

- Inspect the Spark Plug: Examine the spark plug for wear and replace it if necessary to ensure reliable ignition.

- Clean or Replace Filters: Regular maintenance of air and fuel filters can prevent performance issues.

- Examine Hoses: Look for cracks or wear in fuel hoses to address any leaks promptly.

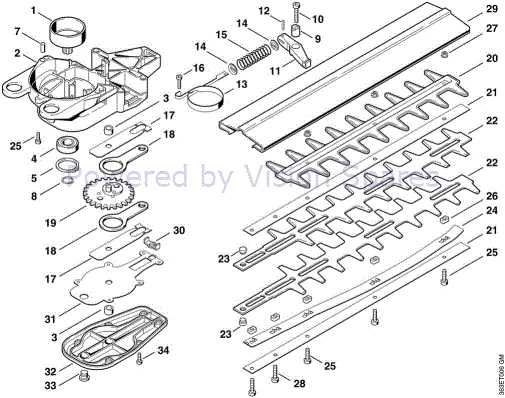

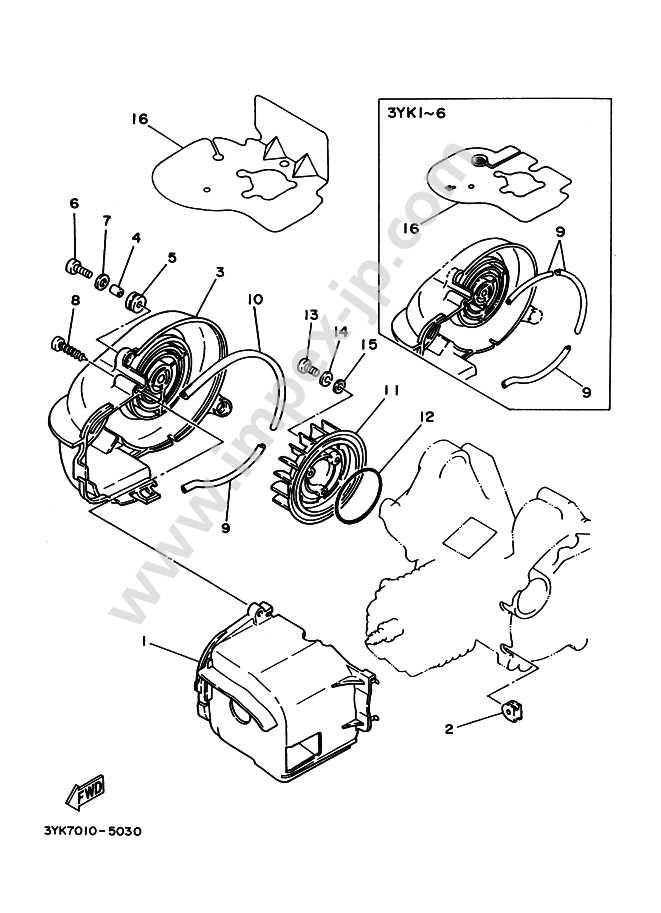

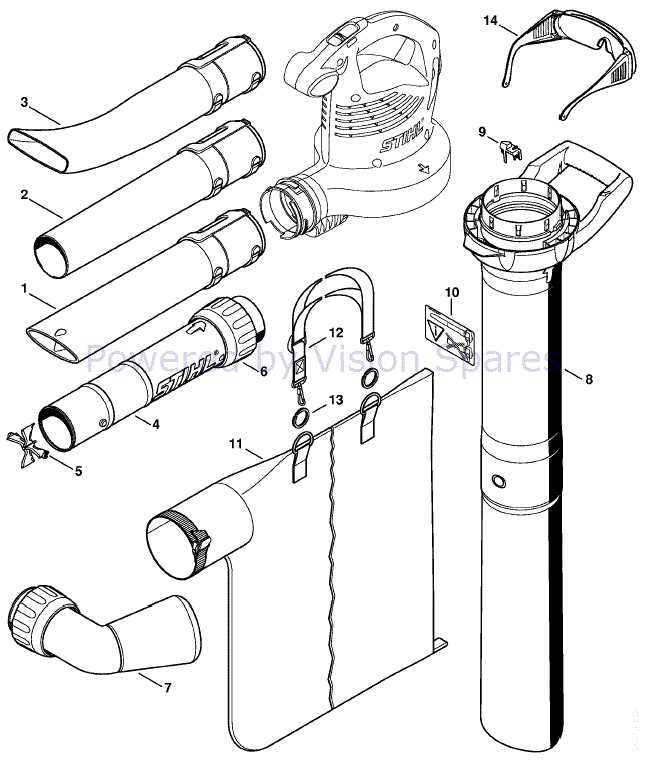

How to Interpret Parts Diagrams

Understanding the layout and components of machinery can be challenging. Visual representations serve as valuable tools that break down complex systems into manageable sections. By learning to navigate these illustrations, users can identify necessary components and facilitate repairs or maintenance more efficiently.

Key Elements to Consider

- Labels: Clear identification of each component is crucial. Pay attention to the annotations that describe the parts.

- Numbers: Many illustrations use numerical references to correspond with lists of items, allowing for easy cross-referencing.

- Sections: Often, these visual aids are divided into sections, focusing on specific areas of the machinery for detailed analysis.

Steps to Effective Interpretation

- Familiarize Yourself: Spend time getting to know the layout and common symbols used in the representation.

- Cross-Reference: Use accompanying lists to match numbers and names with their visual counterparts.

- Identify Relationships: Look for how components interact with one another to gain a deeper understanding of the system.

- Seek Additional Resources: Sometimes, guides or manuals provide further clarification on specific parts and their functions.

By mastering the art of reading these illustrations, individuals can enhance their ability to troubleshoot and maintain machinery effectively, ensuring longevity and optimal performance.

Identifying Replacement Parts

Understanding how to find suitable components for your equipment is essential for maintaining its performance and longevity. By recognizing the correct elements needed for repairs, users can ensure efficient operation and avoid potential complications. This process involves familiarizing oneself with the various pieces that comprise the machinery, as well as their specific functions and interrelations.

When seeking substitutes, it is important to consider factors such as compatibility, durability, and specifications. Identifying the right elements can often be facilitated by consulting detailed visuals or listings that outline the necessary components, making the selection process straightforward.

| Component Name | Description | Common Issues |

|---|---|---|

| Filter | Essential for maintaining airflow and cleanliness. | Clogging and reduced efficiency. |

| Blade | Primary tool for cutting and trimming tasks. | Worn edges leading to ineffective performance. |

| Fuel Line | Transfers fuel from the tank to the engine. | Leaking or blockage causing power loss. |

| Spark Plug | Ignites the air-fuel mixture in the engine. | Failure to start or irregular running. |

| Throttle Cable | Controls engine speed and power output. | Unresponsive or inconsistent throttle action. |

Utilizing a systematic approach to identify and source these components will not only enhance the efficiency of your machinery but also contribute to a safer and more enjoyable user experience. Regular maintenance and timely replacement of worn elements are key to optimal operation.

Tools Needed for Repairs

Proper maintenance and repairs require a specific set of instruments to ensure efficiency and safety. Having the right tools on hand can significantly streamline the repair process, allowing for quicker and more effective fixes.

Below is a list of essential tools that are commonly needed for conducting repairs:

- Screwdrivers: Various sizes and types, including flathead and Phillips, are crucial for loosening and tightening screws.

- Wrenches: Adjustable and fixed wrenches are necessary for gripping and turning nuts and bolts.

- Pliers: Needle-nose and standard pliers are useful for gripping, twisting, and cutting wire.

- Socket Set: A set of sockets allows for quick adjustments and tight fittings on bolts.

- Torque Wrench: This tool ensures that fasteners are tightened to the manufacturer’s specifications, preventing damage.

- Cutting Tools: A utility knife or wire cutters are essential for trimming materials and wires as needed.

In addition to these primary tools, consider the following items for enhanced efficiency:

- Safety Gear: Gloves, goggles, and masks protect against injuries and dust.

- Measuring Tools: Rulers and calipers ensure precision in measurements during repairs.

- Cleaning Supplies: Brushes and cloths help maintain cleanliness and visibility while working.

Being equipped with the appropriate tools will not only simplify the repair process but also enhance the overall quality of the work performed.

Step-by-Step Repair Process

This section outlines a systematic approach to fixing your equipment, ensuring that you can efficiently address any issues that arise. By following these steps, you can achieve a thorough and effective repair, restoring functionality with confidence.

- Gather Tools and Materials

- Identify necessary tools such as wrenches, screwdrivers, and pliers.

- Collect replacement components required for the repair.

- Ensure you have safety gear, including gloves and goggles.

- Disassemble the Equipment

- Carefully remove outer casing or coverings to access internal parts.

- Take note of the order and orientation of components as you detach them.

- Store small pieces in labeled containers to prevent loss.

- Inspect Components

- Examine each part for wear, damage, or corrosion.

- Identify which elements need replacement or repair.

- Document any findings for reference during reassembly.

- Replace or Repair Damaged Parts

- Install new components as necessary, ensuring a secure fit.

- If applicable, perform repairs on salvaged pieces following manufacturer guidelines.

- Lubricate moving parts to ensure smooth operation.

- Reassemble the Equipment

- Follow your notes to reattach components in the correct order.

- Tighten screws and bolts to specified torque levels.

- Double-check for any leftover parts or tools before closing.

- Test the Equipment

- Power on the machine to ensure it operates correctly.

- Observe for any unusual noises or malfunctions.

- Make necessary adjustments or corrections if issues persist.

By adhering to this detailed process, you can successfully navigate the repair of your machinery, promoting longevity and optimal performance.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment requires consistent care and attention. Regular maintenance not only enhances performance but also minimizes the risk of unexpected breakdowns. By adopting a proactive approach, you can keep your machine running smoothly for years to come.

1. Regular Cleaning: Keep the exterior and interior of the device free from dirt and debris. Use a soft brush and compressed air to remove any buildup that could affect functionality.

2. Inspect Components: Routinely check all parts for signs of wear or damage. Identifying issues early can prevent larger problems and costly repairs.

3. Lubrication: Apply appropriate lubricants to moving parts to reduce friction and prevent overheating. Regularly replace any worn-out or contaminated oils.

4. Follow Manufacturer’s Guidelines: Always refer to the user manual for specific maintenance schedules and recommendations. Adhering to these guidelines will ensure that you are taking the right steps for optimal care.

5. Store Properly: When not in use, store the equipment in a dry, cool place. Protect it from extreme temperatures and humidity, which can cause deterioration over time.

6. Use Quality Fuel: If your device operates on fuel, ensure that you use high-quality fuel and mix it correctly if necessary. Poor-quality fuel can lead to poor performance and engine damage.

By implementing these maintenance practices, you can enhance the reliability and efficiency of your equipment, ultimately extending its useful life and ensuring it remains a valuable asset for your tasks.

Where to Purchase Parts

When seeking replacement components for your outdoor power equipment, identifying reliable sources is crucial. Numerous options exist for acquiring these essential items, ranging from authorized dealers to online marketplaces. Understanding where to find high-quality replacements can greatly enhance the longevity and performance of your machinery.

Authorized Retailers

Visiting certified retailers can provide peace of mind when searching for replacements. These establishments often stock original components, ensuring compatibility and reliability. Engaging with knowledgeable staff can also offer insights into the best options for your specific model.

Online Platforms

The internet offers a vast array of choices for obtaining essential items. E-commerce sites frequently feature a wide selection of products, often at competitive prices. When shopping online, it’s advisable to read customer reviews and verify seller credibility to ensure you receive authentic components.

In summary, whether you choose to shop at physical stores or browse online, it’s important to prioritize quality and reliability when sourcing replacements for your equipment.

Comparing Stihl BG72 with Other Models

This section explores the distinctions and similarities between a specific leaf blower and various alternative models available in the market. By examining their specifications, performance capabilities, and user feedback, we aim to provide a clearer perspective for potential buyers considering their options.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Engine Power (cc) | 27.2 | 30.0 | 24.5 |

| Air Speed (mph) | 150 | 160 | 140 |

| Weight (lbs) | 9.5 | 10.5 | 8.8 |

| Fuel Capacity (oz) | 16 | 20 | 15 |

| Noise Level (dB) | 70 | 75 | 68 |

When evaluating these models, users should consider how each one aligns with their specific requirements, such as power, ease of use, and maintenance. The choice ultimately depends on individual preferences and the intended application.

Frequently Asked Questions

This section aims to address common inquiries related to maintenance and repair of outdoor power tools. Understanding the essential components and their functions can help users troubleshoot issues and ensure optimal performance.

What should I do if my equipment is not starting?

If your machine is having trouble starting, first check the fuel level and quality. Ensure that the ignition system is functioning correctly and inspect the air filter for clogs. Sometimes, a thorough cleaning of the spark plug can also resolve the issue.

How can I find the right components for repairs?

To identify the correct components for your repairs, consult the user manual specific to your model. You can also refer to online resources and forums where enthusiasts share their experiences and recommendations. Utilizing the right terminology will aid in your search for compatible items.

Customer Reviews and Experiences

Feedback from users plays a crucial role in understanding the effectiveness and reliability of any equipment. These insights often highlight personal interactions, showcasing both positive and negative aspects that potential buyers may consider before making a decision. Customers share their thoughts on performance, durability, and usability, creating a comprehensive picture of the product’s real-world applications.

Many users express satisfaction with the functionality and efficiency, noting how well the device meets their needs. Common praise includes its ease of use, maintenance requirements, and the quality of the results achieved. Enthusiasts often share their success stories, illustrating how the tool has enhanced their projects and streamlined their workflows.

Conversely, some reviews address challenges faced during operation. These experiences can provide valuable lessons for prospective users, offering insight into possible limitations and maintenance tips. Constructive criticism often emphasizes areas for improvement, helping manufacturers understand user expectations and adjust their offerings accordingly.

Overall, customer feedback serves as a vital resource for both potential buyers and manufacturers, fostering a community of shared knowledge that can enhance the user experience and product development.