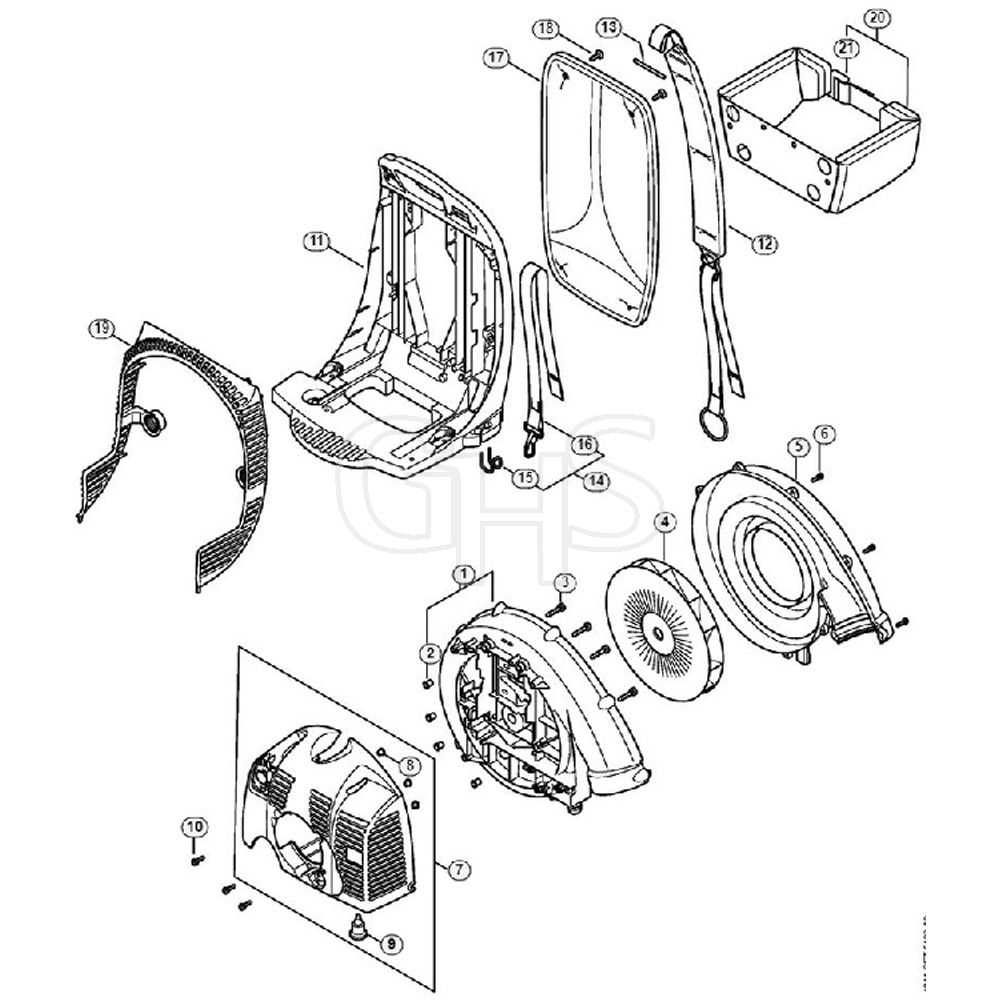

Comprehensive Guide to Stihl BR 800 C Parts Diagram

When it comes to maintaining high-performance machinery, having a clear understanding of its individual elements is essential. This knowledge empowers users to optimize functionality and ensure longevity, contributing to seamless operation. The intricate relationships between various components often determine the overall efficiency of the device.

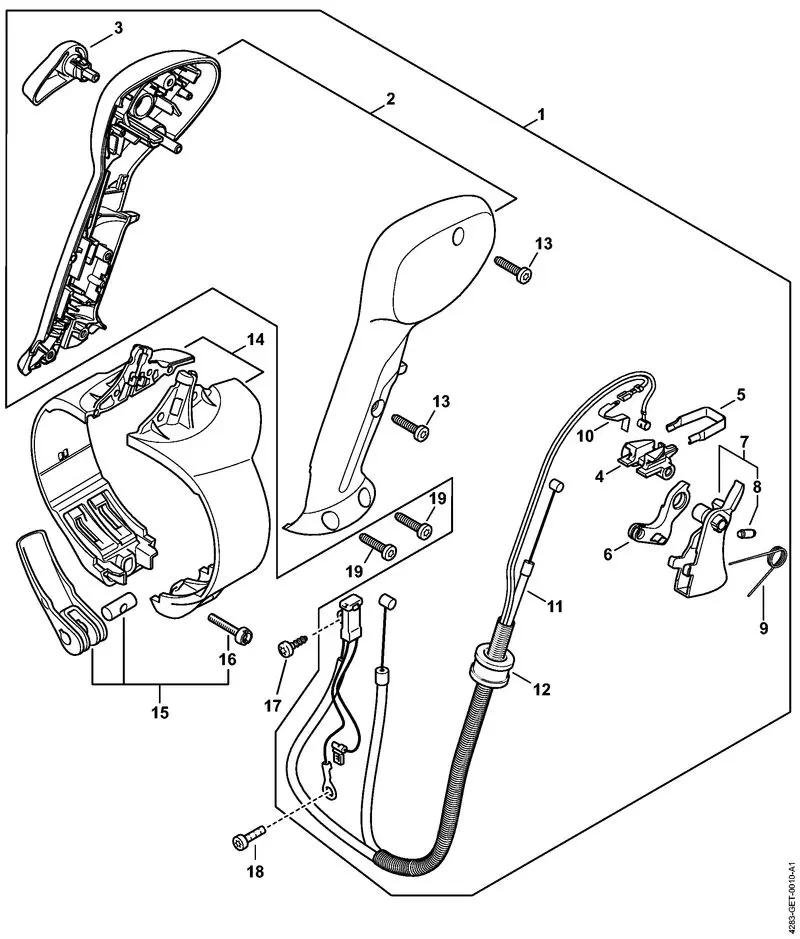

In this section, we will explore the essential elements that make up the specified tool. By examining the layout and connections of these parts, you will gain insights into their roles and how they interact. Such comprehension not only enhances your ability to troubleshoot issues but also equips you with the confidence to make informed decisions during maintenance and repairs.

Whether you’re a seasoned professional or a novice user, delving into the specifics of your equipment can reveal the ultimate secrets to achieving peak performance. Understanding each component’s function and placement fosters a deeper connection with your machinery, ensuring that you can address any challenges that may arise effectively.

Understanding Stihl BR 800 C Components

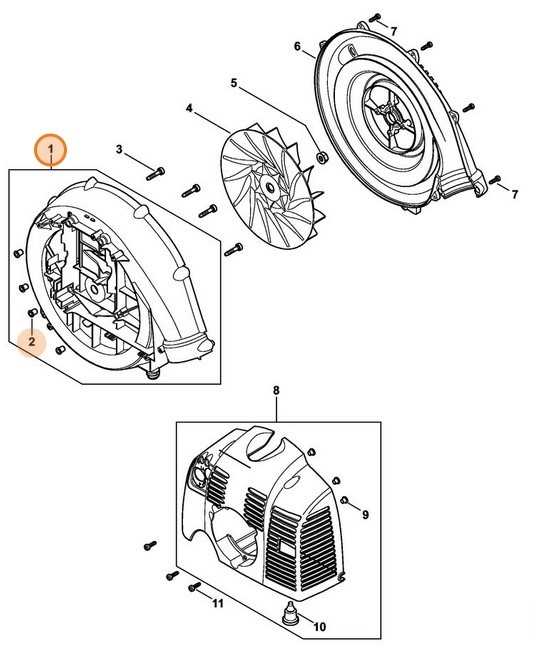

The intricate design of outdoor power equipment reveals a multitude of essential elements that work in harmony to achieve optimal performance. Each component plays a vital role, ensuring efficiency and reliability during operation. Grasping the functionality of these individual parts is crucial for effective maintenance and troubleshooting.

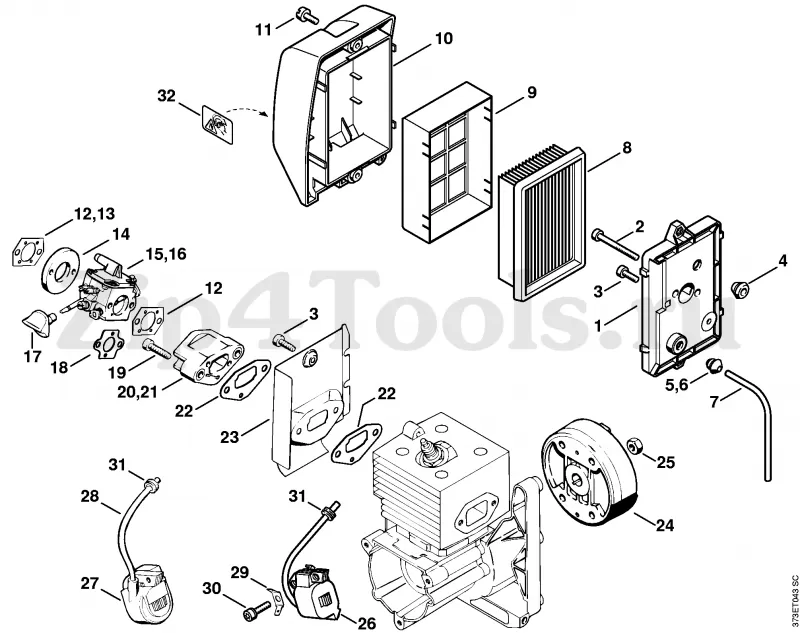

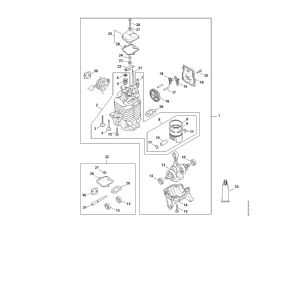

Engine: The powerhouse of the machine, responsible for generating the necessary energy for operation. Its design impacts overall performance and fuel efficiency.

Air Filter: This vital element ensures clean air enters the engine, protecting it from dust and debris. Regular maintenance of the filter can enhance the longevity of the equipment.

Fuel System: Comprising the tank, lines, and pump, this system is essential for delivering fuel to the engine. A well-functioning fuel system ensures smooth operation and prevents stalling.

Ignition: Responsible for starting the engine, this component sparks the fuel-air mixture. Proper care of the ignition system is crucial for reliable starts.

Throttle Control: This feature allows the user to regulate power output and adjust performance based on the task at hand, enhancing usability.

Exhaust: Efficiently expels gases produced during combustion. A well-maintained exhaust system minimizes emissions and enhances performance.

Understanding these components empowers users to optimize their equipment’s performance and ensure longevity, making it easier to tackle various outdoor tasks.

Importance of a Parts Diagram

Understanding the components of any machinery is crucial for effective maintenance and repair. A visual representation of these elements allows users to grasp their arrangement and function, ensuring smoother operations and troubleshooting.

Clarity in identifying individual pieces helps in efficient assembly and disassembly. When issues arise, having a detailed illustration enables users to delve into potential problems swiftly, enhancing overall productivity.

Furthermore, such illustrations serve as a valuable reference during reassembly, reducing the risk of errors. This leads to the ultimate goal of ensuring optimal performance and longevity of the equipment.

Key Features of Stihl BR 800 C

The powerful blower in question stands out in its class for its exceptional performance and innovative design. Engineered to handle demanding tasks, it combines efficiency and user-friendly features to deliver optimal results in yard maintenance and landscaping.

High Engine Power: This machine boasts a robust engine that provides substantial airflow and velocity, enabling users to clear debris and leaves with minimal effort. The increased power translates into higher productivity, making it an ideal choice for professionals and homeowners alike.

Lightweight Construction: Designed for comfort, this blower features a lightweight frame that reduces fatigue during extended use. The ergonomic design ensures that users can maneuver easily without compromising on power or performance.

Advanced Noise Reduction: The blower incorporates innovative technology to minimize noise levels, making it suitable for use in residential areas without disturbing neighbors. This feature enhances the overall user experience while promoting a more peaceful environment.

User-Friendly Controls: Equipped with intuitive controls, this blower allows for easy operation, enabling users to adjust settings quickly and efficiently. The simplified interface ensures that both novice and experienced users can operate the machine effectively.

Durability and Reliability: Built with high-quality materials, this equipment is designed to withstand harsh conditions. Its robust construction guarantees longevity, ensuring that it remains a reliable tool for years to come.

Common Replacement Parts Overview

Maintaining outdoor power equipment is essential for optimal performance and longevity. Understanding the various components that may require periodic replacement can enhance efficiency and reliability. This section delves into frequently changed elements that users should be aware of to ensure their machinery operates smoothly.

Among the most crucial components are filters, which play a vital role in keeping the engine clean and functioning properly. Regular replacement of these elements helps prevent debris from entering the engine, ensuring a longer lifespan and better performance.

Another important aspect to consider is the cutting head, which endures significant wear during operation. Upgrading or changing this part can dramatically improve cutting efficiency, making it easier to tackle tough jobs.

Additionally, spark plugs are essential for reliable ignition and efficient combustion. Regular checks and timely replacements can lead to smoother starts and improved fuel efficiency, reducing overall operational costs.

Lastly, hoses and fuel lines are key for proper fuel delivery. Over time, these can deteriorate, leading to leaks or blockages. Replacing these components when necessary helps maintain fuel flow and engine performance, ensuring consistent operation.

How to Use the Diagram Effectively

Understanding a visual representation of components can greatly enhance your ability to maintain and repair equipment. Utilizing such illustrations allows you to quickly identify each element, ensuring you have the necessary information at your fingertips. This guide will provide you with strategies to maximize your experience with these helpful resources.

Familiarize Yourself with the Layout: Before diving into any maintenance task, take a moment to study the arrangement of the illustration. Recognizing the organization will help you locate specific elements swiftly, reducing time spent searching.

Focus on Key Areas: Pay special attention to critical sections within the visual. Highlighting or marking these areas can assist you in prioritizing your work, making it easier to address issues as they arise.

Cross-Reference with the Manual: Always have the equipment’s manual handy while using the visual guide. This will allow you to clarify any uncertainties and ensure that you are interpreting the information correctly.

Practice Systematic Inspection: When performing maintenance, refer back to the illustration regularly. A systematic approach will help you ensure that no components are overlooked, enhancing the overall effectiveness of your service.

Take Notes: As you work through tasks, jot down any observations or changes made. This practice not only reinforces your understanding but also provides a reference for future maintenance.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the long-term functionality of any equipment. By adopting a systematic approach to maintenance, you can enhance performance and prolong the life of your tools.

- Clean the exterior regularly to prevent debris buildup.

- Check and replace filters as needed to maintain airflow.

- Inspect and sharpen cutting elements to ensure efficiency.

- Monitor fuel and oil levels, refilling as necessary.

Following these guidelines can help you achieve optimal performance and minimize the risk of breakdowns.

Identifying Wear and Tear Signs

Recognizing the signs of deterioration is essential for maintaining equipment efficiency and longevity. Over time, various components may exhibit changes that can affect performance. Understanding these indicators allows users to take proactive measures, ensuring reliable operation and minimizing potential breakdowns.

Common signs of wear include unusual noises during operation, which may signal mechanical issues. Additionally, visual inspections can reveal cracks, fraying, or discoloration on parts that are frequently exposed to stress. Accumulation of debris in critical areas can also indicate that maintenance is needed to prevent further damage.

Another critical aspect to monitor is the performance itself. A noticeable decrease in power or responsiveness often points to underlying problems. Regular checks can help identify these issues early, allowing for timely interventions that can extend the life of the equipment.

Tools Needed for Disassembly

To successfully take apart a machine for maintenance or repair, having the right tools is crucial. The process can vary in complexity, so being prepared will save time and ensure safety.

Here are the essential tools you will need:

- Screwdrivers: A set of both flat-head and Phillips screwdrivers to remove screws securely.

- Wrenches: Adjustable wrenches and socket sets to handle various nuts and bolts.

- Pliers: Needle-nose and standard pliers for gripping and twisting components.

- Hex Keys: Also known as Allen wrenches, useful for hexagonal bolts.

- Torque Wrench: To ensure bolts are tightened to the manufacturer’s specifications.

- Cutting Tools: Wire cutters or snips for any wiring that may need to be removed.

Additionally, consider having a magnetic tray or container to organize small parts and screws as you disassemble the unit. This will help you keep track of everything and make reassembly much easier.

Finally, always wear appropriate safety gear, such as gloves and goggles, to protect yourself during the disassembly process.

Where to Find Authentic Parts

Locating genuine components for your equipment is essential for optimal performance and longevity. Ensuring that you choose the right sources can significantly impact the efficiency of your machine.

- Authorized Dealers: Seek out certified retailers who specialize in offering original replacements.

- Official Websites: Many manufacturers provide direct access to their inventory online.

- Reputable Distributors: Look for established distributors known for their commitment to quality and authenticity.

- Online Marketplaces: Exercise caution by checking seller ratings and reviews when shopping on e-commerce platforms.

- Local Repair Shops: Experienced technicians often have access to genuine components or can guide you to trusted suppliers.

By choosing the right channels, you can ensure that your machinery remains in peak condition, ultimately enhancing its functionality and durability.

Common Repairs for This Model

Maintenance and repair are essential for ensuring the longevity and performance of any outdoor power tool. For this specific unit, there are several common issues that users may encounter over time. Addressing these problems promptly can help maintain optimal functionality and reduce the risk of further damage.

Typical Issues and Solutions

- Fuel System Blockages:

Clogs in the fuel line can lead to poor performance. Regularly inspect and clean the fuel filter and lines to ensure smooth operation.

- Air Filter Maintenance:

A dirty air filter can restrict airflow, affecting engine efficiency. Check and clean or replace the air filter as needed to maintain proper airflow.

- Starting Problems:

If the unit has trouble starting, it may be due to a faulty spark plug. Inspect and replace the spark plug if it shows signs of wear or damage.

- Worn Bearings:

Over time, bearings can wear down, leading to increased friction and noise. Regularly check and replace any worn bearings to ensure smooth operation.

Preventive Measures

- Regularly check and tighten all fasteners to prevent vibrations from loosening components.

- Store the unit in a dry place to prevent moisture-related issues.

- Perform seasonal maintenance, including lubrication and inspections, to catch potential problems early.

Upgrading Your Equipment Performance

Enhancing the efficiency of your machinery is essential for achieving optimal results in any task. By focusing on key components and making strategic modifications, you can significantly improve functionality, longevity, and overall effectiveness. This process not only boosts productivity but also ensures that your investment yields the best possible returns.

Key Modifications for Enhanced Efficiency

Consider upgrading critical elements such as the engine, fuel system, and air intake. These modifications can lead to improved power output and fuel efficiency, ultimately transforming your equipment into a high-performance tool. Regular maintenance and timely replacements of worn-out parts further support sustained performance gains.

Adopting Advanced Accessories

Incorporating advanced attachments and accessories tailored to your specific needs can provide the ultimate advantage. These enhancements not only facilitate versatility but also allow for a more tailored approach to different tasks, ensuring that your equipment remains adaptable and efficient in various conditions.