Understanding the Stihl BR200 Parts Diagram for Efficient Repairs

When it comes to maintaining outdoor machinery, having a clear visual representation of its components can be invaluable. This section delves into the intricate details of the various elements that make up essential tools for yard care. Knowing how each piece fits into the whole not only aids in troubleshooting but also enhances the overall efficiency of your equipment.

For enthusiasts and professionals alike, being familiar with the assembly and disassembly of these machines can lead to better performance and longevity. Recognizing individual components helps users to identify wear and tear, facilitating timely replacements. Moreover, a comprehensive overview allows for more informed decisions regarding maintenance and upgrades.

In the following sections, you will find a detailed overview of the essential elements, including their functions and interrelations. Understanding these aspects will empower you to take charge of your machinery, ensuring that it operates smoothly and effectively for years to come.

Understanding the Stihl BR200

This segment aims to provide insight into a popular model of leaf blowers, emphasizing its design and functionality. Such equipment is essential for maintaining outdoor spaces, making yard work more efficient and less labor-intensive. Understanding the components and operation of this machine is crucial for both users and technicians alike.

The machine is equipped with a powerful engine, which plays a vital role in generating the airflow needed to clear debris effectively. Familiarity with the internal mechanisms can help in troubleshooting and maintenance, ensuring longevity and optimal performance.

| Feature | Description |

|---|---|

| Engine Type | Two-stroke engine for efficient power output |

| Weight | Lightweight design for ease of use |

| Airflow Rate | High airflow capacity for quick debris clearance |

| Fuel Efficiency | Designed to maximize fuel consumption |

Understanding these features enhances the user’s ability to select the right tool for their needs, optimizing performance during yard maintenance tasks.

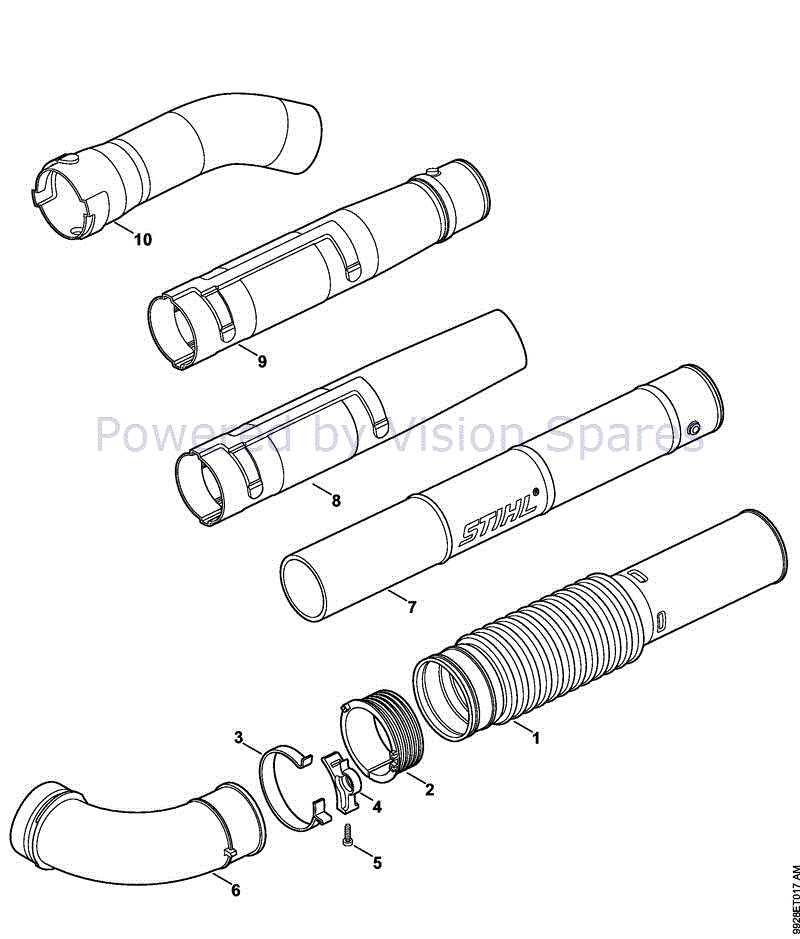

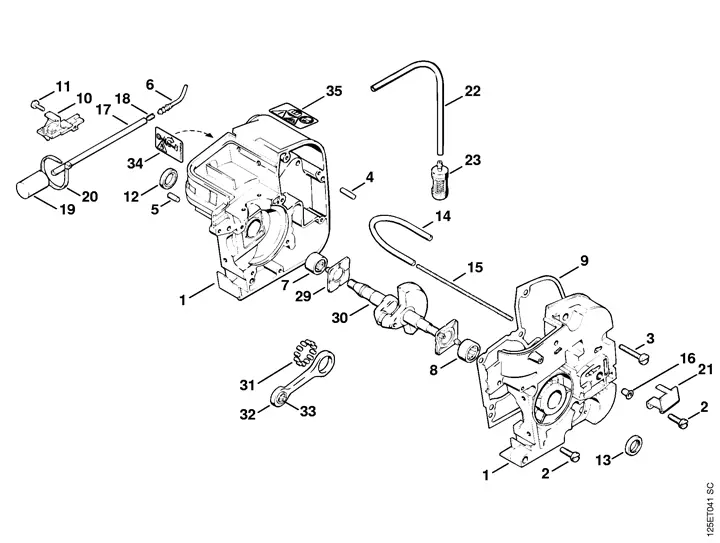

Key Components of the BR200

This section explores the essential elements that contribute to the functionality and efficiency of the machine. Understanding these critical components is vital for maintenance and optimal performance, ensuring that users can achieve the best results in their tasks.

Engine Assembly

The engine assembly is the powerhouse of the equipment, providing the necessary energy to operate. It is designed for durability and efficiency, enabling the device to handle various outdoor tasks with ease. Regular checks on this component can enhance longevity and performance.

Blower Housing

The blower housing plays a crucial role in directing airflow effectively. Its design ensures that debris is moved efficiently, allowing for a clean working environment. Proper maintenance of this part is essential to maintain optimal airflow and overall effectiveness.

Importance of a Parts Diagram

A visual representation of components plays a crucial role in understanding the assembly and functionality of machinery. It serves as a guide for maintenance, repairs, and upgrades, ensuring users can navigate complex systems effectively.

Benefits of Having a Visual Reference

- Enhances understanding of individual elements and their relationships.

- Facilitates easier troubleshooting and problem-solving.

- Streamlines the repair process by providing clear identification of needed items.

Efficient Maintenance and Upgrades

- Allows for better planning during service, reducing downtime.

- Encourages the use of correct replacements, which improves longevity.

- Assists in identifying opportunities for enhancement or modifications.

In summary, a comprehensive visual guide is invaluable for both novice and experienced users, promoting efficiency and reliability in the operation of equipment.

How to Read the Diagram

Understanding a visual representation of components is essential for effective maintenance and repair tasks. Such illustrations serve as a guide, helping users identify various elements and their connections within a machine. By mastering the art of interpreting these visuals, you can streamline your work and ensure everything functions optimally.

Identifying Key Elements

Begin by familiarizing yourself with the primary symbols and notations used in the illustration. Each part will typically be labeled with a unique identifier, often accompanied by a reference number. This allows you to cross-reference with lists or manuals to find additional details about specifications or replacement options. Pay attention to any color coding, as this may indicate different categories or functions within the assembly.

Understanding Relationships and Connections

Next, focus on the layout of the components. The arrangement often reflects their physical relationships, showing how they connect or interact with one another. Arrows and lines are commonly employed to illustrate these connections, so take time to trace each path and understand how energy or materials flow through the system. This knowledge is crucial for diagnosing issues and making informed repairs.

Common Replacement Parts for BR200

Maintaining optimal performance in outdoor power equipment often requires replacing certain components over time. Identifying and understanding these crucial elements can enhance the longevity and efficiency of your device, ensuring it operates smoothly and effectively. This section highlights some of the frequently needed components that users might consider when upkeep is necessary.

Essential Components

Among the vital elements to keep an eye on are the air filter, fuel filter, and spark plug. The air filter is essential for maintaining clean airflow, which directly affects engine performance. A clogged filter can lead to reduced efficiency and increased fuel consumption.

Maintenance Items

Additionally, it is important to replace the fuel filter regularly to prevent contaminants from entering the fuel system. This ensures that the engine receives clean fuel, which is crucial for smooth operation. The spark plug should also be checked periodically, as it ignites the fuel-air mixture. A worn-out plug can cause misfiring or hard starting, ultimately impacting performance.

Incorporating these essential replacements into your maintenance routine will help keep your equipment running at its best, maximizing its lifespan and efficiency.

Tools Required for Repairs

When undertaking maintenance or restoration tasks, having the right tools is essential for achieving effective results. Proper equipment not only enhances efficiency but also ensures safety during the repair process. Below is a list of common tools that are beneficial for various repair activities.

| Tool | Purpose |

|---|---|

| Screwdriver Set | For removing and tightening screws on different components. |

| Wrench Set | To adjust and secure bolts and nuts. |

| Pliers | For gripping, twisting, and cutting wire or other materials. |

| Hex Key Set | Essential for working with hexagonal screws and fittings. |

| Torque Wrench | To apply a specific torque to fasteners, ensuring proper tightness. |

| Utility Knife | For cutting various materials with precision. |

| Multimeter | For testing electrical connections and diagnosing issues. |

| Cleaning Brushes | To remove debris and residue from components. |

Step-by-Step Maintenance Guide

Regular upkeep is essential for ensuring the longevity and optimal performance of your equipment. This guide provides a systematic approach to maintaining your device, focusing on key components that require attention. Following these steps will help you avoid potential issues and keep your machinery running smoothly.

1. Cleaning the Exterior: Begin by removing any debris and dirt from the surface. Use a soft brush or cloth to wipe down the exterior, ensuring that air vents and other openings are free from obstructions.

2. Inspecting the Filters: Check the air and fuel filters for blockages. Replace any filters that appear dirty or damaged, as this will enhance performance and efficiency.

3. Checking the Spark Plug: Remove the spark plug and inspect it for wear and carbon build-up. Clean it if necessary, or replace it if it shows signs of excessive wear. Proper spark plug maintenance is crucial for reliable ignition.

4. Lubricating Moving Parts: Apply appropriate lubricant to all moving parts, including joints and pivot points. This reduces friction and helps prevent wear over time.

5. Examining the Fuel System: Ensure that the fuel lines are intact and free from leaks. Replace any damaged hoses to prevent fuel loss and maintain efficiency.

6. Reviewing Safety Features: Test all safety mechanisms, such as switches and guards, to ensure they function correctly. Regularly checking these features can prevent accidents and injuries.

7. Final Check: After completing the maintenance tasks, conduct a thorough inspection to ensure everything is in order. Perform a test run to verify that the device operates as intended.

By following this comprehensive maintenance guide, you can enhance the performance and reliability of your equipment, ensuring it remains in peak condition for years to come.

Identifying Parts by Model Number

Recognizing components by their specific identification number is essential for ensuring compatibility and functionality. Each unit comes with a unique identifier that helps users find the correct elements needed for maintenance or replacement. Understanding how to interpret these numbers can save time and reduce the risk of purchasing the wrong items.

Importance of Model Identification

When seeking replacements, knowing the precise model number allows for accurate selection. It eliminates confusion and ensures that the components fit correctly and perform as intended. Moreover, it facilitates easy communication with suppliers or technicians when discussing needs or issues.

How to Find Model Numbers

Model numbers are typically located in several places on the unit. Common locations include:

| Location | Description |

|---|---|

| Body | Often stamped or printed directly on the main housing. |

| Manual | Usually listed in the user guide that comes with the equipment. |

| Label | A sticker or plate, often near the engine or motor, displaying the model number. |

By knowing where to look, users can efficiently identify their units and ensure they acquire the right components for optimal performance.

Where to Purchase Replacement Parts

Finding suitable components for your outdoor equipment is crucial for maintaining its performance and longevity. There are various avenues available for sourcing these essentials, ensuring you can keep your machinery running smoothly.

Here are some recommended options for acquiring necessary items:

- Authorized Dealers: These retailers provide genuine components and often have knowledgeable staff who can assist you with your specific needs.

- Online Marketplaces: Websites such as eBay, Amazon, or specialized platforms offer a wide selection of items, often at competitive prices. Always check seller ratings and reviews.

- Local Repair Shops: Many repair services carry commonly needed components. Supporting local businesses can be beneficial and convenient.

- Manufacturer Websites: The official site often has a dedicated section for replacement items, providing assurance of quality and compatibility.

When purchasing, ensure that you verify the compatibility of the items with your equipment model to avoid any issues during installation. Prioritize quality over price to ensure optimal performance.

Benefits of OEM vs Aftermarket Parts

When it comes to maintaining equipment, the choice between original components and third-party alternatives can significantly impact performance and longevity. Each option presents distinct advantages that can affect functionality, warranty coverage, and overall satisfaction with the product.

Original components are manufactured by the same company that produced the equipment, ensuring compatibility and adherence to strict quality standards. These items often come with a guarantee, providing peace of mind for the user. Their precise engineering typically leads to better performance and durability, reducing the likelihood of malfunction.

On the other hand, third-party alternatives can offer a cost-effective solution, often at a lower price point. Many of these alternatives are designed to meet or exceed the specifications of original components, making them a viable option for budget-conscious consumers. Additionally, a wider selection may provide enhanced features or innovative designs that aren’t available with original offerings.

Ultimately, the decision hinges on individual needs and preferences, weighing the reliability of original manufacturing against the potential savings and variety presented by third-party choices. Each option has its place, and understanding the implications of both can lead to more informed decisions regarding equipment maintenance.

Tips for Efficient Parts Management

Effective management of components is crucial for maintaining optimal performance and prolonging the lifespan of equipment. By implementing strategic practices, individuals and organizations can ensure that they have the right items on hand while minimizing waste and downtime.

Organizing Your Inventory

- Implement a systematic labeling system to easily identify items.

- Utilize storage solutions such as bins or shelves to categorize components by type or size.

- Conduct regular audits to assess stock levels and identify items that need replenishment.

Utilizing Technology

- Adopt inventory management software to track components in real-time.

- Set up alerts for low stock levels to avoid last-minute shortages.

- Use digital records to streamline ordering processes and reduce errors.

By focusing on organization and leveraging technology, individuals can enhance their management strategies, ensuring that all necessary components are readily available when needed.