Comprehensive Guide to Stihl BR800X Parts Diagram

When it comes to maintaining outdoor machinery, comprehending the intricate assembly of its components is essential for optimal performance. This section delves into the various elements that contribute to the functionality of your device, providing insights into how each part interacts within the overall system. A well-informed approach can significantly enhance both longevity and efficiency.

Identifying the specific elements involved not only aids in troubleshooting but also empowers users to carry out necessary repairs or replacements effectively. By exploring the layout and interconnections of these essential components, operators can develop a deeper appreciation for their equipment’s design and engineering. This knowledge is crucial for anyone looking to ensure their machinery remains in peak condition.

In this guide, we will break down the key parts that constitute your outdoor device, highlighting their roles and functions. From the most prominent features to the less noticeable details, understanding each aspect will enable you to manage maintenance tasks with confidence. Let’s embark on this journey to discover the intricate workings of your machinery!

Understanding Stihl BR800X Components

To fully appreciate the functionality of any high-performance outdoor equipment, it’s essential to familiarize oneself with its key elements. Each component plays a crucial role in ensuring optimal performance, efficiency, and durability. This section aims to shed light on the various parts that contribute to the overall operation of this powerful tool.

Key Elements and Their Functions

At the heart of the machine lies the engine, which provides the necessary power for operation. This unit transforms fuel into energy, driving the entire mechanism. Surrounding this powerhouse are various accessories designed to enhance performance, such as air filters and exhaust systems that ensure proper airflow and emissions management.

Maintenance and Upkeep

Understanding the significance of each element not only aids in efficient usage but also highlights the importance of regular maintenance. Components like spark plugs and fuel lines require periodic checks to prevent issues and prolong the life of the equipment. Being aware of these parts enables users to perform necessary replacements and repairs, ensuring the tool remains in peak condition.

Key Features of the BR800X

This powerful outdoor tool is designed for exceptional performance and ease of use. With its robust construction and advanced engineering, it stands out in the market for its efficiency and reliability in handling tough tasks.

- High Airflow Capacity: Engineered to deliver impressive air volume, making it effective for clearing debris quickly.

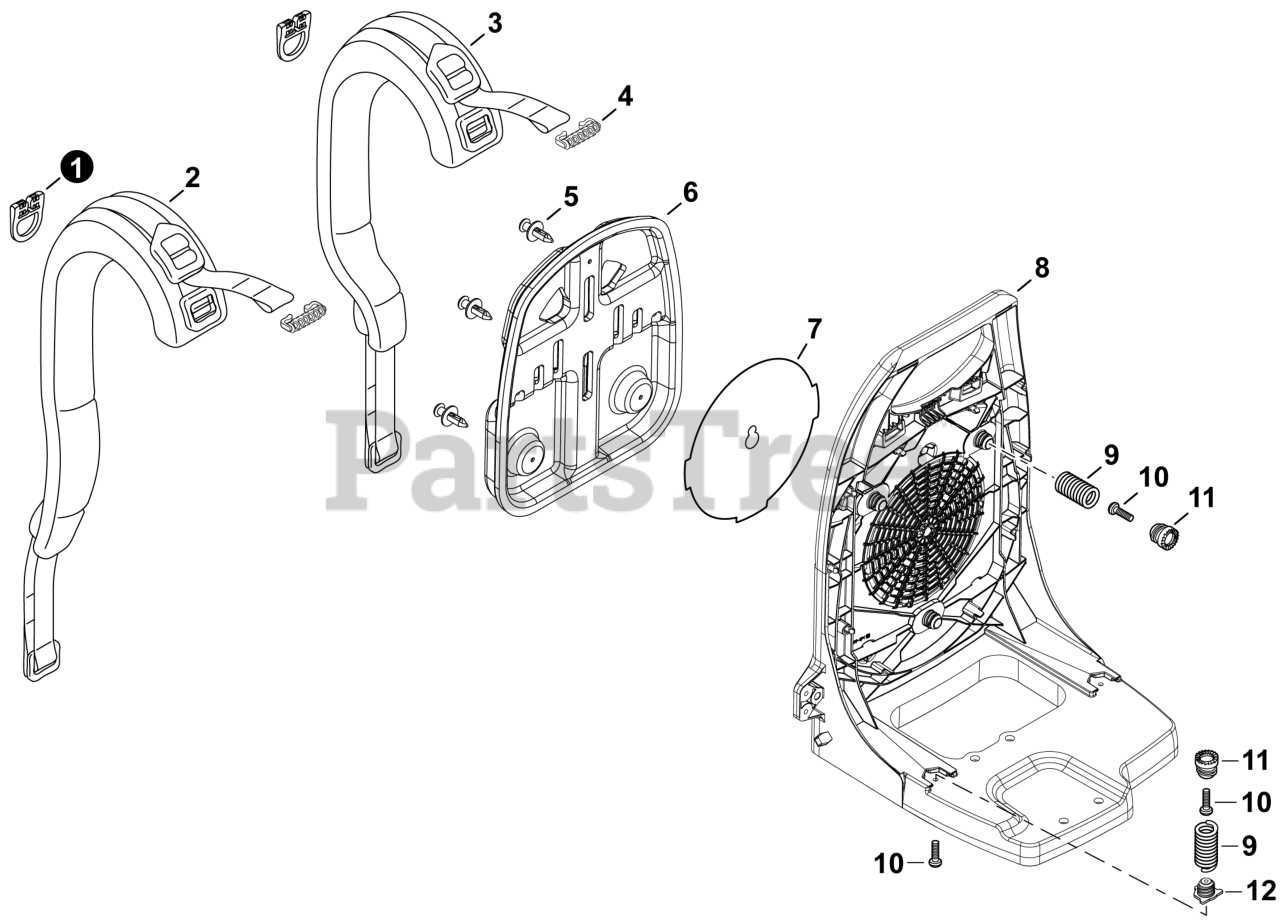

- Ergonomic Design: Features a comfortable grip and adjustable harness, reducing fatigue during prolonged use.

- Powerful Engine: Equipped with a high-performance motor that ensures optimal power and efficiency.

- Low Emission Technology: Designed with environmental considerations in mind, minimizing harmful exhaust emissions.

- Durable Construction: Built with high-quality materials that enhance longevity and withstand rigorous conditions.

Overall, this equipment combines innovative features that cater to both professional landscapers and homeowners, making yard maintenance more efficient and effective.

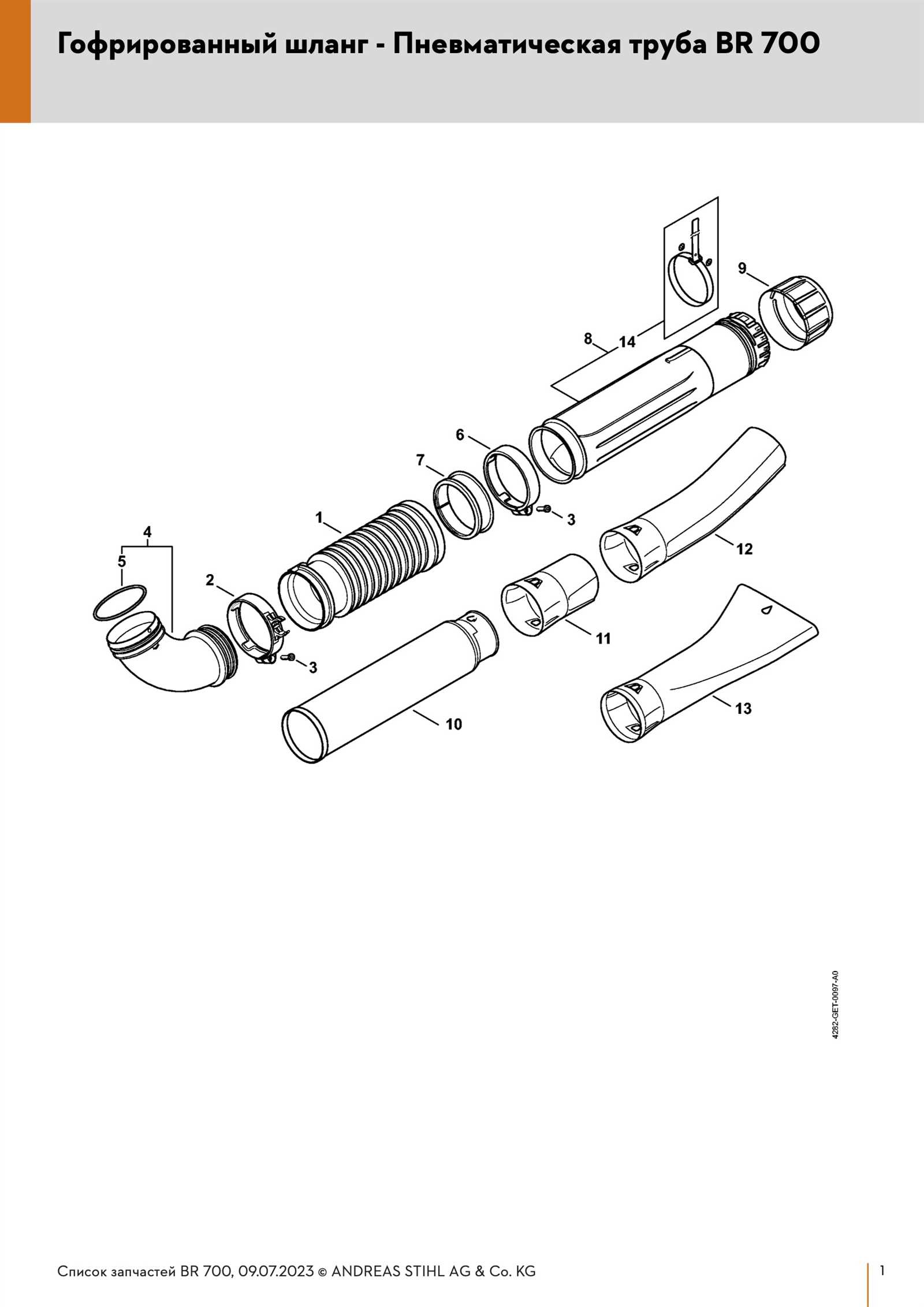

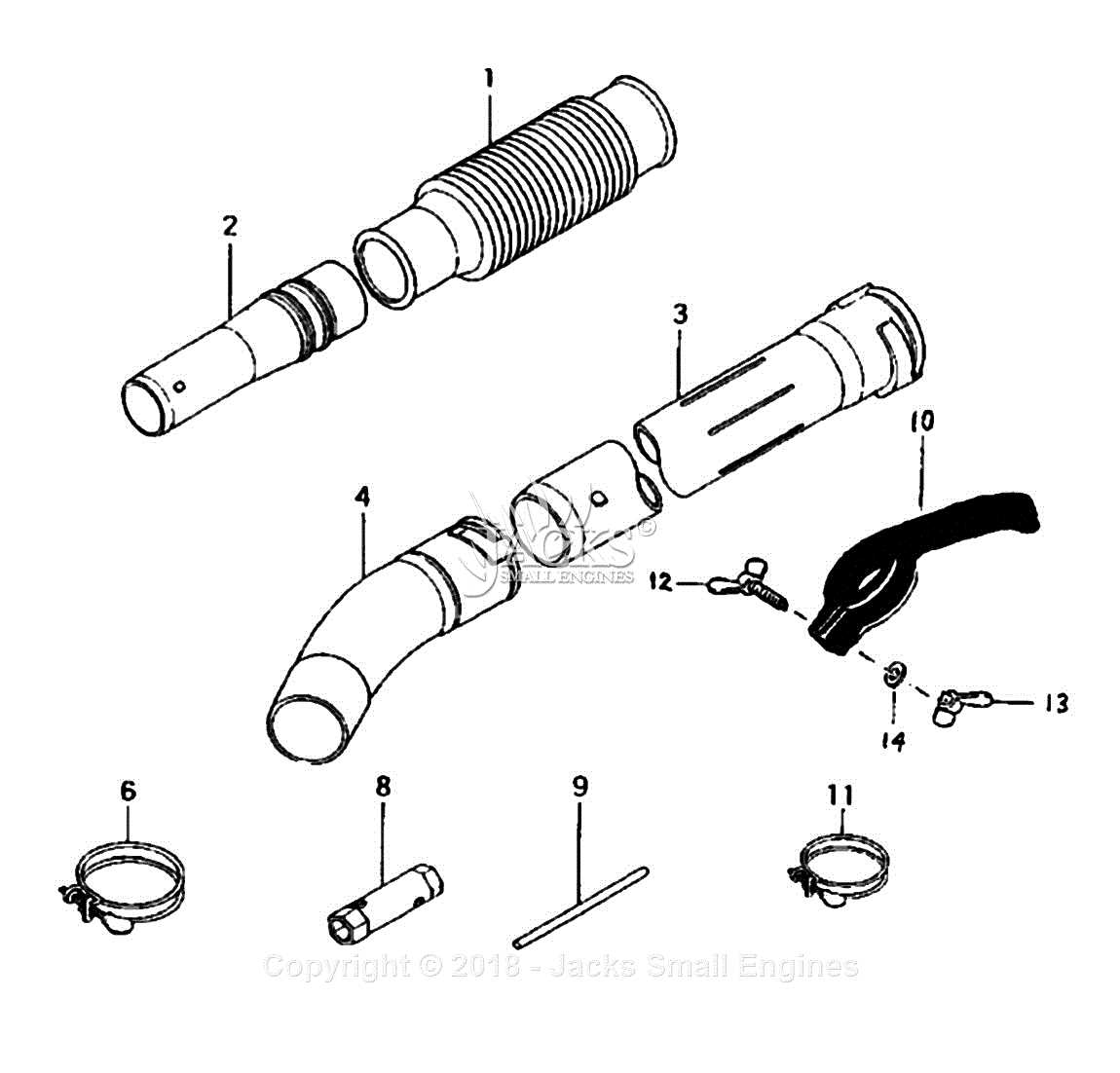

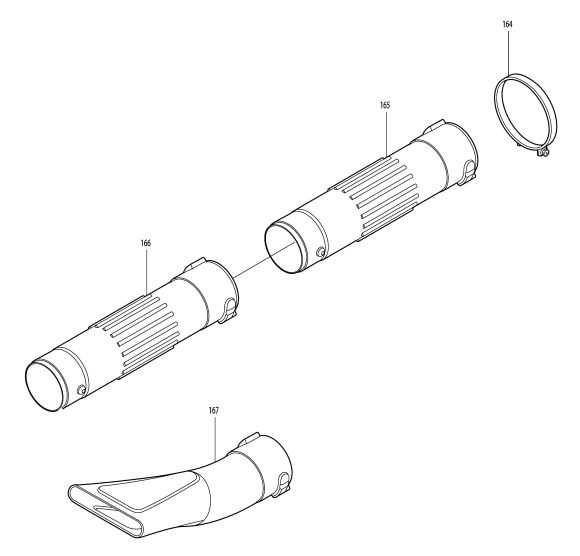

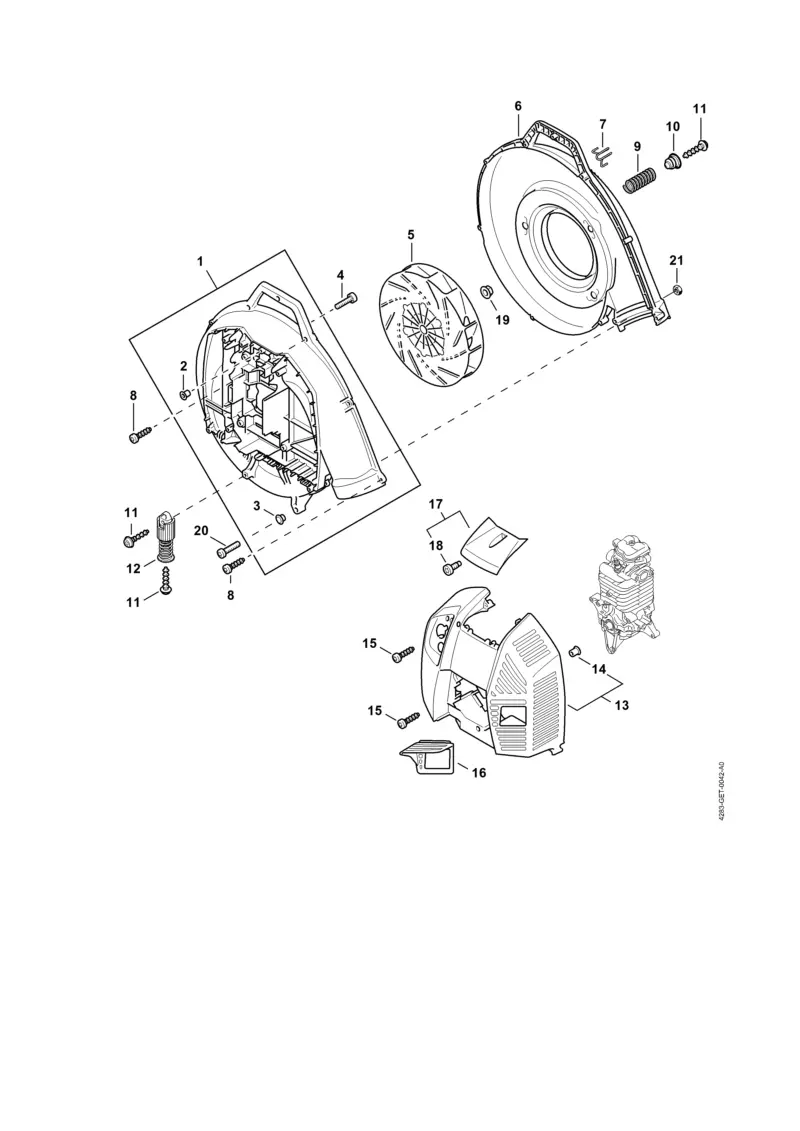

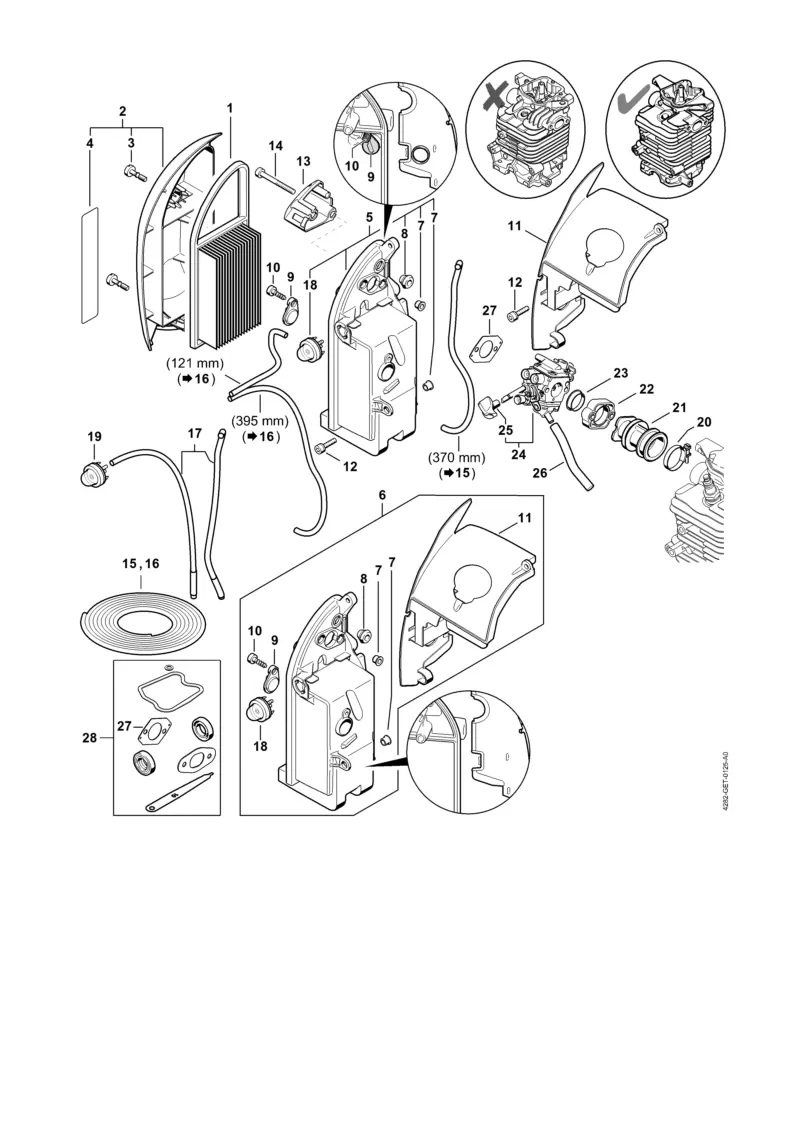

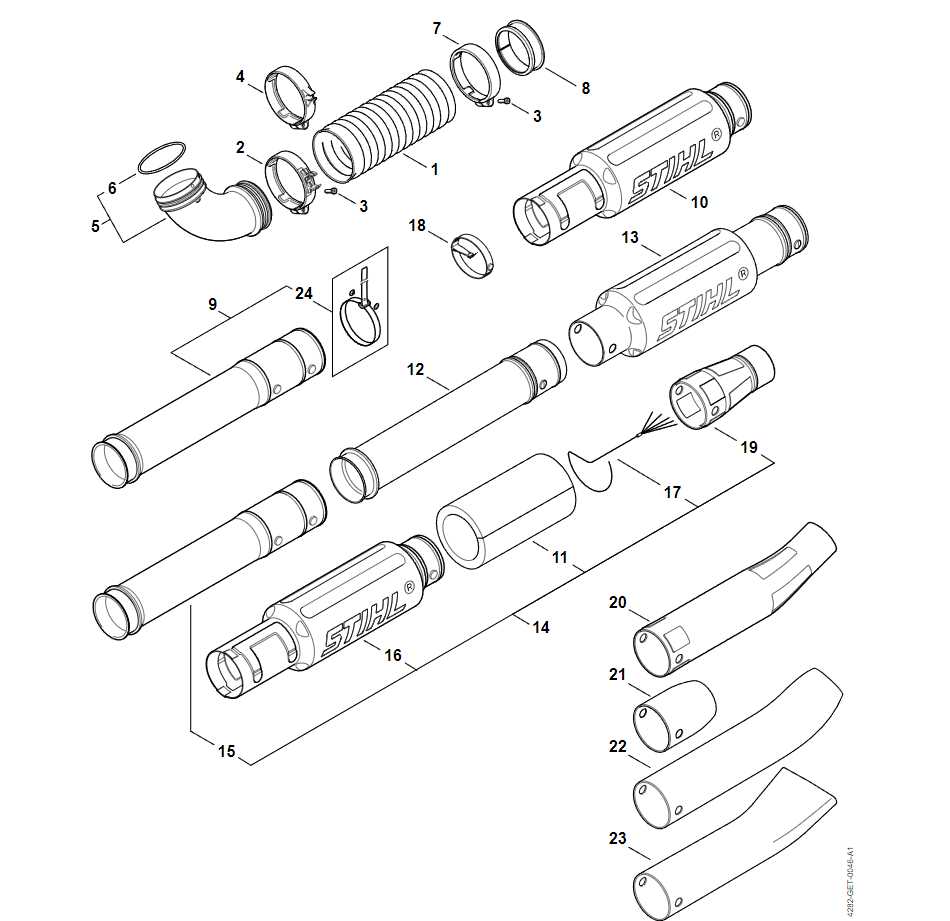

Importance of Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools, allowing users to identify each element accurately and comprehend its function within the whole system. These illustrations not only enhance clarity but also facilitate troubleshooting, making the repair process more efficient.

Effective communication is one of the primary benefits of these visual aids. Technicians and users can easily refer to a detailed layout when discussing issues or solutions, ensuring that everyone involved is on the same page. This eliminates confusion and promotes a smoother workflow.

Moreover, these visuals play a significant role in parts replacement. By having a clear overview of the assembly, users can determine which components need to be acquired for repairs, thus saving time and reducing the risk of errors. This organized approach helps maintain the longevity and performance of the equipment.

Additionally, using these representations encourages proper handling and assembly. When users can visualize the correct placement and orientation of each part, it minimizes the likelihood of damage during maintenance tasks. Overall, these tools are invaluable for anyone looking to ensure their machinery operates at peak performance.

How to Access the Diagram

Understanding the layout of your equipment is crucial for effective maintenance and repairs. To find detailed illustrations and breakdowns of components, you can explore various resources available online. These resources often include manuals, manufacturer websites, and dedicated forums where users share insights and visuals.

One of the most straightforward ways to obtain these illustrations is to visit the official website of the manufacturer. They typically provide downloadable manuals that contain comprehensive guides and visuals for different models. Alternatively, you can search for community-driven platforms where enthusiasts discuss and upload relevant documents.

For those who prefer direct access, many retailers also offer physical copies of manuals or digital downloads. By searching for the specific model, you can often find a wealth of information that will assist in understanding how each part interacts with the whole unit.

Utilizing these resources effectively will empower you to perform maintenance tasks with confidence, ensuring that your equipment remains in optimal condition.

Common Replacement Parts Overview

Maintaining outdoor power equipment requires an understanding of various components that may need to be replaced over time. Regular wear and tear can affect performance, making it essential to identify which elements require attention. This section will highlight some frequently needed components to ensure your equipment operates efficiently and reliably.

Key Components

Several critical elements often necessitate replacement, including the air filter, spark plug, and fuel lines. The air filter plays a vital role in maintaining airflow to the engine, while a worn spark plug can lead to poor ignition and reduced power. Fuel lines may degrade over time, causing leaks and affecting fuel delivery.

Additional Items to Consider

Beyond the primary components, there are other parts that may require replacement to optimize performance. The ignition coil and carburetor can also wear out, leading to starting issues or uneven operation. Regular inspection of these items can help prevent more significant problems down the line, ensuring smooth and effective functionality.

Identifying Parts by Serial Number

Understanding how to pinpoint specific components through unique identification numbers can greatly enhance maintenance efficiency and ensure the right replacements are selected. These identifiers serve as a crucial link between the equipment and its respective components, allowing for accurate sourcing and troubleshooting.

The Importance of Serial Numbers

Unique identification codes play a vital role in the following aspects:

- Traceability: They provide a direct line to the manufacturing history and specifications of the equipment.

- Compatibility: Ensuring that the correct components are used for repairs or upgrades.

- Warranty Verification: Establishing authenticity for warranty claims and service records.

How to Use Serial Numbers Effectively

To maximize the benefits of these identification numbers, follow these steps:

- Locate the serial number on the equipment; it is often found on a metal plate or label.

- Refer to the manufacturer’s website or catalog for a comprehensive list of components associated with that number.

- Contact customer support for assistance in case of uncertainty regarding compatibility or sourcing.

By following these guidelines, users can streamline their maintenance process and ensure that their machinery operates at peak performance.

Maintenance Tips for BR800X

Proper upkeep is essential for ensuring optimal performance and longevity of your equipment. Regular maintenance not only helps in avoiding unexpected breakdowns but also enhances efficiency during operation. Following a structured maintenance routine will allow users to keep their machine running smoothly and effectively.

Routine Checks

Conducting routine inspections is crucial. Check for wear and tear on key components and ensure that all parts are securely fastened. This proactive approach can prevent minor issues from escalating into major problems.

| Task | Frequency | Notes |

|---|---|---|

| Inspect air filter | Every 10 hours | Clean or replace as necessary |

| Check fuel system | Every 25 hours | Ensure no leaks are present |

| Sharpen cutting blades | Every 50 hours | Maintain sharpness for optimal cutting |

| Examine spark plug | Every 100 hours | Replace if worn or damaged |

Storage and Winterization

Proper storage techniques are essential for the longevity of your equipment. When not in use, ensure that the machine is stored in a dry and secure location. For winter storage, drain fuel to prevent gum formation and consider using a fuel stabilizer. Protecting your equipment from extreme temperatures and moisture will significantly enhance its lifespan.

Where to Purchase Genuine Parts

Finding authentic components for your equipment is crucial for ensuring optimal performance and longevity. Reliable sources offer a range of options to secure the necessary items that meet the manufacturer’s specifications.

Authorized Dealers: One of the best places to start is through certified distributors. They carry a comprehensive inventory and can provide expert advice on selecting the right pieces.

Official Online Stores: Many manufacturers operate official online platforms where you can browse and order components directly. This guarantees that what you receive is genuine and fits your machinery perfectly.

Local Repair Shops: Often, local service centers have access to original items and can help you obtain what you need. Additionally, they can offer installation services and maintenance tips.

Specialty Retailers: Some retailers specialize in specific types of equipment and often have a wide range of authentic components available for purchase. Researching reputable shops can lead you to quality options.

By exploring these avenues, you can ensure that you are equipping your machine with the best possible materials, ultimately enhancing its efficiency and durability.

Common Issues and Solutions

When operating powerful outdoor equipment, users may encounter various challenges that can impact performance. Understanding these common problems and their remedies can help ensure smooth operation and longevity of the machine. Below are some frequent issues along with practical solutions to address them effectively.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Engine won’t start | Empty fuel tank, faulty spark plug, or clogged air filter | Refill with fresh fuel, replace or clean the spark plug, and clean or replace the air filter. |

| Loss of power | Dirty fuel filter, dull cutting blade, or incorrect fuel mixture | Replace the fuel filter, sharpen or replace the cutting blade, and ensure the fuel mixture is correct. |

| Excessive vibration | Loose components, unbalanced cutting head, or worn-out bearings | Tighten all screws and bolts, balance the cutting head, and replace any worn-out bearings. |

| Overheating | Blocked cooling vents, low oil level, or prolonged use | Clean any debris from cooling vents, check and top up oil levels, and allow for breaks during operation. |

Upgrading Your BR800X Equipment

Enhancing your outdoor power tool can significantly boost its performance and efficiency. Whether you’re looking to improve functionality or simply update components for better reliability, there are several avenues to explore. Investing in quality upgrades not only extends the lifespan of your machine but also ensures that it meets your evolving needs.

Performance Enhancements

One of the most effective ways to enhance your equipment is by focusing on its performance. Consider upgrading the engine components to achieve better fuel efficiency and increased power output. Air filters and spark plugs are crucial elements that can impact overall efficiency. Regularly replacing these parts can lead to smoother operation and reduced emissions.

Comfort and Usability

Another aspect to consider is user comfort. Upgrading the handle grips or adding a shoulder strap can make prolonged use much more manageable. Additionally, implementing a more ergonomic design can help reduce fatigue during extended tasks, allowing you to work more effectively without compromising your physical well-being.