Complete Overview of Stihl FS 108 Parts Diagram

The proper maintenance of outdoor machinery is crucial for ensuring long-term performance and reliability. Knowing the specific structure and arrangement of each component helps in keeping the equipment in optimal working condition. Understanding how each element fits together and interacts can greatly simplify any necessary repairs or replacements.

In this section, we will explore the detailed configuration of essential components used in popular brush-cutting machines. By focusing on key elements, you’ll gain a clearer understanding of how the internal mechanisms operate and how to identify the right replacement parts when needed.

Whether you’re conducting routine maintenance or addressing a specific issue, having a clear understanding of the various sections of the equipment will empower you to make more informed decisions. This guide will provide you with all the necessary details to ensure your machine runs smoothly for years to come.

Understanding the Components of Stihl FS 108

In any advanced tool, each element plays a crucial role in ensuring proper functionality and efficiency. The same applies to this device, where every mechanical detail has been designed with precision to contribute to the overall performance. By examining its various elements, you can gain a deeper appreciation of how all the mechanisms work together to provide a smooth operational experience.

From the engine to the cutting attachment, each part is crafted to meet specific needs. The engine ensures powerful performance, while the handle and shaft provide stability and control. Additionally, the fuel system, air filters, and ignition elements ensure consistent operation. Recognizing the significance of each component can help in maintaining and optimizing the tool’s effectiveness.

Key Features of the Stihl FS 108

This versatile tool offers a combination of performance, durability, and ease of use, making it ideal for various outdoor tasks. Its design and engineering focus on user comfort, efficiency, and long-lasting operation, providing reliable performance in a range of environments.

- Powerful Engine: Equipped with a robust engine, this model ensures efficient cutting through dense vegetation and challenging terrains.

- Ergonomic Design: The lightweight build and comfortable grip allow for extended use without causing fatigue, enhancing the user experience during prolonged work sessions.

- Durable Construction: Built with high-quality materials, it withstands rough conditions, ensuring a long lifespan and consistent performance even in demanding situations.

- Efficient Fuel Consumption: Engineered for optimal fuel efficiency, it allows longer operation times while minimizing refueling needs, making it eco-friendly and cost-effective.

- Easy Maintenance: Designed with user-friendly components, routine maintenance is simple, ensuring that the tool remains in top condition with minimal effort.

- Versatile Cutting Options: Suitable for various cutting tasks, from trim

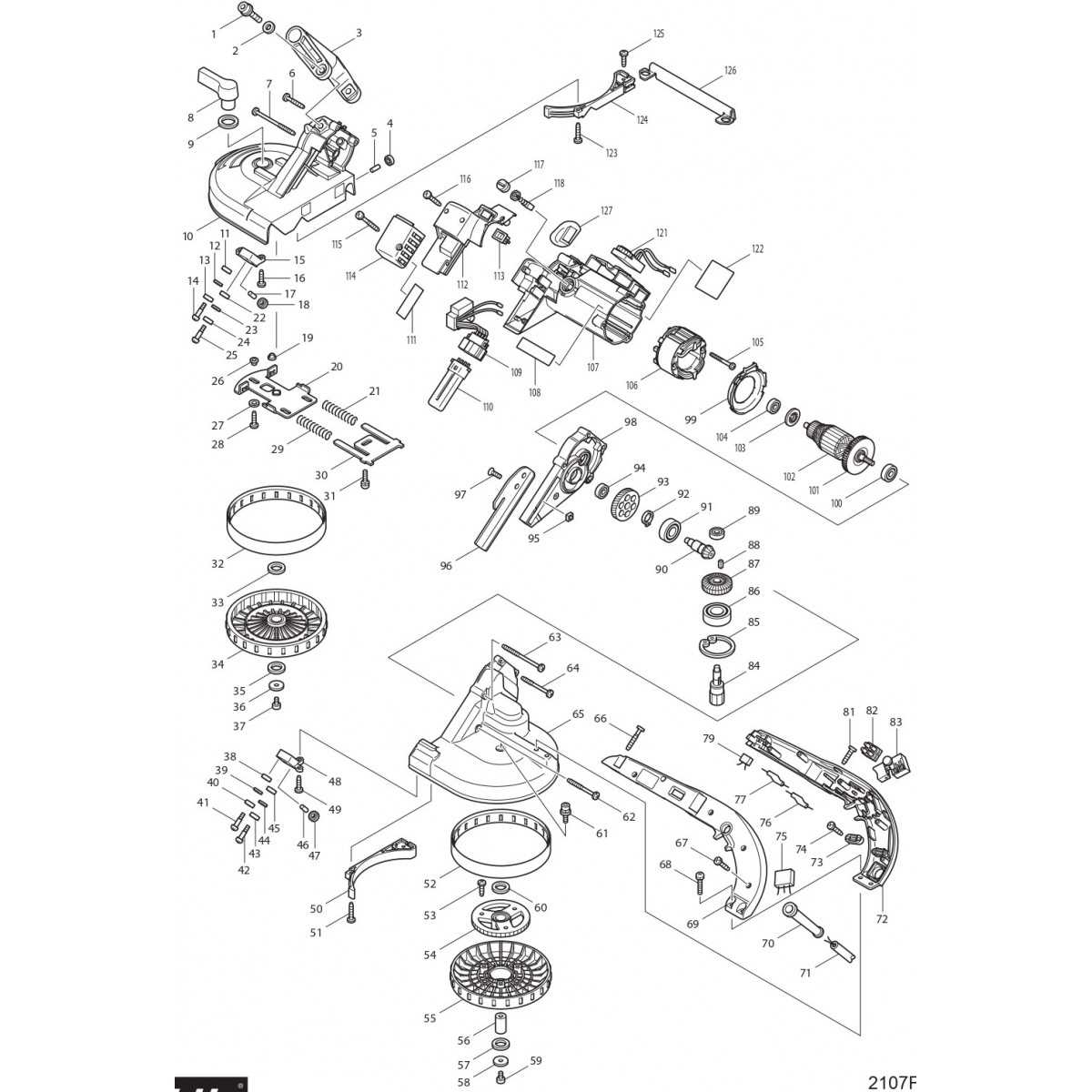

How to Identify Different Parts

Understanding how to recognize various components in any machinery is essential for both maintenance and repair. Each section of the equipment serves a distinct function, and identifying them correctly ensures smooth operation and easier troubleshooting.

Main Structural Elements

The primary frame holds the machine together and is often made from durable materials. Look for sturdy sections that provide support, especially near the engine. These sections are designed to endure pressure and often have distinct shapes, making them easier to distinguish from smaller, more intricate elements.

Functional Mechanisms

The operational components are responsible for performing the machine’s tasks. These include moving parts, often connected by fasteners or springs. Pay attention to their size and shape–they are typically smaller than structural elements and may be made of lighter materials, aiding in their functionality. Identifying these components is key to understanding how the device performs its duties.

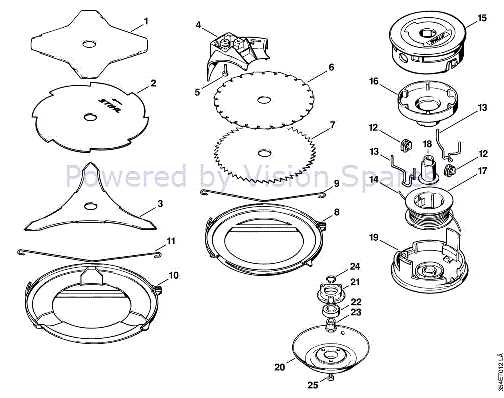

Exploring the Cutting Mechanism

The efficiency and performance of any grass trimmer depend significantly on the design and functionality of its cutting mechanism. Understanding how this system works can help users maintain and optimize the tool’s performance, ensuring a smooth and consistent cutting experience. In this section, we will look into the primary components and their interaction during operation.

Key Elements of the System

The core of the cutting mechanism includes several essential components working in unison. These parts are responsible for transferring power from the engine to the cutting blade or string, enabling effective trimming. Each element plays a crucial role in the tool’s overall efficiency and precision.

Operational Dynamics

As the engine powers the system, rotational energy is transferred through a series of linkages to the cutting implement. This motion allows the blade or string to rotate at high speeds, creating the necessary force to cut through grass, weeds, and other vegetation. Regular maintenance of these moving parts ensures

Maintenance Tips for Optimal Performance

Regular upkeep is essential to ensure the longevity and efficiency of your equipment. Proper care and timely inspections can help prevent issues before they arise, ensuring smooth operation in a variety of conditions. Implementing a consistent maintenance routine will not only extend the lifespan of the machine but also enhance its overall functionality.

Keep Components Clean

One of the simplest yet most effective ways to maintain peak performance is to keep critical components free from debris. Dirt and grime can hinder the operation of moving parts, causing wear over time. After each use, make it a habit to thoroughly clean the equipment, paying special attention to areas prone to buildup. This will help avoid potential damage and ensure smooth functionality.

Lubrication and Tightening

Proper lubrication is key to reducing friction and preventing premature wear on moving parts. Regularly apply the appropriate lubricants to all necessary areas, following the manufacturer’s recommendations. Additionally, inspect bolts and fasteners, ensuring they are securely tightened to avoid loosening during operation. Regular checks and adjustments will promote safe and efficient use.

Incorporating these simple maintenance practices will help ensure your

Common Wear and Tear Areas

Every mechanical device experiences certain components that are more susceptible to deterioration over time. Identifying these areas is essential for maintaining efficiency and prolonging the lifespan of the equipment. Regular inspections can help in recognizing these common issues before they lead to significant failures.

- Cutting Blades: The cutting edges often face significant wear due to contact with various surfaces. Regular sharpening or replacement is necessary to ensure optimal performance.

- Fuel Lines: Over time, fuel lines can become brittle or cracked, leading to leaks. Inspecting these lines periodically can prevent fuel wastage and potential hazards.

- Air Filter: Dust and debris can clog the air filter, affecting the engine’s air intake. Routine cleaning or replacement is crucial for maintaining engine efficiency.

- Drive Shaft: This component may experience wear due to the constant rotation and stress during operation. Regular lubrication and checks can extend its lifespan.

- Throttle Cable: Cables can stretch or fray, leading to a decrease in responsiveness. Monitoring the condition of the throttle cable ensures smooth operation.

By paying attention to these vulnerable components, users can take proactive measures to address wear and prolong the functionality of their equipment.

Blade and Guard Replacement Guide

Proper maintenance of cutting equipment is essential for optimal performance and safety. Replacing the blade and guard is a crucial part of this upkeep, ensuring that your device operates efficiently and reduces the risk of accidents. This guide will walk you through the necessary steps to successfully perform this replacement.

Step 1: Gather the Necessary Tools

Before you begin, ensure you have all required tools on hand, including a wrench, screwdriver, and safety gloves. Having these items ready will streamline the process and keep you protected throughout the procedure.

Step 2: Safety Precautions

Always prioritize safety by disconnecting the power source before starting any maintenance work. Wear appropriate protective gear, such as gloves and goggles, to safeguard against potential hazards during the replacement process.

Step 3: Remove the Existing Blade and Guard

Start by loosening the screws or bolts that secure the guard to the equipment. Carefully detach the guard and set it aside. Next, locate the blade attachment mechanism, typically secured with a nut or bolt. Use the wrench to loosen and remove the blade, taking care to note the orientation for the new blade installation.

Step 4: Install the New Blade and Guard

Align the new blade with the attachment mechanism, ensuring it is positioned correctly. Secure it tightly using the nut or bolt, ensuring there is no movement. Next, attach the guard by aligning it with the mounting points and fastening it securely with screws or bolts.

Step 5: Final Checks

Once the new components are in place, double-check that all attachments are secure. Reconnect the power source and test the equipment to ensure it operates smoothly and safely. Regular maintenance checks will help prolong the lifespan of your cutting tool.

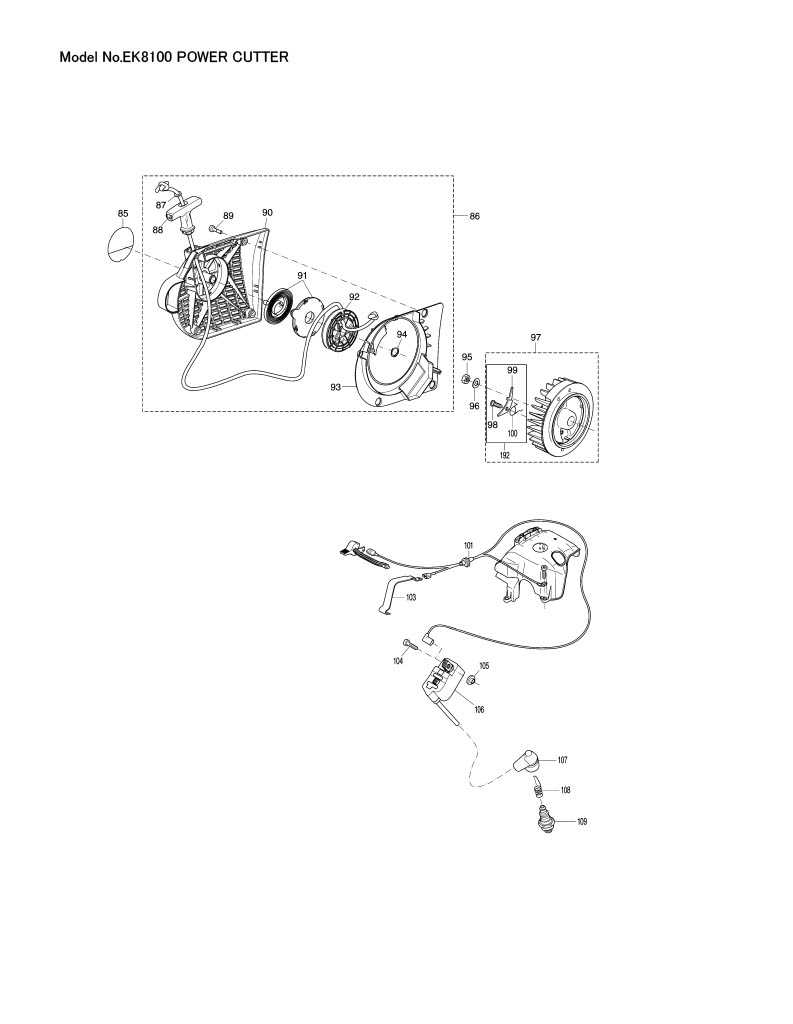

Fuel System Overview

The fuel system is a critical component of any outdoor power equipment, ensuring that the engine receives the proper mixture of fuel and air for efficient combustion. Understanding the various elements of this system is essential for maintaining optimal performance and longevity of the machine.

Key Components

- Fuel Tank: The storage container that holds the fuel, designed to provide a steady supply to the engine.

- Fuel Lines: Tubes that transport fuel from the tank to the engine, often made from durable materials to withstand various conditions.

- Carburetor: A device that mixes air and fuel in the correct ratio before it enters the combustion chamber, playing a crucial role in engine efficiency.

- Fuel Filter: A component that removes impurities from the fuel, preventing clogging and ensuring smooth operation.

- Purge Bulb: A manual pump that helps prime the fuel system, allowing for easier starting by removing air from the lines.

Maintenance Tips

- Regularly check and clean the fuel filter to ensure proper flow and performance.

- Inspect fuel lines for cracks or leaks, replacing them as necessary to prevent fuel loss.

- Use the recommended fuel type and avoid mixing with old or contaminated fuel.

- Clean the carburetor periodically to maintain optimal air-fuel mixture.

Troubleshooting Engine Issues

When experiencing difficulties with an engine, it is essential to systematically identify and resolve potential problems. This process involves understanding common symptoms, inspecting various components, and applying effective solutions to restore optimal functionality.

Common Symptoms

Engines may exhibit a range of issues, including poor performance, difficulty starting, or stalling during operation. Identifying the specific symptom can guide you toward the underlying cause. For instance, if the unit struggles to start, it may indicate fuel delivery problems or ignition system failures.

Inspection and Solutions

Begin by checking the fuel system for blockages or contamination. Ensure the fuel filter is clean and the fuel lines are free from leaks. Additionally, inspect the spark plug for wear and replace it if necessary. If the engine still fails to perform, examine the air intake for obstructions. A clean air filter is crucial for efficient combustion.

Implementing these troubleshooting techniques can significantly enhance the performance and reliability of your engine.

Proper Handlebar Adjustments for Comfort

Ensuring a comfortable grip and optimal control during operation is crucial for an enjoyable experience. Proper handlebar modifications can significantly reduce fatigue and enhance performance, allowing for longer periods of use without discomfort.

Understanding Handlebar Height

Adjusting the height of the handlebars is vital for achieving the right posture. Here are some key considerations:

- Handlebars should be positioned at a height that allows the operator to maintain a relaxed grip.

- Ensure that the elbows are slightly bent to prevent strain on the arms and shoulders.

- Consider your height and reach when adjusting, aiming for a natural stance while standing or walking.

Angle Adjustments for Enhanced Comfort

The angle of the handlebars can also impact your comfort level. Here are some tips for optimal adjustment:

- Experiment with different angles to find the one that feels most comfortable during operation.

- Ensure that the angle allows for a straight wrist position to avoid strain.

- Check the grip’s alignment with your hands; a natural position will improve control and reduce fatigue.

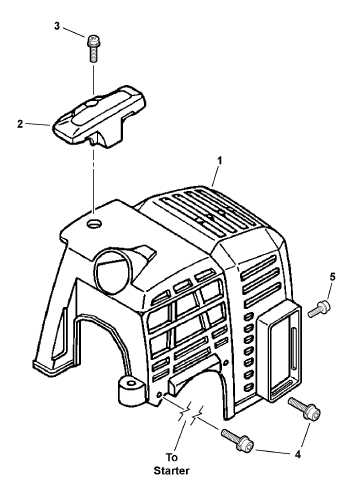

Assembly Instructions for Stihl FS 108

Proper assembly of the trimmer is crucial for optimal performance and safety. This section provides a comprehensive guide to the assembly process, ensuring that all components are correctly installed and securely fastened. Following these instructions will help maintain the equipment’s efficiency and longevity.

Preparation Steps

Before beginning the assembly, gather all necessary tools and components. Ensure that the work area is clean and well-lit to facilitate an efficient assembly process. Verify that all parts are included and undamaged, as any imperfections can affect functionality.

Assembly Procedure

Start by connecting the handlebar to the main shaft, ensuring it is positioned at a comfortable angle for operation. Secure it tightly using the provided screws. Next, attach the cutting head by aligning it with the drive shaft and twisting it until it locks into place. Double-check all connections and ensure that there are no loose components. Finally, perform a visual inspection to confirm that everything is assembled correctly.

Following these guidelines will help achieve a safe and effective assembly, allowing for seamless operation of your trimming equipment.