Understanding the Parts Diagram of Stihl FS 250

When it comes to maintaining your outdoor machinery, having a clear visual representation of its components is essential. Such illustrations not only aid in identification but also enhance your ability to perform repairs efficiently. With the right guide, you can navigate through the intricate assembly of your tools with confidence.

Knowledge of the various elements within your equipment allows for better upkeep and troubleshooting. Whether you’re a seasoned professional or a weekend warrior, understanding how each part contributes to overall functionality is crucial. An organized visual can serve as the ultimate resource for your maintenance needs.

Moreover, access to comprehensive schematics can simplify the process of sourcing replacements or upgrades. By delving into the specifics of each component, you empower yourself to make informed decisions, ensuring your machinery operates at peak performance. Embrace the journey of exploration and mastery of your outdoor tools!

Understanding the Stihl FS 250

This section explores the essential components and functionalities of a popular outdoor power tool designed for efficient grass and weed management. By examining its key features and specifications, users can gain insight into its operation and maintenance requirements.

Key Features

Among the notable characteristics are its robust engine, user-friendly design, and various attachments. These elements contribute to its versatility and effectiveness in different landscaping tasks.

Maintenance Overview

Proper upkeep is vital for optimal performance. Regular inspections and timely replacements of specific components ensure longevity and reliability.

| Component | Function |

|---|---|

| Engine | Powers the machine for cutting and trimming |

| Cutting Head | Handles various vegetation types |

| Handle Grip | Provides control and comfort during operation |

Key Features of Stihl FS 250

This versatile outdoor power tool is designed for efficiency and durability, making it an ideal choice for both professional landscapers and homeowners. Its robust construction ensures longevity while providing the necessary power to tackle various cutting tasks.

One of the standout characteristics is its lightweight design, which enhances maneuverability and reduces user fatigue during extended operation. The ergonomic handle contributes to comfortable handling, allowing for precise control in tight spaces.

Moreover, the high-performance engine delivers impressive torque, enabling swift and effective cutting through thick vegetation. With adjustable cutting heads, users can easily switch between different tasks, enhancing the tool’s versatility.

Additionally, advanced vibration dampening technology minimizes discomfort, making it suitable for prolonged use without compromising user experience. Coupled with easy-start features, this tool is designed to streamline your outdoor maintenance efforts.

In summary, this equipment stands out for its balance of power, comfort, and adaptability, making it a reliable choice for various gardening and landscaping needs.

Importance of Parts Diagrams

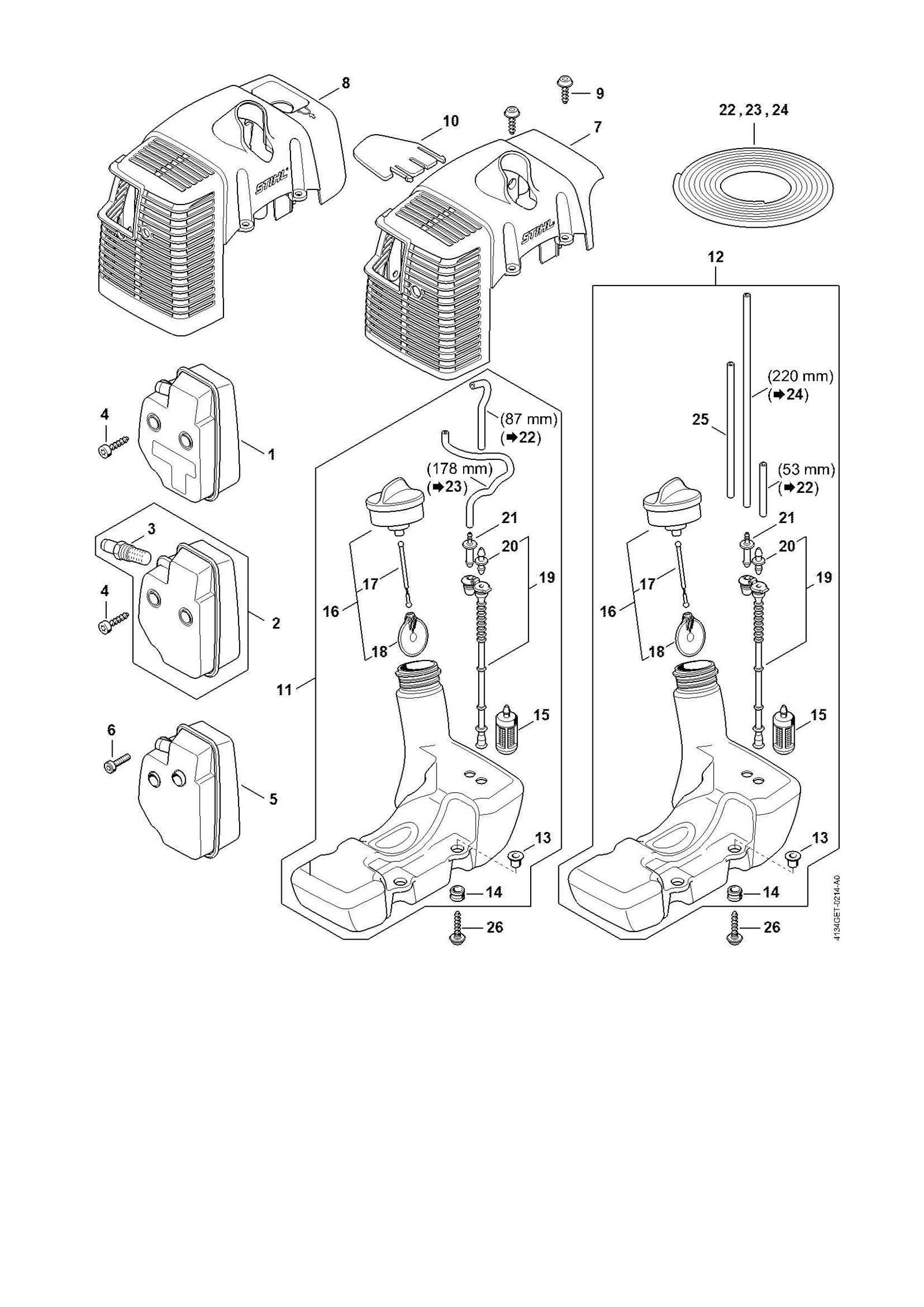

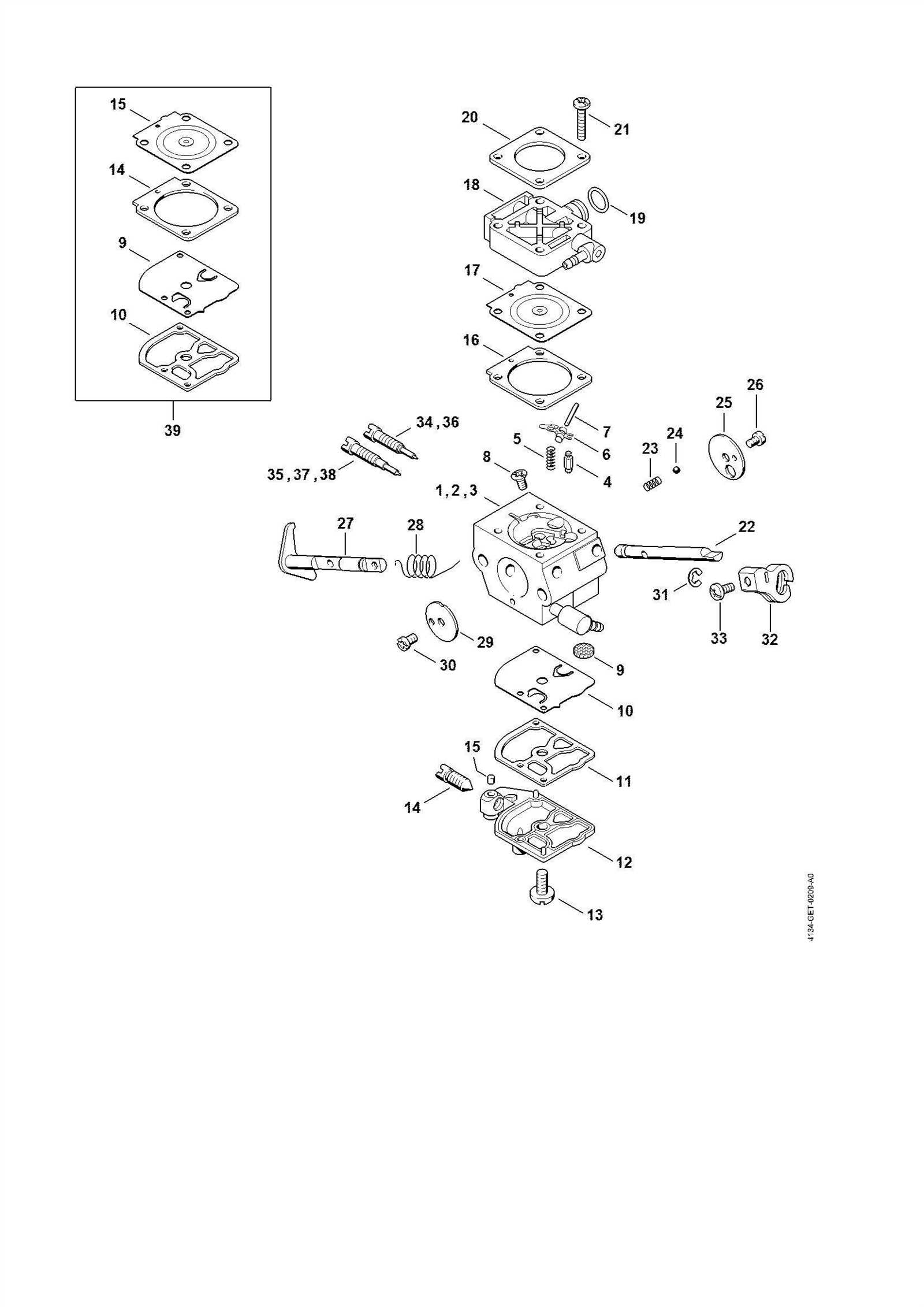

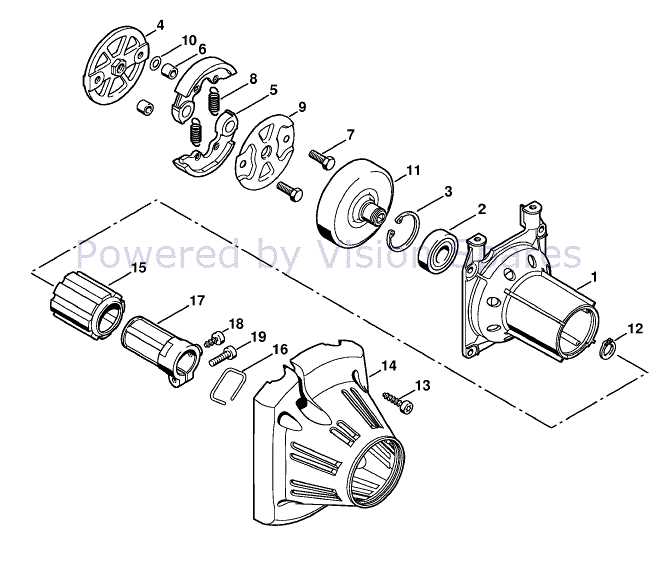

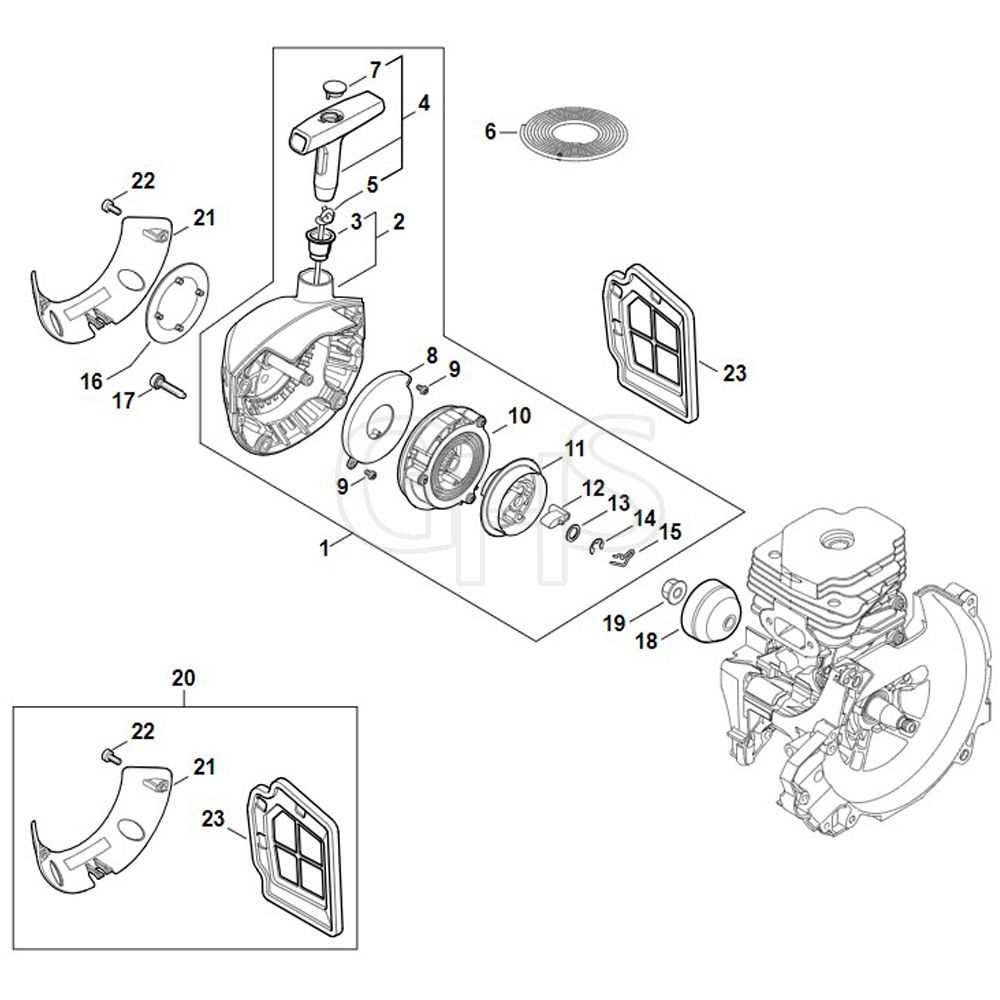

Visual representations of components play a crucial role in maintenance and repair tasks. They provide a clear overview of how individual elements interact within a machine, facilitating efficient troubleshooting and assembly. By illustrating the relationships between various parts, these resources empower users to identify issues and understand the overall structure of the equipment.

Enhanced Understanding

Having a visual guide significantly improves comprehension. Users can quickly grasp the layout and function of each segment, making it easier to locate and address specific concerns. This understanding reduces the time spent on repairs and enhances overall productivity.

Streamlined Maintenance

Utilizing visual aids during upkeep simplifies the process. By clearly indicating where components are located and how they fit together, users can execute tasks with precision and confidence. This not only ensures proper functioning but also prolongs the lifespan of the machinery.

| Benefit | Description |

|---|---|

| Clarity | Visual aids provide a straightforward view of component arrangement. |

| Efficiency | Faster identification of parts leads to quicker repairs. |

| Confidence | Users feel more assured in performing maintenance tasks. |

Common Parts for Stihl FS 250

In the realm of outdoor power equipment, understanding the essential components is crucial for maintenance and efficient operation. Each unit comprises various elements that contribute to its functionality and durability. Familiarity with these components ensures that users can effectively address any issues that may arise during use.

Engine: The heart of the machine, this unit provides the necessary power for operation. Its performance directly impacts the effectiveness of the equipment in various tasks.

Fuel Tank: This container holds the energy source, ensuring that the engine receives the required fuel for operation. Proper maintenance of this part is vital to prevent leaks and ensure optimal performance.

Cutting Head: A crucial element for trimming and clearing vegetation, this component varies in design depending on the intended use. Regular inspection and replacement of cutting tools are important for maintaining efficiency.

Throttle Trigger: This mechanism allows the user to control the engine speed, offering precision in operation. A malfunctioning trigger can affect the overall performance and safety of the device.

Air Filter: Essential for maintaining engine health, this filter prevents debris from entering the engine. Regular cleaning and replacement can extend the life of the machine significantly.

Spark Plug: This small yet vital component ignites the fuel-air mixture within the engine, playing a key role in its operation. Routine checks can help in ensuring reliable starts and efficient functioning.

Understanding these key components allows users to maintain their equipment effectively, ensuring longevity and reliable performance during use. Proper care and timely replacements can make a significant difference in overall operation.

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair of any machinery. These visual guides provide a clear layout of individual elements and their relationships, making it easier to identify, source, and replace necessary items. Familiarizing yourself with this format can greatly enhance your ability to work on equipment efficiently.

When approaching a schematic, pay attention to the following key features:

| Feature | Description |

|---|---|

| Labels | Each component is typically labeled with a reference number or code, helping you locate the exact item in the accompanying list. |

| Connections | Lines or arrows often indicate how parts are connected or interact with one another, giving insight into assembly and functionality. |

| Views | Diagrams may show multiple perspectives of components, such as front, side, and top views, allowing for a comprehensive understanding of size and placement. |

| Key/Legend | A legend may be included to explain symbols or colors used, providing additional context for interpreting the illustration accurately. |

By grasping these aspects, you’ll be better equipped to navigate the complexities of any machinery and ensure successful repairs or upgrades. Taking the time to analyze these visuals can lead to greater efficiency and a deeper understanding of how your equipment operates.

Maintenance Tips for FS 250

Proper upkeep of your outdoor power equipment ensures longevity and optimal performance. Regular maintenance not only enhances efficiency but also minimizes the risk of unexpected failures.

- Clean the Equipment: After each use, remove debris and grass clippings to prevent buildup.

- Inspect the Cutting Head: Regularly check for wear and replace any damaged components promptly.

- Check Fuel System: Ensure the fuel is fresh and inspect hoses for leaks or cracks.

- Sharpen Blades: Keeping blades sharp improves cutting performance and reduces strain on the engine.

- Change Air Filter: A clean air filter is crucial for proper airflow and engine efficiency.

- Regular Oil Changes: Follow the manufacturer’s recommendations for oil changes to keep the engine running smoothly.

By incorporating these practices into your routine, you can significantly extend the life of your equipment and ensure it operates at its ultimate capability.

Where to Find Replacement Parts

Locating suitable components for your equipment can be a straightforward task if you know where to look. Numerous sources provide access to high-quality replacements, ensuring your tools remain in optimal condition for use. Below are some common options you might consider when searching for these essential items.

| Source | Description |

|---|---|

| Authorized Dealers | Official retailers often carry a comprehensive selection of components tailored for specific models. |

| Online Retailers | Numerous e-commerce platforms offer a wide variety of options, making it easy to compare prices and availability. |

| Local Hardware Stores | Many neighborhood shops may stock essential items or can order them for you upon request. |

| Salvage Yards | Used components can be a cost-effective solution, often found in good condition. |

Identifying Compatible Accessories

When selecting additional components for your equipment, it’s essential to ensure they align seamlessly with your machine’s specifications and performance requirements. Understanding the unique features and compatibility criteria will enhance your operational efficiency and prolong the lifespan of your tools.

Begin by consulting the manufacturer’s guidelines to identify recommended attachments that meet the standards for your model. Pay attention to aspects such as size, functionality, and intended use. This diligence will not only facilitate optimal performance but also prevent potential damage or malfunctions.

Moreover, consider exploring aftermarket options, ensuring they are designed to fit your model accurately. Reading reviews and seeking advice from experienced users can provide valuable insights into the reliability and effectiveness of these alternatives.

Ultimately, investing time in researching compatible accessories will empower you to make informed decisions, leading to a more effective and satisfying experience with your equipment.

Common Repairs for FS 250 Models

Regular maintenance and timely repairs are essential for ensuring the longevity and efficiency of outdoor power equipment. Understanding common issues that may arise can help operators address problems swiftly and keep their machines in top working condition. This section outlines frequent repairs that users may encounter, along with tips for handling these tasks effectively.

Frequent Issues and Solutions

Here are some of the most typical problems and their respective solutions:

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Engine Won’t Start | Failure to ignite or unusual noises | Check fuel level, inspect spark plug, and clean air filter |

| Excessive Vibration | Shaking during operation | Inspect cutting head for damage and ensure proper assembly |

| Overheating | Machine becomes too hot | Clean cooling fins and check fuel mixture |

| Fuel Leaks | Visible liquid near the engine | Inspect hoses and gaskets for cracks or damage |

Maintenance Tips

Regular inspections and maintenance practices can significantly reduce the likelihood of encountering issues. Make it a habit to clean filters, check the fuel system, and inspect the cutting components regularly. Proper storage during off-seasons can also prolong the life of the equipment.

Benefits of Genuine Stihl Parts

Utilizing authentic components for your outdoor equipment ensures optimal performance and longevity. These elements are specifically designed to work in harmony with the machinery, providing numerous advantages.

- Quality Assurance: Genuine components undergo rigorous testing to meet high standards.

- Enhanced Performance: Original parts contribute to superior functionality and efficiency.

- Durability: Authentic materials are crafted to withstand demanding conditions, reducing wear and tear.

- Warranty Protection: Using genuine elements often maintains warranty coverage, safeguarding your investment.

- Compatibility: Original parts are guaranteed to fit perfectly, preventing operational issues.

Investing in genuine components ultimately leads to better maintenance and a more reliable experience with your equipment.