Comprehensive Guide to Stihl FS 55 Parts Diagram

When it comes to maintaining your outdoor machinery, having a clear understanding of its various elements is essential. Each component plays a crucial role in ensuring optimal performance, longevity, and efficiency. By familiarizing yourself with the inner workings of your device, you can address issues effectively and enhance your overall experience.

In this section, we will explore the intricate layout of the essential parts that contribute to your equipment’s functionality. Knowing how these elements interact allows you to identify potential problems and perform necessary repairs or upgrades with confidence.

Moreover, this knowledge not only empowers you as a user but also helps in making informed decisions when sourcing replacements or upgrades. A comprehensive grasp of the mechanical architecture ultimately leads to better maintenance practices and improved operational effectiveness.

Overview of Stihl FS 55 Parts

This section provides a comprehensive look at the components that make up a well-known cutting tool model. Understanding the various elements involved is essential for effective maintenance and repair, ensuring optimal performance during operation. Each segment plays a vital role in the overall functionality, contributing to the durability and efficiency of the equipment.

Key Components

- Engine Assembly

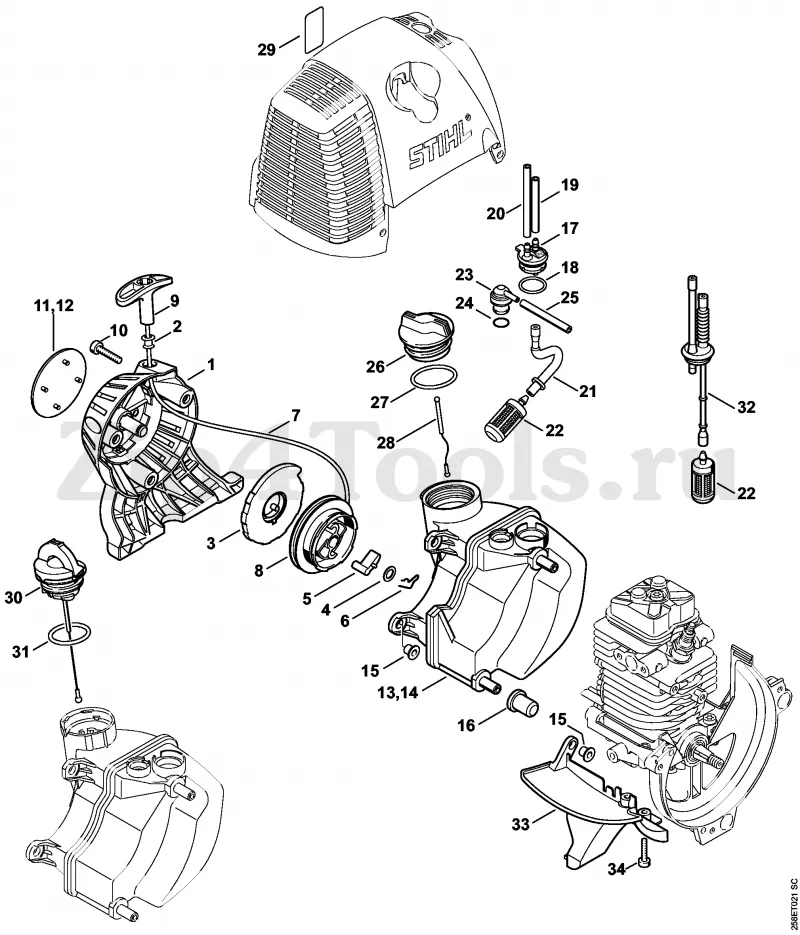

- Fuel System

- Cutter Head

- Handle and Shaft

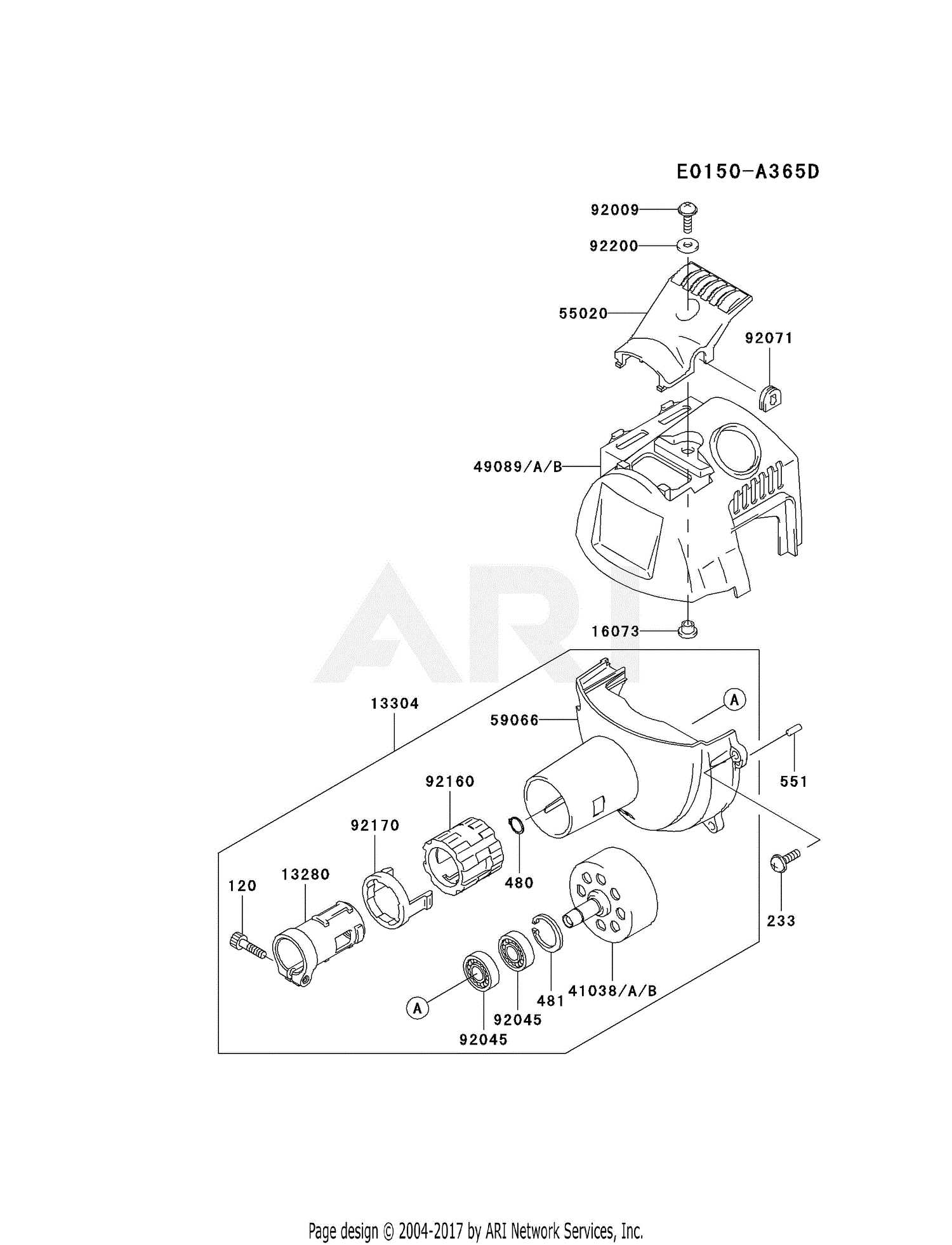

- Starter Mechanism

Importance of Regular Maintenance

Regular upkeep of these components not only prolongs the lifespan of the tool but also enhances safety during use. A well-maintained cutting device ensures reliable performance and minimizes the risk of malfunctions.

- Inspect the engine regularly for signs of wear.

- Check the fuel system for leaks or blockages.

- Ensure the cutter head is sharp and properly attached.

- Examine the handle and shaft for any damage.

- Test the starter mechanism for smooth operation.

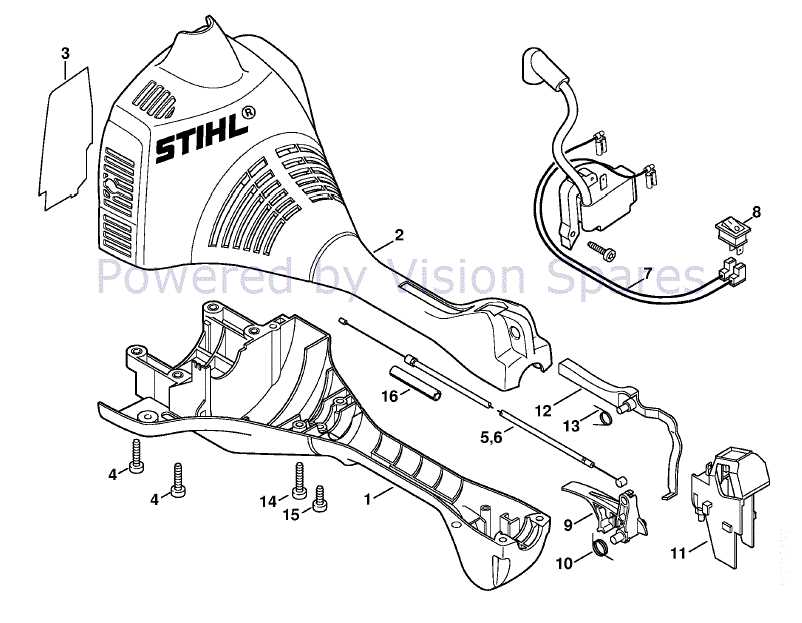

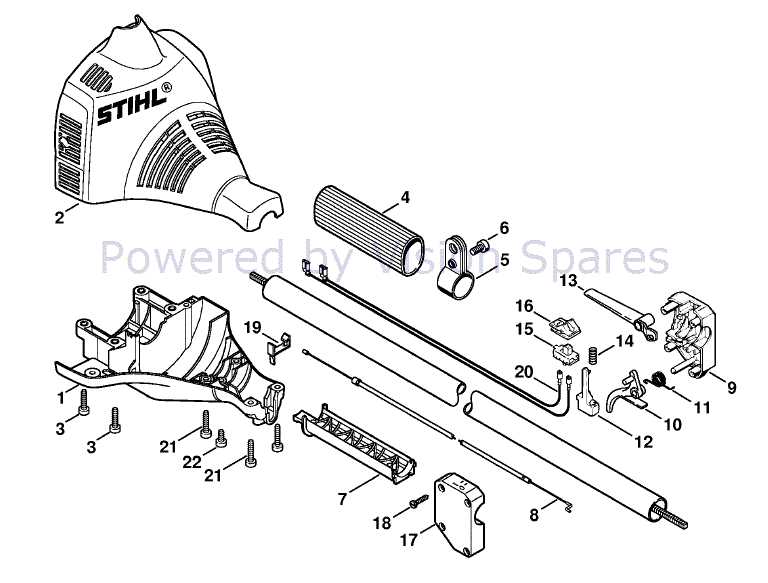

Understanding the Parts Diagram

Grasping the intricacies of a component layout is essential for effective maintenance and repair. A well-structured visual representation aids in identifying various elements, ensuring that each piece is recognized and properly managed.

| Component | Description |

|---|---|

| Handle | The part that provides control and maneuverability. |

| Blade | The cutting instrument designed for efficiency. |

| Fuel Tank | Holds the necessary energy source for operation. |

| Air Filter | Ensures clean air enters the engine for optimal performance. |

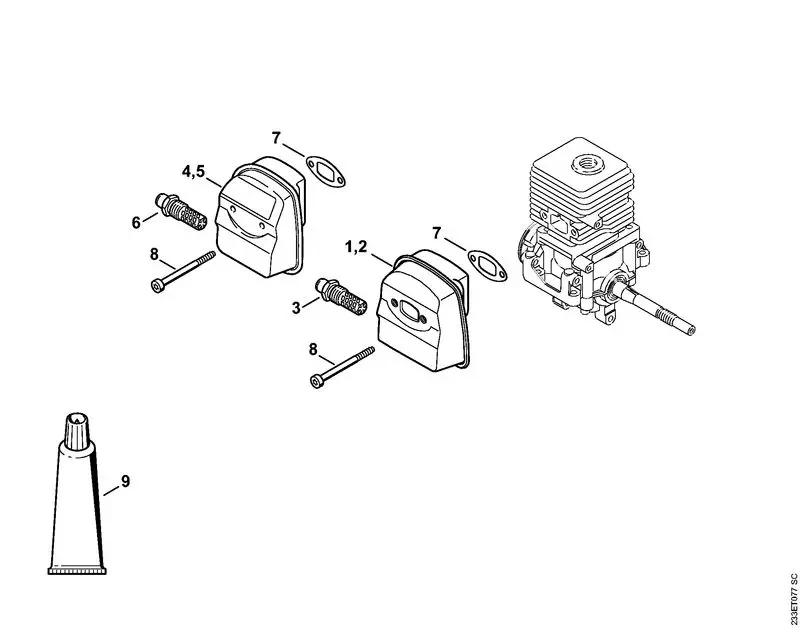

Key Components of the FS 55

The efficiency and functionality of the FS 55 depend on several essential elements that work harmoniously together. Each component plays a vital role in ensuring the device operates at peak performance, making it crucial to understand their individual contributions.

One of the primary elements is the engine, which provides the necessary power for operation. Additionally, the cutting head is designed to deliver precision and effectiveness in trimming tasks. The fuel system ensures optimal combustion, while the ignition system is responsible for reliable starting and consistent operation.

Moreover, the shaft serves as the backbone, connecting the engine to the cutting head, enhancing maneuverability. The handle provides comfort and control, allowing the user to navigate various terrains easily. Lastly, the protective guard is vital for safety, ensuring the operator is shielded from debris during use.

How to Read the Diagram

Understanding technical illustrations is crucial for effective maintenance and repair. These visuals serve as a guide, helping you identify components and their relationships within the machinery. Familiarizing yourself with the layout will enhance your ability to troubleshoot and replace necessary elements efficiently.

| Symbol | Description |

|---|---|

| Tool required for assembly or disassembly | |

| Fasteners needed for securing parts | |

| ⚙️ | Moving components that interact during operation |

| ️ | Maintenance tasks indicated for each component |

By decoding these symbols and their meanings, you can gain a clearer understanding of how each section fits into the whole. This knowledge is vital for achieving the ultimate performance of your equipment.

Common Replacement Parts Explained

When maintaining outdoor power equipment, understanding the various components that may require periodic substitution is essential. This knowledge can help ensure optimal performance and longevity of the machine. Below, we delve into several frequently replaced elements and their functions, providing clarity on their importance in the overall operation.

Key Components and Their Functions

Each part plays a crucial role in the efficiency of your equipment. Here’s a breakdown of the most common elements that may need to be replaced over time:

| Component | Description | Function |

|---|---|---|

| Cutting Head | Assembly that holds the cutting line or blades. | Responsible for trimming grass and vegetation effectively. |

| Fuel Filter | Device that removes impurities from fuel. | Ensures clean fuel reaches the engine, improving performance. |

| Air Filter | Filter that cleans the air entering the engine. | Prevents dust and debris from damaging internal components. |

| Spark Plug | Electrode that ignites the fuel-air mixture. | Essential for starting and running the engine smoothly. |

Importance of Regular Maintenance

Regular checks and timely replacements of these components can prevent larger issues and enhance the performance of your outdoor equipment. Understanding how each element contributes to the overall function is vital for maintaining efficiency and reliability.

Maintenance Tips for FS 55

Proper upkeep is essential for ensuring the longevity and optimal performance of your equipment. Regular maintenance not only enhances efficiency but also prevents unexpected breakdowns, ultimately saving time and money. Following a few simple practices can keep your machine running smoothly and effectively.

First, always check the air filter regularly. A clean filter allows for better airflow, which is crucial for engine performance. If the filter appears dirty, clean or replace it as necessary to maintain proper function.

Next, pay attention to the cutting line. Ensure it is replaced when worn out to achieve the best cutting results. Regularly inspecting the line can help prevent tangling and ensure a clean cut during operation.

Additionally, lubricating moving parts is vital. Use the appropriate oil to reduce friction and wear, which can extend the lifespan of your equipment. Make it a habit to check lubrication levels frequently.

Lastly, store your equipment in a dry, protected environment to prevent rust and damage from the elements. Proper storage conditions will help maintain the integrity of all components and ensure readiness for future use.

Identifying Worn-Out Components

Recognizing when equipment components have deteriorated is essential for maintaining optimal performance. By understanding the signs of wear, users can prolong the lifespan of their tools and ensure efficiency during operation.

Common Indicators of Wear

- Visible Damage: Look for cracks, fraying, or deformation.

- Reduced Performance: Noticeable drops in power or speed.

- Unusual Noises: Sounds that differ from normal operation can indicate issues.

- Difficulty in Operation: Struggles in starting or handling may suggest wear.

Steps for Assessment

- Conduct a visual inspection of all accessible parts.

- Test the functionality under typical conditions.

- Compare performance with previous benchmarks.

- Consult user manuals for specific maintenance recommendations.

Ordering Parts for Your Trimmer

When maintaining your trimming tool, securing the right components is crucial for optimal performance. Understanding how to efficiently procure these items ensures that your equipment remains in excellent working condition, ready for any task.

Identify Your Needs: Before placing an order, take a moment to assess what is necessary for your machine. This may include wear items, such as blades or filters, which require regular replacement.

Research Sources: Explore various suppliers, both online and local, to find reputable vendors. Compare prices and check reviews to ensure you are dealing with trustworthy sources.

Verify Compatibility: Always confirm that the components you select are compatible with your specific model. Consult the manufacturer’s resources or expert guides for assistance in this area.

Place Your Order: Once you have gathered all necessary information, proceed to order the components. Ensure you double-check quantities and shipping details to avoid delays.

By following these steps, you can effectively manage the procurement of essential items for your trimming tool, enhancing its longevity and performance.

DIY Repair: Tools Needed

When undertaking repairs on outdoor power equipment, having the right tools at your disposal is essential for a successful outcome. Whether you’re fixing a trimmer or any similar machine, the correct instruments not only make the job easier but also ensure safety and precision.

Here’s a list of essential tools that will assist you in your repair tasks:

- Screwdrivers: Both flathead and Phillips screwdrivers are vital for removing and securing screws.

- Wrenches: A set of adjustable wrenches will help you tackle various nut and bolt sizes.

- Socket Set: This is useful for loosening and tightening fasteners in hard-to-reach areas.

- Pliers: Needle-nose and regular pliers can help with gripping and bending tasks.

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications.

- Fuel Mixing Bottle: If applicable, this is crucial for preparing the right fuel mixture.

- Protective Gear: Safety goggles and gloves are important to protect yourself during repairs.

Having these tools on hand will streamline the repair process and enhance your efficiency, allowing you to restore your equipment to optimal working condition with confidence.

Safety Precautions During Repairs

When undertaking maintenance tasks, ensuring safety is paramount. Various hazards may arise, necessitating awareness and adherence to proper procedures. By following essential guidelines, you can create a secure environment for both yourself and your equipment.

Essential Guidelines

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use gloves, goggles, and sturdy footwear to minimize injury risk. |

| Disconnect Power Source | Before starting repairs, ensure the device is unplugged or powered off. |

| Work in a Ventilated Area | Maintain airflow to avoid inhaling harmful fumes during maintenance. |

| Use Proper Tools | Utilize the correct tools to prevent accidents and ensure effective repairs. |

Emergency Preparedness

Being ready for unexpected situations is crucial. Have a first aid kit accessible and familiarize yourself with emergency contact numbers. This preparation can make a significant difference in critical moments.

Expert Recommendations for Efficiency

To achieve optimal performance and longevity in outdoor power equipment, it is essential to follow expert advice that enhances efficiency. Whether you are a professional landscaper or a gardening enthusiast, understanding the nuances of maintenance and operation can make a significant difference in your experience.

Regular Maintenance: Adopting a consistent maintenance schedule is crucial. This includes cleaning, lubricating moving parts, and inspecting components for wear and tear. Regular upkeep not only extends the lifespan of the equipment but also ensures that it operates at peak efficiency.

Using Quality Fuel: The type of fuel used can greatly affect performance. Always opt for high-quality fuel that meets the manufacturer’s specifications. This helps prevent engine issues and promotes smoother operation, leading to better results during use.

Correct Usage Techniques: Mastering the proper techniques for operating your equipment can enhance both safety and efficiency. Familiarize yourself with the user manual and practice recommended methods for handling and maneuvering the tool effectively.

Proper Storage: Storing equipment correctly during off-seasons is vital. Ensure that machines are clean and dry before storage, and consider using protective covers. This prevents rust and damage, keeping the equipment in prime condition for future use.

By implementing these expert recommendations, users can significantly improve the performance and durability of their outdoor tools, leading to a more enjoyable and efficient gardening or landscaping experience.

Where to Find Additional Resources

Exploring reliable sources for supplementary materials can enhance your understanding and maintenance capabilities. Whether you are seeking guides, tutorials, or community support, numerous avenues exist to assist you in your endeavors.

Online Platforms

- Official Manufacturer Websites

- User Forums and Community Groups

- Video Tutorials on Platforms like YouTube

Printed Materials

- Owner’s Manuals

- Maintenance Guides

- Technical Reference Books