Comprehensive Guide to Stihl FS 70 R Parts Diagram

The efficient operation of your garden tool relies on the intricate interplay of its various elements. Each component serves a vital role, contributing to the overall functionality and performance. Grasping the arrangement and significance of these parts can enhance maintenance and repair tasks, ensuring longevity and reliability.

To truly maximize your equipment’s potential, it’s essential to familiarize yourself with its structure. By exploring the various sections, you can identify wear and tear or potential upgrades. This knowledge ultimately empowers you to maintain your tool effectively, preventing unexpected downtime.

In this guide, we will explore the essential elements of your trimmer, offering insights into their arrangement and purpose. Whether you’re a seasoned user or a newcomer, understanding these components will be key to achieving optimal results in your gardening endeavors.

Understanding Stihl FS 70 R

This section aims to provide a comprehensive overview of a popular model of outdoor power equipment, highlighting its key features and functionality. The tool is designed for efficiency and ease of use, making it suitable for various landscaping tasks.

Key Features

- Lightweight and portable design for easy maneuverability.

- Powerful engine ensuring high performance.

- Adjustable handle for user comfort.

- Versatile attachments for different tasks.

Benefits of Use

- Enhances productivity in yard maintenance.

- Reduces user fatigue with ergonomic design.

- Reliable operation with minimal maintenance requirements.

- Adaptable to various terrains and vegetation types.

Understanding the features and benefits of this equipment can significantly improve your experience and efficiency in outdoor tasks.

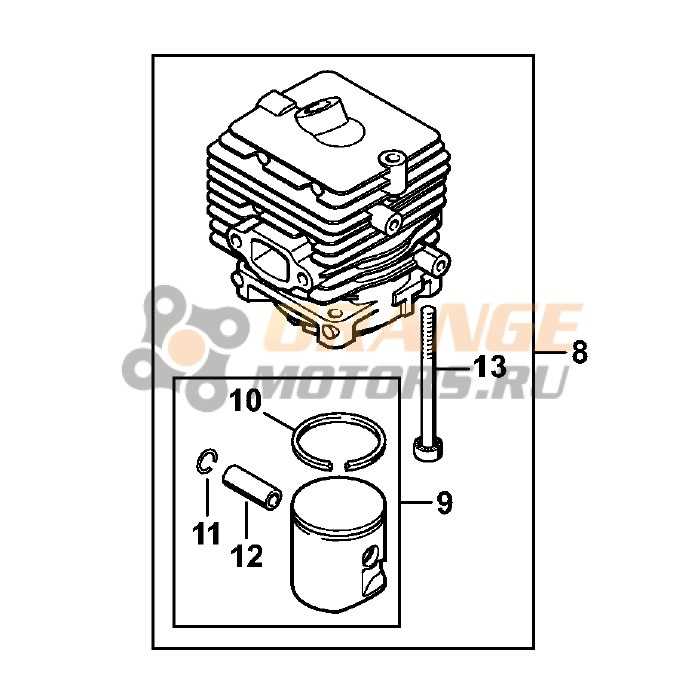

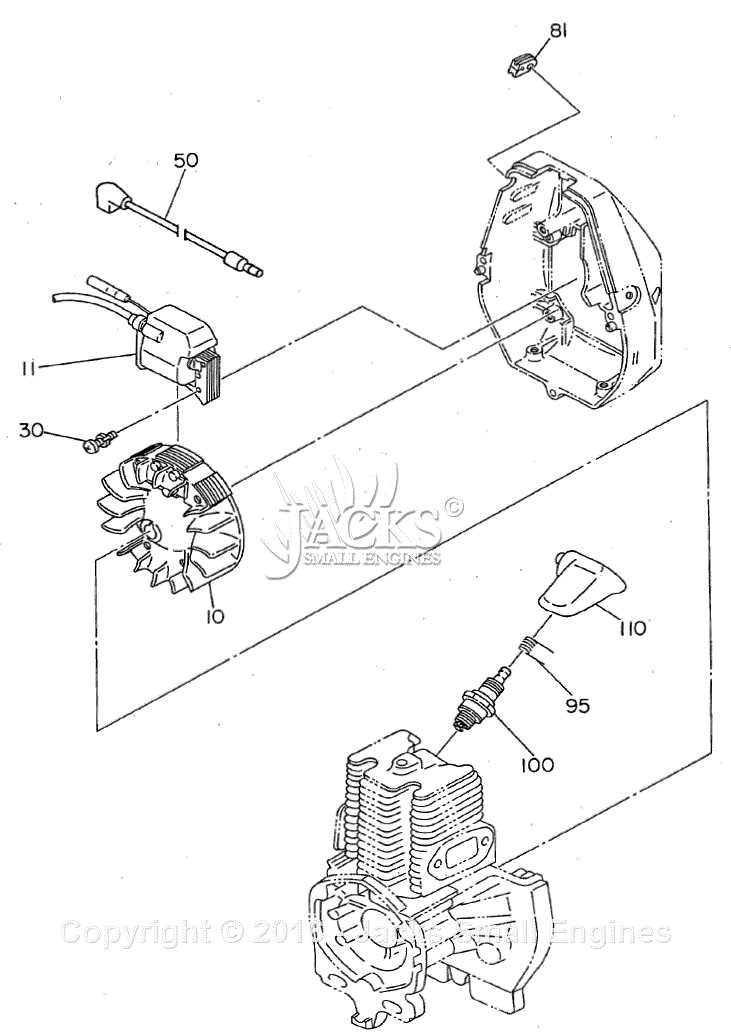

Key Components of the FS 70 R

This section focuses on the essential elements that contribute to the functionality and performance of the FS 70 R model. Understanding these components can enhance maintenance practices and overall user experience.

Major Elements

| Component | Description |

|---|---|

| Engine | Powers the device, providing necessary torque and speed for efficient operation. |

| Cutting Head | Designed to hold various cutting tools, facilitating different applications. |

| Fuel Tank | Holds the fuel needed to operate the engine, influencing runtime. |

Additional Features

Beyond the major elements, other features like the handle design and safety mechanisms also play a crucial role in user comfort and operational safety.

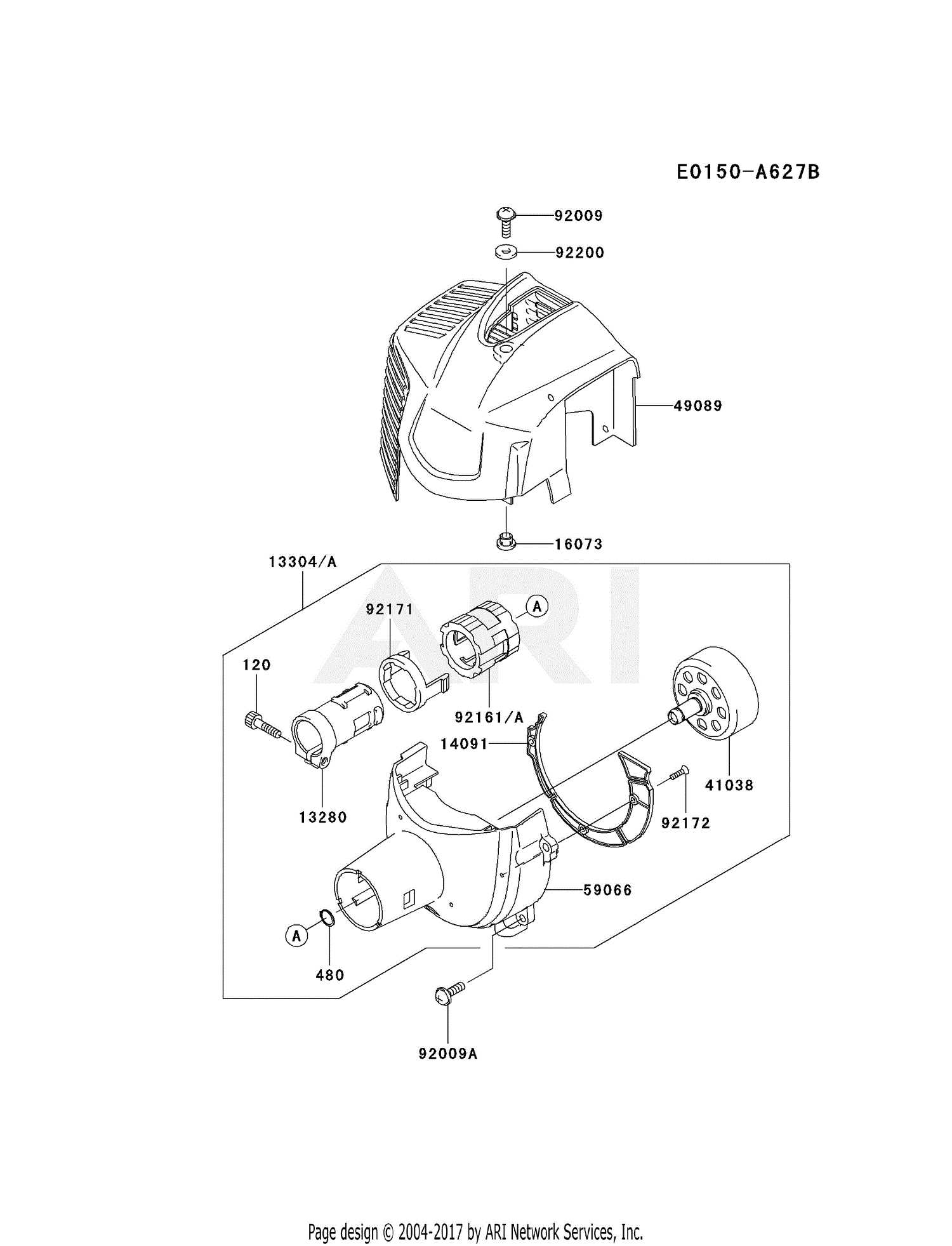

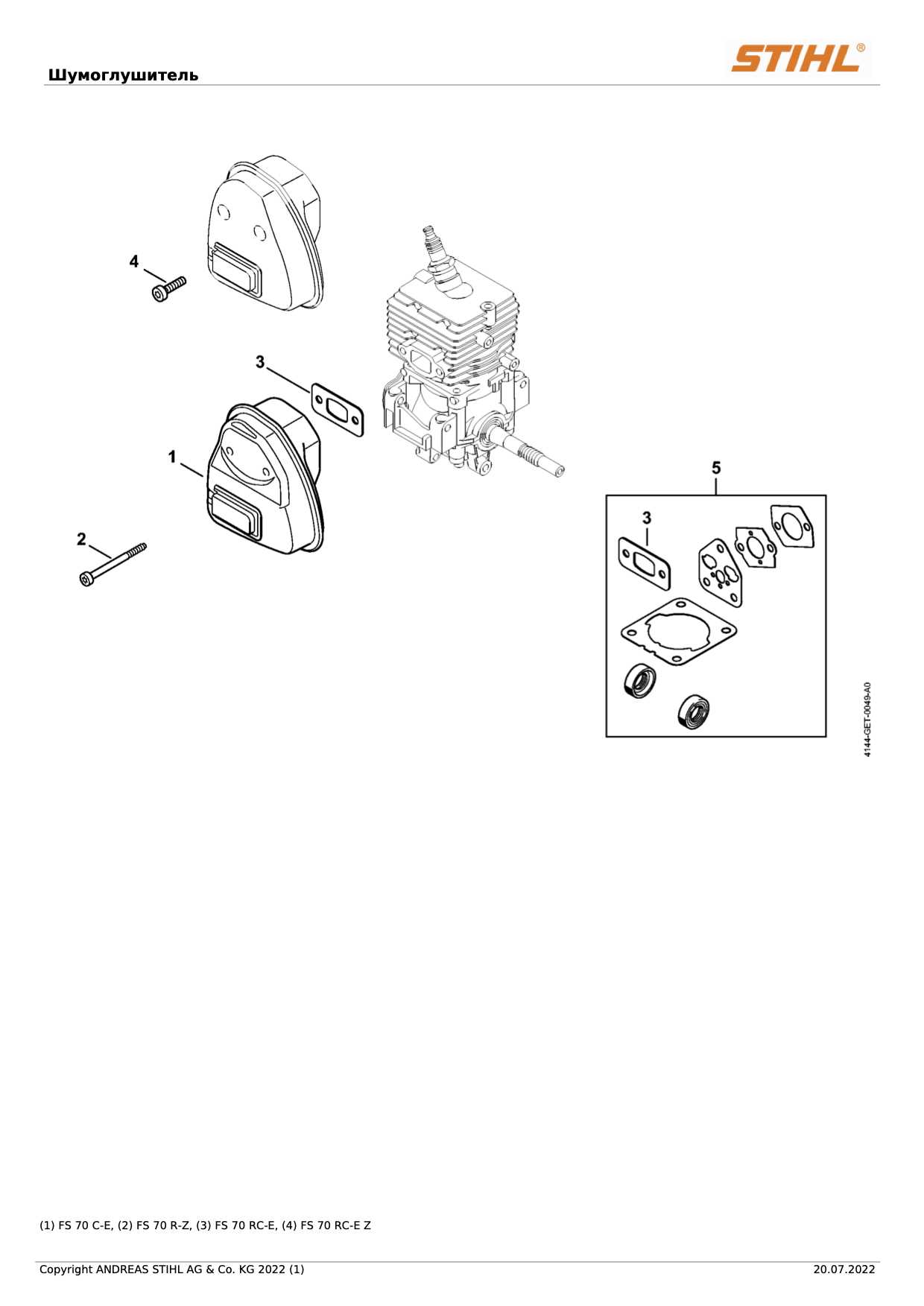

Parts Diagram Overview

This section provides a comprehensive look at the components of a specific machine, highlighting their arrangement and interconnections. Understanding these elements is crucial for maintenance and troubleshooting, ensuring optimal performance and longevity.

Key Elements: Each segment plays a vital role in the overall functionality, and recognizing their positions can facilitate easier repairs and replacements. Familiarity with these components not only aids in efficient operation but also empowers users to tackle any issues that may arise.

In this overview, we aim to enhance your knowledge of the various elements involved, ultimately contributing to a better understanding of the equipment’s design and usage.

How to Read a Parts Diagram

Understanding a visual representation of components is crucial for efficient maintenance and repairs. It allows users to identify each element and comprehend its function within a system. By mastering this skill, you can enhance your troubleshooting capabilities and streamline your repair processes.

Key Elements to Consider

- Labels: Each component will typically have a corresponding label or number.

- Legend: A legend may explain symbols or colors used in the illustration.

- Arrangement: Components are usually arranged in a way that reflects their physical layout.

Steps to Effectively Interpret the Illustration

- Start by reviewing the legend to understand the symbols.

- Identify key components and their corresponding numbers.

- Trace connections to see how each part interacts with others.

- Refer to the accompanying documentation for detailed descriptions.

Essential Maintenance Tips

Proper upkeep of your equipment is crucial for optimal performance and longevity. Regular attention can prevent costly repairs and ensure your tools operate efficiently.

- Regular Cleaning: Keep the exterior free from dirt and debris to prevent corrosion.

- Check Fuel and Oil: Ensure the right fuel mixture and oil levels for smooth operation.

- Inspect Blades: Regularly examine cutting components for wear and sharpen as needed.

- Tighten Bolts and Screws: Periodically check and secure all fasteners to maintain stability.

- Store Properly: Keep equipment in a dry, safe place to avoid damage from the elements.

Following these guidelines will help you maintain peak functionality and extend the life of your machinery.

Common Issues and Solutions

Operating outdoor power equipment can sometimes lead to various challenges. Understanding these common problems and their solutions is essential for ensuring optimal performance and longevity of your machine. Below, we explore typical issues users may encounter and offer practical remedies to enhance functionality.

Frequent Problems

- Engine Won’t Start

- Loss of Power During Operation

- Excessive Vibration

- Fuel Leaks

- Overheating

Solutions to Common Problems

- Engine Won’t Start:

- Check the fuel level and ensure it is fresh.

- Inspect the spark plug for wear and replace if necessary.

- Examine the air filter for blockages and clean or replace it.

- Loss of Power:

- Inspect the fuel lines for clogs or damage.

- Ensure the cutting head is not obstructed.

- Check the throttle settings for proper operation.

- Excessive Vibration:

- Verify that the cutting attachment is securely fastened.

- Check for any signs of wear or damage in the attachment.

- Balance the cutting head if necessary.

- Fuel Leaks:

- Inspect fuel lines and connections for cracks or loose fittings.

- Replace damaged seals or gaskets promptly.

- Overheating:

- Ensure adequate airflow around the engine.

- Check the cooling fins for debris and clean if required.

- Monitor fuel quality and avoid overheating by not overworking the machine.

By addressing these common issues, users can significantly improve the reliability and efficiency of their equipment, leading to a more enjoyable and productive experience.

Ordering Replacement Parts

When maintaining outdoor power equipment, obtaining the right components is essential for optimal performance. Ensuring that you have access to the correct items can significantly enhance the longevity and efficiency of your machinery.

Identifying Your Needs

Before making a purchase, it’s crucial to identify the specific components required. Consult your user manual or a trusted online resource to determine the necessary items based on your model. This attention to detail will help you avoid costly mistakes and ensure a proper fit.

Where to Purchase

Replacement items can be sourced from various outlets, including authorized retailers, online marketplaces, and specialty stores. Consider factors such as pricing, availability, and shipping options. Always opt for reliable suppliers to guarantee the quality of your purchases.

Compatibility with Other Models

This section explores the interoperability of the equipment with various other models within the same brand. Understanding these connections is essential for users seeking efficiency and functionality in their tools. Many users benefit from knowing which components can be exchanged or used interchangeably, enhancing versatility and convenience.

Similar Models

Several models share key features and specifications, making them suitable for compatible accessories and attachments. Here are some notable examples:

- Model A: Similar engine specifications and design.

- Model B: Compatible attachment points for additional tools.

- Model C: Shared performance characteristics, enhancing cross-usage.

Benefits of Compatibility

Utilizing components from compatible models offers several advantages:

- Cost Efficiency: Users can save money by using existing components rather than purchasing new ones.

- Increased Versatility: Different attachments can enhance the functionality of the main device.

- Ease of Maintenance: Shared components simplify the repair and maintenance process.

By exploring the compatibility of different models, users can maximize the performance and longevity of their equipment.

Tools Required for Repairs

When embarking on maintenance tasks, having the right equipment is essential for achieving optimal results. Proper tools ensure efficiency and can prevent damage during repairs, making the process smoother and more effective.

Essential Tools

- Wrenches

- Screwdrivers

- Socket Set

- Pliers

- Measuring Tape

Additional Equipment

- Work Gloves

- Safety Goggles

- Lubricants

- Cleaning Brushes

Equipping yourself with these instruments will allow you to tackle various tasks confidently and efficiently.

Step-by-Step Repair Guide

This section provides a comprehensive approach to troubleshooting and fixing common issues with your outdoor equipment. By following the outlined steps, you can effectively restore functionality and ensure optimal performance.

Preparation

- Gather necessary tools: wrenches, screwdrivers, and safety gear.

- Find a clean, well-lit workspace to prevent misplacing components.

- Refer to the user manual for specific guidelines and safety tips.

Repair Steps

- Identify the problem: check for leaks, unusual noises, or performance issues.

- Disassemble the unit carefully, keeping track of all screws and small parts.

- Inspect each component for wear or damage; replace as necessary.

- Clean all parts thoroughly to remove dirt and debris.

- Reassemble the unit, ensuring all pieces fit snugly and correctly.

- Test the equipment to confirm that the issue has been resolved.

Where to Find Genuine Parts

When maintaining your outdoor equipment, sourcing authentic components is crucial for optimal performance and longevity. Ensuring that you use high-quality replacements not only enhances efficiency but also provides peace of mind, knowing your machinery operates as intended.

The best approach to locate reliable replacements is to start with authorized dealers. These retailers specialize in providing genuine components, often backed by manufacturer warranties. They possess the expertise to assist you in finding the exact items needed for your specific model.

Additionally, online marketplaces dedicated to outdoor machinery often feature sections for original components. When using these platforms, it’s important to verify the seller’s credibility and check customer reviews to avoid counterfeit items. Look for vendors who offer clear return policies to protect your investment.

Local repair shops are also a valuable resource. Many of these establishments maintain connections with suppliers, enabling them to procure authentic components quickly. Engaging with professionals can also provide insights into proper installation and maintenance techniques.

Lastly, manufacturer websites typically have sections for locating authorized dealers or retailers. Utilizing these resources ensures you are obtaining the right items, tailored specifically for your equipment, guaranteeing both quality and compatibility.

Benefits of Using Original Parts

Utilizing authentic components ensures optimal performance and longevity of your equipment. These high-quality elements are designed to fit perfectly and work seamlessly with the overall system, minimizing the risk of malfunction and enhancing efficiency.

Reliability and Performance

Original components are manufactured to meet strict standards, providing reliability that generic alternatives often lack. This guarantees that your machinery operates at its best, delivering consistent results in every use.

Long-Term Savings

While authentic elements may come at a higher initial cost, they often save money over time by reducing the frequency of replacements and repairs. Investing in quality translates to fewer headaches and improved durability, making it the ultimate choice for serious users.