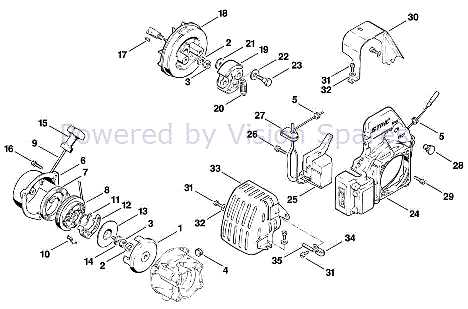

Stihl FS 80 AV Parts Diagram Overview

The intricate workings of any outdoor equipment often require a closer look to ensure optimal performance and longevity. This section delves into the essential elements that comprise these machines, shedding light on their functionalities and interrelationships. By gaining insight into each component, users can make informed decisions regarding maintenance and repairs.

Familiarity with the various pieces that make up your device can enhance your understanding of how it operates. Each part plays a pivotal role, contributing to the overall efficiency and effectiveness of the tool. Recognizing the significance of these elements can empower users to address issues promptly, ensuring that their equipment remains in peak condition.

In the following sections, you will find detailed illustrations and explanations that clarify the arrangement and purpose of each component. Whether you’re troubleshooting a problem or planning routine maintenance, having a clear visual reference can simplify the process, ultimately leading to a more reliable and productive experience.

Understanding Stihl FS 80 AV Components

In order to maintain optimal performance and longevity of a string trimmer, it is essential to grasp the various elements that comprise the machinery. Each component plays a critical role in the functionality of the device, ensuring efficient operation and effective trimming. A thorough understanding of these parts allows for informed maintenance and troubleshooting, ultimately enhancing the user experience.

| Component | Description |

|---|---|

| Engine | Power source that drives the entire unit, converting fuel into mechanical energy. |

| Cutting Head | Houses the line or blade used for trimming grass and weeds, responsible for cutting performance. |

| Throttle Trigger | Controls the engine speed by adjusting the fuel and air mixture, allowing for variable cutting power. |

| Fuel Tank | Stores the fuel needed for engine operation, designed for easy refueling and to prevent spills. |

| Handlebar | Provides support and maneuverability, allowing the user to control the direction and angle of the trimmer. |

| Gearbox | Transmits power from the engine to the cutting head, often featuring different gear ratios for various tasks. |

Recognizing and understanding these components is essential for effective use and maintenance. Proper care ensures the equipment operates smoothly and lasts longer, making it an invaluable tool for lawn care and landscaping.

Importance of Parts Diagrams

Understanding the intricate components of machinery is crucial for maintenance and repair tasks. Visual representations of these elements serve as essential tools for both novice and experienced users. They provide clarity, enabling efficient troubleshooting and assembly.

Here are several key benefits of utilizing these visual guides:

- Enhanced Clarity: Detailed illustrations simplify the identification of each element, making it easier to locate and understand their functions.

- Streamlined Repairs: With a clear view of the assembly, users can quickly pinpoint issues, reducing the time needed for repairs.

- Improved Organization: Visual aids help in organizing the workflow, ensuring that all necessary components are accounted for before starting a project.

- Educational Resource: These guides serve as excellent learning materials for individuals looking to deepen their knowledge of mechanical systems.

By utilizing these visual resources, users can significantly enhance their efficiency and effectiveness in handling equipment, ultimately leading to better performance and longevity of the machinery.

Common Issues with FS 80 AV

The FS 80 AV model is a reliable tool, but like any machinery, it can encounter various challenges during operation. Understanding these common problems can help users maintain performance and extend the lifespan of the equipment. This section outlines the frequent issues faced by users and offers insights into potential causes and solutions.

Typical Problems

Users may experience a range of issues with this equipment, which can affect efficiency and usability. Identifying the symptoms early can prevent more significant malfunctions.

| Issue | Possible Cause | Suggested Solution |

|---|---|---|

| Engine Won’t Start | Fuel Blockage or Dirty Filter | Check and replace the fuel filter; ensure the fuel is fresh. |

| Loss of Power | Worn Spark Plug | Inspect and replace the spark plug as necessary. |

| Excessive Vibration | Loose or Damaged Components | Tighten all screws and bolts; replace any damaged parts. |

| Fuel Leaks | Worn Fuel Lines | Inspect fuel lines for wear and replace them if needed. |

Maintenance Tips

Regular maintenance can significantly reduce the likelihood of encountering these issues. Ensuring that all components are in good condition and following recommended service schedules can help keep the machine operating smoothly.

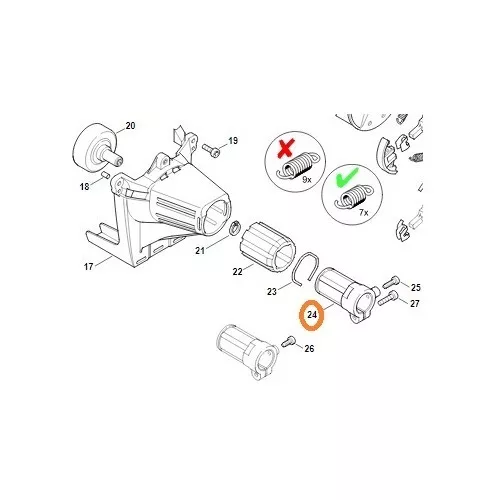

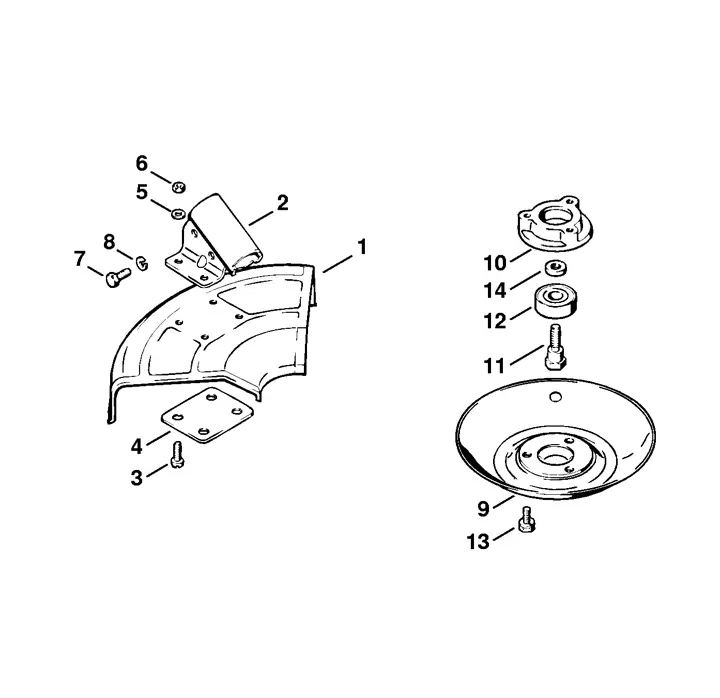

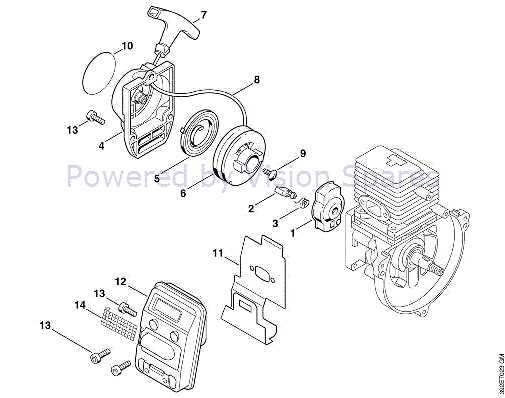

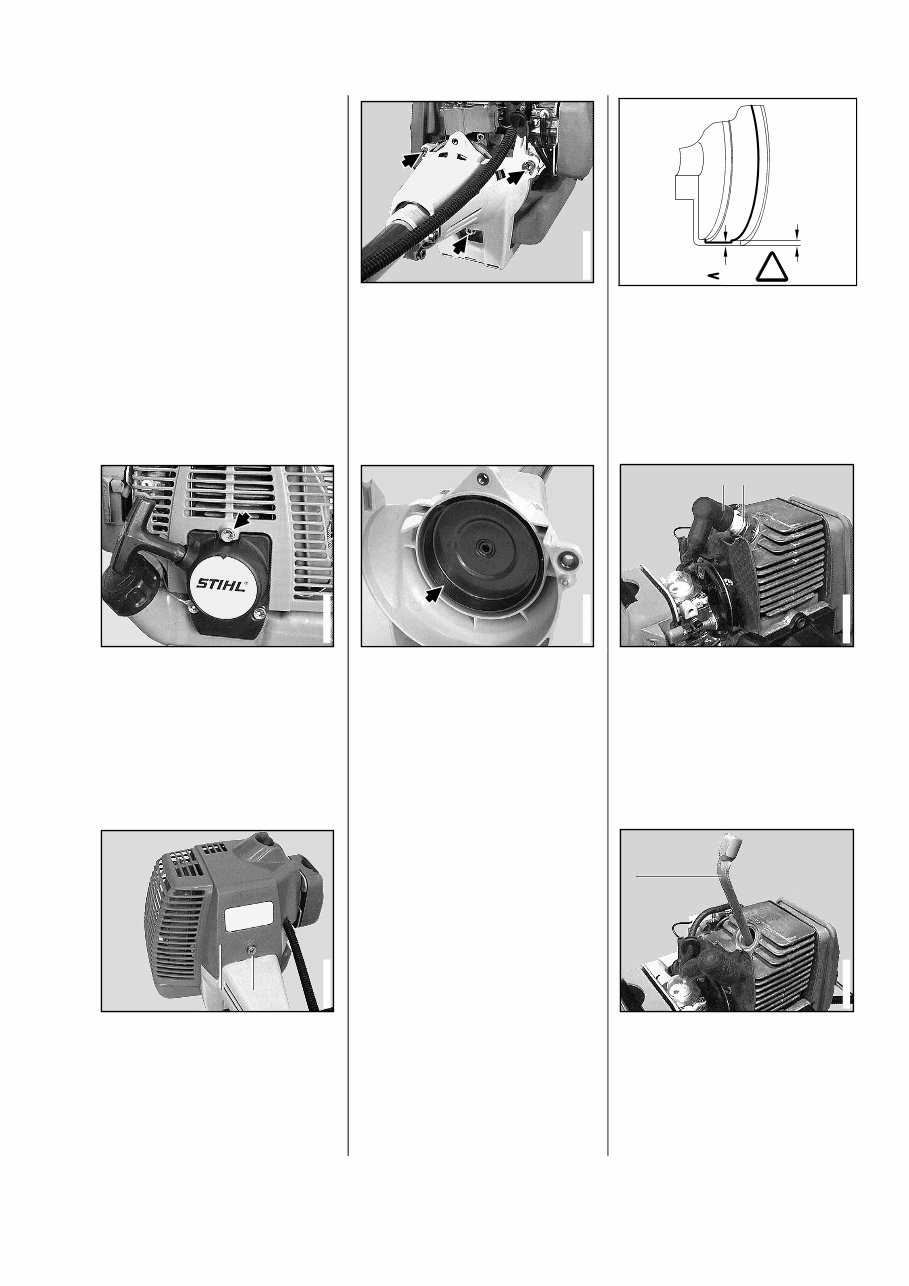

How to Read Parts Diagrams

Understanding technical illustrations can significantly enhance your ability to maintain and repair equipment. These visual representations provide an organized overview of components and their relationships, making it easier to identify what you need for repairs or upgrades.

To start, familiarize yourself with the overall layout. Typically, these visuals are divided into sections, each representing a specific assembly or subsystem. Pay attention to the numbering system; each item is often labeled, allowing you to cross-reference with a list of components.

Color coding can also be present, helping differentiate various parts based on function or assembly type. Highlighting can indicate components that are critical or require special attention during the maintenance process.

Additionally, take note of the annotations that accompany the illustration. These notes may provide essential details regarding installation, compatibility, or maintenance procedures. Understanding these can save time and prevent errors during assembly or disassembly.

Finally, don’t hesitate to refer to the accompanying documentation for more context. A thorough grasp of these visuals empowers you to tackle projects with confidence and precision.

Key Parts of the Stihl FS 80

The efficient functioning of any outdoor power tool relies heavily on its essential components. Understanding these key elements not only aids in maintenance but also enhances overall performance. This section highlights the critical features that contribute to the reliability and effectiveness of this particular model.

Engine and Power System

The engine serves as the powerhouse, providing the necessary energy for operation. Its design ensures optimal fuel efficiency and minimal emissions. Complementing the engine is the ignition system, which plays a vital role in starting and running the machine smoothly.

Cutting Mechanism

The cutting apparatus is crucial for achieving precise results. This system includes the cutting head and various attachments designed for different tasks. Regular inspection and replacement of these elements can significantly improve cutting efficiency and prolong the tool’s lifespan.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the long-lasting performance of your equipment. By following a few simple practices, you can significantly enhance the lifespan and efficiency of your tools. Regular maintenance not only prevents costly repairs but also ensures safety and reliability during operation.

Regular Cleaning: Keeping your machinery clean is crucial. Remove dirt, debris, and grass clippings after each use to prevent buildup that can lead to mechanical issues. A clean surface allows for better air circulation and cooling.

Inspect Components: Regularly examine the various elements of your tool for signs of wear and tear. Look for cracks, rust, or other damage that may compromise performance. Early detection of issues can save you time and money in the long run.

Lubrication: Ensure that moving parts are adequately lubricated. Using the right type of oil reduces friction and wear, contributing to smoother operation. Refer to the manufacturer’s guidelines for specific recommendations on lubrication intervals and products.

Fuel Management: Use fresh fuel and follow recommended fuel-to-oil ratios. Stale fuel can lead to poor performance and damage to the engine. Empty the tank if the equipment will be stored for an extended period.

Proper Storage: Store your equipment in a dry, sheltered place to protect it from the elements. Use covers to shield from dust and moisture, and ensure that the area is well-ventilated to prevent corrosion.

By incorporating these maintenance tips into your routine, you can ensure that your equipment remains in optimal condition, ready to perform whenever you need it.

Where to Find Replacement Parts

Locating suitable components for your outdoor equipment can significantly enhance its performance and longevity. Whether you’re a professional or a DIY enthusiast, knowing where to source quality replacements is essential for maintaining the efficiency of your tools.

Here are some reliable options to consider:

| Source | Description |

|---|---|

| Authorized Dealers | These retailers specialize in genuine components and can provide expert advice on the best options for your specific model. |

| Online Marketplaces | Websites like Amazon and eBay often have a wide range of components available, including user reviews to help guide your purchase. |

| Local Repair Shops | Neighborhood technicians can not only supply components but also offer installation services, ensuring proper fit and function. |

| Manufacturer Websites | Visiting the official website of your equipment’s brand can provide access to a complete catalog of components, often with installation guides. |

| Specialty Online Retailers | There are numerous websites dedicated to outdoor equipment, providing a vast inventory of components, often at competitive prices. |

By exploring these sources, you can find the necessary components to keep your equipment running smoothly and effectively.

Upgrading Components for Better Performance

Enhancing the functionality of your equipment can significantly boost its efficiency and longevity. By focusing on specific elements, users can achieve a notable improvement in performance, ensuring that tasks are completed with ease and precision.

Consider the following aspects when upgrading components:

- Engine Efficiency: Optimizing the engine can lead to better fuel consumption and increased power output.

- Cutting Tools: Selecting sharper or more durable cutting attachments can reduce strain and improve cutting speed.

- Vibration Dampening: Upgrading to high-quality vibration reduction systems can enhance comfort during prolonged use.

- Cooling Systems: Improving the cooling mechanism can prevent overheating and extend the life of the machine.

- Fuel System: Installing a more efficient fuel delivery system can improve combustion and overall performance.

By carefully choosing which elements to upgrade, users can tailor their equipment to better meet their needs, ultimately resulting in a more satisfying experience. Each modification can contribute to a smoother, more powerful operation, allowing for greater productivity in various tasks.

Safety Precautions During Repairs

When undertaking maintenance tasks on outdoor power equipment, it is essential to prioritize safety to prevent accidents and injuries. Proper precautions ensure that repairs are conducted efficiently and securely, safeguarding both the user and the machinery.

Essential Safety Measures

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and hearing protection.

- Work in a well-ventilated area to avoid inhaling fumes or harmful particles.

- Ensure the equipment is powered down and disconnected from any power source before starting repairs.

- Keep a clean and organized workspace to minimize the risk of slips and falls.

Handling Tools and Components

- Use tools that are specifically designed for the tasks at hand to avoid damage and personal injury.

- Inspect all tools for any defects before use, replacing or repairing them as necessary.

- Store sharp objects safely and out of reach when not in use.

- Follow manufacturer instructions closely to ensure proper handling of components.

Identifying OEM vs. Aftermarket Parts

When it comes to maintaining equipment, understanding the distinction between original components and those produced by third-party manufacturers is crucial. Each type offers unique benefits and potential drawbacks, influencing both performance and longevity. Recognizing these differences can help users make informed choices that best suit their needs.

Key Differences

- Quality: Original components typically undergo rigorous testing and quality control, ensuring reliability and durability.

- Price: Third-party options are often more affordable, appealing to budget-conscious consumers.

- Warranty: Components from the original manufacturer often come with a warranty, providing peace of mind.

- Compatibility: Original components are designed specifically for the equipment, guaranteeing a perfect fit and optimal performance.

Identifying Original vs. Third-Party Options

- Check the packaging for branding and logos.

- Look for part numbers; original items usually have unique identifiers.

- Research the manufacturer; reputable third-party suppliers will have reviews and customer feedback.

- Examine materials and craftsmanship; original components often have a more refined finish.

Being aware of these factors will enhance your understanding of what you are purchasing and ensure that your equipment remains in optimal working condition.

Repairing vs. Replacing Components

When maintaining outdoor power equipment, the decision to fix or substitute components can significantly impact performance and longevity. Each option presents unique advantages and drawbacks, making it essential to weigh them carefully based on specific circumstances and user needs.

Repairing damaged or worn components can be a cost-effective solution. It often requires less time and fewer resources, allowing users to restore functionality without investing in new items. This approach also promotes sustainability, as it reduces waste and minimizes the environmental footprint of equipment maintenance. However, repairs may not always guarantee long-term effectiveness, especially if the underlying issues persist.

On the other hand, replacing components can provide a fresh start, ensuring optimal performance and reliability. New parts often come with warranties, offering peace of mind and reducing future maintenance concerns. Nonetheless, this option typically involves a higher initial investment and may require more time for sourcing and installation. Moreover, if a piece of equipment is nearing the end of its life cycle, investing in replacements might not be the most prudent choice.

Ultimately, the choice between repairing and replacing hinges on factors such as the extent of damage, overall equipment condition, and individual budget considerations. Assessing these elements will help users make informed decisions that best suit their needs.

Resources for Stihl Owners

For those who take pride in maintaining their outdoor power equipment, access to quality information and support is essential. A variety of resources are available to help enthusiasts keep their machines in optimal condition, ensuring reliability and longevity.

Online Communities: Engaging with fellow users through forums and social media groups can provide valuable insights and tips. Members often share their experiences, troubleshooting advice, and recommendations for maintenance.

Official Manuals: Each machine typically comes with a comprehensive guide that covers operating procedures, safety precautions, and maintenance schedules. These manuals are crucial for understanding the specific needs of your equipment.

Local Dealers: Authorized dealers offer not only sales but also expert service. They can provide assistance with repairs, offer genuine accessories, and ensure that users have the best products for their models.

Video Tutorials: Platforms like YouTube host a wealth of instructional videos that demonstrate repairs and maintenance techniques. Visual guidance can enhance understanding and make complex tasks more approachable.

Parts Suppliers: Numerous suppliers specialize in replacement components and accessories, ensuring that users can find exactly what they need. Quality components are essential for maintaining performance and safety.

By utilizing these resources, owners can enhance their knowledge, improve maintenance practices, and ultimately enjoy a better experience with their equipment.