Understanding the Stihl FS 94 Parts Diagram for Better Maintenance

When it comes to maintaining your cutting equipment, comprehending its individual elements is crucial for optimal performance and longevity. Each component plays a vital role in ensuring smooth operation, making it essential to familiarize yourself with their functions and arrangements.

Having a clear overview of the various segments not only aids in efficient troubleshooting but also empowers users to undertake repairs and replacements with confidence. This knowledge enhances the overall user experience and promotes a deeper connection with your tool.

In this section, we will delve into the intricate layout of these vital parts, highlighting their significance and how they interact within the system. By understanding the ultimate assembly, you’ll be better equipped to tackle any challenges that may arise during maintenance.

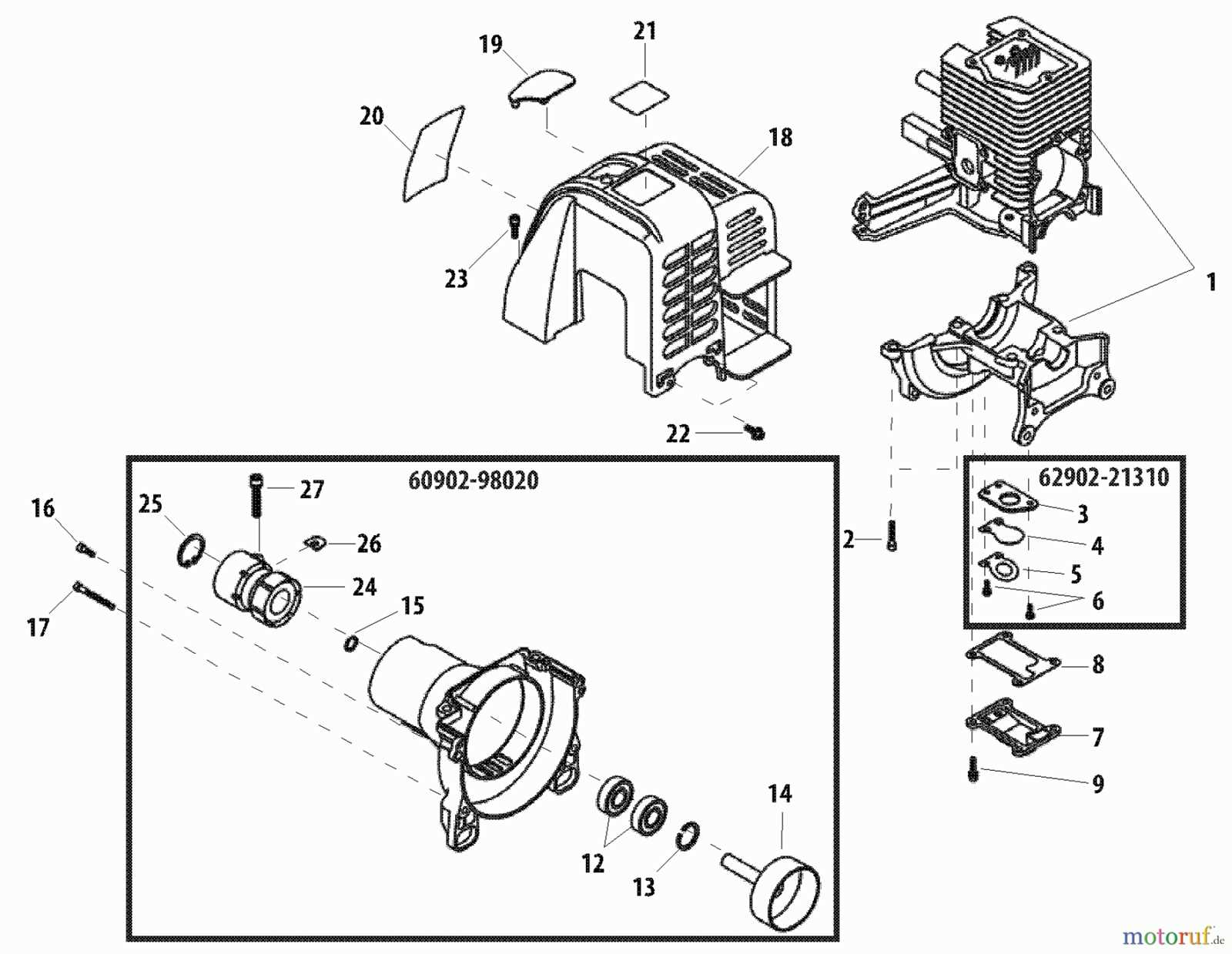

Understanding Stihl FS 94 Components

Familiarizing oneself with the various elements of a cutting tool is essential for optimal performance and maintenance. Each component plays a significant role in the overall functionality, contributing to efficiency and durability. Recognizing how these parts work together can enhance the user experience and prolong the life of the equipment.

Here is a breakdown of some key components typically found in such equipment:

| Component | Description |

|---|---|

| Engine | The heart of the machine, providing the necessary power for operation. |

| Handle | Offers control and comfort during use, essential for maneuverability. |

| Cutting Head | Houses the blade or line, directly interacting with the vegetation. |

| Fuel Tank | Stores the fuel required for the engine, crucial for operation. |

| Air Filter | Ensures clean air reaches the engine, promoting efficient combustion. |

| Throttle Control | Regulates engine speed, allowing for precise cutting capabilities. |

Understanding these components not only aids in proper handling but also assists in identifying potential issues that may arise during use, thereby enhancing maintenance practices.

Parts Diagram Overview

This section provides an insightful look into the essential components of a specific tool, illustrating how each element contributes to its overall functionality. Understanding the arrangement and relationship of these elements is crucial for effective maintenance and repair.

| Component | Description |

|---|---|

| Engine | The power source that drives the entire mechanism. |

| Cutting Head | Where the actual cutting action takes place, equipped with various blades or lines. |

| Handle | Provides control and maneuverability during operation. |

| Fuel Tank | Holds the energy source needed for operation. |

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and restoration tasks. The following tools are fundamental for anyone looking to keep their machinery in optimal condition, ensuring both efficiency and safety during repairs.

Basic Hand Tools

- Wrenches

- Screwdrivers

- Pliers

- Hex keys

Power Tools

- Drills

- Impact drivers

- Grinders

Equipping yourself with these essentials will facilitate smoother and more efficient repair processes.

Common Issues with FS 94 Parts

When operating a popular outdoor power tool, users may encounter various challenges related to its components. Understanding these common problems can enhance the maintenance and longevity of the equipment, ensuring optimal performance during usage.

Frequent Problems

- Wear and Tear: Over time, certain elements may become worn out, leading to reduced efficiency and functionality.

- Fuel Line Issues: Clogs or leaks in the fuel delivery system can cause the engine to run poorly or stall unexpectedly.

- Starting Difficulties: Users often report challenges in starting the machine, which can be attributed to spark plug malfunctions or air filter blockages.

- Vibration and Noise: Excessive vibrations or unusual sounds during operation may indicate loose or damaged components.

Prevention and Solutions

- Regularly inspect and replace worn components to maintain optimal performance.

- Check fuel lines for clogs or leaks to ensure smooth fuel flow.

- Perform routine maintenance on spark plugs and air filters for easier starting.

- Tighten any loose parts and replace damaged ones to minimize vibrations.

Addressing these common issues promptly can lead to a more efficient and reliable experience with the equipment.

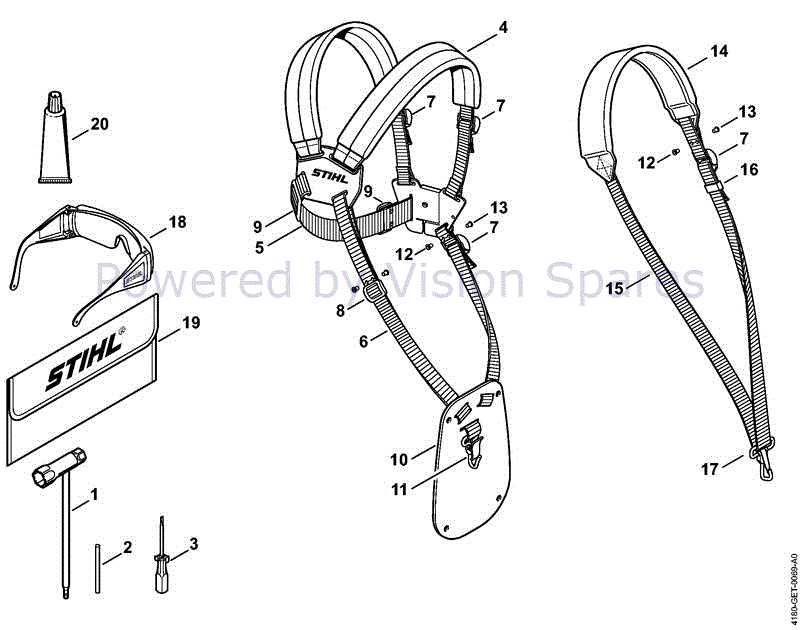

Step-by-Step Assembly Guide

This guide provides a clear and concise approach to assembling your outdoor equipment efficiently. By following each step methodically, you can ensure proper installation and optimal performance, allowing you to enjoy your tool’s full capabilities.

Preparation

Before beginning the assembly, gather all necessary components and tools. Ensure that your workspace is clean and organized to avoid any distractions or misplaced items. Familiarizing yourself with each element will facilitate a smoother process.

Assembly Steps

1. Base Attachment: Start by securing the base to the main body. Align the holes and use the appropriate fasteners to secure them tightly. Ensure that everything is flush and properly aligned.

2. Handle Installation: Next, attach the handle. Position it according to the manufacturer’s guidelines and tighten the screws adequately. A secure handle is crucial for safe operation.

3. Connecting the Shaft: Attach the shaft to the base, making sure it fits snugly. Use the designated locking mechanism to hold it in place, ensuring stability during use.

4. Final Checks: Once all components are assembled, conduct a thorough inspection. Check that all screws and fasteners are tightened and that moving parts operate smoothly.

By adhering to these steps, you will achieve a successful assembly, ready for efficient use in your outdoor tasks.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the extended life of your equipment. Implementing a consistent maintenance routine not only enhances performance but also minimizes the risk of unexpected breakdowns. Below are some key strategies to keep your tool running smoothly for years to come.

Routine Cleaning

- Clean the exterior after each use to remove dirt and debris.

- Inspect and clear the air filter regularly to ensure proper airflow.

- Check for any signs of wear or damage on the cutting components.

Regular Inspections

- Examine fuel lines and connections for leaks or cracks.

- Monitor spark plug condition and replace it as needed for optimal ignition.

- Assess the cutting head for any obstructions or build-up that may affect performance.

By following these maintenance tips, you can significantly extend the lifespan of your equipment and maintain its efficiency, ensuring that it meets your needs over time.

Replacement Parts: Where to Buy

Finding suitable components for your equipment can significantly enhance its performance and longevity. Understanding the various sources available for sourcing these items is crucial for maintaining optimal functionality.

Authorized Dealers

Visiting authorized retailers ensures you acquire high-quality replacements. These locations typically offer:

- Genuine components

- Expert advice and support

- Warranty coverage on products

Online Marketplaces

The internet provides a vast array of options for purchasing components. Consider these platforms:

- Official brand websites

- Specialized e-commerce sites

- General marketplaces like Amazon or eBay

Always check seller ratings and reviews to ensure reliability.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is crucial for both personal well-being and the longevity of the equipment. Proper precautions can prevent accidents and injuries, creating a secure environment for effective repairs. Understanding the potential hazards and employing appropriate protective measures is essential.

Always wear suitable protective gear, including gloves, goggles, and hearing protection, to shield against debris and loud noises. It is also important to work in a well-ventilated area to avoid inhaling harmful fumes. Before starting any repairs, ensure that the machine is turned off and disconnected from any power source to eliminate the risk of accidental activation.

Maintain a clean workspace free from clutter to reduce tripping hazards and facilitate easy access to tools and components. Familiarize yourself with the specific safety guidelines associated with the equipment you are handling, as this knowledge is vital for avoiding common pitfalls during the repair process.

Lastly, take your time and avoid rushing through repairs. A careful, methodical approach can significantly enhance safety and lead to a successful outcome. Prioritize caution and preparedness to ensure that every maintenance task is performed with the utmost diligence.

Comparing FS 94 to Other Models

This section aims to provide an insightful comparison of the FS 94 model with its counterparts in the market. By examining various features, performance metrics, and user experiences, we can better understand where this particular unit stands in relation to others within its category.

Power and Performance: When evaluating different models, one of the most crucial aspects is the power output. The FS 94 is designed for efficiency, delivering robust performance that rivals many competitors. Models such as the FS 70 and FS 130 offer their own strengths, yet each comes with unique specifications that may cater to different user needs.

Weight and Maneuverability: Weight is another critical factor, especially for prolonged use. The FS 94 strikes a balance between being lightweight and offering enough durability for tough tasks. In contrast, some models might prioritize sturdiness over ease of handling, which can affect user comfort during extended periods of operation.

Fuel Efficiency: Fuel consumption varies significantly among different options. The FS 94 boasts impressive fuel efficiency, making it a more economical choice for frequent users. Comparatively, other models may consume more fuel, which could lead to higher operational costs over time.

Ergonomics and Design: User comfort is paramount, and the FS 94 features ergonomic designs that enhance the overall experience. While some alternatives may offer additional accessories, the core design of the FS 94 focuses on ease of use and minimizing fatigue, a significant advantage for those who operate these tools regularly.

In summary, the FS 94 presents a compelling option when compared to similar models. By analyzing various aspects, users can make informed decisions based on their specific requirements and preferences.

Upgrading Parts for Better Performance

Enhancing your equipment’s efficiency can significantly impact its overall functionality and lifespan. By selecting superior components, you can unlock the true potential of your machine, allowing for smoother operation and increased productivity.

Benefits of Enhanced Components

Upgrading to high-quality alternatives often results in improved durability and resistance to wear. Investing in advanced materials can lead to better performance under demanding conditions, ensuring that your equipment runs optimally for longer periods. This not only enhances efficiency but also reduces maintenance costs over time.

Choosing the Right Upgrades

When considering enhancements, focus on compatibility and performance specifications. Opt for reputable brands that are known for their reliability. This approach will ensure that the new components integrate seamlessly with your machine, providing the ultimate boost in performance you seek.

Expert Insights on Stihl Products

In the realm of outdoor equipment, understanding the intricacies of machinery can significantly enhance user experience and longevity of tools. Knowledge of various components, their functionalities, and maintenance tips is invaluable for both professionals and enthusiasts alike. This section aims to provide expert insights into essential features and best practices for optimal performance.

| Feature | Importance |

|---|---|

| Durability | Ensures long-lasting use and reliability in tough conditions. |

| Efficiency | Enhances productivity and reduces operational costs. |

| Ease of Maintenance | Simplifies upkeep, leading to better performance over time. |

| Safety Features | Reduces risk of accidents, promoting safe handling. |

By delving into these aspects, users can make informed decisions and achieve the ultimate satisfaction from their outdoor tools.