Understanding the Stihl FS108 Parts Diagram for Effective Maintenance

Maintaining and repairing your outdoor power tools can be a daunting task, especially when faced with a complex assembly of components. Having a clear visual reference can significantly enhance your understanding of how each part functions and fits together. This knowledge is essential for ensuring the longevity and efficiency of your equipment.

In this guide, we delve into the intricate details of a specific model, providing a clear visual representation of its various elements. By examining the arrangement and interconnections of these components, you can better comprehend their roles and how to address any issues that may arise during operation.

Whether you’re a seasoned professional or a casual user, familiarizing yourself with the layout of your machinery empowers you to tackle maintenance and repairs with confidence. This exploration not only facilitates effective troubleshooting but also enhances your overall experience with your tools.

Overview of Stihl FS108 Parts

This section provides a comprehensive look at the various components of a popular outdoor power tool. Understanding these elements is essential for maintenance, repairs, and optimizing performance. Each part plays a crucial role in the overall functionality of the equipment, ensuring it operates efficiently for various tasks.

Key Components

Among the essential elements are the engine assembly, fuel system, and cutting mechanism. The engine is the heart of the machine, delivering the power needed for operation. The fuel system ensures the engine receives the right mixture of air and fuel, while the cutting mechanism is vital for achieving desired results in landscaping and gardening.

Maintenance and Replacement

Regular upkeep is necessary to prolong the lifespan of each component. Identifying wear and tear can prevent more significant issues down the line. Timely replacement of worn parts not only enhances performance but also ensures safety during operation. For optimal results, familiarizing oneself with the various components and their functions is highly recommended.

Importance of Parts Diagrams

Understanding the intricate assembly of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools, providing clarity and guidance for users. They facilitate a better grasp of components and their interrelations, ensuring efficient troubleshooting and assembly.

Utilizing these visual aids offers several benefits:

- Enhanced Clarity: Diagrams simplify complex systems, making it easier to identify each element and its function.

- Improved Accuracy: Clear visuals help in accurately reassembling parts, reducing the likelihood of errors.

- Time Efficiency: Quick reference guides allow for faster identification of needed components during repairs.

- Better Understanding: Visual aids foster a deeper comprehension of how various parts interact within the machine.

For anyone involved in equipment maintenance, mastering these visual references can lead to significant improvements in both performance and longevity of machinery.

Key Components of FS108

Understanding the essential elements of this outdoor power equipment is crucial for effective maintenance and optimal performance. Each component plays a significant role in ensuring the reliability and efficiency of the machine. Below is a breakdown of the primary parts that contribute to its functionality.

| Component | Description |

|---|---|

| Engine | The heart of the machine, responsible for generating power and driving the cutting mechanism. |

| Fuel Tank | Stores the necessary fuel for operation, designed for easy refilling and minimizing spills. |

| Cutting Head | Equipped with various attachments for trimming and mowing, adjustable for different tasks. |

| Handle | Provides control and stability during operation, ergonomically designed for user comfort. |

| Throttle Control | Allows the operator to regulate engine speed, enhancing versatility in various working conditions. |

| Air Filter | Prevents dust and debris from entering the engine, ensuring smooth operation and longevity. |

Understanding the Assembly Process

The assembly process is a critical phase in the construction of various machinery, ensuring that each component fits together seamlessly to create a functional unit. A clear comprehension of this procedure can greatly enhance efficiency and reduce the likelihood of errors. Proper sequencing, familiarity with each part, and adherence to guidelines play essential roles in achieving a successful outcome.

Key Components of the Assembly Process

In order to facilitate a smooth assembly, it’s essential to understand the key elements involved. This includes recognizing the specific roles each part plays and how they interact within the larger system. By breaking down the components, one can better appreciate their importance and the necessity of precision in the assembly.

| Component | Description |

|---|---|

| Frame | The structural foundation that supports all other components. |

| Engine | The power source that drives the entire mechanism. |

| Handle | The part that enables user control and maneuverability. |

| Cutting Mechanism | The component responsible for executing the primary function. |

| Safety Features | Elements designed to protect the user during operation. |

Steps for Effective Assembly

Following a systematic approach during assembly can minimize complications. Start with a thorough inspection of all components, ensuring they are in optimal condition. Then, refer to the assembly instructions closely, taking care to align each piece accurately. Finally, perform a functional test to confirm that everything operates as intended, making adjustments if necessary.

Common Issues with FS108 Parts

When working with outdoor power tools, users often encounter a variety of challenges related to specific components. Understanding these common difficulties can aid in better maintenance and troubleshooting, ensuring optimal performance and longevity of the equipment.

Frequent Mechanical Failures

One of the most prevalent issues involves mechanical failures due to wear and tear. Over time, certain elements can degrade, leading to reduced efficiency and potential malfunctions. Regular inspections are essential to catch these problems early.

| Component | Common Failure Mode | Symptoms |

|---|---|---|

| Cutter Head | Cracking or breakage | Inconsistent cutting, vibrations |

| Fuel Lines | Leaks or blockages | Difficulty starting, reduced power |

| Throttle Control | Sticking or failure | Unresponsive engine, erratic speed |

Performance-Related Concerns

Another significant category involves performance-related concerns that may arise from improper installation or usage. These issues can often be resolved through proper techniques and adherence to manufacturer guidelines.

| Issue | Possible Cause | Solution |

|---|---|---|

| Engine Stalling | Fuel starvation | Check fuel levels and filter |

| Excessive Vibration | Imbalanced components | Inspect and replace worn parts |

| Poor Cutting Performance | Dull blades | Sharpen or replace blades |

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and efficiency of your outdoor equipment. By adopting a systematic approach to maintenance, you can enhance performance, minimize breakdowns, and extend the overall lifespan of your tools. Here are some vital tips to consider.

1. Clean After Use: Always remove debris, dirt, and grass clippings after each session. This prevents buildup that can lead to rust and corrosion, affecting the functionality of the machine.

2. Check and Replace Filters: Air and fuel filters should be inspected regularly. Clogged filters can restrict airflow and fuel flow, leading to poor performance. Replace them as necessary to maintain optimal operation.

3. Inspect the Cutting Head: Regularly examine the cutting head for wear and tear. Replace any worn parts promptly to ensure efficient cutting and to avoid further damage to other components.

4. Lubricate Moving Parts: Applying lubricant to moving parts reduces friction and wear. This simple step can significantly enhance the efficiency and longevity of the equipment.

5. Store Properly: When not in use, store the equipment in a dry and sheltered place. Protecting it from the elements reduces the risk of damage and extends its life.

6. Follow Manufacturer Guidelines: Always refer to the user manual for specific maintenance recommendations. Adhering to these guidelines ensures that you are using the equipment correctly and caring for it as intended.

By integrating these maintenance practices into your routine, you can ensure that your outdoor tools remain reliable and effective for years to come.

Where to Find Replacement Parts

Finding the right components for your equipment can significantly enhance its performance and longevity. Whether you’re a professional or a hobbyist, having access to quality replacements is crucial. This section will guide you through various sources where you can acquire the necessary items for your tools.

Authorized Dealers

One of the most reliable options for sourcing components is through authorized dealers. These retailers specialize in genuine products and often provide expert advice on compatibility and installation.

Online Retailers

In today’s digital age, numerous online platforms offer a vast selection of items. This can often lead to competitive pricing and convenience. Be sure to check customer reviews to ensure the quality of the merchandise.

| Source | Benefits |

|---|---|

| Authorized Dealers | Genuine products, expert support |

| Online Retailers | Wide selection, competitive prices |

| Local Hardware Stores | Immediate availability, personal service |

| Second-Hand Marketplaces | Cost-effective options, unique finds |

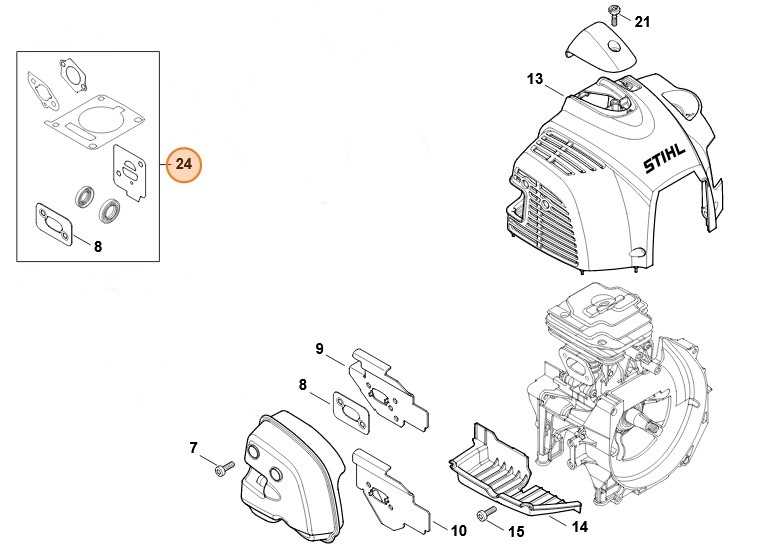

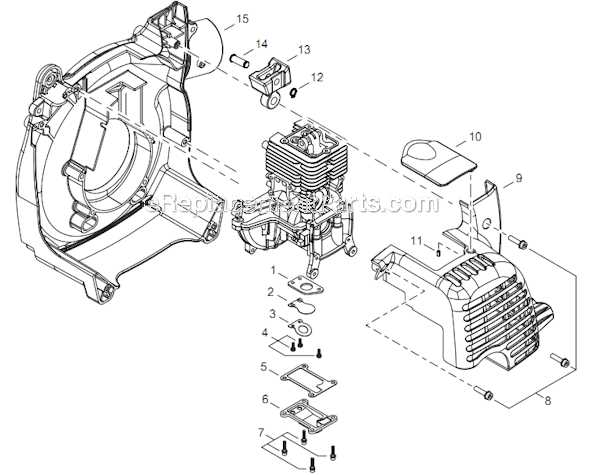

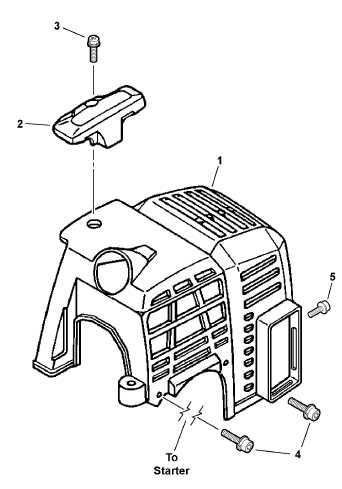

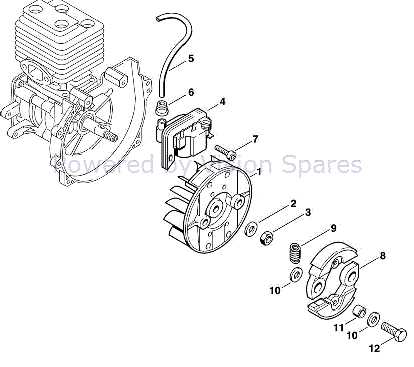

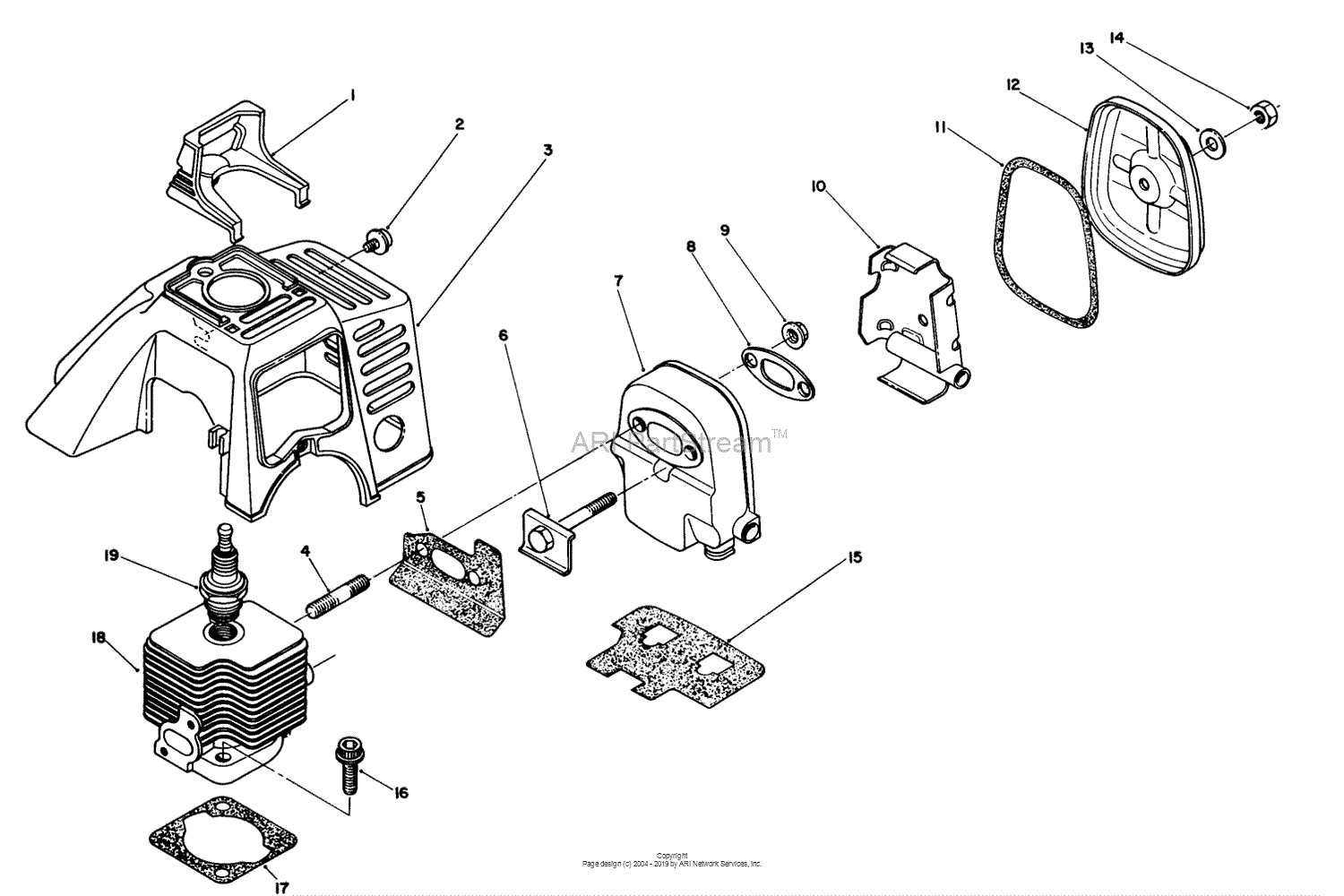

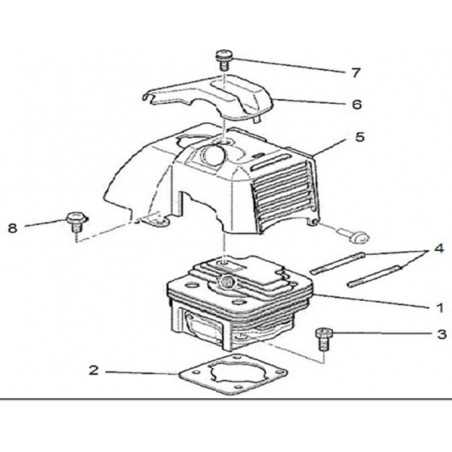

How to Read Parts Diagrams

Understanding visual schematics is essential for effective maintenance and repair. These illustrations provide a detailed view of components and their relationships, helping users identify necessary elements for assembly or replacement. Familiarity with these graphics enables you to efficiently navigate the intricacies of equipment.

Key Elements of Visual Schematics

Each illustration typically includes several key features. Numbers or letters next to each component indicate specific items, often correlating with a list that provides further details. Additionally, lines and arrows may show how parts connect or interact, giving a clearer understanding of the overall assembly. Color coding can also enhance clarity, helping to distinguish between different types of elements or materials.

Interpreting the Information

To make the most of these visuals, start by familiarizing yourself with the legend or key provided, if available. This will clarify what each symbol or notation represents. As you study the illustration, take note of the arrangement of components and their respective numbers. Cross-reference these with any accompanying documentation to ensure you have a complete understanding of what is needed for your project.

Tools Needed for Repair

When undertaking maintenance or restoration tasks, having the right instruments is essential for efficiency and effectiveness. A well-equipped toolkit not only facilitates the repair process but also ensures safety and precision in handling various components.

- Screwdrivers: Both flathead and Phillips types are necessary for removing and securing screws.

- Wrenches: A set of adjustable and socket wrenches will help in loosening and tightening nuts and bolts.

- Pliers: Needle-nose and standard pliers are useful for gripping, twisting, and cutting wires or small parts.

- Hex keys: Also known as Allen wrenches, these are essential for hexagonal screws and fasteners.

- Replacement parts: Ensure you have all the necessary components that may need replacing during the process.

- Cleaning supplies: Brushes, cloths, and appropriate solvents will help maintain cleanliness and functionality of parts.

Having these tools at hand will streamline the repair process, allowing for a more organized and successful maintenance experience.

Customer Reviews and Experiences

Understanding user feedback is crucial for assessing the quality and performance of outdoor power equipment. Customer reviews offer valuable insights into real-world experiences, helping potential buyers make informed decisions. This section highlights the thoughts and evaluations of users regarding their experiences with a specific model, emphasizing reliability, ease of use, and overall satisfaction.

| Review Date | Rating | Customer Comment |

|---|---|---|

| 2023-08-15 | 5/5 | This tool exceeded my expectations! It’s powerful and easy to maneuver. |

| 2023-09-10 | 4/5 | Great performance, but the weight can be a bit much during long sessions. |

| 2023-09-25 | 3/5 | Good for light tasks, but struggled with tougher jobs. Overall, decent value. |

| 2023-10-05 | 5/5 | I love how quiet it is! Perfect for residential areas. |

User experiences reveal a range of perspectives, showcasing both strengths and areas for improvement. Overall, the feedback reflects a positive reception, with many highlighting its efficiency and user-friendly design, while a few noted considerations for weight and power suitability.