Understanding the Stihl FS110 Parts Diagram for Optimal Maintenance

Maintaining any piece of machinery requires a solid understanding of how its various elements work together. Knowing the arrangement and relationship of individual pieces is crucial for both troubleshooting and regular upkeep. Having a visual representation can greatly enhance your ability to quickly identify specific sections and comprehend their functionality.

In this guide, we will explore a comprehensive breakdown of a popular model, focusing on the various components that make up its internal structure. Whether you’re addressing routine maintenance or tackling more complex mechanical issues, understanding the layout of the key elements is essential for efficient repair and replacement.

By diving deeper into the arrangement of each element, you will gain a clearer insight into how each segment operates in harmony with the rest of the unit. This knowledge not only saves time but ensures long-term reliability and smoother operation of the equipment.

Overview of Stihl FS110 Components

The machine in question is designed with a range of critical elements that ensure its efficient operation. Each individual part contributes to the overall functionality, durability, and performance, making it suitable for various tasks. Below, we explore the primary components and their roles in the machine’s design.

Engine Assembly

At the core of this model lies a powerful engine system. This component is responsible for delivering the necessary energy to drive the equipment, allowing it to handle demanding tasks with ease.

- Air filter – Ensures that clean air enters the engine, promoting longevity and performance.

- Fuel tank – Stores fuel for efficient energy transfer to the engine.

- Exhaust system – Manages the release of gases produced during operation, ensuring optimal airflow.

Handle and Control System

The control section includes ergonomically designed elements that allow for easy manipulation and precise control over the machine.

- Throttle – Adjusts the speed of the engine, providing smooth acceleration.

- Safety switch – Prevents accidental startups, enhancing operator safety.

- Grip handles – Offer comfort and reduce fatigue during prolonged use.

Understanding the Trimmer’s Main Parts

A well-maintained grass cutter is essential for efficient yard work. To get the most out of your equipment, it’s important to familiarize yourself with the primary components that ensure its smooth operation. Knowing the key sections of your trimmer will help you diagnose issues, perform maintenance, and extend its lifespan.

Power System

The power system is the engine of the trimmer, responsible for driving the cutting mechanism. Whether it’s a fuel-powered or electric model, this system includes the motor, fuel tank or battery, and other essential elements that generate power for the tool.

- Motor: The heart of the machine, converting energy into motion.

- Fuel Tank or Battery: Stores the energy source needed for operation.

- Starter: Engages the engine to initiate the process.

Cutting Assembly

The cutting assembly handles the actual trimming of grass or weeds. This part involves the cutting head and line, as well as the guard that protects the user from debris.

- Cutting Head: Holds the trimming line and spins to cut vegetation.

- Trimming Line: The replaceable line that cuts through grass and weeds.

- Guard: Shields the user from flying debris while the tool is in use.

Fuel System Components and Their Functions

The fuel system plays a crucial role in the operation of outdoor power equipment, ensuring that the engine receives the right mixture of fuel and air for optimal performance. Understanding the various components involved can enhance maintenance practices and improve efficiency.

| Component | Function |

|---|---|

| Fuel Tank | Stores the fuel necessary for the engine’s operation. |

| Fuel Line | Transports fuel from the tank to the carburetor. |

| Carburetor | Mixes fuel with air to create a combustible mixture. |

| Fuel Filter | Removes impurities from the fuel before it reaches the engine. |

| Purge Bulb | Helps prime the fuel system for easier starting. |

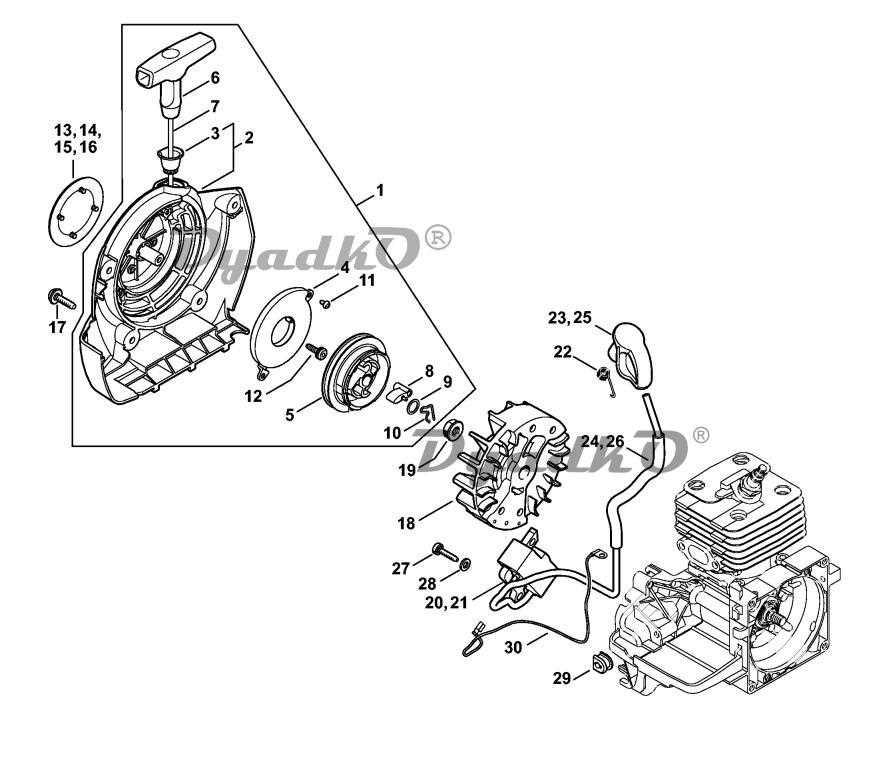

How the Ignition System Works

The ignition system is a crucial component in the functioning of small engines, playing a vital role in the combustion process. Its primary purpose is to create a spark that ignites the air-fuel mixture within the engine’s cylinder, enabling the engine to run efficiently. Understanding how this system operates can help in troubleshooting and maintaining optimal performance.

The ignition system is also equipped with various components such as the flywheel, which often contains magnets that help generate power for the ignition coil. Additionally, the electronic control module may regulate the timing and duration of the spark, ensuring that the engine runs smoothly under different conditions. Regular maintenance and inspection of these elements can prevent ignition-related issues and prolong the engine’s lifespan.

Gearbox and Drive Shaft Configuration

The configuration of the gearbox and drive shaft plays a crucial role in the performance and efficiency of outdoor power equipment. Understanding how these components interact can enhance functionality and longevity, ensuring optimal power transfer from the engine to the cutting tools.

Gearbox Overview

The gearbox is designed to manage torque and speed, allowing the operator to effectively control the equipment. Its construction typically features robust materials to withstand wear and tear, contributing to the overall durability of the system.

Drive Shaft Mechanics

The drive shaft serves as the link between the gearbox and the cutting apparatus, transmitting rotational energy. Proper alignment and maintenance of this component are essential for minimizing vibrations and maximizing performance.

| Component | Function |

|---|---|

| Gearbox | Regulates speed and torque |

| Drive Shaft | Transfers rotational energy |

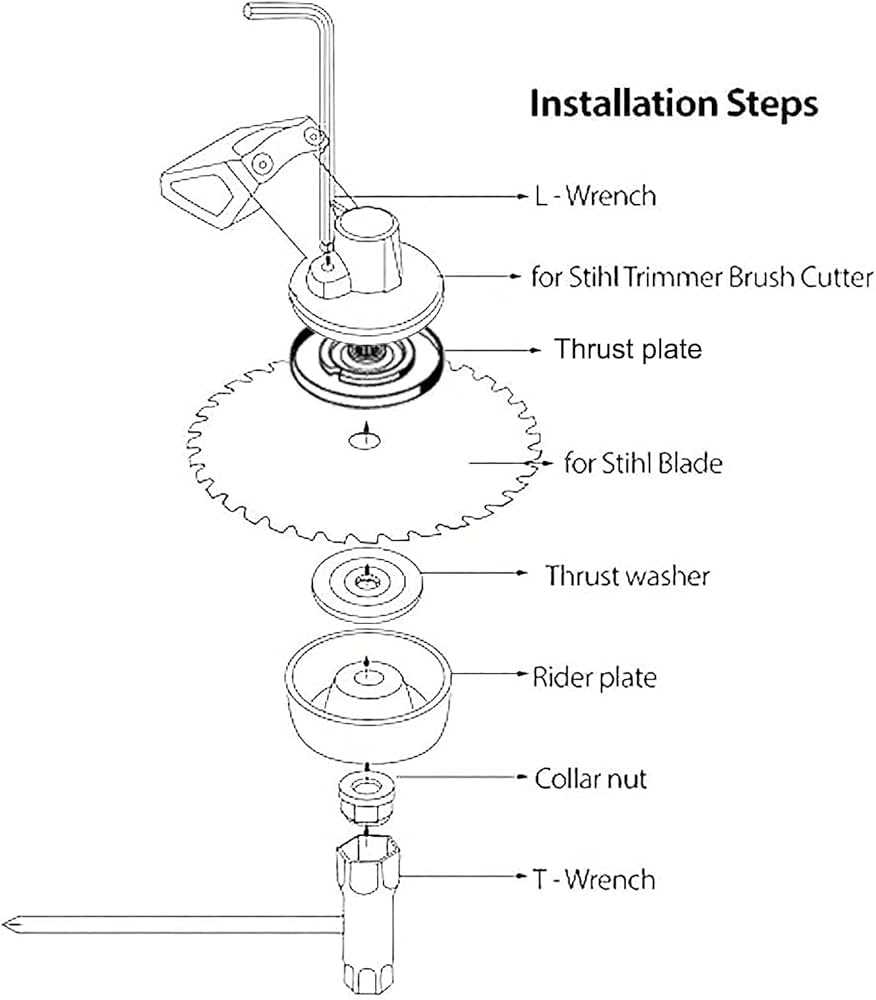

Examining the Cutting Attachment Mechanism

The cutting attachment mechanism is a crucial component that significantly impacts the performance and efficiency of outdoor power equipment. Understanding its structure and function allows users to optimize usage and maintenance for better results.

Key Components

- Cutting Head

- Drive Shaft

- Spool Assembly

- Blade Adapter

Functionality Overview

This mechanism operates through the transfer of power from the engine to the cutting tool, ensuring effective cutting action. Regular inspection and proper assembly are vital for maintaining optimal performance.

Handle and Control Layout Explained

The configuration of the handle and control system is essential for optimal operation and user comfort. A well-designed layout ensures that the operator can easily access various functions while maintaining a secure grip, which enhances both control and safety during use.

Grip Design: The ergonomic shape of the handle allows for a natural hand position, reducing fatigue during extended use. This design promotes better leverage and control, making it easier to maneuver the tool.

Control Placement: Strategically located controls enable quick adjustments and responses to changing conditions. Common controls include throttle, stop, and start functions, which are intuitively placed for accessibility.

Safety Features: Integrated safety mechanisms are crucial in preventing accidental activation. Features such as a safety lock or a trigger interlock ensure that the device operates only when intended, providing peace of mind for the user.

Understanding the handle and control layout is vital for maximizing efficiency and safety during operation. Proper familiarity with these components can lead to a more enjoyable experience while achieving the ultimate performance from the tool.

Air Filter and Engine Protection

The maintenance of a clean air filtration system is crucial for ensuring optimal performance and longevity of any power equipment. A well-functioning filter prevents debris and contaminants from entering the combustion chamber, thereby enhancing efficiency and reducing wear on internal components.

Regular inspection and replacement of the air filtration unit are essential practices for maintaining engine health. Failure to address air quality can lead to diminished performance, increased fuel consumption, and potential damage to the engine. By prioritizing this aspect of maintenance, users can ultimately ensure smoother operation and reliability.

In addition to filtration, engine protection features contribute significantly to safeguarding the machinery against overheating and excessive strain. These elements work together to create an effective barrier, promoting a longer lifespan and more reliable service. Regular checks and timely interventions are vital for achieving peak operational standards.

Throttle Cable and Carburetor Linkage

The throttle cable and carburetor linkage are vital components in the operation of outdoor power equipment. They ensure proper communication between the operator’s controls and the engine’s fuel delivery system. A well-functioning linkage allows for precise adjustments in power output, contributing to efficiency and performance during use.

Understanding the configuration and function of these elements is essential for maintenance and troubleshooting. A malfunctioning cable can lead to improper throttle response, while a misaligned linkage may affect the air-fuel mixture, resulting in poor engine performance.

| Component | Function | Common Issues |

|---|---|---|

| Throttle Cable | Transmits operator input to the throttle mechanism. | Wear and tear, fraying, or breaking. |

| Carburetor Linkage | Connects the throttle control to the carburetor for fuel regulation. | Misalignment, stiffness, or detachment. |

Regular inspection of these components can prevent operational issues and enhance the longevity of the equipment. Proper adjustments and replacements should be carried out as necessary to maintain optimal functionality.

Vibration Dampening System Overview

The vibration dampening mechanism is a crucial feature designed to enhance user comfort and tool performance. By minimizing the transmission of vibrations from the engine and cutting apparatus to the operator, it not only improves handling but also reduces fatigue during extended use. This system is vital for maintaining efficiency and ensuring safety in various applications.

Functionality and Benefits

The primary function of the vibration dampening system is to absorb and dissipate oscillations that occur during operation. By utilizing specialized components, this system effectively isolates the user from disruptive vibrations. This leads to several benefits: improved control, reduced physical strain, and enhanced overall productivity. Users can focus on their tasks without the distraction of excessive vibration, allowing for more precise operation.

Components of the System

The dampening assembly typically consists of a combination of springs, rubber mounts, and other shock-absorbing materials. Each component plays a significant role in enhancing the system’s effectiveness. Springs provide flexibility, while rubber elements add an additional layer of cushioning. Together, these parts work to create a more comfortable working experience, significantly reducing the impact of vibrations on the operator.

Starter Assembly and Recoil Mechanism

The starter assembly is a crucial component of many outdoor power tools, facilitating the initial ignition of the engine. It typically consists of a recoil mechanism that enables smooth operation and reliable performance. Understanding this assembly is essential for maintenance and troubleshooting.

The recoil mechanism functions by storing energy in a spring when the starter cord is pulled. Upon release, the energy is transferred to the engine, allowing it to start effectively. This mechanism is designed to provide a quick and efficient start, reducing the effort required by the user.

Common issues with this assembly include a stuck or broken recoil spring, which can prevent the engine from starting. Regular inspection and maintenance of the starter assembly can help ensure that the mechanism operates smoothly, prolonging the life of the equipment. Keeping the cord in good condition and free from wear is also vital for optimal performance.

For effective repair or replacement, it is important to understand the specific components involved in the starter assembly. Familiarity with parts such as the pulley, spring, and housing can assist users in making informed decisions when addressing any issues that arise.

Clutch and Transmission Structure

The clutch and transmission assembly plays a crucial role in the overall functionality of power equipment. This system ensures that power generated by the engine is efficiently transferred to the cutting tools, enabling optimal performance and control.

- Clutch Mechanism: The clutch acts as a connection point that engages and disengages the engine power.

- Components:

- Clutch shoes

- Spring mechanism

- Drum assembly

- Functionality: When the engine reaches a specific RPM, the clutch engages, allowing the cutting attachment to spin.

The transmission, on the other hand, is responsible for modulating the speed and torque delivered to the cutting equipment. Its design influences efficiency and adaptability to different working conditions.

- Transmission Types:

- Gear-driven systems

- V-belt systems

- Key Features:

- Torque conversion

- Speed adjustments

- Durability under load

Understanding the intricate design of the clutch and transmission is essential for maintenance and enhancing the machine’s performance.

Common Replacement Parts for FS110

Regular maintenance and timely replacements are essential for ensuring optimal performance of your outdoor equipment. Understanding the frequently needed components can help users keep their machines running smoothly and efficiently.

Fuel Filter: This essential element helps maintain clean fuel flow, preventing debris from entering the engine. Replacing it periodically can enhance longevity.

Air Filter: A clean air filter is crucial for efficient airflow, directly impacting performance. Regular checks and replacements will aid in maintaining power and fuel efficiency.

Spark Plug: This component ignites the fuel-air mixture. Over time, it can wear out, leading to starting issues or poor performance. Regular changes are recommended.

Trimmer Line: As one of the most frequently used items, the cutting line should be replaced regularly to ensure effective trimming. Different diameters and types are available for various tasks.

Blades: When tackling tougher vegetation, sharp and appropriate blades are essential. Dull blades can hinder efficiency and may require frequent replacement.

Throttle Cable: This cable connects the throttle trigger to the engine, ensuring responsive operation. A frayed or damaged cable can affect control and should be replaced promptly.

By keeping an eye on these critical components, users can significantly enhance the reliability and efficiency of their equipment, ensuring it remains in peak condition.