Understanding the Stihl FS111RX Parts Diagram for Efficient Maintenance

Maintaining optimal performance in your gardening equipment requires a clear understanding of its individual elements. Each part plays a crucial role in ensuring the machine operates efficiently, contributing to its overall longevity and effectiveness. By familiarizing yourself with the components, you can better address any issues that may arise during use.

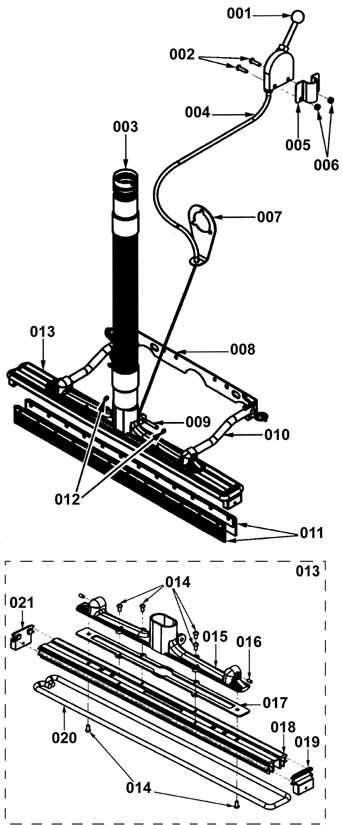

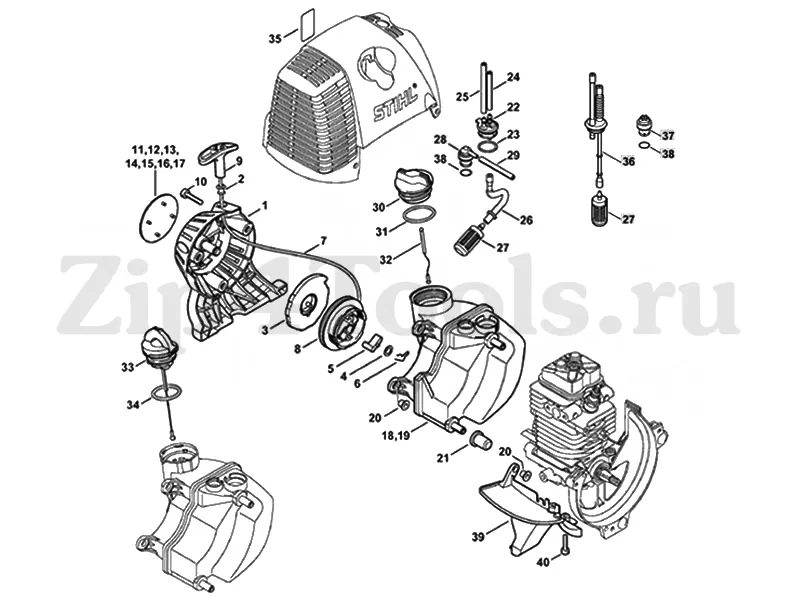

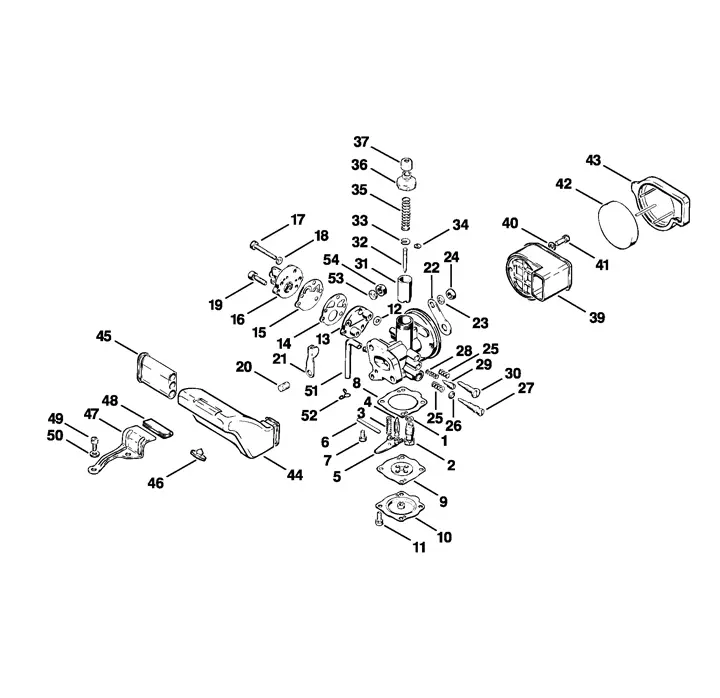

Visualizing the assembly of your equipment can be immensely helpful. A detailed illustration showcasing the various sections and their functions provides valuable insight into how everything fits together. This knowledge not only aids in troubleshooting but also enhances your ability to perform maintenance tasks with confidence.

Whether you’re a seasoned user or new to this type of machinery, having a comprehensive view of the inner workings will empower you. Understanding how each part interacts and supports the overall function can lead to more informed decisions regarding repairs and upgrades, ensuring your tools remain reliable and efficient.

Understanding the Stihl FS111RX

This section aims to provide insight into a specific type of outdoor power equipment designed for efficient lawn maintenance and landscaping tasks. It is essential to recognize the various components and their functions, as this knowledge can enhance the user experience and prolong the lifespan of the tool.

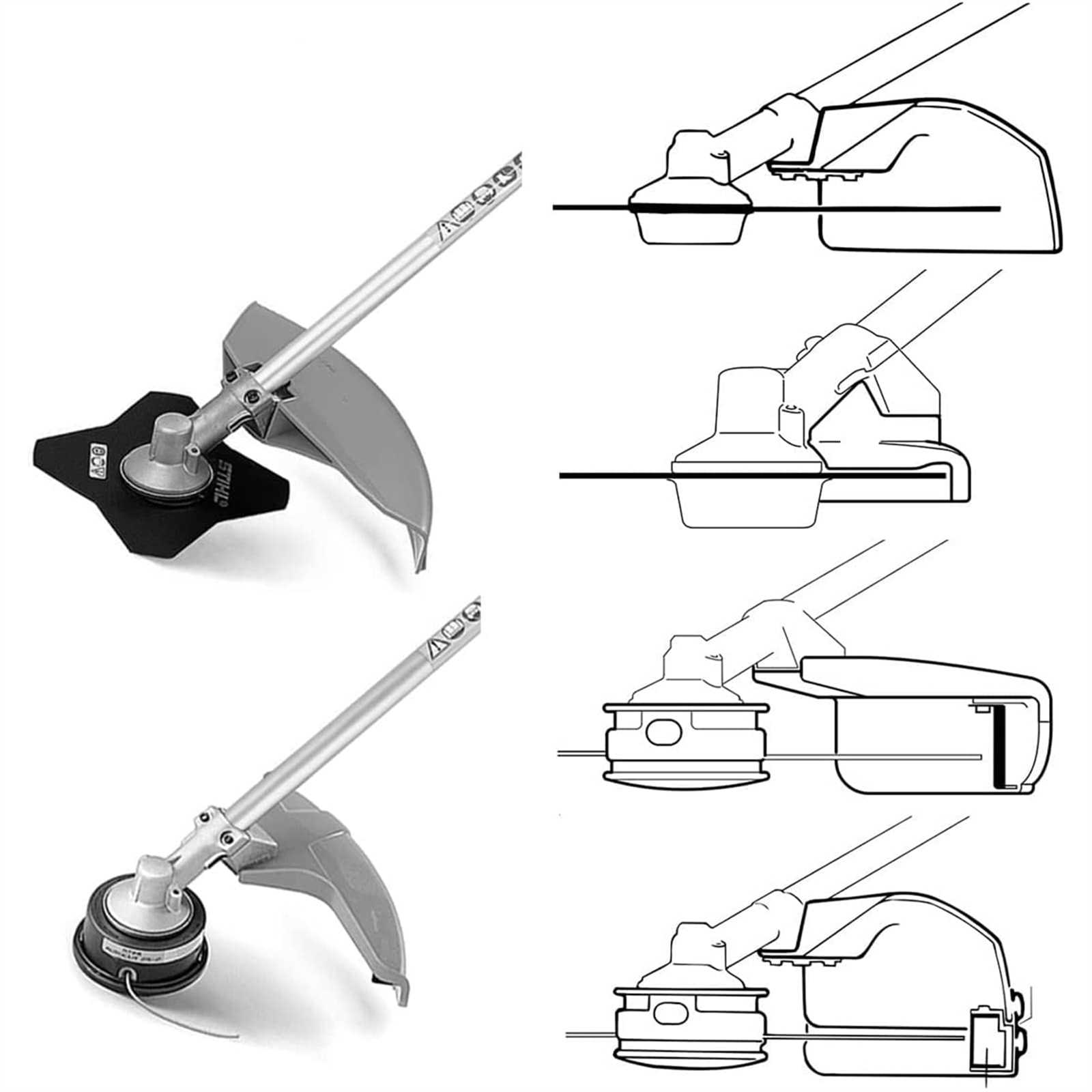

Key Features: The machine is equipped with a powerful engine that ensures robust performance in various conditions. Its ergonomic design allows for comfortable handling, minimizing user fatigue during extended use. Additionally, the versatility of attachments enables a wide range of applications, from trimming to edging.

Maintenance Tips: Regular upkeep is crucial for optimal operation. Users should familiarize themselves with the main components to ensure proper servicing. This includes checking the fuel system, air filter, and cutting tools, all of which play a vital role in maintaining efficiency and effectiveness.

Understanding the intricate details of this equipment can significantly improve its performance and durability. By investing time in learning about its features and maintenance requirements, users can maximize their investment and achieve outstanding results in their outdoor projects.

Key Features of the FS111RX

This model is designed for professionals who demand power and efficiency in their outdoor equipment. Its robust engine and ergonomic design make it a top choice for tackling tough landscaping tasks, providing a perfect balance of performance and comfort for extended use.

Powerful Engine

The high-performance engine offers exceptional torque and speed, ensuring that even the most challenging jobs can be completed swiftly. With a fuel-efficient design, users benefit from longer run times without frequent refueling, enhancing productivity on the job.

User-Friendly Design

The ergonomic features include a lightweight frame and adjustable handles, allowing for easy maneuverability and reduced operator fatigue. Coupled with a vibration-reducing system, this equipment ensures a comfortable experience during prolonged use, making it suitable for both professional landscapers and enthusiastic gardeners.

Importance of Parts Diagrams

Understanding the layout and components of any machinery is crucial for effective maintenance and repair. Visual representations of the various elements provide clear insights into how everything fits together, ensuring that users can address issues efficiently.

Here are some key reasons why these visual guides are essential:

- Clarity: They offer a straightforward way to identify each element, making it easier to understand the structure and function of the machine.

- Efficiency: Quick reference aids in speeding up repair processes, as users can quickly locate the necessary components.

- Reduced Errors: By clearly showing how parts interact, the likelihood of mistakes during reassembly or repair is minimized.

- Cost-Effectiveness: Proper identification and handling of components can prevent unnecessary expenses related to misdiagnosis or incorrect part orders.

- Improved Knowledge: Familiarity with the layout enhances a user’s overall understanding of the equipment, fostering better care and longevity.

In summary, these visual tools are not just helpful; they are indispensable for anyone looking to maintain and service their equipment effectively.

Common Parts for Stihl FS111RX

Understanding the essential components of a cutting tool is crucial for its efficient operation and maintenance. This section will delve into the frequently utilized elements that contribute to the performance and longevity of your equipment. Familiarity with these items ensures you can easily identify, replace, or maintain them when necessary.

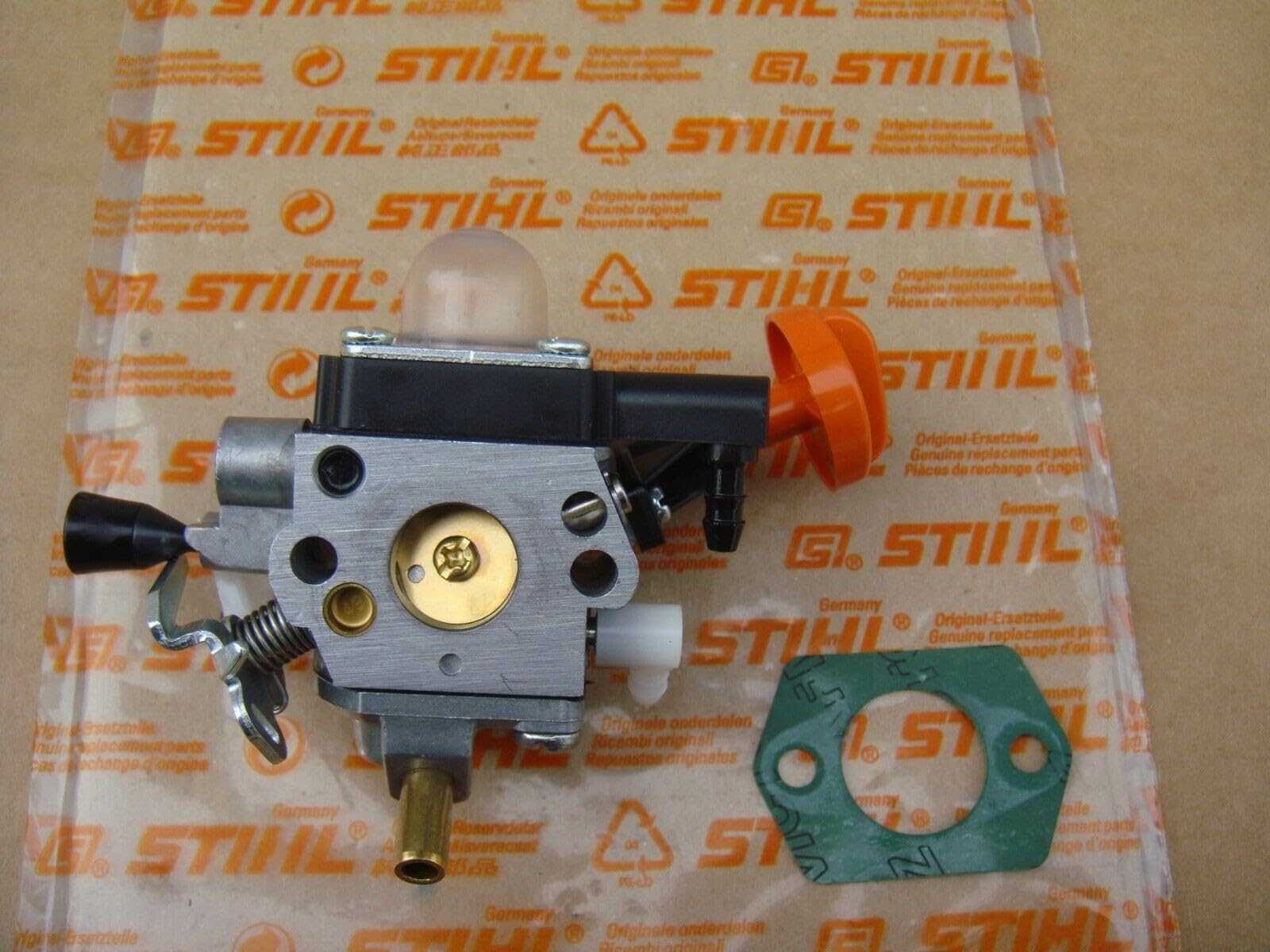

Engine Components

The heart of the machine lies in its engine, where the ignition system and fuel delivery mechanisms play pivotal roles. Key elements such as spark plugs and carburetors are vital for starting and running the engine smoothly. Regular inspection and replacement of these components can prevent operational issues and enhance efficiency.

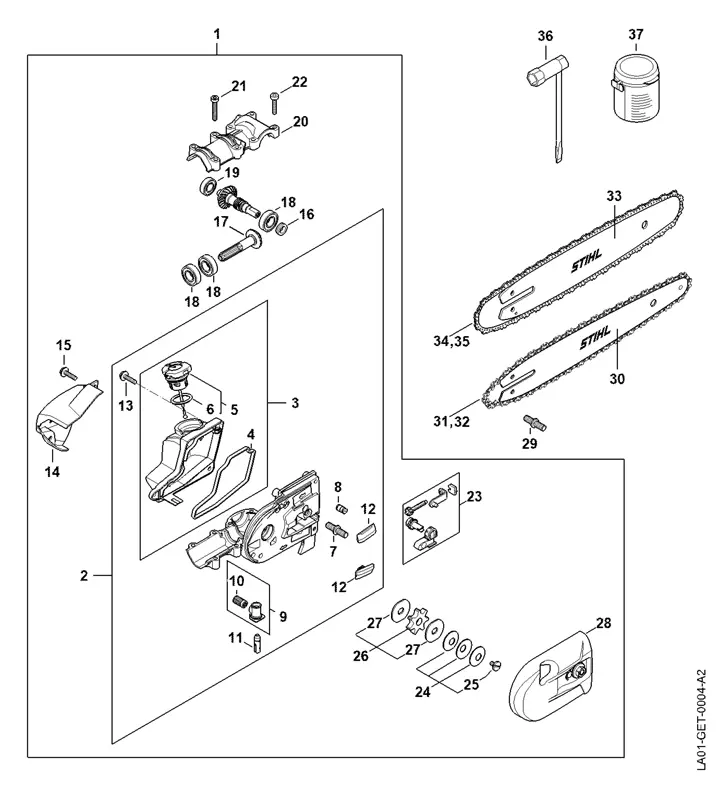

Cutting Equipment

The cutting head and associated attachments are fundamental to the tool’s functionality. Blades and trimmer lines are designed for various tasks, ensuring versatility. Choosing the right type and maintaining these elements will significantly impact the effectiveness of your work and the quality of the results.

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repairs. These visual aids provide a detailed overview of how various elements are arranged and interact with one another, facilitating easier identification and replacement of specific parts. Mastering the ability to interpret these illustrations can save time and reduce frustration during troubleshooting.

Familiarize Yourself with the Legend: Most illustrations will include a legend or key that explains symbols and numbers. This section is crucial, as it clarifies what each symbol represents, helping you to quickly locate the components you need.

Identify the Main Components: Begin by identifying the primary sections of the visual representation. Focus on the larger assemblies before diving into the smaller parts. This will provide a clearer understanding of how everything fits together.

Follow the Connections: Pay attention to how components are connected. Arrows and lines often indicate relationships and pathways, guiding you through the assembly. Understanding these connections is vital for disassembly and reassembly.

Check Part Numbers: Each item usually has a corresponding number or code. Use these references to find specific components in catalogs or stores. Accurate identification ensures you purchase the correct replacements.

Take Notes: While studying the illustration, jot down any observations or questions. This practice can help clarify your thoughts and guide your next steps during repairs.

By following these guidelines, you can confidently navigate a visual representation of components, making the maintenance process more efficient and straightforward.

Maintenance Tips for Your Trimmer

Regular upkeep of your grass cutting tool is essential for ensuring optimal performance and longevity. By implementing a consistent maintenance routine, you can avoid common issues and enhance the efficiency of your device. Below are some practical tips to help you keep your trimmer in top shape.

- Clean After Use: Always remove grass clippings and debris after each use. This prevents buildup that can affect performance.

- Inspect Cutting Head: Regularly check the cutting head for wear and tear. Replace any damaged components promptly to maintain cutting efficiency.

- Check Fuel Mixture: Ensure that the fuel mixture is correct. A poor fuel mix can lead to engine problems and reduced performance.

Additionally, consider the following maintenance practices:

- Change the air filter periodically to ensure optimal airflow to the engine.

- Sharpen or replace the cutting line as needed to maintain a clean cut.

- Inspect and tighten screws and bolts regularly to prevent any loose components during operation.

- Store the trimmer in a dry place to prevent rust and damage from moisture.

By following these maintenance tips, you can enhance the reliability and effectiveness of your trimming equipment, ensuring it serves you well for many seasons to come.

Finding Replacement Parts Easily

Locating suitable components for your outdoor equipment can often seem daunting. However, with the right approach and resources, you can simplify the process and ensure that your machinery remains in optimal condition. Understanding where to look and how to identify the right items is key to maintaining efficiency.

Utilizing Online Resources

In today’s digital age, numerous websites specialize in providing detailed information on various tools and machinery. These platforms often feature comprehensive catalogs, allowing you to search for specific items based on model numbers or descriptions. Forums and community groups can also be invaluable, as fellow enthusiasts frequently share their experiences and recommendations for sourcing specific components.

Local Retailers and Service Centers

Another effective method is to visit local retailers or authorized service centers. These establishments typically stock a variety of components and can offer personalized advice. Speaking directly with knowledgeable staff can also help you find the correct items quickly, as they can assist in identifying the necessary specifications. Networking with professionals in the industry can further enhance your search, leading to quicker resolutions and reliable purchases.

Comparing OEM vs. Aftermarket Parts

When it comes to maintaining and repairing equipment, the choice between original manufacturer components and alternative options is crucial. Each category offers distinct advantages and drawbacks that can significantly impact performance, longevity, and overall user experience. Understanding these differences helps users make informed decisions tailored to their specific needs.

Advantages of Original Manufacturer Components

Original manufacturer components are designed specifically for compatibility and performance. They often come with a guarantee of quality, ensuring that each item meets strict manufacturing standards. This can result in enhanced durability and optimal functionality, reducing the likelihood of failures and subsequent repairs. Additionally, using these components may help maintain warranty coverage, providing peace of mind for the user.

Benefits of Alternative Options

On the other hand, alternative options typically present a cost-effective solution for those looking to save money. Many of these components can offer comparable performance at a fraction of the price. Furthermore, a wider variety of choices allows users to select items that may not be available through the original manufacturer, catering to unique needs or preferences. However, it’s important to conduct thorough research on the quality and reliability of these alternatives to avoid potential issues down the line.

Troubleshooting Common Issues

When operating outdoor power equipment, encountering problems can be frustrating. Understanding common challenges and their solutions is essential for maintaining optimal performance. This section aims to provide insights into frequent malfunctions and practical steps to resolve them, ensuring efficient and effective use of your machine.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Engine Won’t Start | Fuel issues, spark plug failure, air filter blockage | Check fuel quality, replace the spark plug, clean or replace the air filter |

| Uneven Cutting | Dull blade, incorrect cutting height, debris build-up | Sharpen or replace the blade, adjust cutting height, clear debris |

| Overheating | Lack of lubrication, clogged vents, prolonged use | Ensure proper oil levels, clean cooling vents, allow cool-down periods |

| Excessive Vibration | Loose components, damaged parts, unbalanced blade | Tighten all fasteners, inspect for damage, balance the blade |

| Fuel Leaks | Worn seals, loose connections, damaged fuel lines | Inspect and replace seals, tighten connections, replace fuel lines |

By systematically addressing these common issues, you can enhance the reliability and lifespan of your equipment. Regular maintenance and timely repairs are key to preventing future problems and ensuring smooth operation.

Upgrading Components for Better Performance

Enhancing the efficiency of your equipment can significantly improve its functionality and longevity. By focusing on specific components, users can achieve better power output, increased durability, and enhanced overall performance. This section explores various upgrades that can make a tangible difference in how your machinery operates.

Key Components to Consider for Upgrades

- Engine Enhancements: Upgrading the engine can lead to better fuel efficiency and increased torque.

- Cutting Tools: Utilizing higher-quality cutting implements can result in cleaner cuts and reduced wear.

- Air Filters: Opting for advanced air filtration systems improves airflow, enhancing engine performance.

- Fuel System: Upgrading the fuel lines and injectors can optimize combustion, leading to better power output.

Benefits of Component Upgrades

- Increased Efficiency: Well-matched components work together more effectively, boosting overall productivity.

- Cost Savings: Investing in quality upgrades often reduces maintenance costs over time.

- Enhanced Safety: Upgraded parts can minimize the risk of malfunction, ensuring safer operation.

- Extended Lifespan: High-quality components typically last longer, providing better value for your investment.