Understanding the Stihl FS240R Parts Diagram for Efficient Maintenance

When it comes to maintaining and optimizing your outdoor machinery, having a clear visual representation of its elements is essential. Such illustrations serve as valuable guides, enabling users to identify and understand the various parts that contribute to the overall functionality of their tools. This knowledge not only aids in effective repairs but also enhances the lifespan of the equipment.

By examining the intricate layout of each component, operators can gain insights into how different sections interact with one another. Recognizing the role of each part helps in troubleshooting issues that may arise during use. Furthermore, familiarizing oneself with these details fosters a deeper appreciation for the engineering behind such powerful machines.

In this section, we will delve into the specifics of the component arrangement for a popular model. This exploration will highlight essential features, guiding users in their maintenance efforts and ensuring they have the right information at their fingertips when needed. With a comprehensive understanding, anyone can tackle repairs with confidence.

Understanding Stihl FS240R Parts

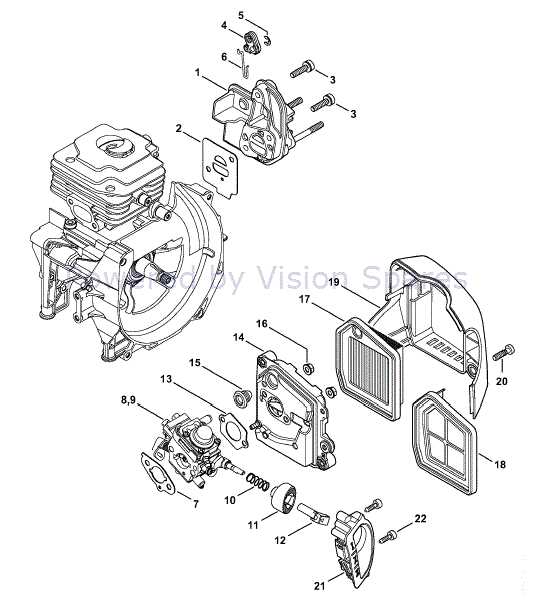

When working with a specific model of outdoor power equipment, comprehending its components is essential for effective maintenance and operation. Each element plays a crucial role in the overall functionality, and knowing their purpose can enhance both performance and longevity. This section delves into the various elements of this particular machine, offering insight into their functions and interconnections.

Key Components Overview

The main segments of the equipment include the engine assembly, cutting head, and the handlebar system. Each part is designed to work in harmony, ensuring smooth operation. Regular inspection and understanding of these components can prevent malfunctions and enhance the user experience.

Essential Features Table

| Component | Description |

|---|---|

| Engine Assembly | Drives the entire system, providing the necessary power for operation. |

| Cutting Head | Utilizes different attachments for various cutting tasks, ensuring versatility. |

| Handlebar System | Offers stability and control, enhancing user comfort during operation. |

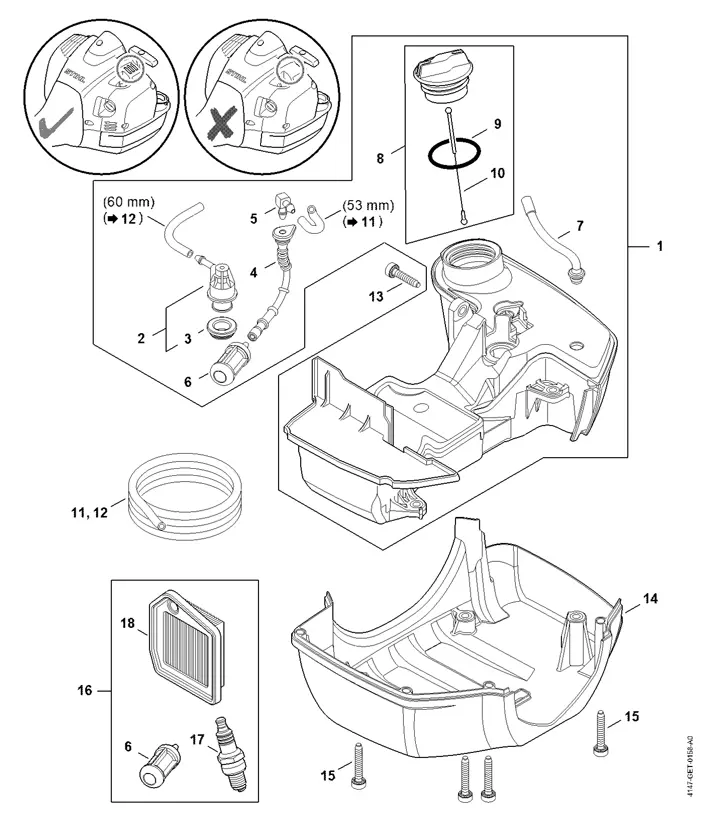

| Fuel Tank | Stores the fuel required for the engine, designed for easy refueling. |

| Throttle Control | Regulates the engine speed, allowing for precision in different tasks. |

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations of individual elements serve as invaluable resources for technicians and hobbyists alike. These illustrations not only enhance comprehension of how each piece fits together but also streamline the troubleshooting process.

When attempting to diagnose issues, having a clear visual reference can significantly reduce the time spent on identifying faulty components. Additionally, these visual aids facilitate ordering replacements, ensuring that the correct items are sourced quickly. This efficiency ultimately leads to reduced downtime and enhanced performance of the equipment.

Furthermore, detailed schematics can assist in the assembly process, guiding users through each step with precision. They can also foster a deeper understanding of the machinery’s functionality, empowering users to carry out more informed maintenance practices. Overall, these illustrations play a critical role in the lifecycle of equipment, promoting longevity and reliability.

Common Issues with FS240R Components

When operating outdoor power equipment, certain challenges can arise from various components. Understanding these issues is essential for maintaining efficiency and ensuring longevity. Below are some prevalent problems encountered with these tools and their respective elements.

Frequent Problems

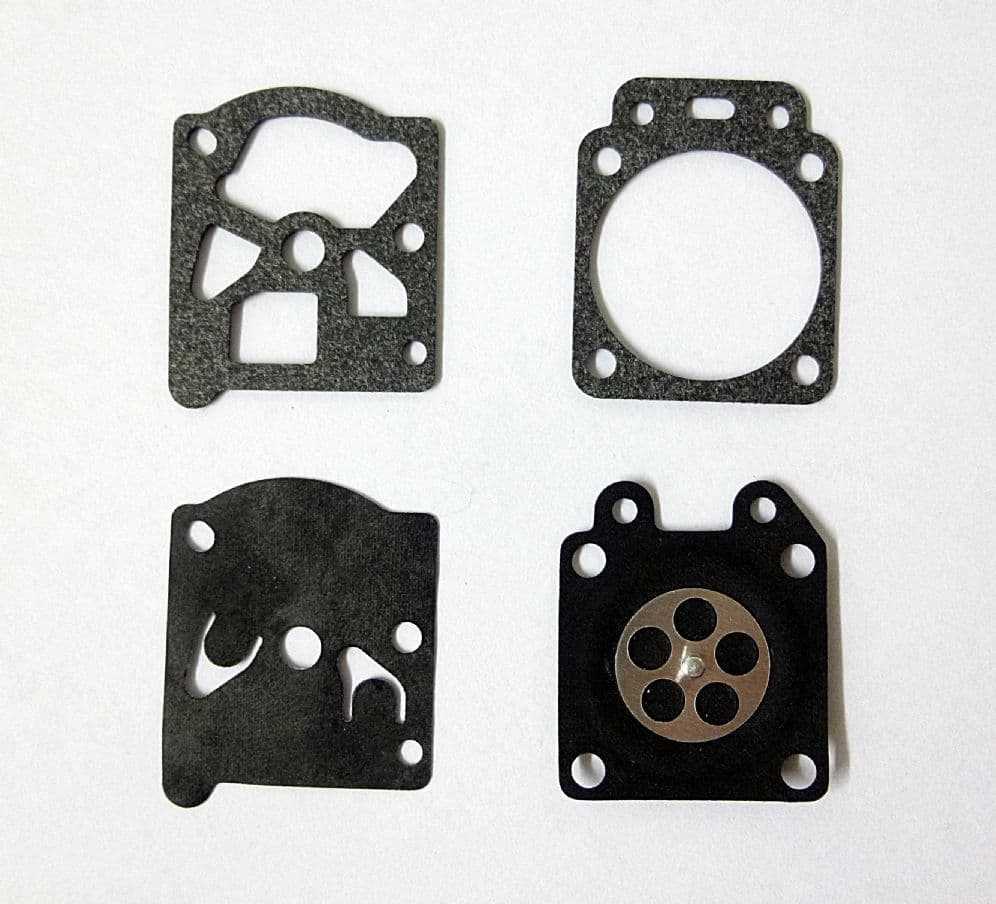

- Fuel System Issues: Clogs in the fuel line or carburetor can lead to poor performance.

- Ignition Failures: A malfunctioning spark plug may prevent the engine from starting.

- Wear and Tear: Regular use can cause components like trimmer heads to wear down, affecting cutting efficiency.

- Vibration Problems: Loose bolts or damaged mounts can lead to excessive vibration, impacting operator comfort and precision.

Maintenance Tips

- Regularly inspect and clean the fuel system to prevent clogs.

- Replace the spark plug annually to ensure reliable ignition.

- Check all components for wear and replace them as needed.

- Tighten any loose screws or bolts to reduce vibration during operation.

Addressing these common issues promptly can significantly enhance the performance and lifespan of your equipment, making regular maintenance a worthwhile investment.

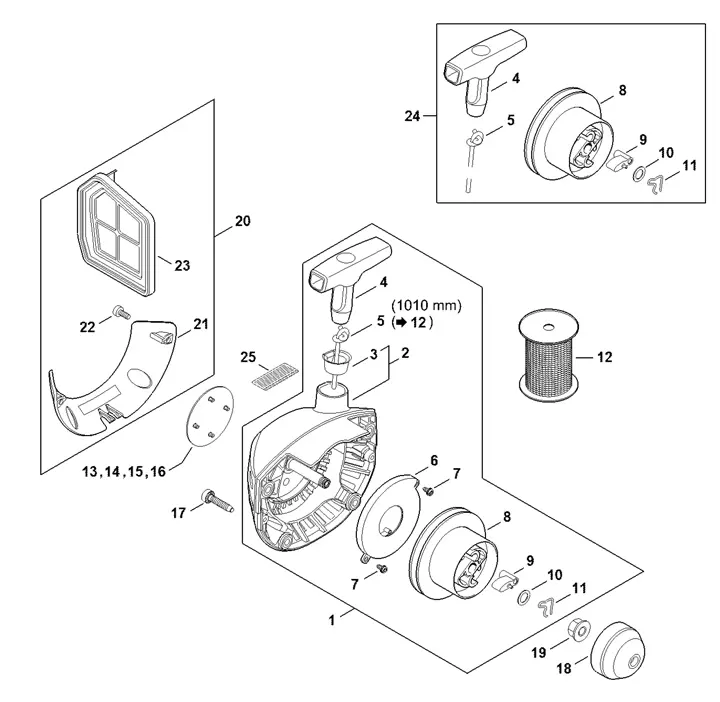

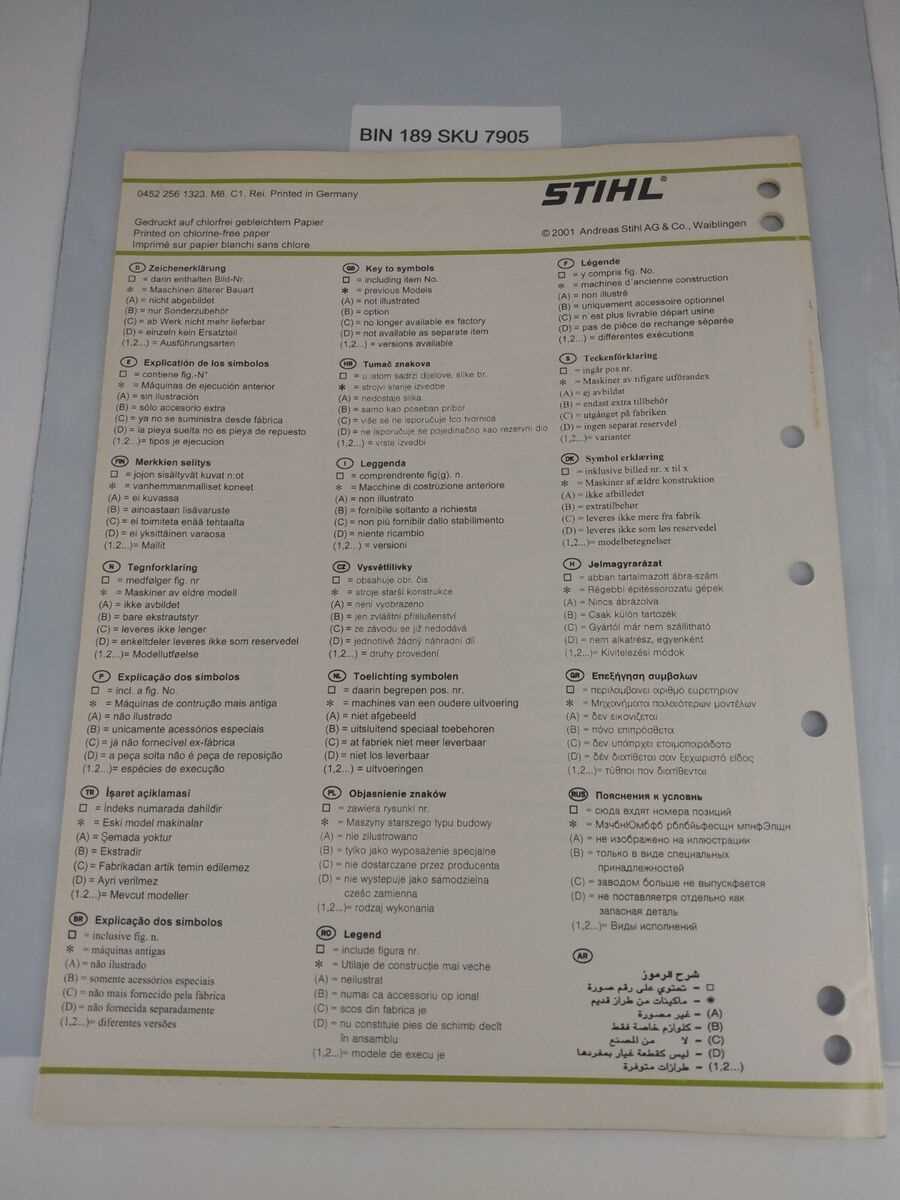

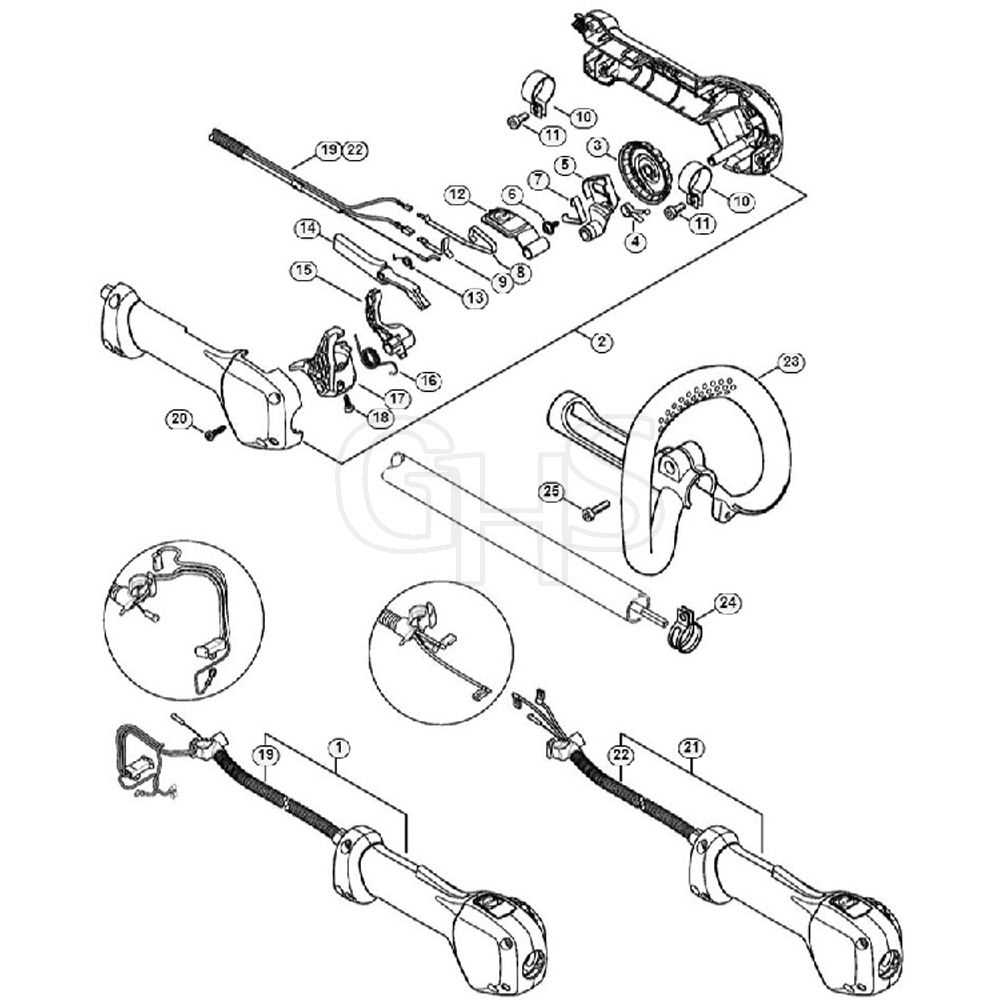

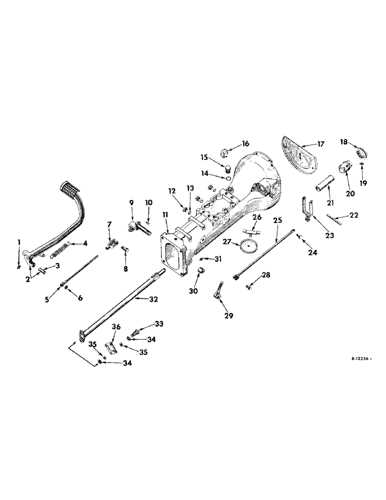

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. Such visual aids provide a comprehensive view of how each element interacts within a machine, allowing users to identify individual pieces and their functions. Familiarizing yourself with this type of illustration can enhance your troubleshooting skills and streamline the replacement process.

Identifying Components

Each item in the illustration is typically labeled with a unique identifier, often a number or letter. This allows for easy reference to accompanying lists or catalogs where detailed specifications can be found. Pay attention to the layout; components are often grouped by function or location, which aids in visualizing the assembly.

Understanding Relationships

The spatial arrangement of items is just as important as their labels. Lines or arrows may indicate connections or the flow of movement between parts. Recognizing these relationships helps in understanding how the assembly operates as a whole. Take note of any annotations that provide additional information about assembly, maintenance, or specific warnings.

By mastering the interpretation of these visuals, you will improve your ability to effectively manage repairs and enhance the longevity of your equipment.

Essential Tools for Repair

When it comes to maintaining and fixing outdoor equipment, having the right instruments is crucial. Proper tools not only facilitate the repair process but also ensure that the work is done efficiently and effectively. Below is a list of essential items that can help you tackle various maintenance tasks with confidence.

Basic Hand Tools

- Wrenches: Adjustable and socket wrenches for loosening and tightening bolts.

- Screwdrivers: A set of both flathead and Phillips screwdrivers for different types of screws.

- Pliers: Needle-nose and slip-joint pliers for gripping and manipulating components.

- Hex Keys: Also known as Allen wrenches, useful for hexagonal socket screws.

Specialized Instruments

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

- Feeler Gauges: Used for measuring gap widths and ensuring precision in adjustments.

- Multimeter: Essential for diagnosing electrical issues and testing continuity.

- Chain Breaker: Specifically designed for repairing and maintaining chains.

Equipping yourself with these tools will not only streamline your repair process but also extend the life of your equipment, ensuring optimal performance in the long run.

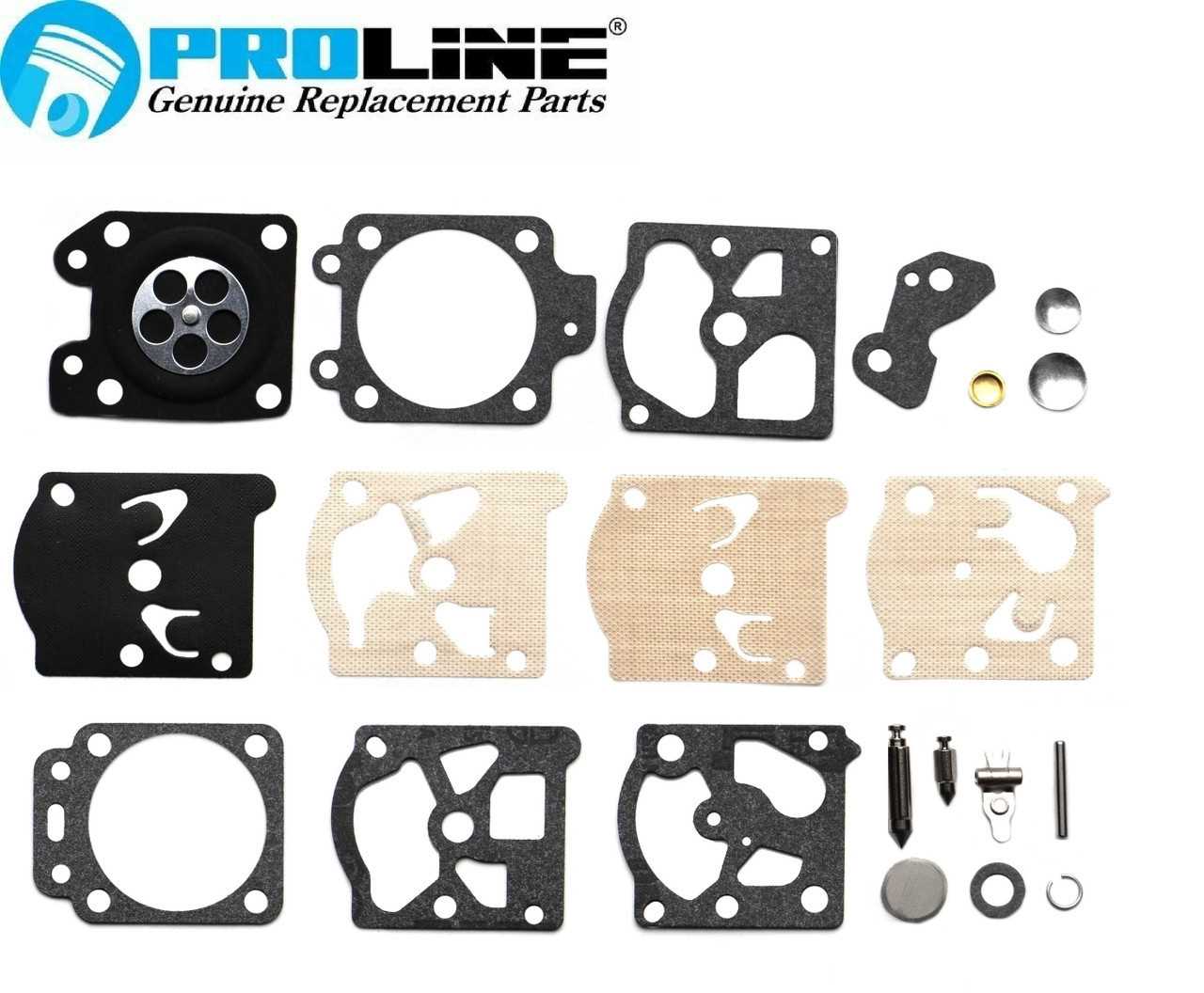

Identifying Genuine Stihl Parts

Ensuring the authenticity of components is crucial for optimal performance and longevity of your equipment. Recognizing legitimate items can save you from potential issues caused by substandard alternatives. It’s essential to be aware of specific features that distinguish authentic products from imitations.

Examine the Packaging: Genuine items typically come in high-quality packaging with clear branding. Look for consistent logos, clear fonts, and detailed information about the manufacturer.

Check for Serial Numbers: Authentic components often have unique serial numbers. Verify these against the manufacturer’s database to confirm legitimacy.

Material Quality: Real items are made from durable materials designed to withstand rigorous use. Inspect the texture and weight; inferior replicas may feel lighter or flimsier.

Purchase from Authorized Dealers: Always buy from recognized retailers or directly from the manufacturer. This greatly reduces the risk of acquiring counterfeit goods.

Consult Documentation: Review the equipment’s manual for references to authorized components. This ensures compatibility and reliability, further solidifying the importance of using verified items.

By following these guidelines, you can confidently select authentic components that enhance the performance and durability of your equipment.

Step-by-Step Repair Guide

This guide provides a systematic approach to restoring your outdoor power equipment. By following these detailed instructions, you can efficiently identify and address common issues, ensuring optimal performance and longevity of your machine.

Step 1: Preparation

Before starting any repair, gather all necessary tools and replacement components. Ensure that you work in a well-lit, organized space to facilitate the process. Always wear appropriate safety gear to protect yourself from potential hazards.

Step 2: Disassembly

Begin by carefully disassembling the unit. Take note of the arrangement of parts by labeling or taking pictures. This will simplify reassembly later. Use the correct tools to avoid damaging any components.

Step 3: Inspection

Examine each part for wear and tear. Look for cracks, corrosion, or other signs of damage. Replace any faulty components as needed. Regular inspection can prevent future breakdowns and improve efficiency.

Step 4: Cleaning

Thoroughly clean all parts using appropriate cleaning agents. Removing dirt and debris will enhance performance and prolong the life of the equipment. Pay special attention to air filters and fuel lines, as these are critical for functionality.

Step 5: Reassembly

Carefully reassemble the unit, ensuring that each component is correctly positioned and securely fastened. Refer to your earlier notes or images to maintain the original configuration. Double-check that all connections are tight.

Step 6: Testing

Once reassembled, test the equipment to ensure it operates correctly. Monitor for unusual noises or performance issues. If any problems arise, revisit the previous steps to troubleshoot further.

Conclusion

By following these steps, you can effectively maintain and repair your outdoor power equipment. Regular upkeep not only enhances performance but also extends the lifespan of your tools.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring that your equipment operates efficiently and remains in peak condition for years to come. By following a few simple guidelines, you can significantly extend the life of your machinery while maintaining optimal performance.

Routine Inspections

- Check for wear and tear on components before each use.

- Ensure all fasteners are secure and free from rust.

- Inspect fuel lines and filters for any blockages or leaks.

Proper Cleaning

- Clean the exterior after every use to prevent dirt buildup.

- Remove debris from air intakes and cooling fins to enhance airflow.

- Use a soft brush or compressed air to clear out any dust from intricate parts.

By incorporating these maintenance practices into your routine, you can help ensure that your equipment remains reliable and effective throughout its lifespan.

Where to Buy Replacement Parts

Finding reliable sources for obtaining components for your equipment is essential for maintaining its performance and longevity. With numerous options available, it’s important to know where to look to ensure you receive quality items that meet your needs.

Authorized Dealers

One of the most trustworthy places to find necessary components is through authorized dealers. These locations typically offer a wide range of original items and have knowledgeable staff who can assist with your inquiries. Purchasing from these dealers guarantees authenticity and compatibility with your machine.

Online Retailers

The internet provides a vast marketplace for purchasing equipment essentials. Numerous online platforms specialize in providing high-quality components, often at competitive prices. When shopping online, ensure to read reviews and check the credibility of the seller to avoid counterfeit products.

Local Repair Shops are also valuable resources, as they often stock essential components and can provide expert advice on installation and maintenance. Whether you choose a dealer, an online store, or a local repair shop, always prioritize quality to keep your equipment running smoothly.

Online Resources for Stihl Users

For enthusiasts and professionals alike, the availability of digital tools and platforms can significantly enhance the experience of using outdoor equipment. Access to reliable information, community forums, and instructional materials can empower users to maintain their tools effectively, troubleshoot issues, and improve their overall skills.

Below are some valuable online resources that cater to the needs of users:

| Resource Type | Description |

|---|---|

| Manufacturer’s Website | The official site offers comprehensive information, including manuals, safety guides, and updates on new models. |

| Online Forums | Dedicated platforms where users can share experiences, ask questions, and get advice from fellow enthusiasts. |

| Video Tutorials | YouTube and other platforms host countless videos that demonstrate maintenance tips, repairs, and operational techniques. |

| Parts Retailers | Websites specializing in replacement components provide detailed catalogs and diagrams to help users find the right items. |

| Social Media Groups | Various social platforms feature groups where users can connect, share photos, and discuss their equipment. |

Utilizing these resources can enhance knowledge and confidence, making it easier to tackle maintenance tasks and engage with the community.

Customer Support and Warranty Information

Ensuring customer satisfaction is a priority for any brand, and having reliable assistance and clear warranty policies is essential for maintaining trust. This section aims to provide vital information regarding support services and warranty coverage for your equipment.

Customer Assistance

For any inquiries or issues, reaching out to customer support is recommended. Trained representatives are available to guide you through troubleshooting processes, answer questions about usage, and provide recommendations for maintenance. You can contact them via phone or online chat for immediate assistance. Additionally, a comprehensive FAQ section on the official website can address common concerns and provide helpful tips.

Warranty Coverage

Most products come with a warranty that guarantees protection against manufacturing defects. The duration and specifics of the coverage may vary, so it is crucial to review the warranty terms provided at the time of purchase. Should you encounter a defect, the warranty often includes repair or replacement options, ensuring that your investment is safeguarded. Always keep your receipt or proof of purchase, as this will be necessary for warranty claims.