Complete Guide to Stihl FS38 Parts Diagram

When it comes to maintaining garden equipment, having a clear view of the inner workings can be incredibly beneficial. This knowledge allows users to identify issues quickly and ensures optimal performance of the device.

Exploring the layout of various elements can provide insights into how each part interacts with the others. By examining these connections, one can appreciate the design and engineering behind efficient gardening tools.

Additionally, comprehending the individual components not only aids in troubleshooting but also enhances the overall user experience. Understanding these intricacies can lead to more informed decisions regarding repairs and upgrades.

In this section, we will delve into a detailed exploration of the assembly of a popular trimmer model, revealing the ultimate guide for enthusiasts and professionals alike. Get ready to uncover the essential features that contribute to effective yard maintenance.

Understanding Stihl FS38 Overview

This section provides an insightful examination of a popular outdoor power tool known for its efficiency and versatility. Designed primarily for cutting grass and maintaining landscaped areas, this device has become a favorite among both homeowners and professionals. By delving into its features, we can better appreciate its functionality and the advantages it offers to users in various settings.

Key Features

The tool boasts a lightweight design, making it easy to maneuver while working in different terrains. Its robust engine provides ample power, allowing for swift cutting and trimming. Additionally, the user-friendly controls ensure that even novice operators can handle it with ease, making yard maintenance a less daunting task.

Applications

This equipment is ideal for a range of applications, from tidying up residential gardens to tackling more extensive commercial landscaping projects. Its adaptability means it can effectively manage overgrown areas and maintain neat edges around flower beds and pathways. Whether used for routine upkeep or more demanding tasks, it proves to be a reliable companion in outdoor maintenance.

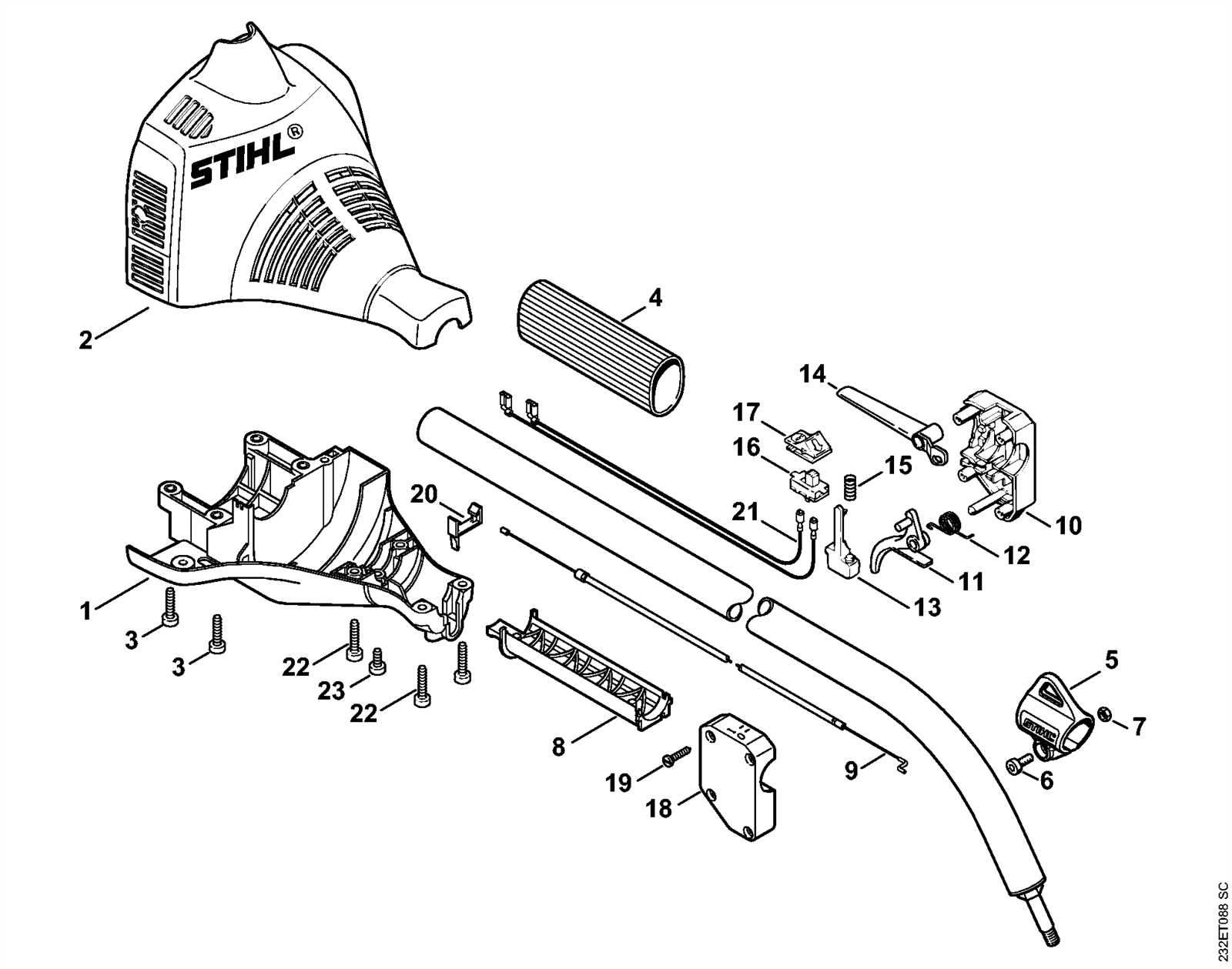

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the assembly and functionality of machinery. These illustrations serve as essential tools for both professionals and hobbyists, enabling them to grasp the intricate relationships between various elements.

Enhanced Understanding

By providing a clear overview, these visual aids help users identify each segment’s position and function. This knowledge is vital for effective maintenance and repair, ultimately prolonging the lifespan of equipment.

Facilitating Repairs

When troubleshooting, having a visual guide simplifies the process of locating issues. Users can easily pinpoint defective parts, ensuring timely and accurate replacements, which enhances overall efficiency.

Key Components of FS38

This section explores the essential elements that contribute to the functionality and performance of a grass trimmer. Understanding these key parts can enhance maintenance and ensure optimal operation.

- Engine: The power source that drives the tool, typically a two-stroke or four-stroke engine.

- Cutting Head: The component responsible for trimming grass and weeds, often equipped with various line or blade options.

- Handle: Provides grip and control, allowing the user to maneuver the device efficiently.

- Fuel Tank: Stores the fuel necessary for the engine’s operation, typically located near the base.

- Throttle Trigger: Controls the engine speed, enabling the user to adjust power as needed.

Each of these parts plays a crucial role in the overall efficiency and usability of the tool, making it important for users to familiarize themselves with their functions and maintenance requirements.

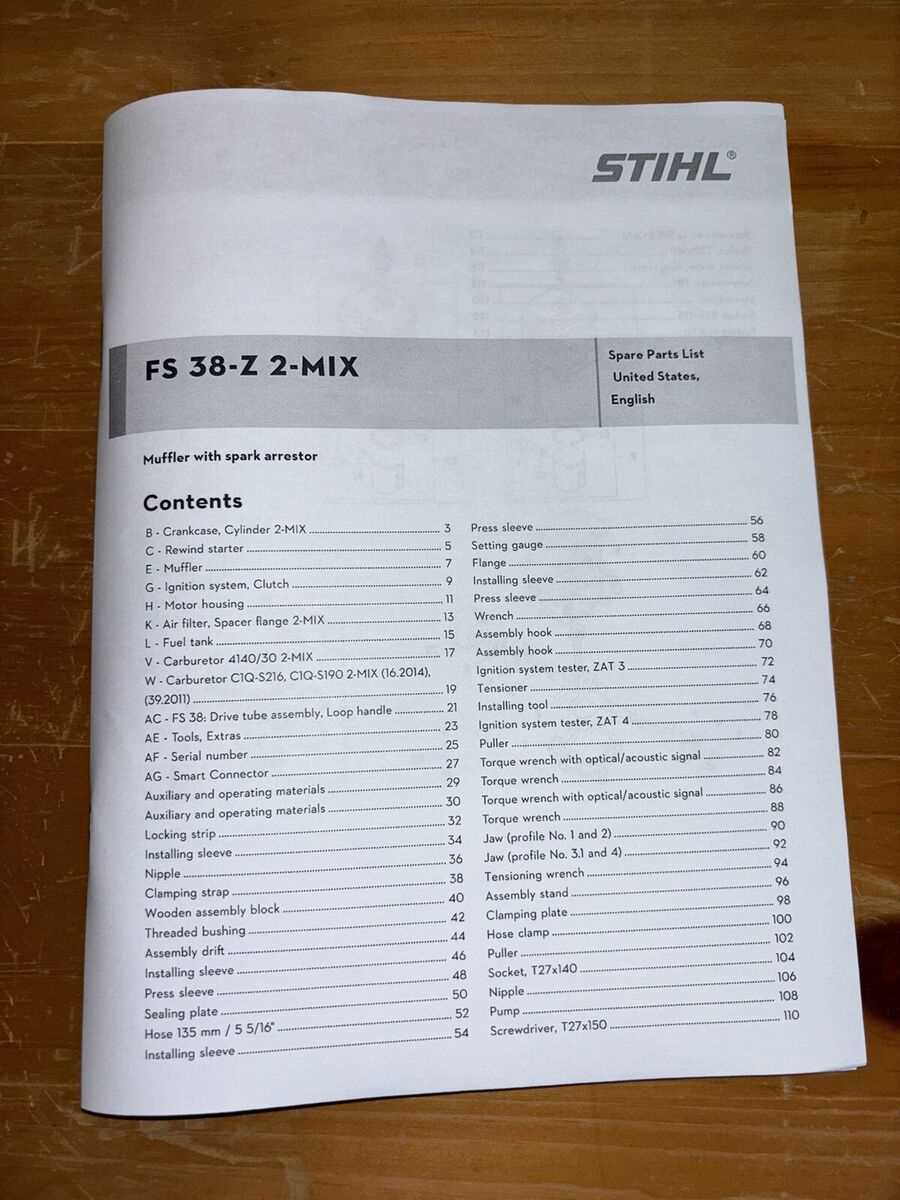

How to Read Parts Diagrams

Understanding component illustrations is essential for effective maintenance and repair. These visuals provide a clear representation of each element’s location and function within a machine. By grasping how to interpret these schematics, users can easily identify the necessary components and their relationships, making the repair process more efficient.

| Symbol | Description |

|---|---|

| Circle | Represents a connection point for various parts. |

| Arrow | Indicates the direction of movement or flow. |

| Number | Corresponds to a specific part in the accompanying list. |

| Box | Denotes a complete assembly of components. |

By familiarizing yourself with these symbols and their meanings, you can confidently approach any repair task, ensuring that you select the right components and understand their arrangement in the overall system.

Common FS38 Issues and Fixes

In the world of outdoor power equipment, encountering challenges with your trimmer is not uncommon. Understanding frequent problems and their solutions can enhance performance and extend the lifespan of your device. Here, we explore typical issues and their effective remedies.

Starting Difficulties

One prevalent problem is difficulty in starting the machine. This can often be attributed to stale fuel or clogged filters. To resolve this, first, ensure that you use fresh fuel mixed at the correct ratio. Additionally, clean or replace the air and fuel filters to improve airflow and fuel delivery. Regular maintenance is crucial to prevent this issue.

Excessive Vibration

Another common concern is excessive vibration during operation, which can be uncomfortable and indicate potential mechanical problems. Check for loose or worn components, such as the cutting head or the mounting system. Tightening or replacing these parts can often mitigate the issue. It’s also advisable to inspect the condition of the drive shaft, as wear here can lead to increased vibrations.

Where to Find Replacement Parts

Finding the right components for your equipment can be crucial for maintaining its performance and longevity. Various sources provide options for obtaining these necessary items, ensuring you can keep your machinery running smoothly.

Online Retailers

- Many e-commerce platforms specialize in outdoor equipment supplies.

- Manufacturer websites often have direct sales or links to authorized dealers.

- Specialty sites may offer a wide range of options, including aftermarket parts.

Local Suppliers

- Visit hardware stores that carry outdoor tools and machinery.

- Check with local repair shops for potential sourcing of specific items.

- Participate in community forums for recommendations on trusted suppliers.

Benefits of Genuine Stihl Parts

Using authentic components for your equipment ensures optimal performance and longevity. These original parts are specifically engineered to meet high standards, providing unmatched reliability and efficiency.

Quality Assurance: Genuine items undergo rigorous testing, guaranteeing they meet the manufacturer’s specifications. This results in superior durability and functionality.

Compatibility: Original components are designed to fit perfectly, minimizing the risk of malfunctions. This compatibility enhances the overall efficiency of your machinery.

Warranty Protection: Using authentic parts often preserves your warranty, offering peace of mind and protection against potential issues.

Support and Availability: Genuine products come with manufacturer support, ensuring easy access to replacement and maintenance resources when needed.

Investing in original components is an ultimate choice for maintaining the performance and reliability of your equipment.

Maintenance Tips for FS38

Proper upkeep of your equipment is essential for ensuring optimal performance and longevity. Regular attention to various components can prevent issues and enhance efficiency, making your tasks easier and more enjoyable.

1. Regular Cleaning: After each use, clear away debris and grass clippings. This prevents buildup that can lead to corrosion and operational problems.

2. Check the Fuel: Always use fresh fuel and check the fuel lines for any signs of wear or damage. Contaminated fuel can hinder performance significantly.

3. Inspect the Blades: Sharpen or replace the cutting elements as needed. Dull blades can strain the engine and reduce cutting efficiency.

4. Lubricate Moving Parts: Regularly apply lubricant to moving components to minimize friction and wear, ensuring smooth operation.

5. Monitor Air Filters: Keep the air filter clean and replace it when necessary. A clean filter allows for better airflow, enhancing engine performance.

6. Seasonal Checks: At the start of each season, conduct a thorough inspection of all critical components to address any potential issues before heavy use.

By following these maintenance guidelines, you can maximize the efficiency and lifespan of your equipment.

Tools Needed for Repairs

When tackling maintenance tasks, having the right instruments can significantly simplify the process and enhance efficiency. Proper tools not only facilitate repairs but also ensure safety and longevity of the equipment. Below is a guide to essential implements that will assist you in your repair endeavors.

Essential Instruments

For effective servicing, gather items such as wrenches, screwdrivers, and pliers. These are fundamental for disassembling components and securing fittings. Additionally, a socket set can be invaluable for tackling various fasteners, ensuring a snug fit and preventing damage during removal.

Safety Gear

Always prioritize safety by equipping yourself with protective gear. Items like gloves, goggles, and ear protection are crucial when working with machinery. These essentials safeguard against potential hazards, enabling a safer and more focused repair experience.

Disassembly Process Explained

The process of taking apart a machine requires careful attention to detail and a clear understanding of its components. This section outlines the essential steps to effectively dismantle a unit, ensuring that each part is handled with care to prevent damage and facilitate reassembly.

Preparation Steps

Before beginning, gather the necessary tools and workspace. Ensure the unit is powered down and disconnected from any power source. This precaution is crucial for safety and will allow for a smooth disassembly process. Make a checklist of the components and their respective locations to assist in reassembly later.

Disassembly Procedure

Start by removing any outer casing or protective covers. Use appropriate tools to avoid stripping screws or damaging clips. As each component is removed, organize them systematically and consider labeling them for easy identification. Careful handling during this phase is vital, as many parts can be fragile. Once the unit is fully disassembled, you can delve into cleaning or replacing individual elements as needed.

Reassembly Tips for FS38

Reassembling your equipment can seem daunting, but with the right approach, it becomes manageable and straightforward. Following a few key guidelines ensures that every component is fitted correctly, enhancing performance and longevity.

Preparation Steps

- Gather all components in a clean, organized space.

- Refer to a detailed guide or manual to understand the assembly order.

- Check for any worn or damaged parts that may need replacement.

Reassembly Process

- Start by assembling the larger components before moving to smaller parts.

- Use the appropriate tools to avoid stripping screws or damaging fittings.

- Double-check each connection to ensure a secure fit.

- Test functionality after reassembly to catch any issues early.

Upgrading Stihl FS38 Components

Enhancing the performance and longevity of your gardening tool can greatly improve efficiency and overall user experience. By carefully selecting and replacing certain elements, you can optimize functionality and adapt the equipment to your specific needs. This process not only boosts productivity but also contributes to the sustainability of the tool over time.

Key Components to Consider: Begin with the engine’s air intake system, as improving airflow can lead to better combustion and power output. Replacing the existing filter with a high-performance variant can make a significant difference.

Another vital area is the cutting mechanism. Upgrading to a more durable blade or line can enhance cutting efficiency and reduce wear. Consider materials designed for increased resilience, ensuring a smoother operation during extended use.

Don’t overlook vibration dampening systems. Investing in superior anti-vibration mounts can greatly improve comfort during operation, allowing for longer work sessions without fatigue.

By systematically evaluating and upgrading these components, users can ensure their equipment remains reliable and effective, adapting to both casual and demanding tasks alike.

Expert Resources for Troubleshooting

When facing challenges with your outdoor power equipment, accessing reliable resources can make a significant difference in effectively diagnosing and resolving issues. Expert insights and comprehensive guides are invaluable tools for both novice and experienced users, helping to streamline the troubleshooting process and minimize downtime.

Here are some recommended resources that provide essential information and support:

| Resource Type | Description |

|---|---|

| Online Forums | Community-driven platforms where users share experiences, solutions, and advice on common problems. |

| Manufacturer’s Manuals | Official documentation that includes detailed instructions, specifications, and maintenance tips. |

| Video Tutorials | Visual guides available on various platforms, demonstrating step-by-step repair and maintenance procedures. |

| Technical Support | Direct assistance from experts who can provide personalized help and troubleshooting advice. |

Utilizing these resources will empower you to effectively tackle issues and enhance the performance of your equipment.