Understanding the Stihl FS45C Parts Diagram for Easy Repairs

Maintaining outdoor machinery can often feel overwhelming, especially when it comes to understanding their internal components. A clear visual representation can greatly simplify the process, providing insights into how each element functions and interacts with others. This knowledge not only aids in effective maintenance but also empowers users to troubleshoot issues more efficiently.

By examining a detailed illustration, one can familiarize themselves with the various segments and assemblies that make up the machinery. Such visuals serve as valuable references, highlighting the essential parts that contribute to the overall performance. Gaining this understanding can lead to better care and longer life for your equipment.

In addition to aiding in maintenance, recognizing the specific features of your machine can enhance safety practices. Knowing where each component is located and how it operates allows users to engage with their equipment confidently and responsibly. With the right resources at hand, anyone can become adept at managing their outdoor tools.

Understanding the Stihl FS45C

This section explores the essential features and components of a popular landscaping tool designed for efficient grass trimming and edging. Understanding its functionality can enhance maintenance and operational effectiveness.

Key Features

- Lightweight design for easy maneuverability

- Powerful engine for optimal performance

- User-friendly controls for a seamless experience

Maintenance Tips

- Regularly check and replace the cutting line.

- Ensure air filters are clean to maintain engine efficiency.

- Inspect the fuel system for leaks or clogs.

Key Features of the FS45C

This model stands out for its blend of power, efficiency, and user-friendly design, making it an ideal choice for various outdoor tasks. The well-engineered components ensure reliability and optimal performance, catering to both novice and experienced users.

Powerful Engine: Equipped with a robust engine, this tool delivers impressive cutting power, allowing for efficient trimming and clearing.

Lightweight Design: Its lightweight structure minimizes fatigue during extended use, enabling users to work comfortably for longer periods.

Easy Start Mechanism: Featuring an innovative starting system, it simplifies ignition, reducing the hassle often associated with similar tools.

Versatile Attachments: Compatibility with various attachments enhances functionality, making it suitable for a range of gardening tasks, from edging to brush cutting.

Durable Construction: Built with high-quality materials, this model is designed to withstand the rigors of outdoor use, ensuring longevity and sustained performance.

User-Centric Features: Ergonomic handles and intuitive controls improve maneuverability and comfort, providing an enjoyable experience for all users.

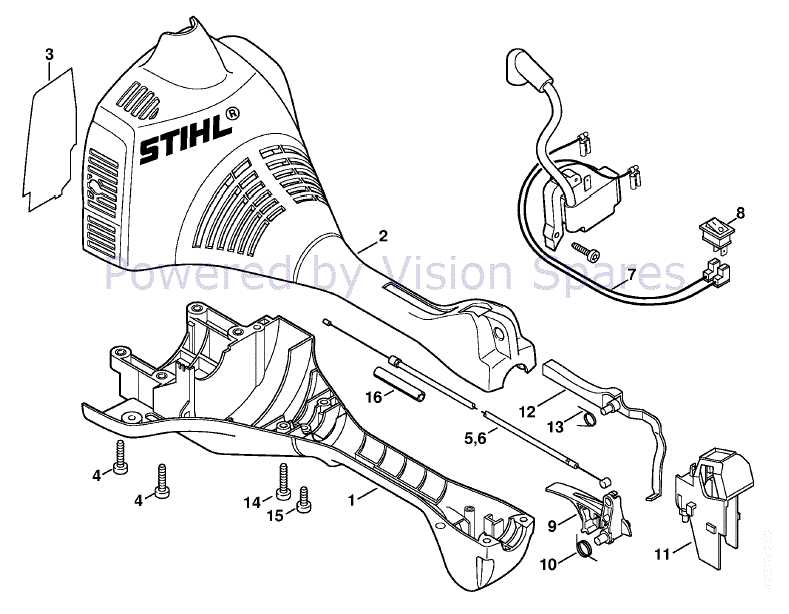

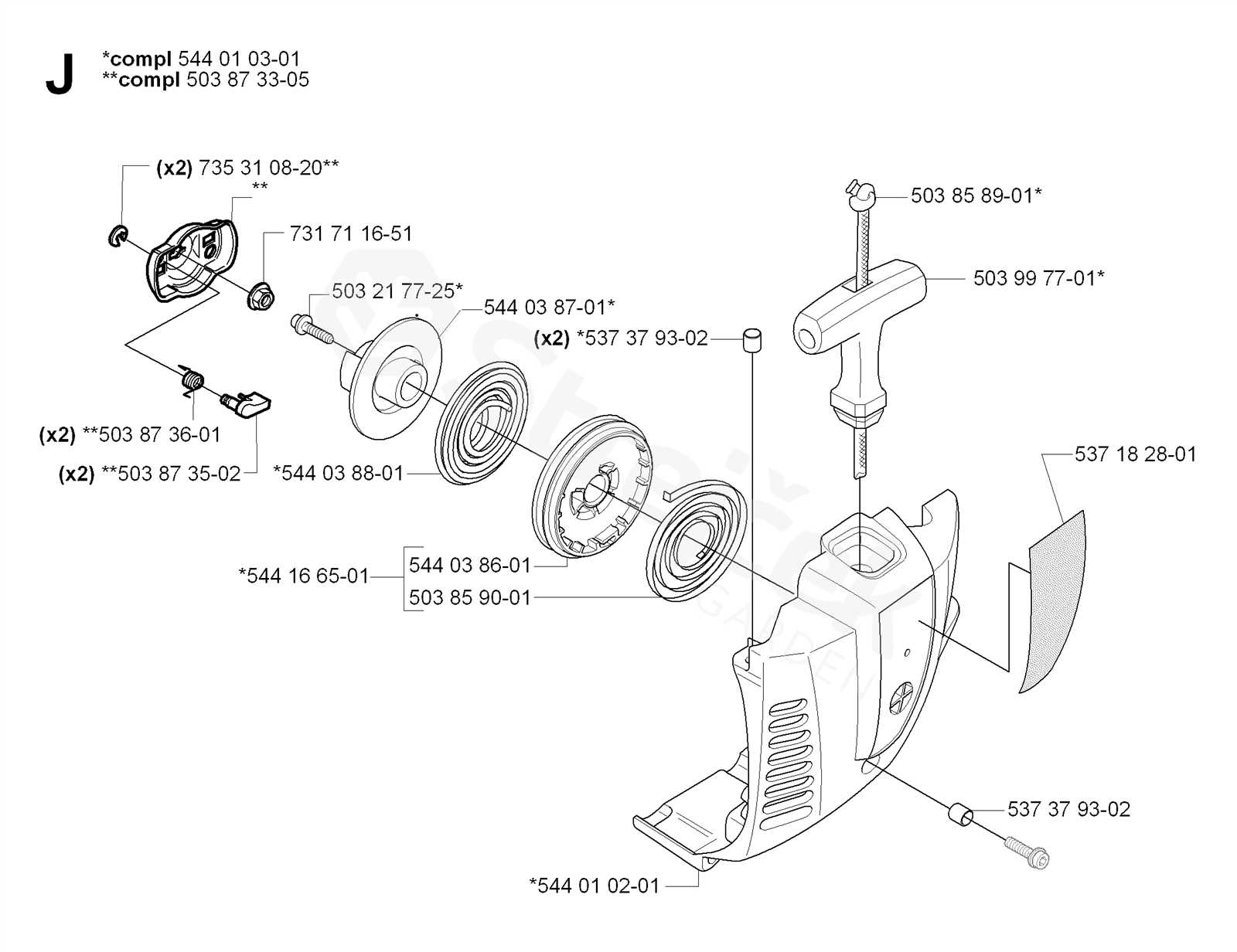

Importance of Parts Diagrams

Understanding the components of a machine and their relationships is crucial for efficient maintenance and repair. Visual representations serve as invaluable tools, providing clarity and aiding in the identification of individual elements. By breaking down complex systems into manageable parts, these illustrations facilitate a more comprehensive grasp of the equipment.

Enhancing Troubleshooting Efficiency

When issues arise, having a clear view of each component helps diagnose problems quickly. Users can refer to visual guides to pinpoint the source of a malfunction, reducing downtime and improving workflow. This streamlined approach not only saves time but also minimizes frustration during the repair process.

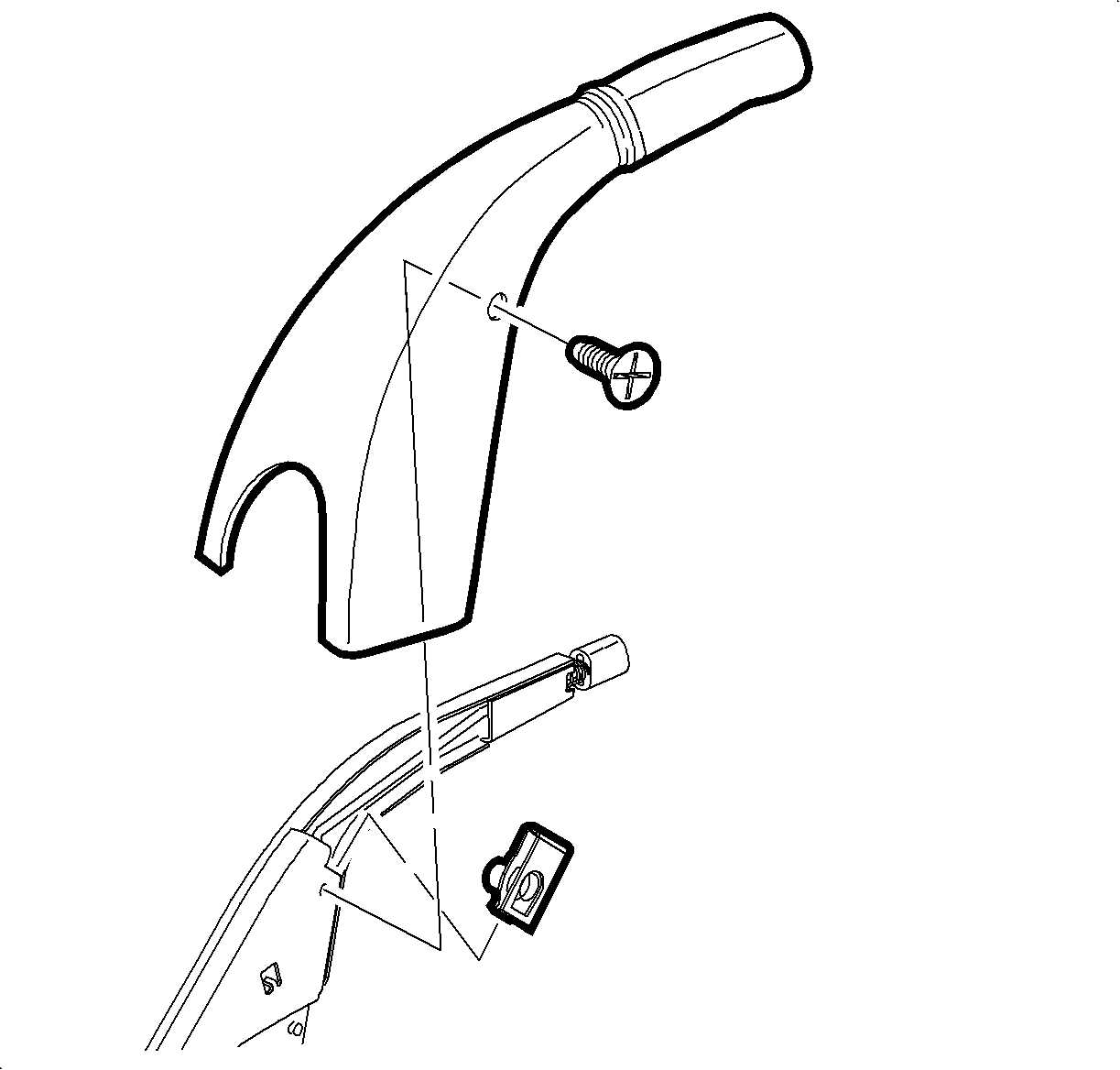

Assisting in Proper Assembly

Reassembling machinery after maintenance requires precision. Visual aids ensure that each piece is placed correctly, preventing errors that could lead to further complications. Clear depictions of how parts fit together support users in reassembly, fostering a greater understanding of the entire system.

| Benefits | Description |

|---|---|

| Quick Diagnosis | Speeds up the identification of problems, allowing for timely repairs. |

| Improved Accuracy | Ensures correct placement of components during reassembly. |

| Increased Understanding | Enhances knowledge of the machinery, fostering better maintenance practices. |

Identifying Common Replacement Parts

Understanding the various components of your outdoor power equipment is essential for maintaining optimal performance. Recognizing the most frequently replaced elements can help ensure that your machine operates efficiently and reliably over time. By familiarizing yourself with these critical items, you can address issues proactively and keep your equipment in top condition.

Among the key components, the cutting tool stands out, as it directly affects the efficiency of the operation. Additionally, the ignition unit is vital for starting the engine smoothly, while the fuel system components play a crucial role in maintaining power and efficiency. Regular checks of these elements can prevent unexpected breakdowns and enhance longevity.

Another significant part to monitor is the air filter, which is essential for maintaining engine performance. A clean filter ensures that the engine receives adequate airflow, promoting optimal combustion. Lastly, the drive mechanism is important for power transfer; keeping it in good condition is vital for smooth operation. Regular inspection and timely replacement of these components can lead to a more reliable and efficient machine.

How to Read a Parts Diagram

Understanding a schematic representation of components can greatly enhance your ability to identify and manage individual elements of equipment. These visual guides provide a clear view of how each piece fits into the overall assembly, aiding in both maintenance and repair tasks. Familiarity with this type of illustration allows users to navigate complex assemblies with confidence.

Start by locating the key that explains symbols and references used in the illustration. This key often includes part numbers, descriptions, and any applicable notes. Each component will typically be labeled, making it easier to pinpoint what you need.

Next, pay attention to the layout, as it often indicates the order of assembly or the relationship between various parts. Note the connections and interfaces, as understanding these can help when disassembling or replacing specific elements.

Finally, ensure you cross-reference the information with any accompanying documentation or manuals. This practice not only clarifies details but also provides additional insights into proper usage and compatibility, ultimately streamlining your repair or maintenance process.

Essential Tools for Repairs

Having the right equipment is crucial for any maintenance or repair task. Proper tools not only enhance efficiency but also ensure safety and precision during the process. Below is a list of fundamental instruments that every repair enthusiast should have on hand.

- Wrenches: A set of adjustable and socket wrenches is essential for loosening and tightening various components.

- Screwdrivers: A variety of flathead and Phillips screwdrivers will accommodate different screw types.

- Pliers: Needle-nose and slip-joint pliers are great for gripping and manipulating parts.

- Utility Knife: A sharp utility knife is invaluable for cutting through materials and packaging.

- Multimeter: This tool is critical for diagnosing electrical issues and measuring voltage, current, and resistance.

Equipping yourself with these basic tools will facilitate effective repairs and enhance your overall experience.

Finding Authentic Stihl Parts

When it comes to maintaining your outdoor power equipment, using genuine components is crucial for optimal performance and longevity. Authentic replacements ensure that your machinery operates as intended, minimizing the risk of malfunctions and enhancing reliability. Identifying legitimate sources for these items can greatly influence the overall experience and functionality of your tools.

Why Genuine Components Matter

Opting for original items over generic alternatives significantly impacts the efficiency and safety of your equipment. Genuine parts are designed specifically for your model, ensuring a perfect fit and seamless integration. This reduces wear and tear on the machinery and helps maintain warranty coverage, which can save you money in the long run.

Where to Find Reliable Sources

To locate authentic replacements, start by checking authorized dealers and certified retailers. These sources typically provide a selection of quality items that meet the manufacturer’s standards. Additionally, visiting the official website can lead you to reputable suppliers and exclusive offers. Remember to verify the seller’s credentials and read customer reviews to ensure a trustworthy purchase.

Maintenance Tips for Longevity

Proper upkeep is essential for maximizing the lifespan and performance of your outdoor power equipment. Regular maintenance not only enhances efficiency but also prevents unexpected breakdowns, ensuring your tools remain reliable over time.

Regular Cleaning: Keep your equipment free from debris and dirt. After each use, clean the exterior and any components that may accumulate grime.

Check Filters: Inspect air and fuel filters regularly. Replacing or cleaning them as needed will help maintain optimal performance.

Lubrication: Ensure all moving parts are adequately lubricated. This minimizes friction and wear, contributing to longer operational life.

Inspect Spark Plug: A clean and properly functioning spark plug is crucial. Replace it as recommended to ensure efficient ignition and performance.

Store Properly: When not in use, store your equipment in a dry, sheltered place. This prevents rust and damage from environmental factors.

Follow Manufacturer Guidelines: Adhere to the specific maintenance schedule and recommendations provided by the manufacturer for best results.

Troubleshooting Common Issues

Every machine can encounter difficulties during operation, leading to frustrating experiences for users. Identifying and resolving these problems promptly can enhance performance and extend the lifespan of the equipment. This section outlines frequent issues that may arise and offers practical solutions to address them.

Engine Won’t Start

If the engine fails to start, check the fuel supply first. Ensure that the fuel is fresh and properly mixed, as stale or incorrect fuel can prevent ignition. Additionally, examine the spark plug for wear or damage; replacing it may restore functionality.

Loss of Power

A noticeable drop in power can stem from various sources. Clogged air filters often restrict airflow, so cleaning or replacing them is essential. Furthermore, inspect the cutting head and line; a worn or damaged line can hinder performance significantly. Regular maintenance is key to avoiding such issues.

Upgrading Components for Better Performance

Enhancing the efficiency of your outdoor power equipment can significantly improve its functionality and longevity. By carefully selecting and upgrading specific elements, users can experience heightened performance, reduced wear, and a more enjoyable operating experience. Whether you’re looking to increase power output or enhance ease of use, targeted upgrades can make a considerable difference.

Key Areas for Improvement

Focus on several crucial areas when considering enhancements. First, upgrading the engine components can lead to better fuel efficiency and increased power. High-performance air filters and exhaust systems can also contribute to a more efficient combustion process, resulting in improved overall output. Additionally, examining the cutting attachment can yield substantial benefits; opting for sharper, more durable blades ensures cleaner cuts and reduced strain on the machine.

Materials and Maintenance

Investing in high-quality materials is essential for any upgrades. Durable components not only withstand regular use but also minimize the need for frequent replacements. Regular maintenance plays a vital role in maintaining performance; keeping parts clean and well-lubricated will extend their lifespan. By combining upgraded elements with diligent care, users can maximize the effectiveness of their equipment and achieve outstanding results.